Bio-trickling device for processing volatile organic waste gas and method thereof

A volatile organic and biological trickling filtration technology, applied in separation methods, chemical instruments and methods, air quality improvement and other directions, can solve the problems of unguaranteed airflow uniformity, difficult backwash operation, pressure drop, etc., and achieve enhanced gas-liquid Mass transfer and biodegradability, small footprint, reduced flow-through height effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

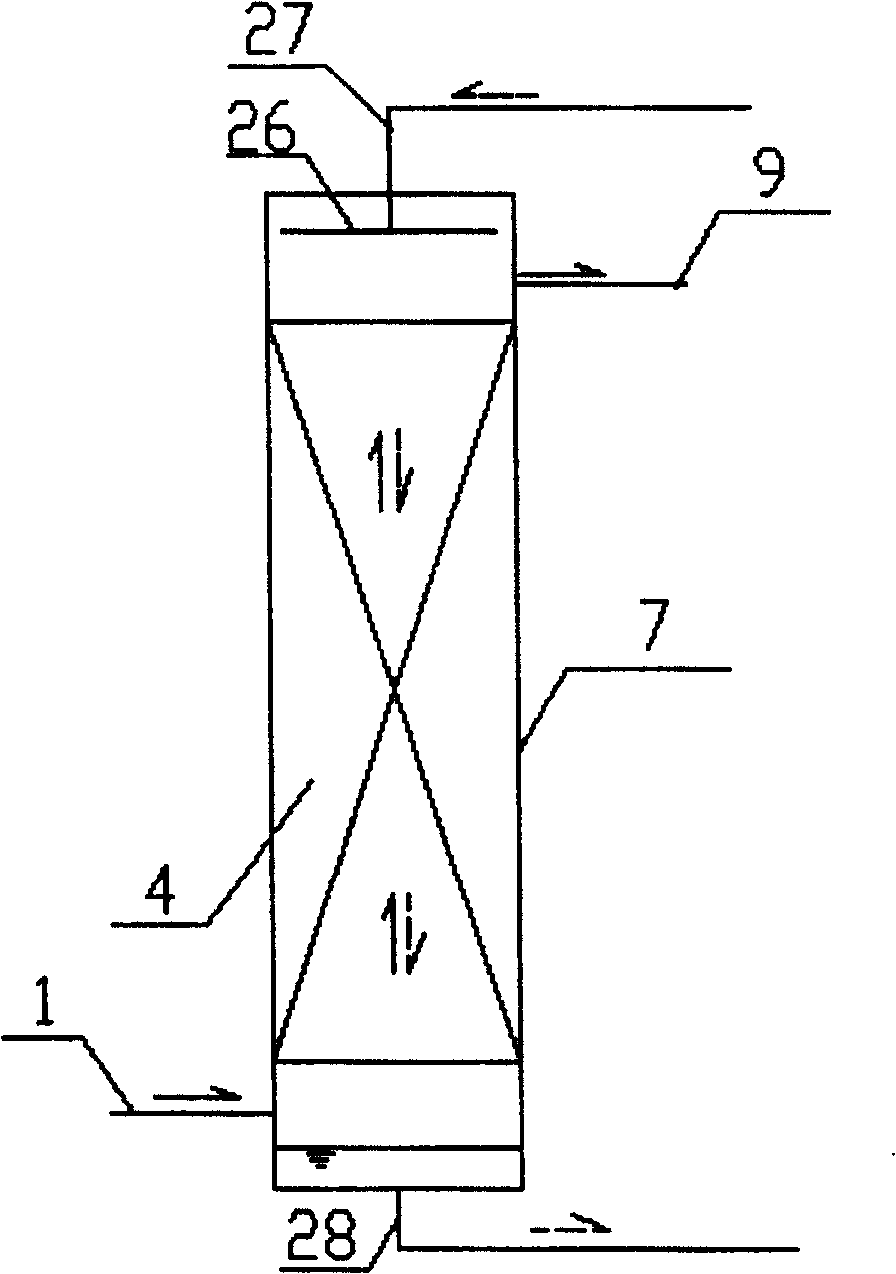

