Patents

Literature

51results about How to "Large gas volume" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

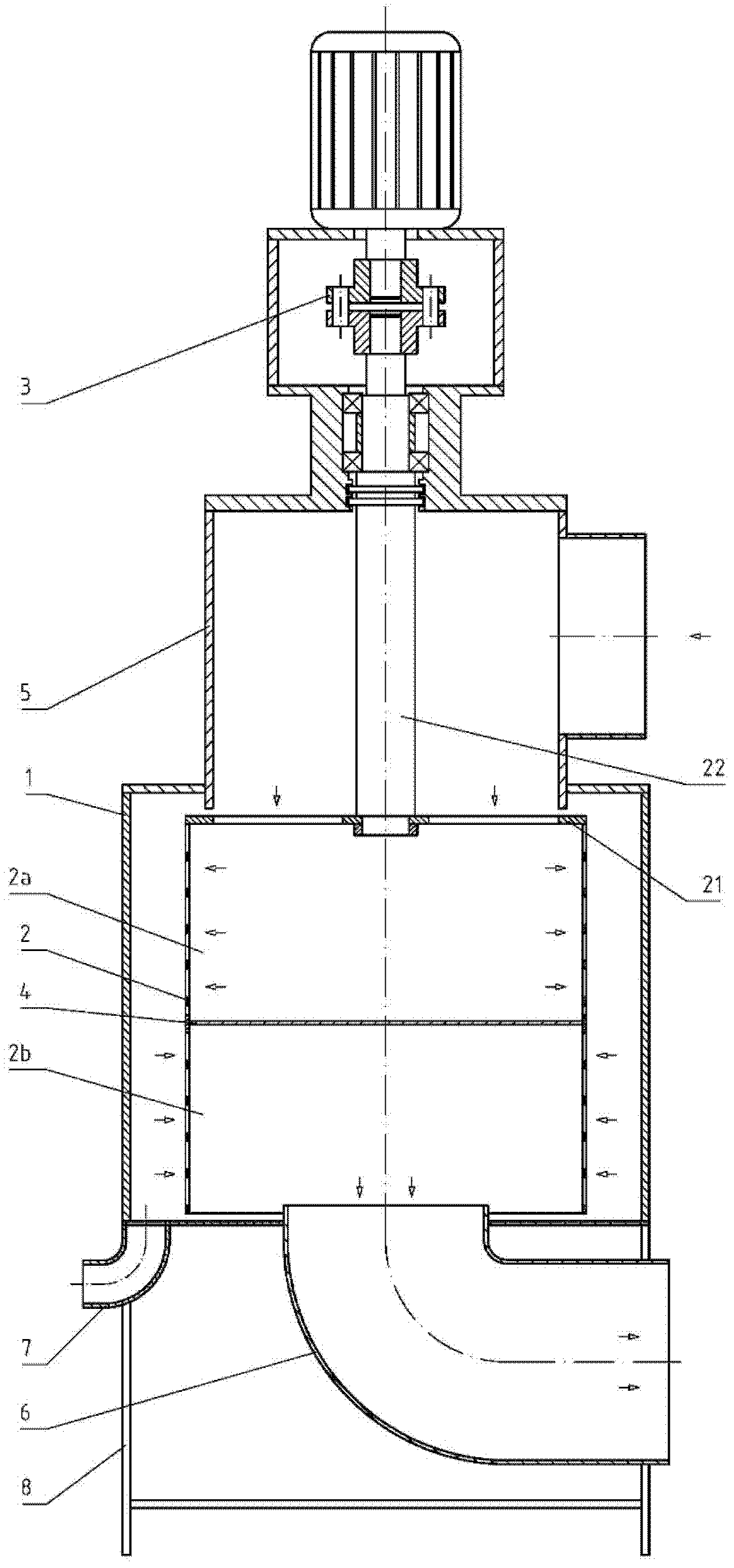

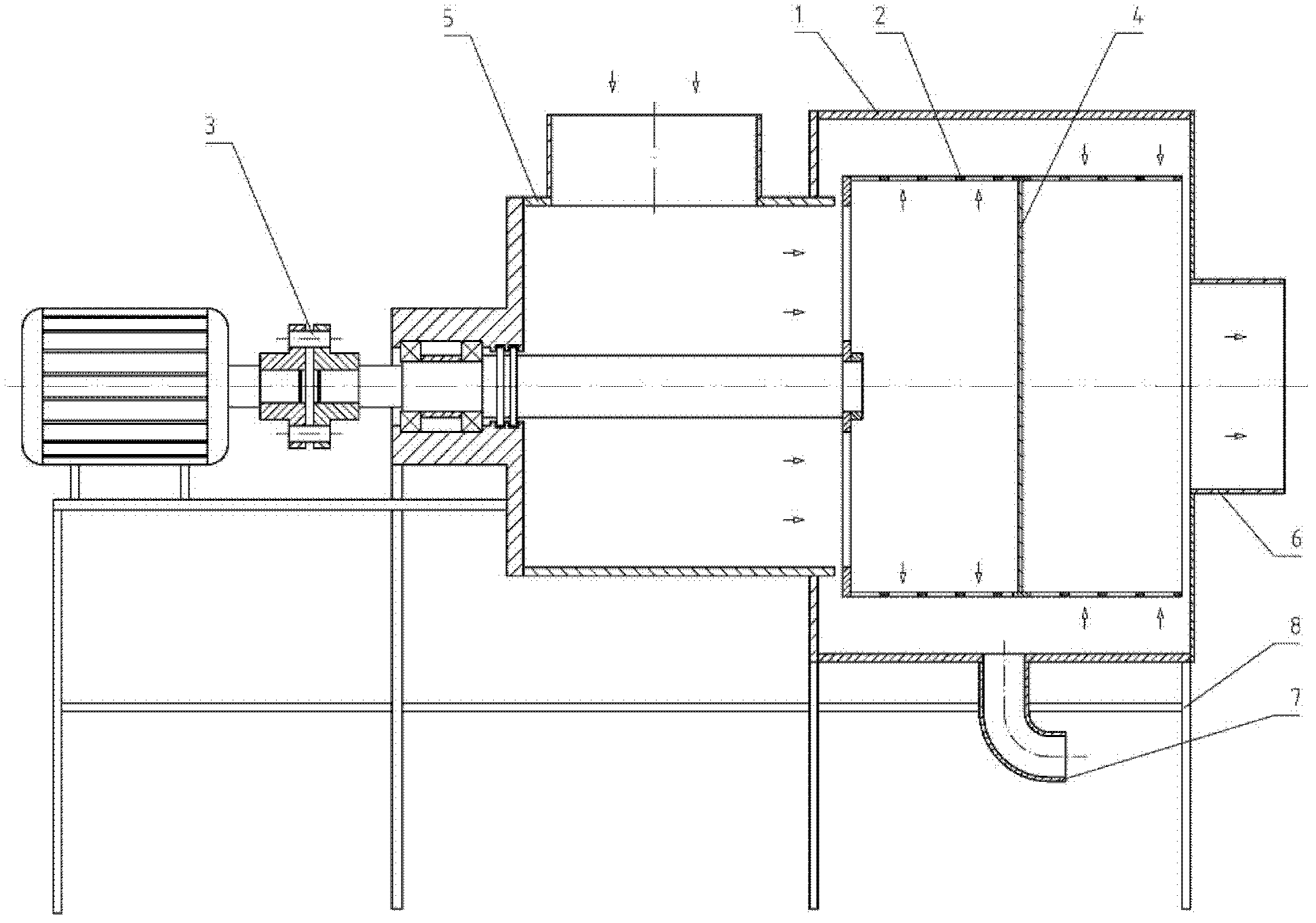

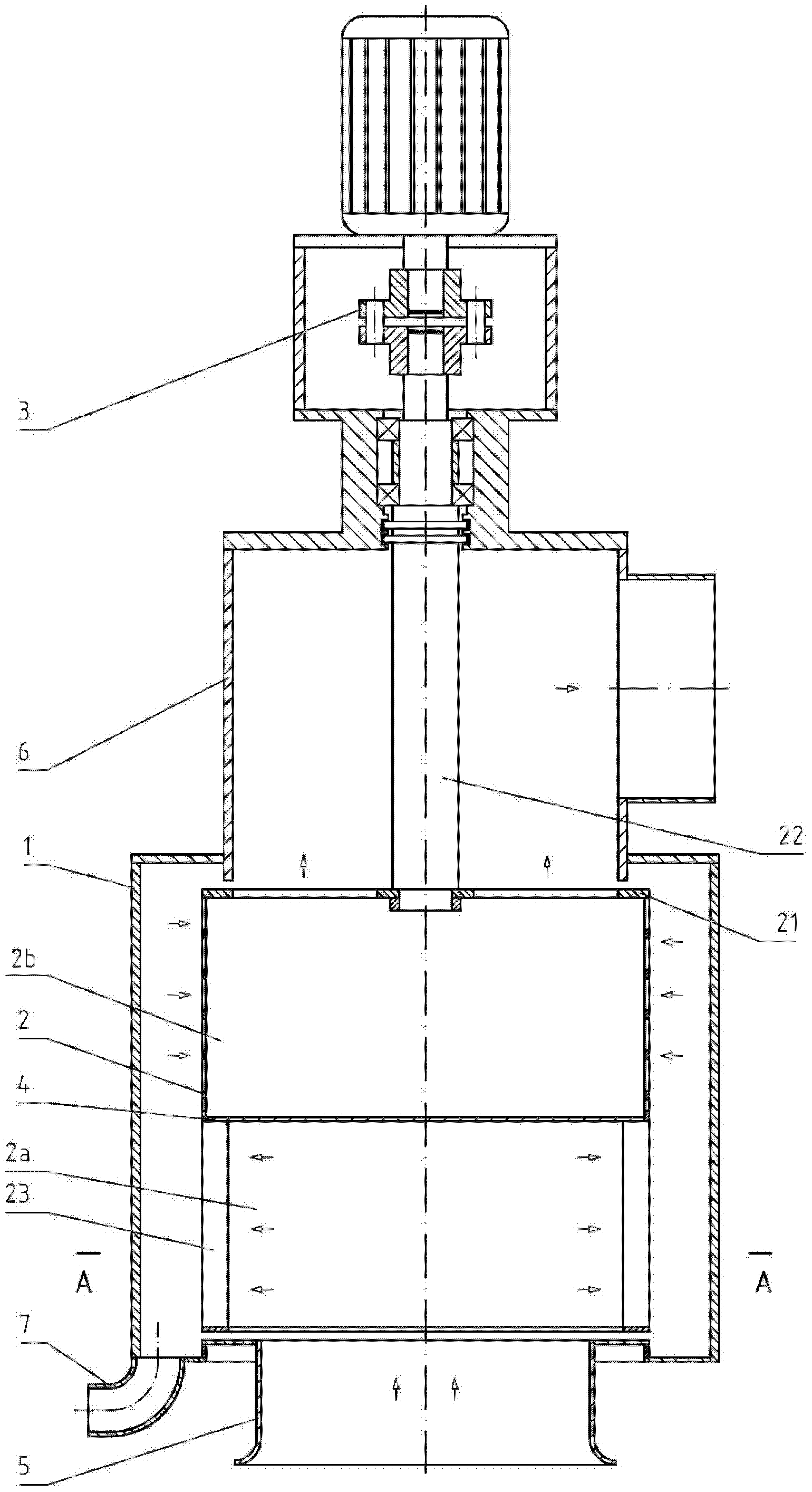

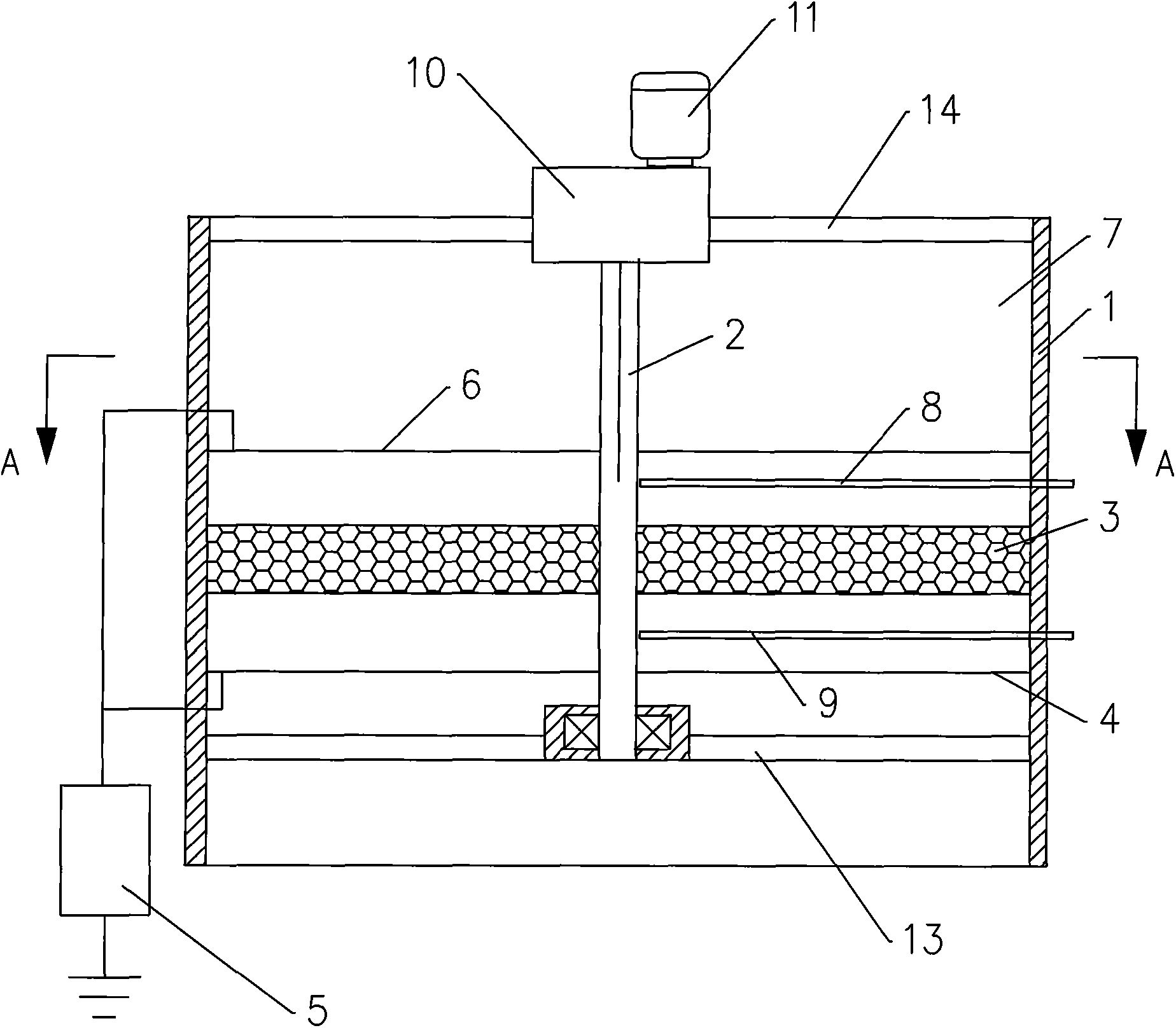

Active centrifugal gas-liquid separation device

InactiveCN102580408AImprove gas-liquid separation efficiencyLarge gas volumeDispersed particle separationDry gasNatural gas

The invention is applied in the industries of medicine, air compression, natural gas, synthetic ammonia, oil refining, coking and the like, and relates to a gas-liquid separation device. The device comprises a shell, an air inlet pipe and an exhaust pipe; a drum driven to rotate by a power device is arranged in the shell; the wall of the drum is provided with air holes; a partition plate is arranged in the drum to partition the drum into an air inlet end and an exhaust end which are respectively communicated with the air inlet pipe and the exhaust pipe; the air inlet pipe is communicated with the exhaust pipe through the air inlet end of the drum, the air holes in the wall of the drum, an air passage and the exhaust end of the drum; and the shell is provided with a drain pipe. Through the device, the separation efficiency of liquid particles with the diameters of over 0.1 micron reaches over 99.5 percent; and the device is large in treated gas quantity and suitable for wet gas with high liquid content, does not require circulation of a large quantity of washing absorption liquid, does not require a high-voltage electrostatic system, has good adaptability to the physical properties of the liquid, has certain capability of separating dry gas components with different densities, and is small in volume, light in weight, small in occupied space and low in manufacturing cost.

Owner:杨东进

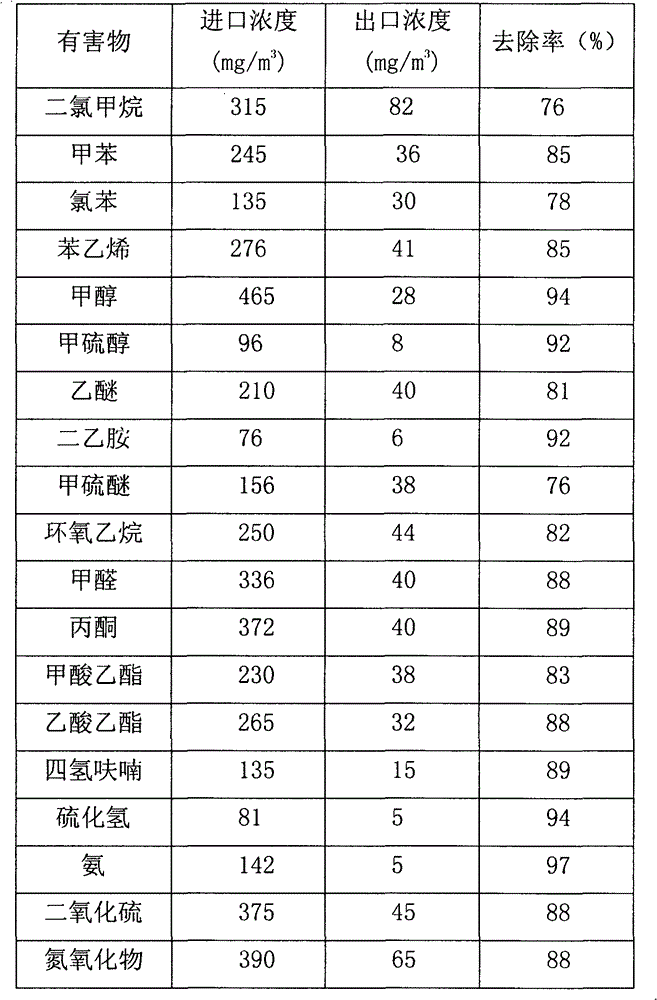

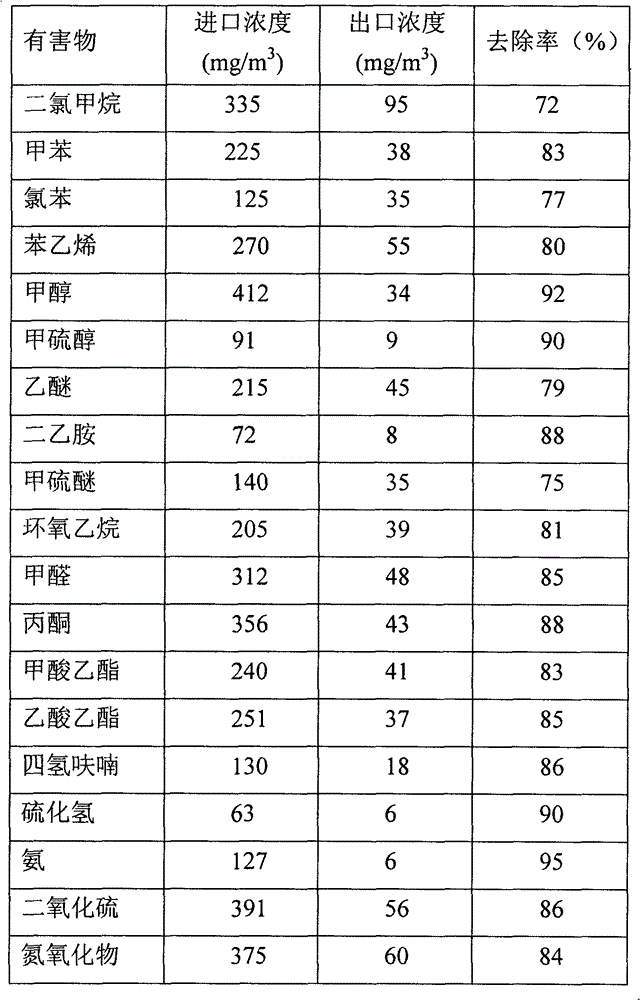

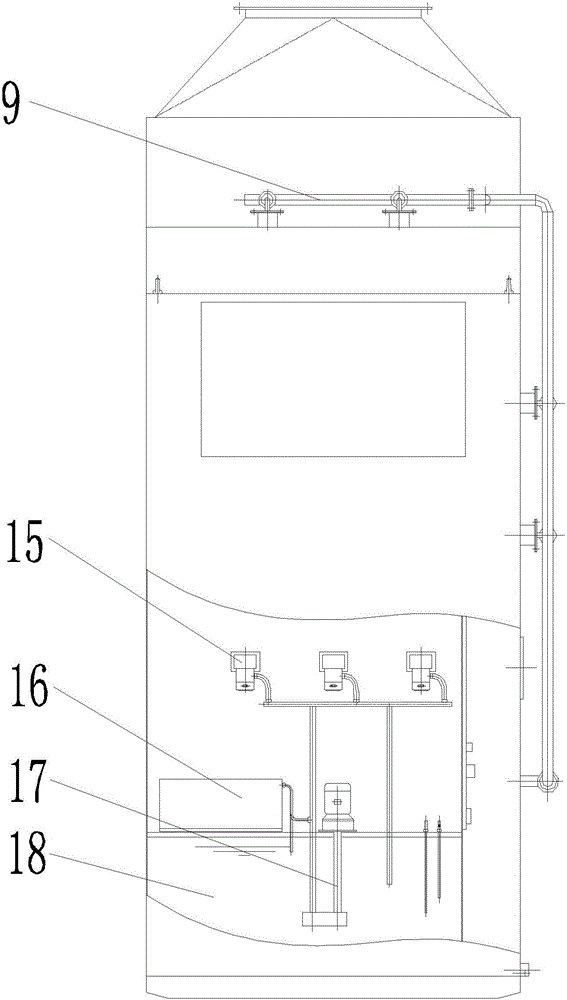

High-concentration odor pollutant waste gas treatment equipment

ActiveCN103495336AImprove processing efficiencySmall footprintDispersed particle filtrationOzone generatorHigh concentration

The invention relates to waste gas treatment equipment and particularly relates to high-concentration odor pollutant waste gas treatment equipment. The high-concentration odor pollutant waste gas treatment equipment provided by the invention comprises a plasma integrated device, an ozone generator, an oxidative purification tower and a photolysis catalytic device, wherein the plasma integrated device and the ozone generator are respectively connected with an air inlet of the oxidative purification tower, and an air outlet of the oxidative purification tower is connected with an air inlet of the photolysis catalytic device. The high-concentration odor pollutant waste gas treatment equipment has the beneficial benefits of small equipment investment, low operation cost, high gas treatment quantity, working stability, small occupied space, high treatment efficiency, no secondary pollution and the like.

Owner:深圳市科德环保科技有限公司

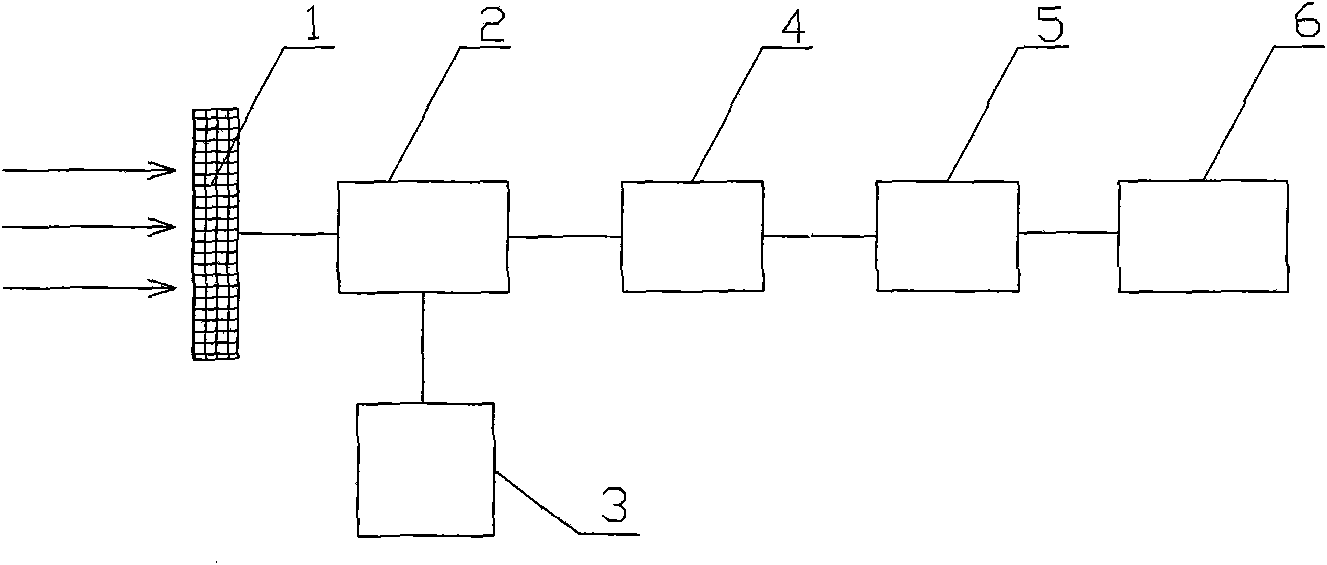

Device and method for combined use of ozone and ultraviolet rays for processing malodorous gas

InactiveCN101612522ALarge gas volumeShort reaction timeDispersed particle separationMedical waste disposalOzone generatorCombined use

The invention belongs to the technical field of waste gas processing, and particularly provides a device and a method for the combined use of ozone and ultraviolet rays for processing malodorous gas. The device of the invention consists of a filter screen, an ozone generator, an intensive mixer, an ultraviolet-catalytic oxidation reactor, an ozone tail gas removing device and a fan; wherein, the ultraviolet-catalytic oxidation reactor is formed by combining a plurality of ultraviolet tubes. The method of the invention comprises the following steps: filtering dust and other particles in the malodorous gas by using the filter screen; then, mixing the malodorous gas with the ozone generated by the ozone generator in the intensive mixer and conducting preliminary reaction; allowing the mixed gas to enter the ultraviolet-catalytic oxidation reactor after mixing; generating active oxygen by activating the ozone gas under the ultraviolet action, and conducting a series of reactions with the malodorous gas; and finally, processing the ozone tail gas by the ozone tail gas removing device. The fan is arranged at the back of the device, thereby ensuring that the reactor is under a negative pressure and preventing the malodorous gas from leaking. The invention for processing the malodorous gas has the advantages of large treatment capacity and high efficiency of the malodorous gas.