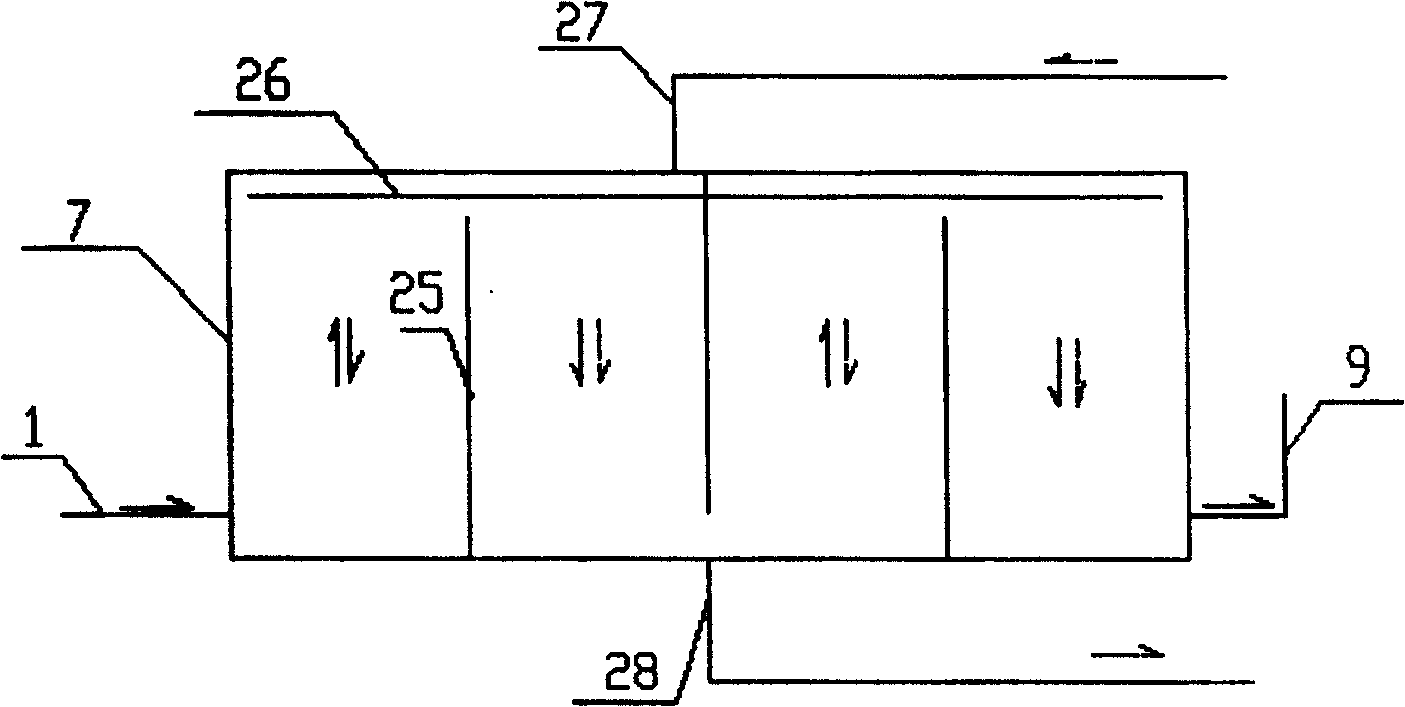

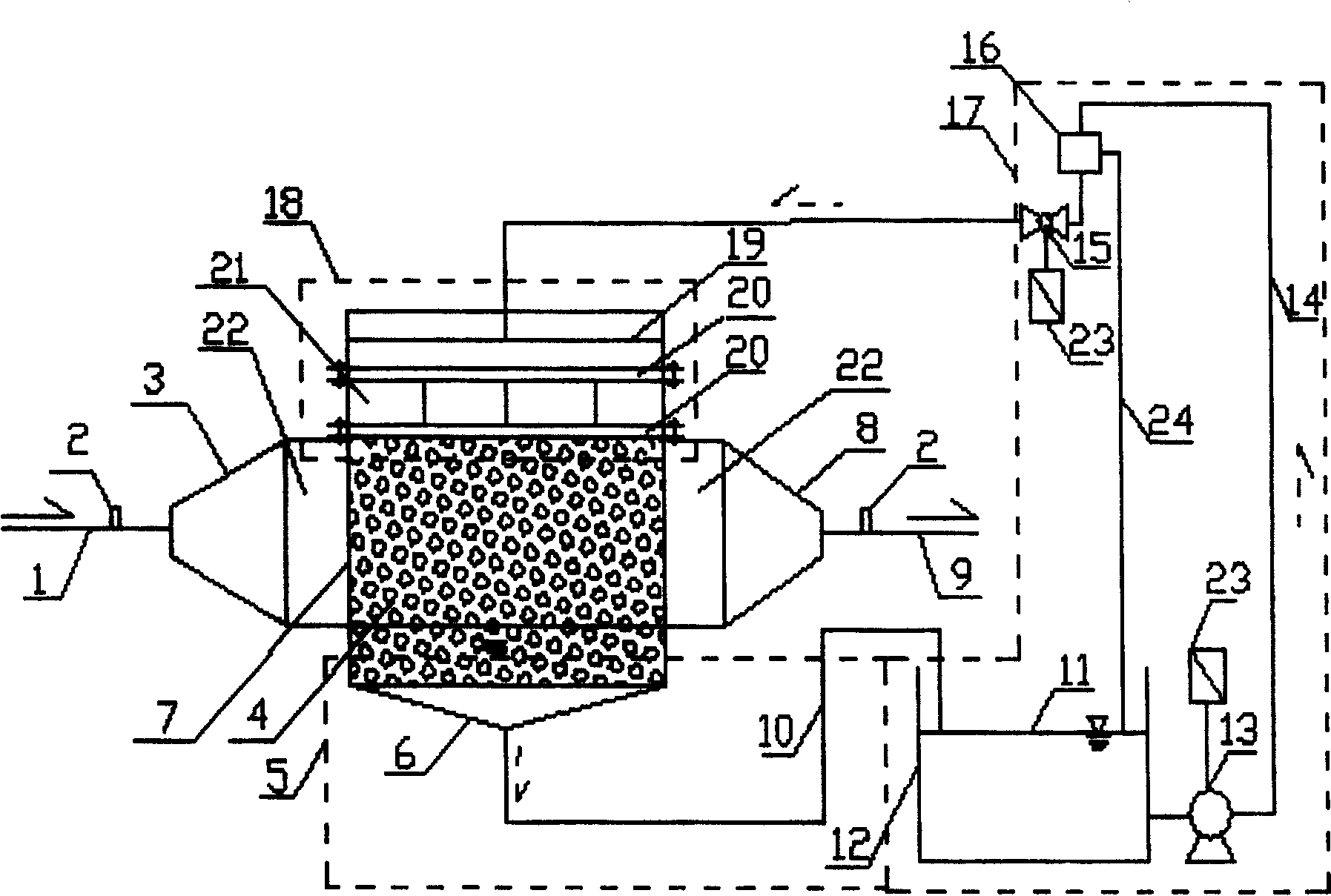

[0026] image 3 The shown biological trickling filter device for treating volatile organic waste gas is composed of an air inlet pipe 1, a reactor main body 7, a nutrient solution automatic quantitative supply device 17, a nutrient solution dripping and distributing device 18, a liquid sealing device 5, and an exhaust pipe 9. The overall appearance of the biological trickling filter device is horizontal. The inlet pipe 1 and the exhaust pipe 9 are respectively located on both sides of the reactor body 7, and the horizontal center lines of the three coincide. The inlet pipe 1 passes through the divergent inlet device 3 and the diversion area. 22 is connected to the reactor main body 7, and the exhaust pipe 9 is connected to the reactor main body 7 through the diversion zone 22 and the tapered exhaust device 8. The structure design is suitable for the treatment of atmospheric volatile organic waste gas, gradually expanding The air intake device 3 and the tapered exhaust device 8 are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com