Owner:许加栋 +1

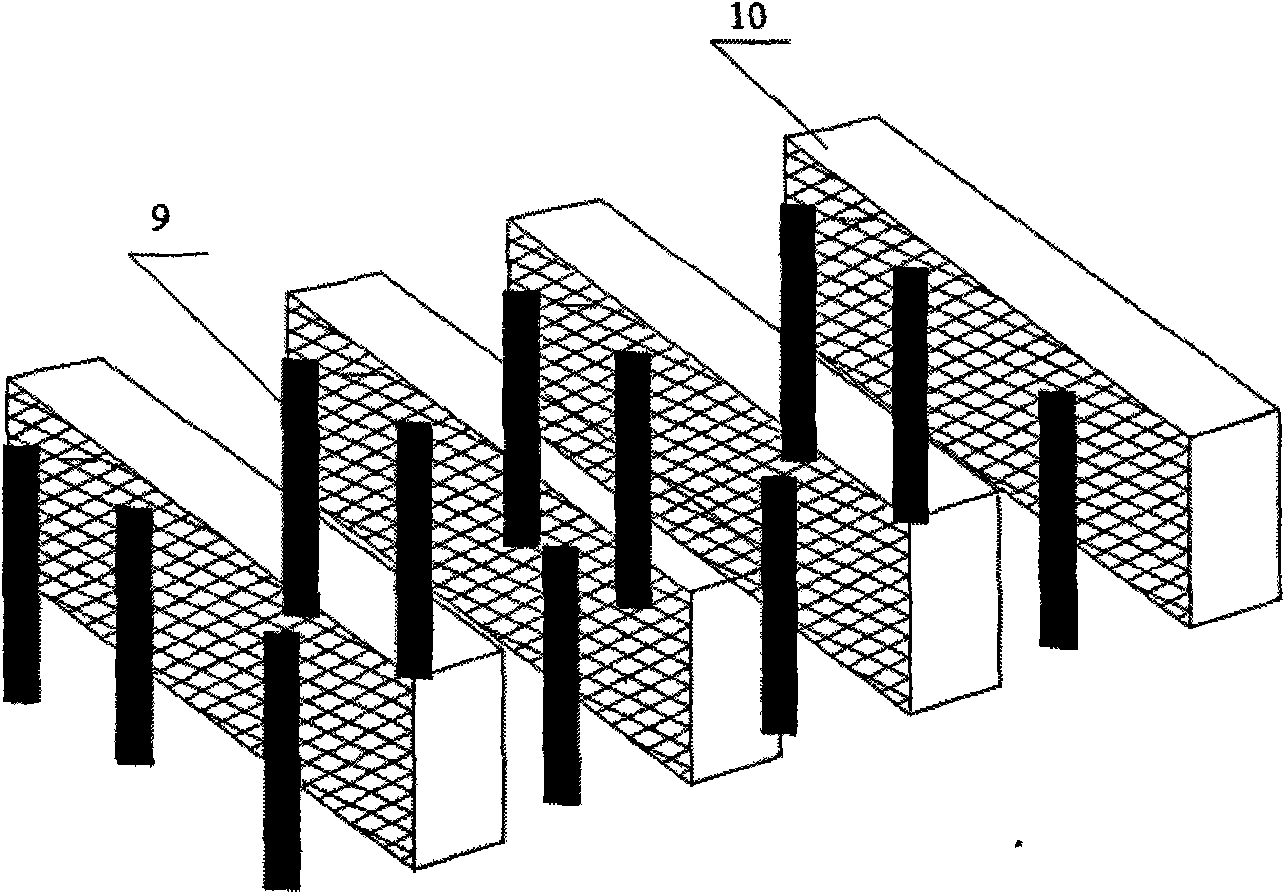

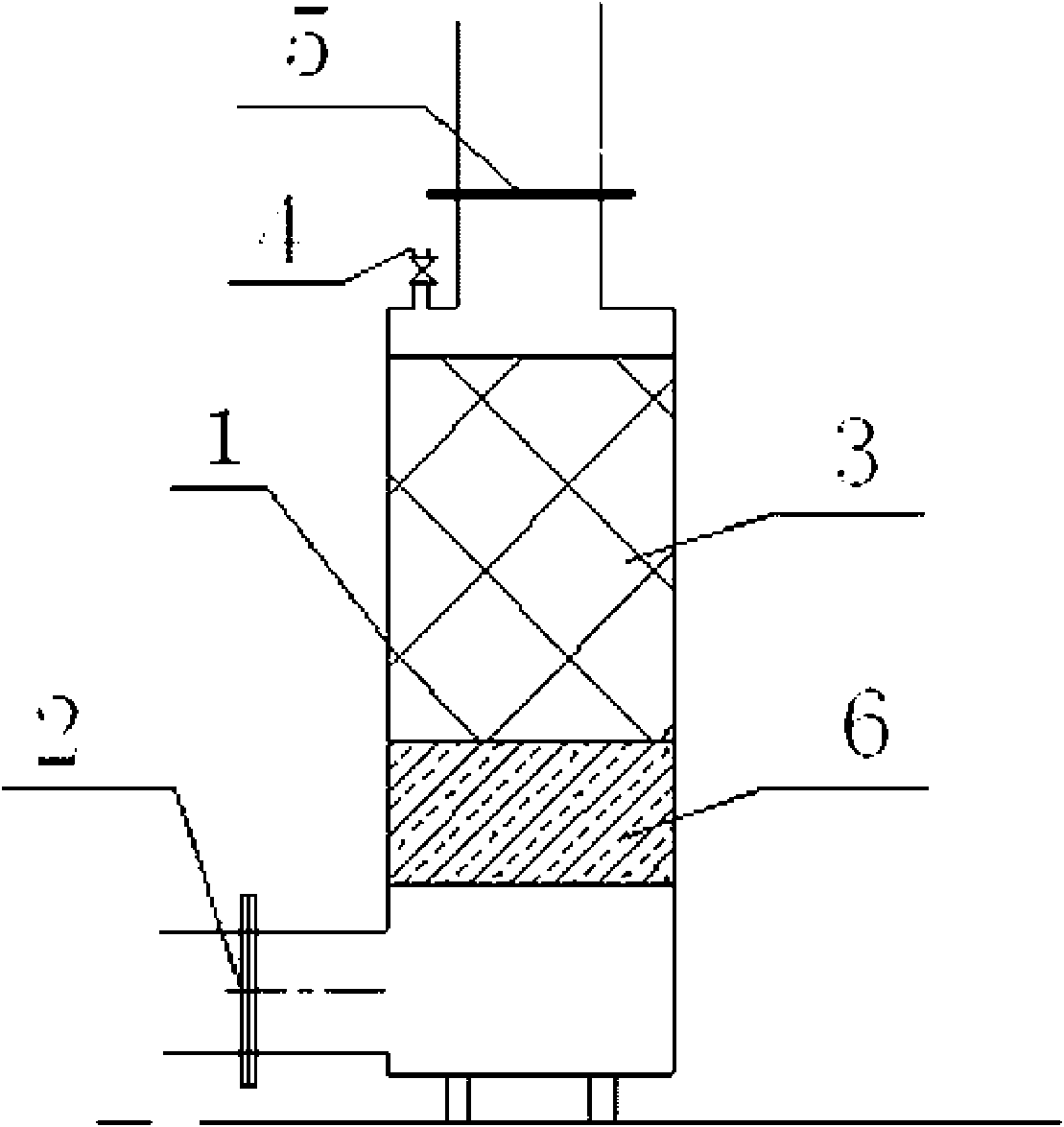

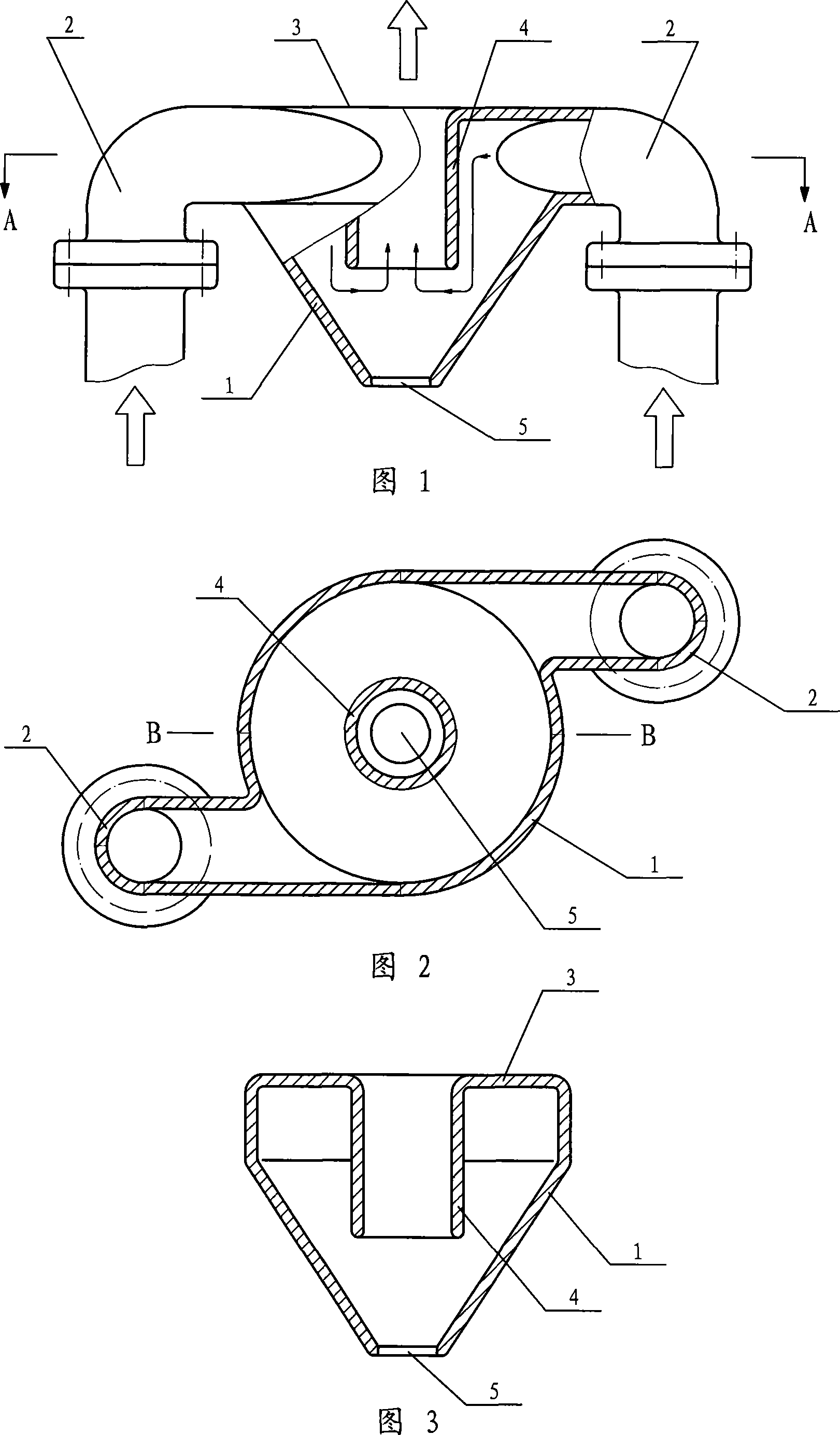

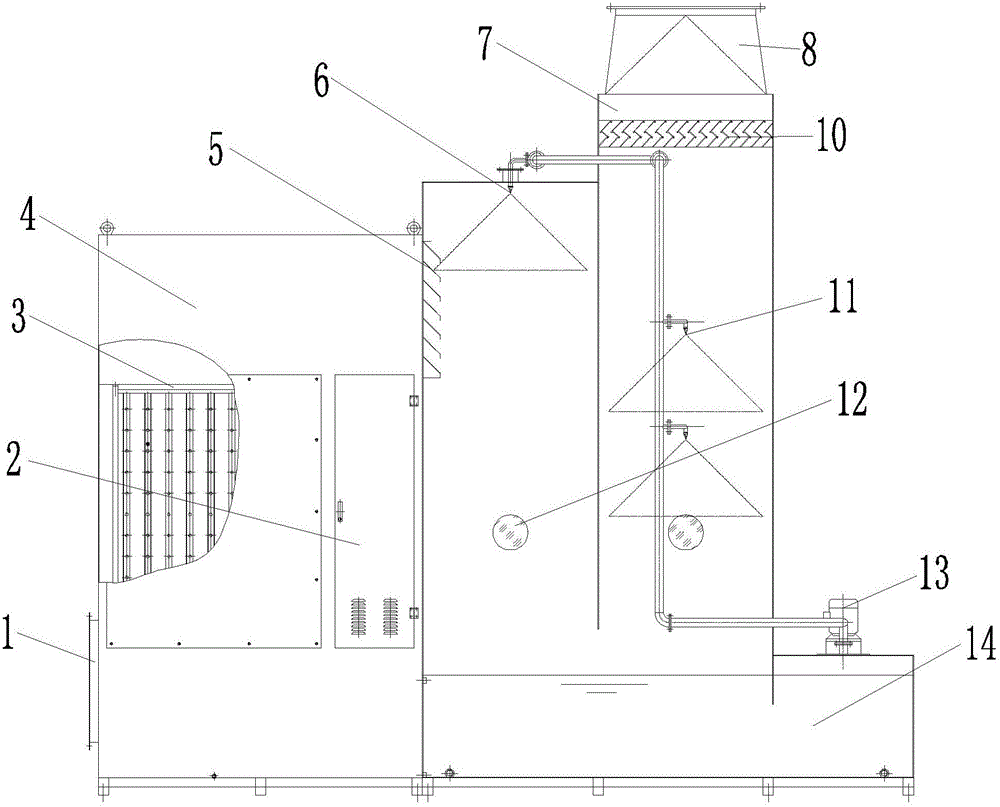

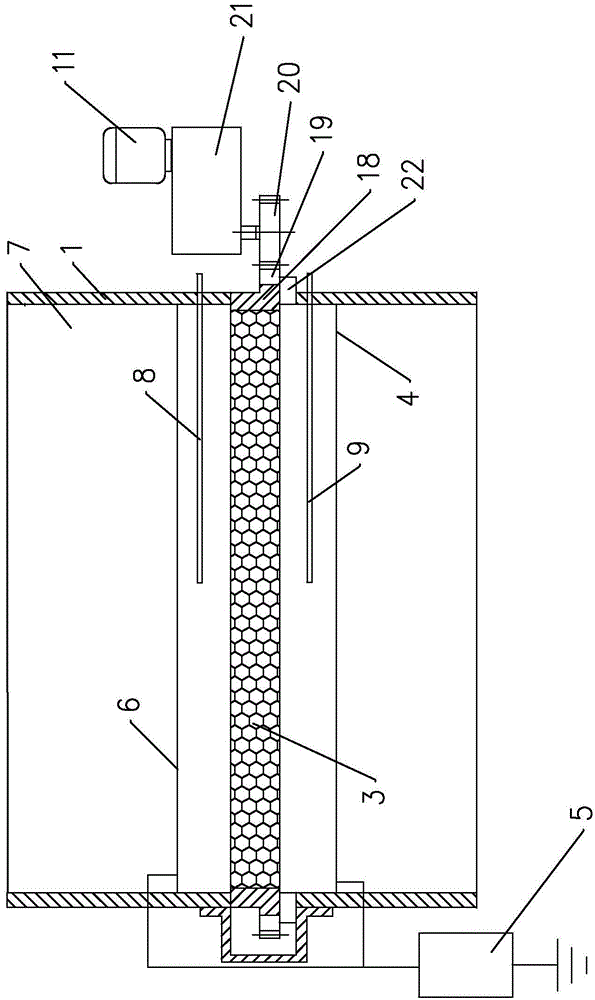

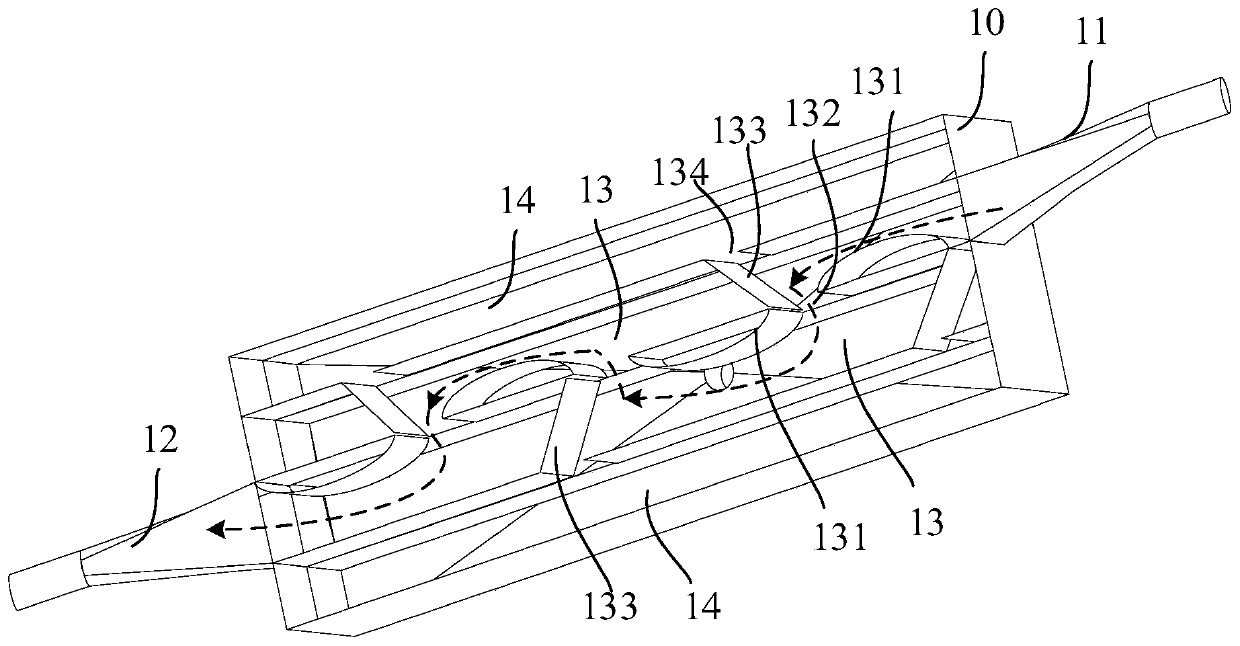

Bio-trickling device for processing volatile organic waste gas and method thereof

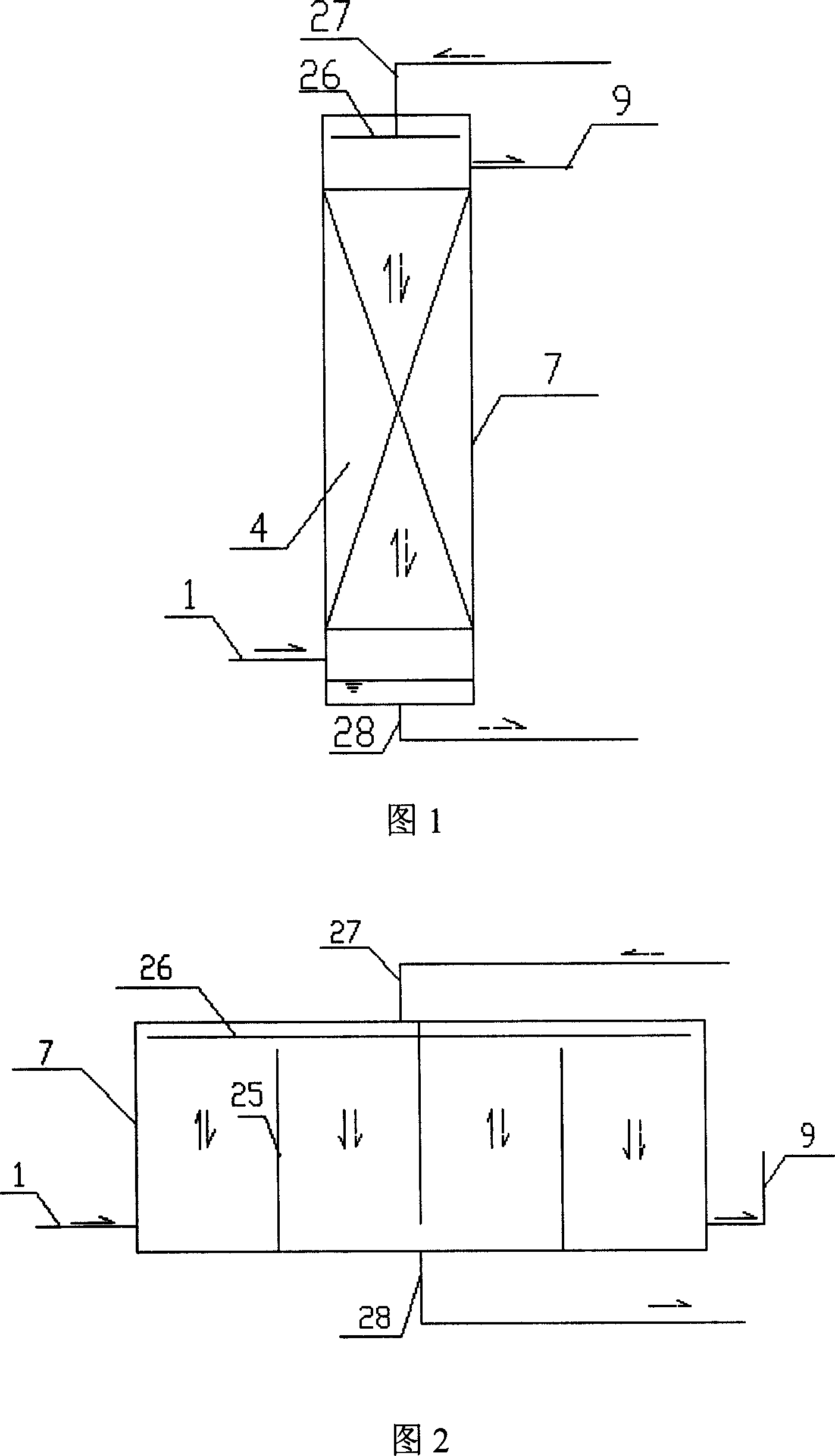

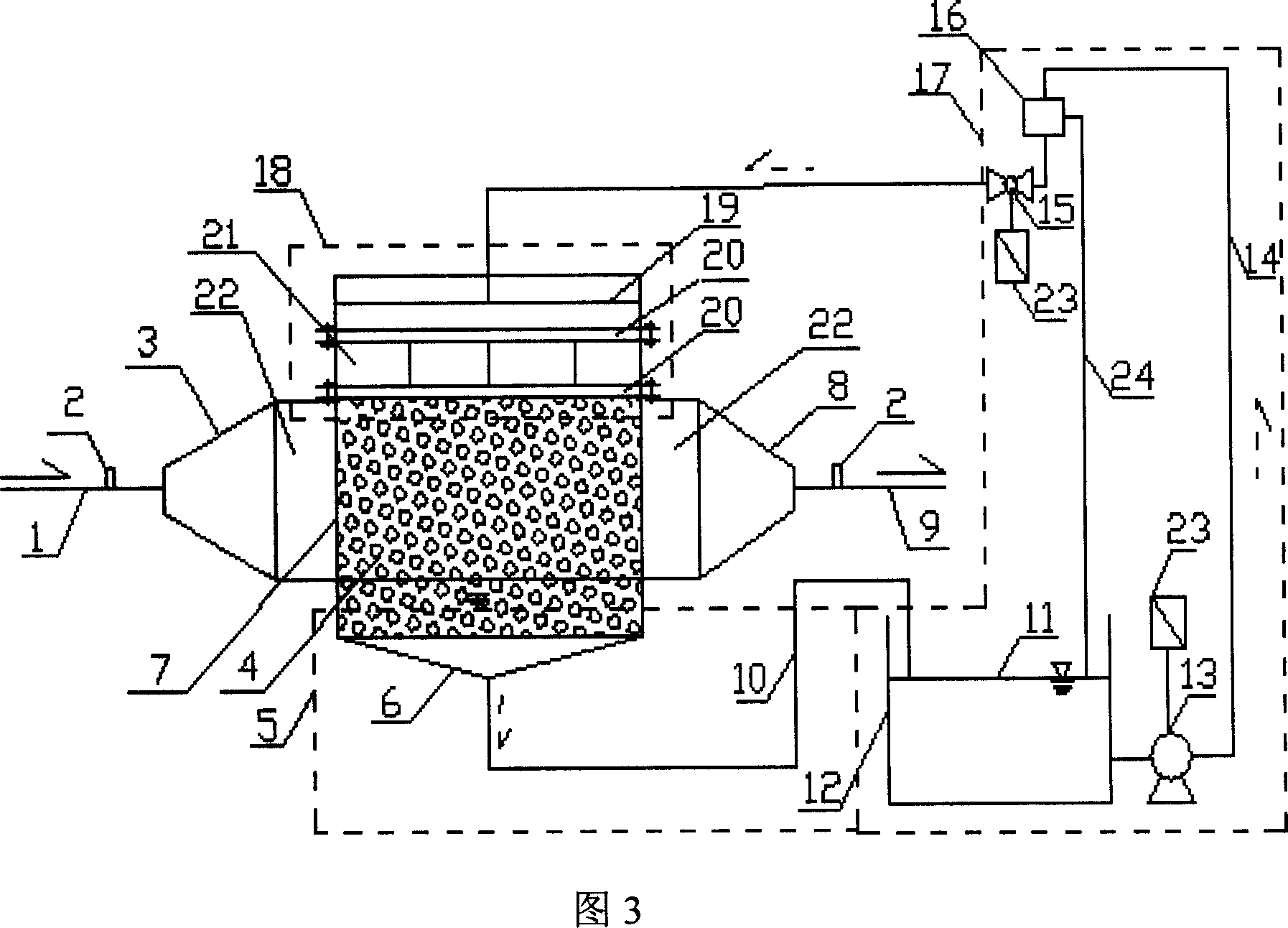

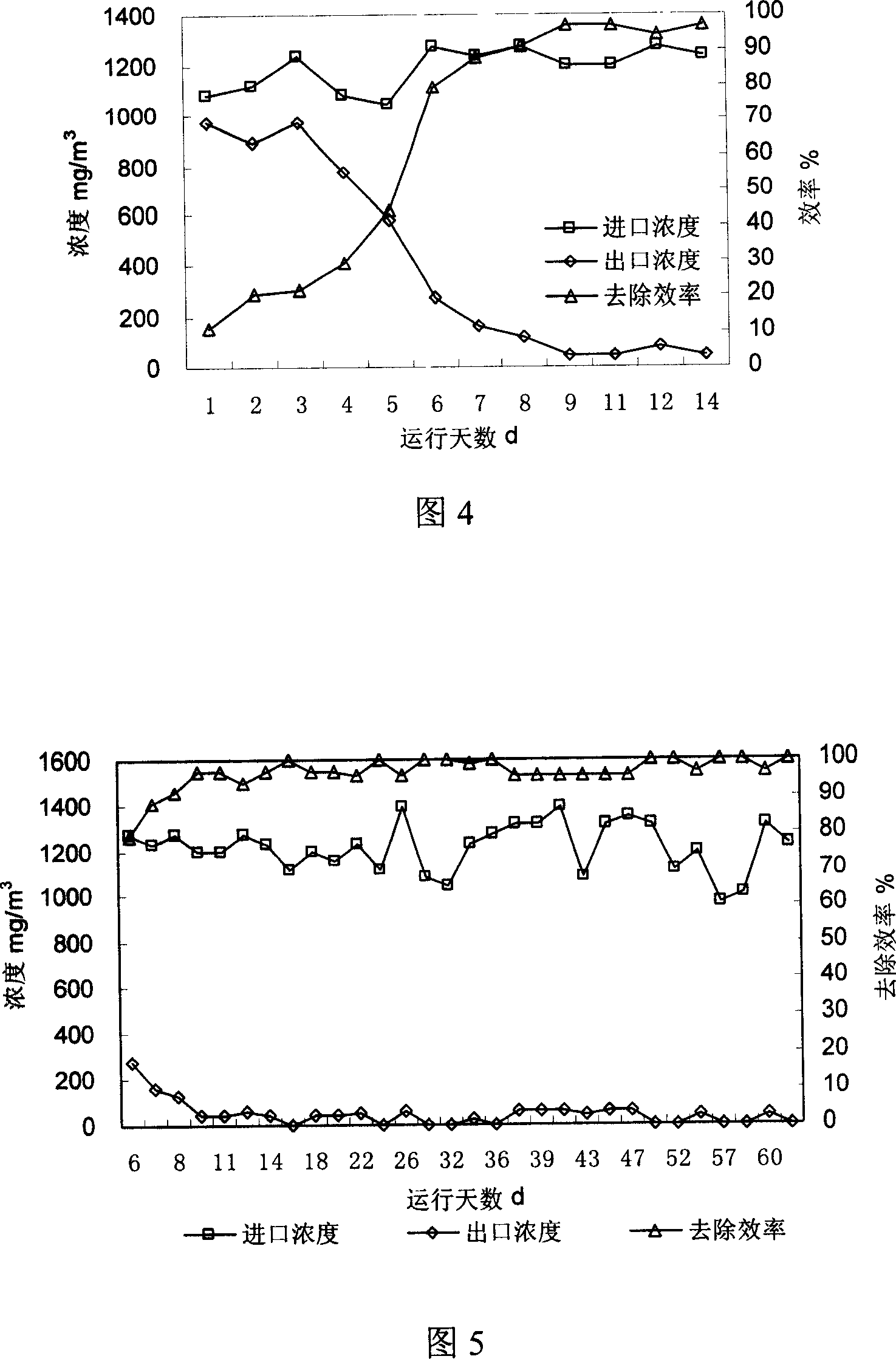

InactiveCN1994533AReduce flow heightIncreased load removal capacityDispersed particle separationAir quality improvementForming gasNutrient solution

The invention relates to a biological drop filter and relative method for treating volatile organic waste gas, wherein it comprises that: feeding volatile organic waste gas into gas inlet tube (1) and main body (7) of reactor to be degraded and purified to be discharged from ventilate tube (9); the nutriment (11) enters into main body (7) via the nutriment distributor (18); the invention is characterized in that: the entrance of volatile organic waste gas is along the horizontal central line of main body 97); the nutriment (11) flows along the main body (7) from up to down, to form gas-liquid alternative contact in the main body (7). The invention can strengthen the biological degrade ability, with small area.

Owner:BEIJING UNIV OF TECH

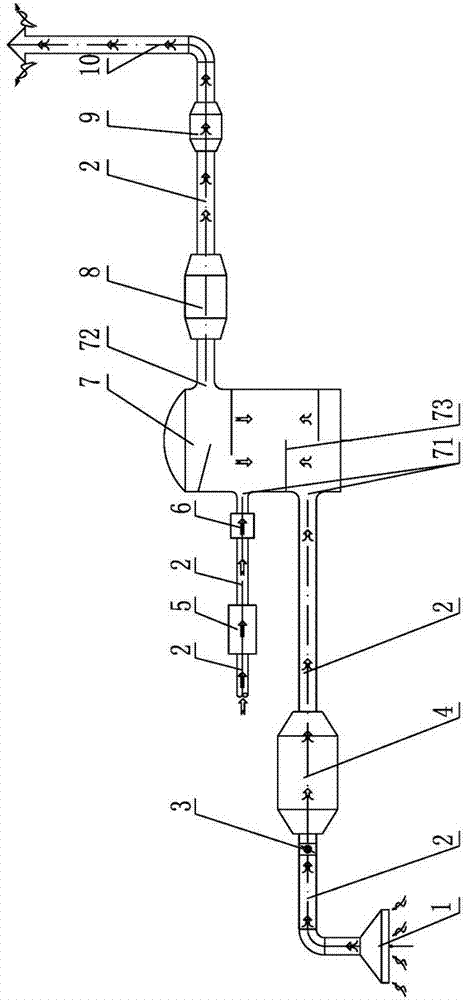

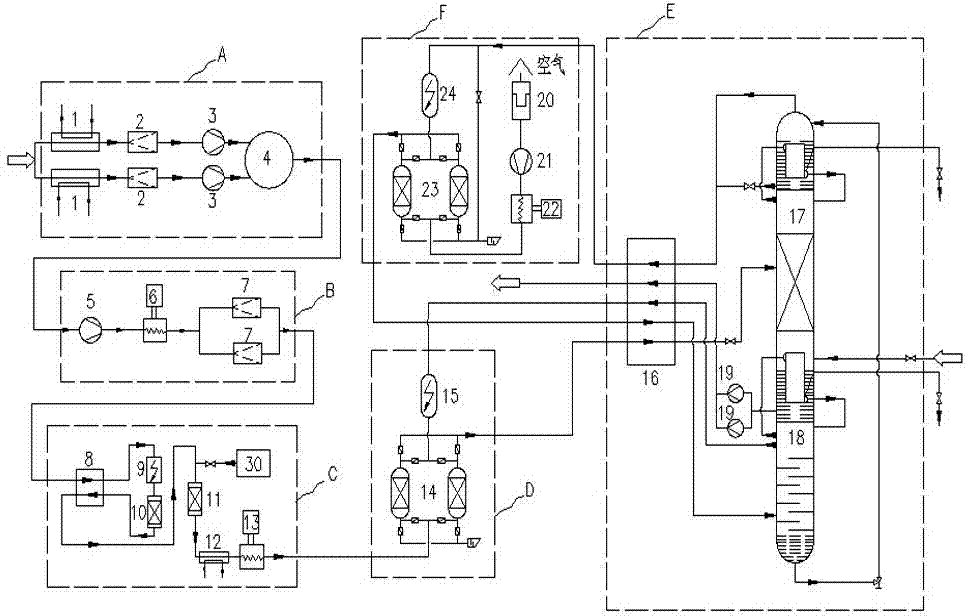

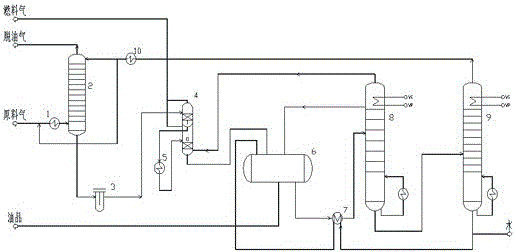

Method and device for purifying and recycling emitted argon in preparation process of monocrystalline silicon

ActiveCN103373716AHigh recovery rateImprove reliabilityNitrogen purification/separationNoble gas compoundsAlkaneAutomatic control

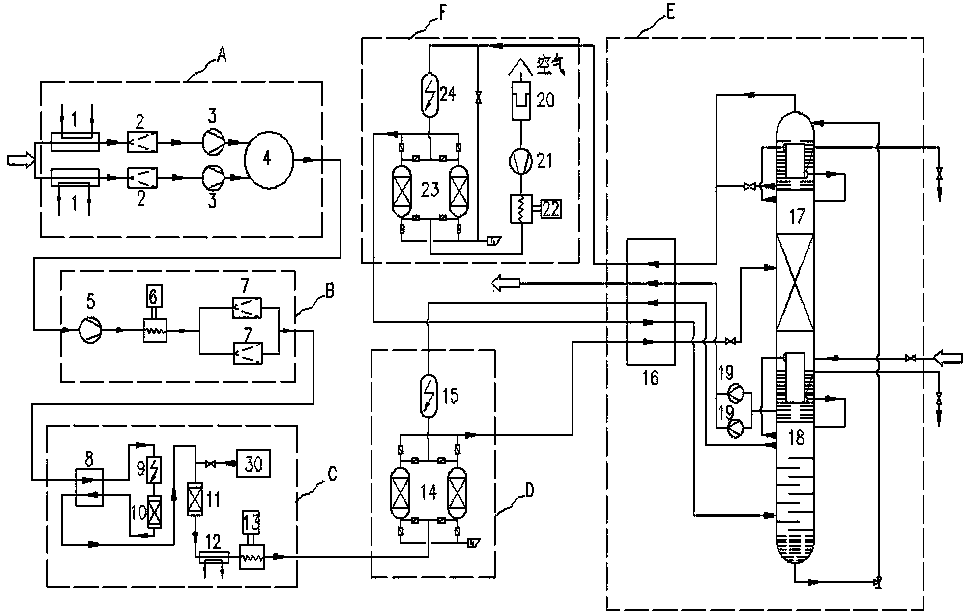

The invention relates to a method and device for purifying and recycling emitted argon in a preparation process of monocrystalline silicon. The method comprises the following steps of: collecting crude argon emitted by a monocrystalline silicon furnace and then carrying out compression oil removal treatment, removing carbon monoxide and alkane by adopting a catalytic oxidation method, removing oxygen by adopting a hydrogenation oxygen removing method, removing carbon dioxide and water by adopting an adsorption method, and removing nitrogen and hydrogen by adopting a high-low pressure dual-tower low-temperature distillation method to finally obtain pure compressed argon which can be directly conveyed to the monocrystalline silicon furnace for being recycled. The device comprises a crude argon collecting and pretreating system for carrying out crude oil filtration on the crude argon emitted by the monocrystalline silicon furnace, a compression oil removing system for filtering refine oil, a catalytic reaction system for removing carbon monoxide, alkane and oxygen components, a crude argon purifying system for removing the carbon dioxide and the water, a low-temperature distillation system for removing the nitrogen and hydrogen components, an air treating system for providing a raw material air source for a process of preparing the nitrogen by the low-temperature distillation system, and an automatic control system for controlling the whole set of device. The method and device can realize that a large quantity of protection argon in the monocrystalline silicon industry is recovered and recycled.

Owner:HANGZHOU HANGYANG

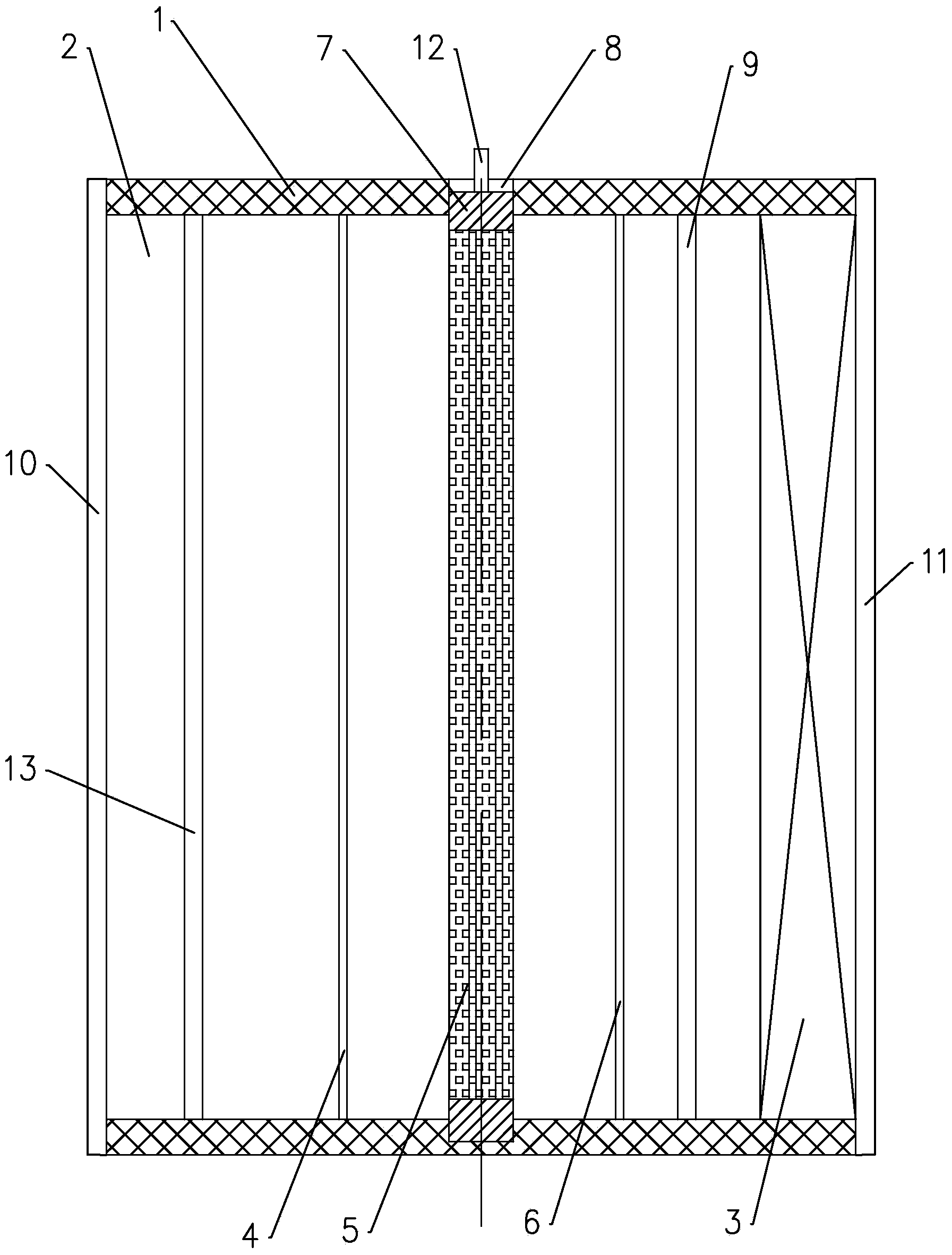

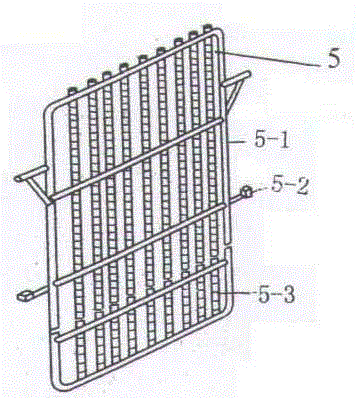

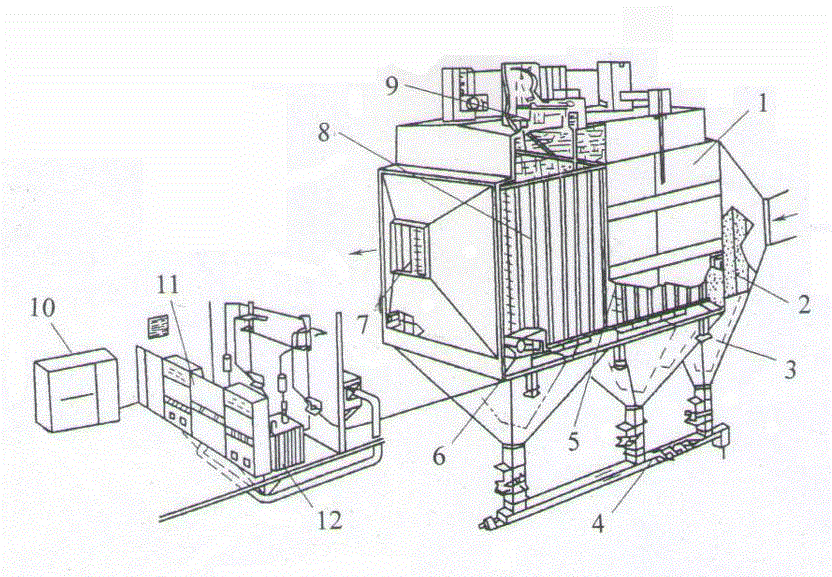

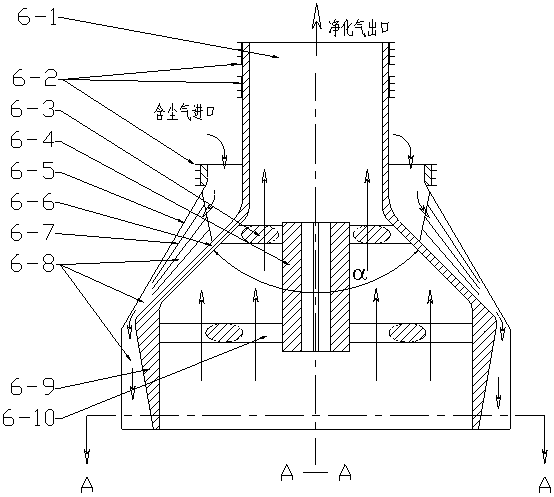

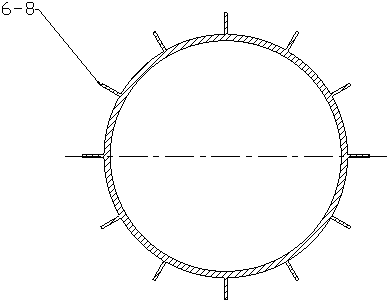

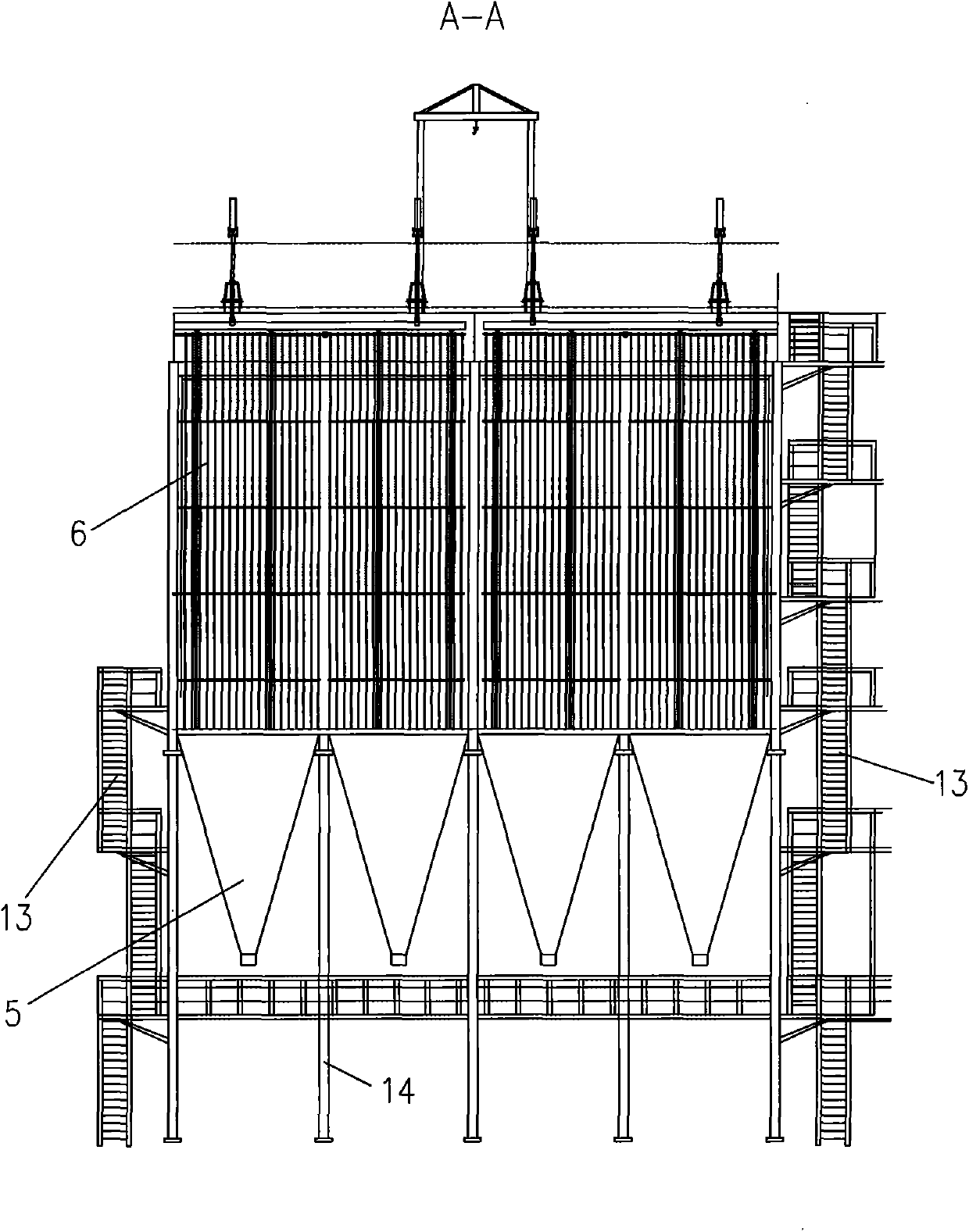

Filtering bag type dust removal device with movable pulse injection and ash removal device

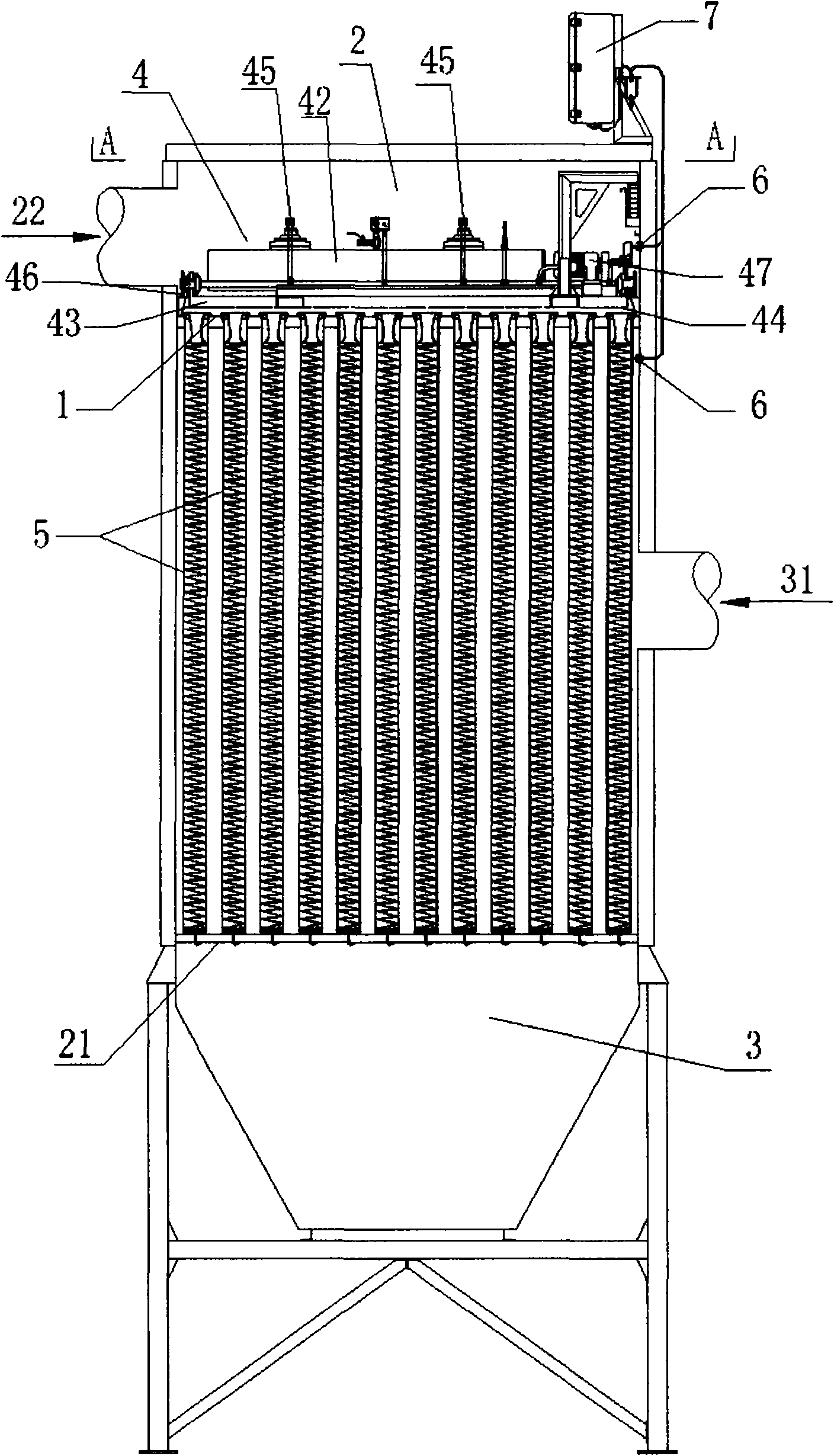

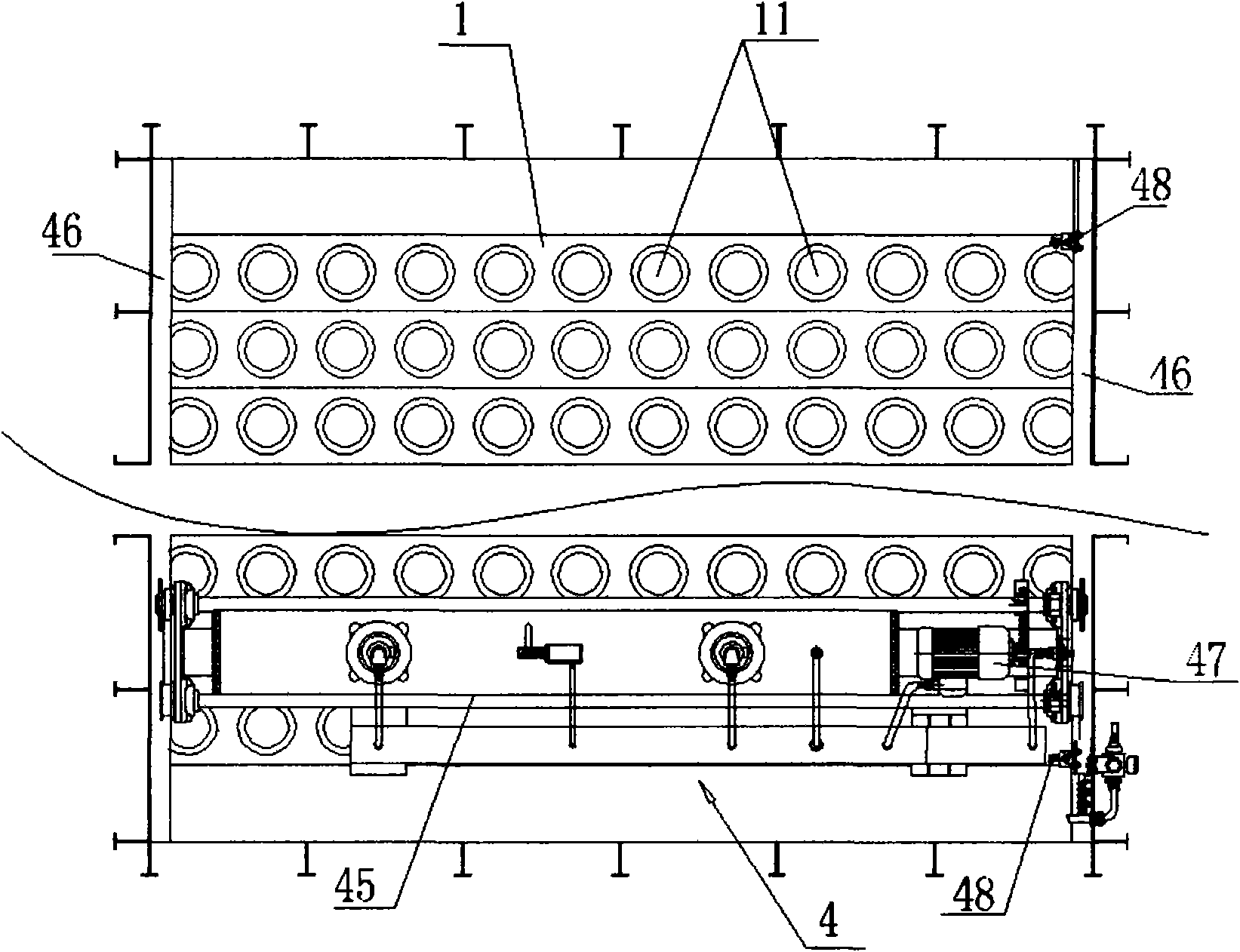

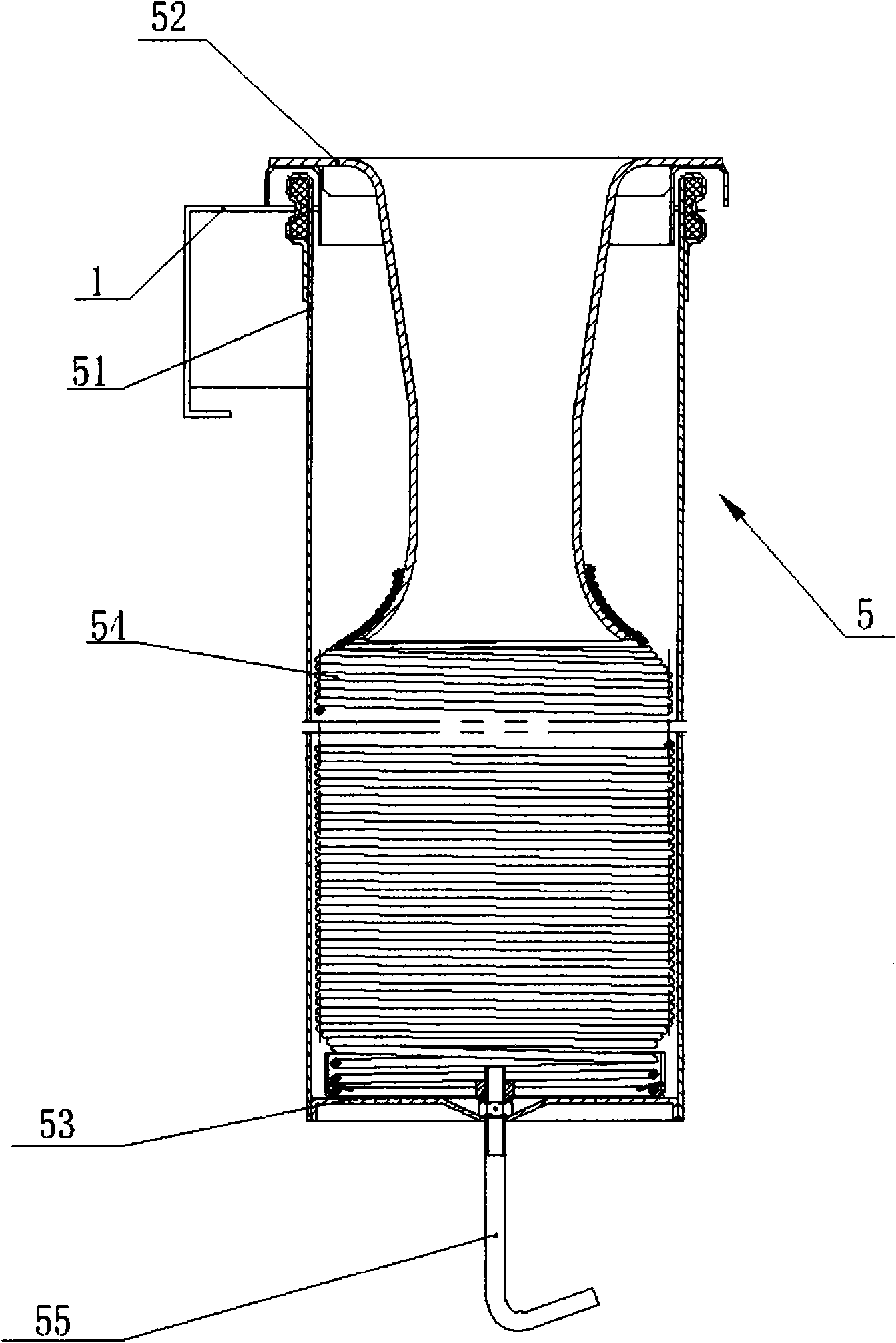

InactiveCN102151444ASolution to short lifeWork lessDispersed particle filtrationInjection portDifferential pressure

The invention relates to a filtering bag type dust removal device, in particular to a filtering bag type dust removal device with a movable pulse injection and ash removal device. The injection device comprises a mobile table, a high-pressure air storage cylinder and an injection row, wherein the mobile table can translate back and forth along the plate surface of a horizontal partition plate; the high-pressure air storage cylinder and the injection row are arranged on the mobile table; a tube wall at the lower part of the injection row is provided with an injection port opposite to each filtering bag of a corresponding line; an electromagnetic pulse valve for controlling the switch-on / switch-off is arranged between the high-pressure air storage cylinder and an injection row communication pipe; a circuit control system comprises pressure air tube filters, a differential pressure adjustment compensator and a mobile injection differential pressure control assembly, wherein one of the pressure air tube filters is arranged in a lower air chamber to detect the real-time pressure; the differential pressure adjustment compensator is connected with the pressure air tube filters by a circuit; the pressure air tube filters are respectively installed at the positions of an upper air chamber and the lower air chamber and are connected with the differential pressure adjustment compensator; and the pressure situations at the positions of the upper air chamber and the lower air chamber are immediately transmitted to the mobile injection differential pressure control assembly to be monitored. The filtering bag type dust removal device can maximally save the consumption of compressed air and reduce the use cost.

Owner:HUI DA ENVIRONMENTAL PROTECTION

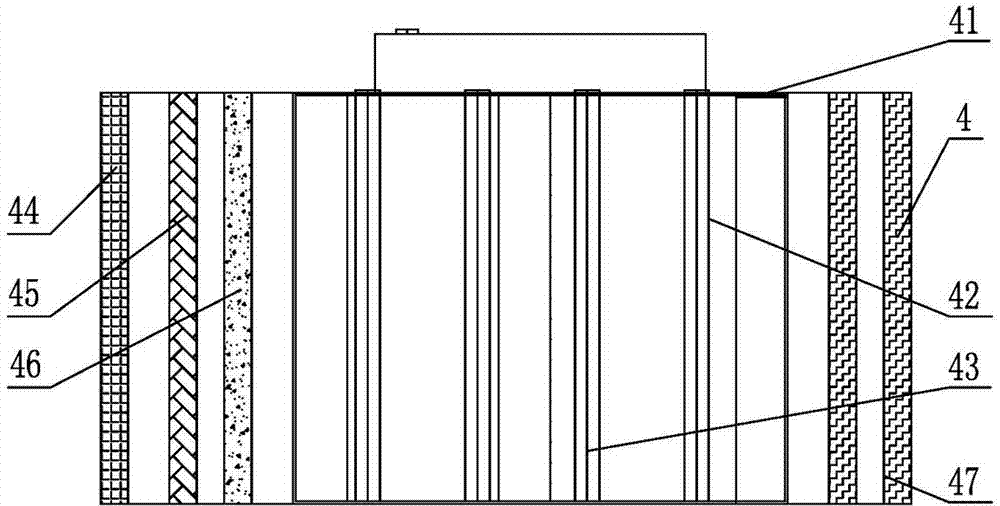

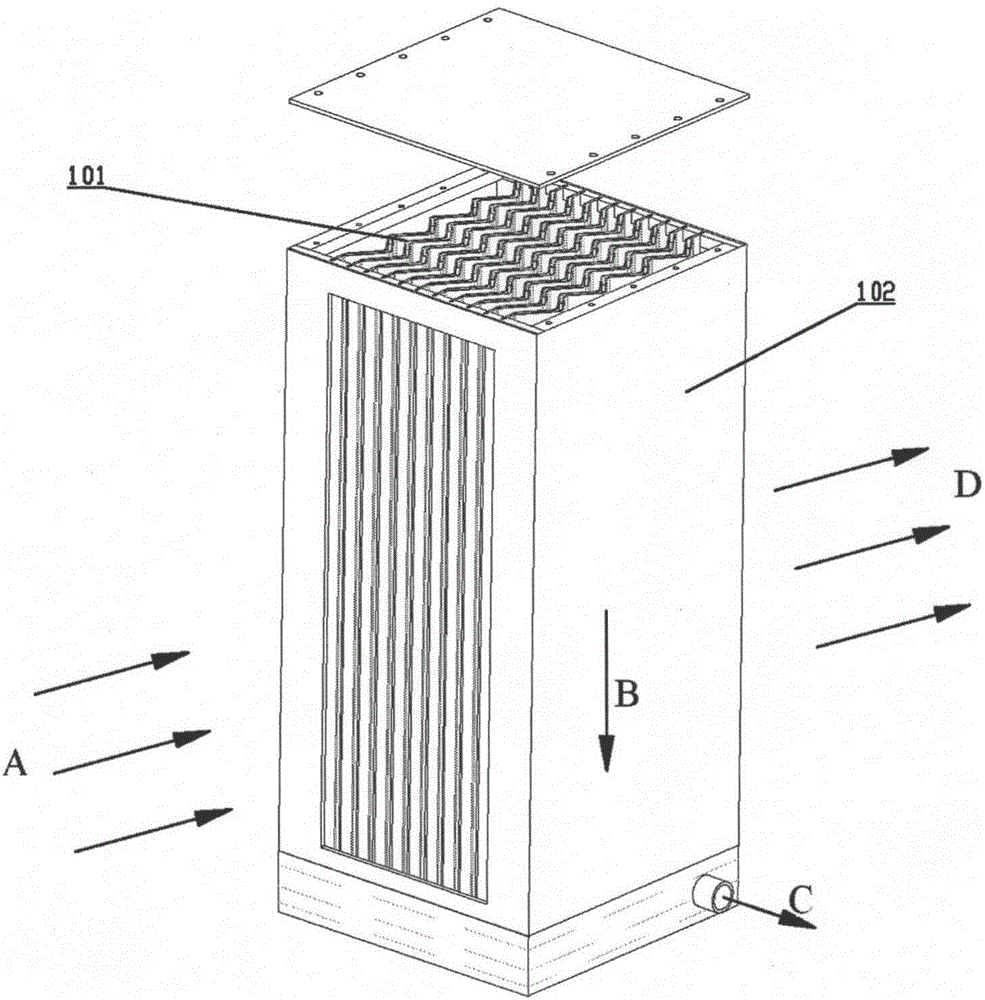

Combined type runoff electric precipitation air purifier

InactiveCN103949345ALarge gas volumeReduce wind resistanceExternal electric electrostatic seperatorElectrode constructionsElectricityPotential difference

The invention discloses a combined type runoff electric precipitation air purifier. The combined type runoff electric precipitation air purifier comprises a shell, wherein an air purification channel is formed in the shell; a front discharging net is arranged in the air purification channel in a direction of the section of the air purification channel; the front discharging net is fixedly connected to the shell; a dust collection electrode net plate is arranged behind the front discharging net in the air purification channel; airflow is capable of flowing through the surface of the dust collection electrode net plate; the dust collection electrode net plate is manufactured by multiple layers of wire nets which are stacked by porous foam metal plates, a plurality of parallel corrugated plates, a plurality of parallel flat plates or honey comb plates, or a plurality of wire net surfaces; a potential difference being 5000-60000V is generated between the front discharging net and the dust collection electrode net plate due to electric connection with a high-voltage direct-current power supply. The invention aims to provide the combined type runoff electric precipitation air purifier. The combined type runoff electric precipitation air purifier is capable of treating a large volume of air in unit of time, low in wind resistance, prominent in effect of removing tiny dust within PM (Particulate Matter) being 2.5, extremely stable in dust collection performance, low in operation cost and long in service life.

Owner:孟金来

High-efficiency gas purification bioreactor based on complex enzyme immobilization technology and purification method thereof

InactiveCN101632900ANo secondary pollutionReduce consumptionDispersed particle separationChemical/physical/physico-chemical processesGlass fiberPurification methods

The invention relates to the technical field of a high-efficiency gas purification bioreactor based on a complex enzyme immobilization technology and a purification method thereof. The high-efficiency gas purification bioreactor comprises a vertical glass fiber reinforced plastic tank body, wherein the lower part of the tank body is provided with a gas inlet, a high-efficiency complex enzyme catalysis filling layer is arranged on an upper cavity, and the top of the tank body is connected with a gas outlet and provided with a safe valve. The bioreactor and the method can use a specific complex enzyme catalytic degradation function to process gas which is difficult to process by the prior pollution treatment art, has the enzyme catalytic degradation function, removes or converts useless gas or harmful gas, remains or obtains useful gas and has low processing cost, high efficiency and convenient use.

Owner:江苏晨翔环境科技股份有限公司

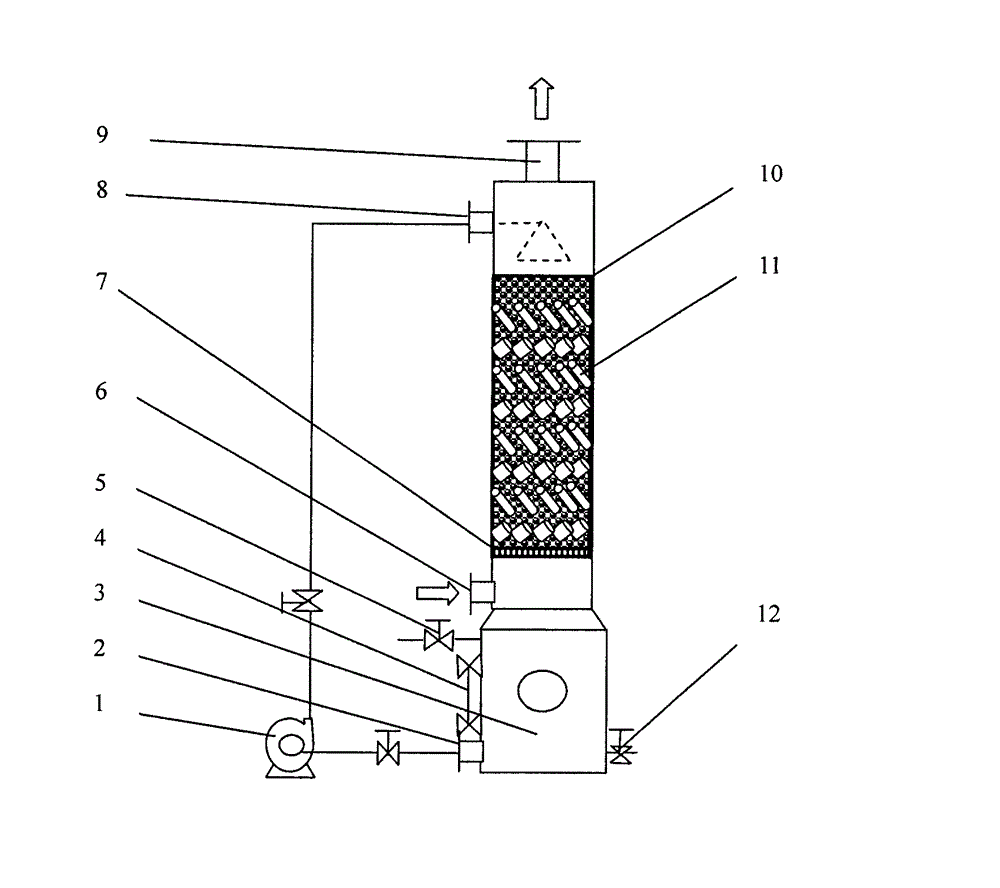

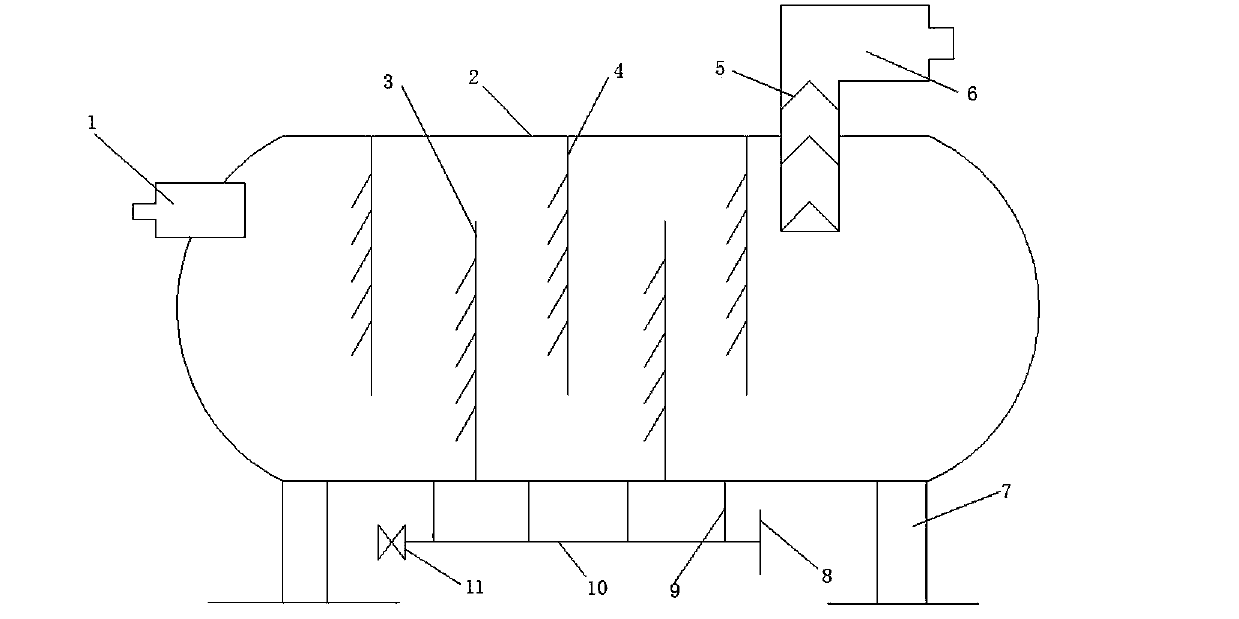

Device and process for purifying harmful gas through combining gas-liquid absorption with micro-electrolysis

InactiveCN102872703AAvoid the possibility of secondary volatilizationLarge gas volumeDispersed particle separationSolubilityElectrolysis

The invention discloses a device and process for purifying harmful gas through combining gas-liquid absorption with micro-electrolysis. The device is composed of an absorption tower, a packing layer and an absorption liquid circulating tank, wherein the packing layer is composed of activated carbon and iron packing. The treatment process is implemented through that: a harmful gas containing airflow to be treated is imported into the device from the lower part of the absorption tower; then, when the harmful gas containing airflow passes through the packing layer composed of activated carbon and iron packing, the harmful gas is effectively absorbed and degraded under the electrode reaction action of multiple micro-batteries formed by the activated carbon and the iron packing; and finally, the purified airflow is discharged from a gas outlet at the upper part of the absorption tower. According to the invention, through adopting a mode of combining liquid absorption and micro electrolytic reaction, the absorption effect is greatly improved, and the possibility of secondary volatilization of harmful substances is also avoided, therefore, the device and process disclosed by the invention are especially applicable to the treatment of harmful gaseous pollutants such as chlorine-containing organic matters, toluene and the like which are poor in water solubility; and the device and process disclosed by the invention are high in treatment efficiency, large in treated gas volume, simple in operation, reliable and practical.

Owner:黄立维

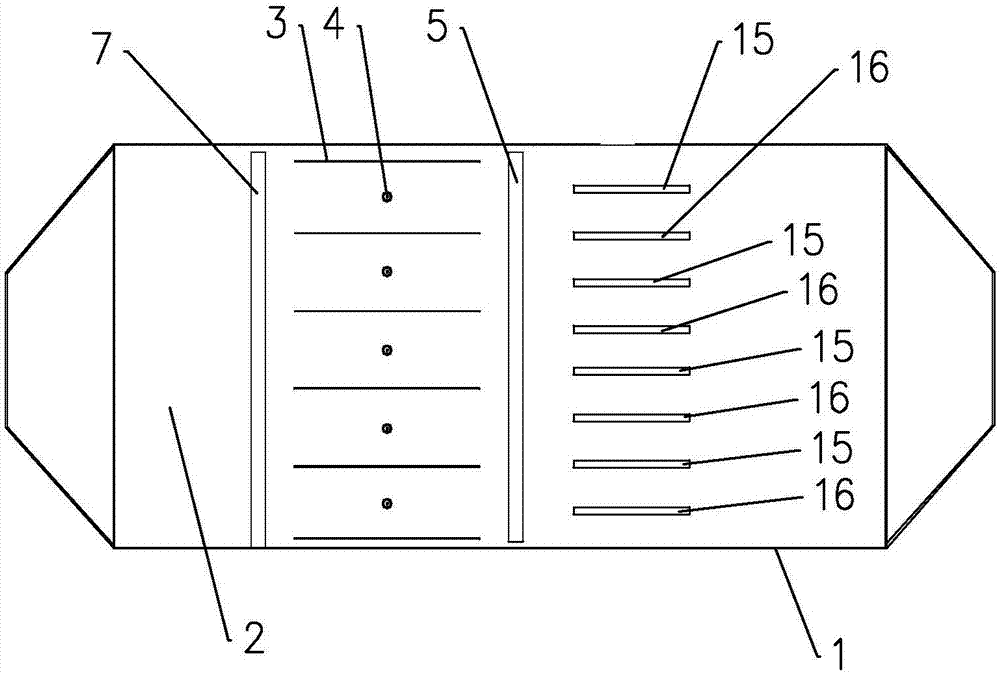

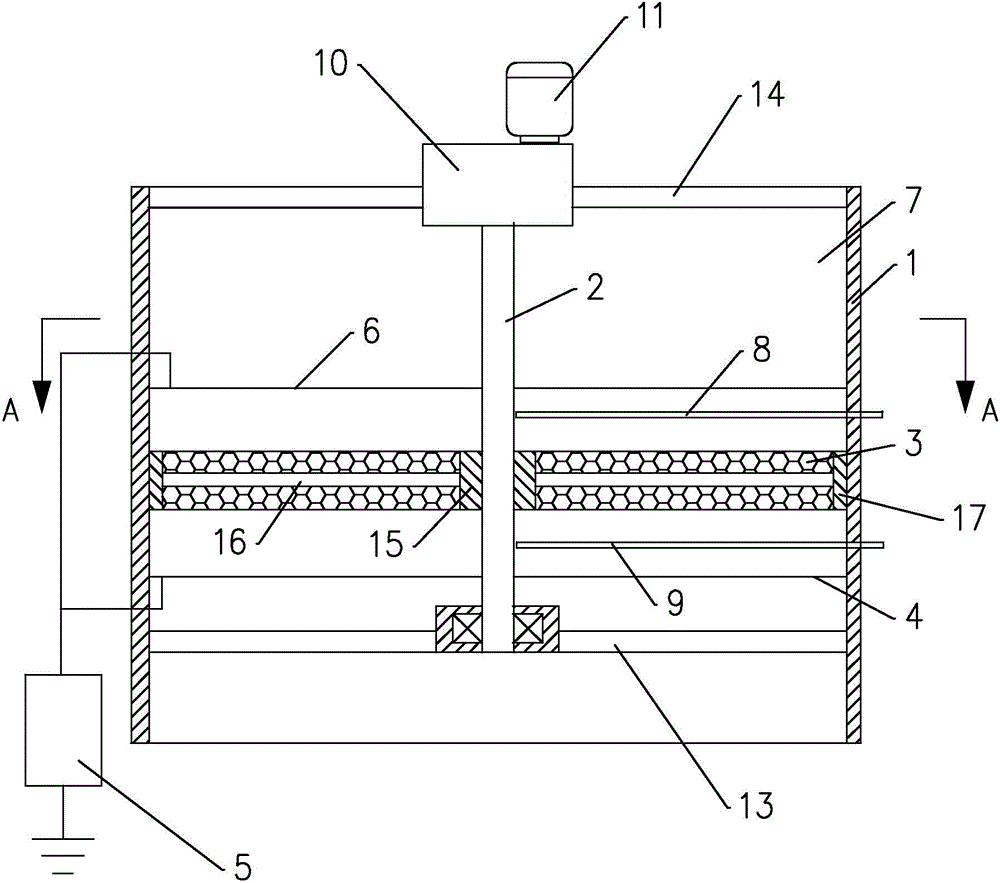

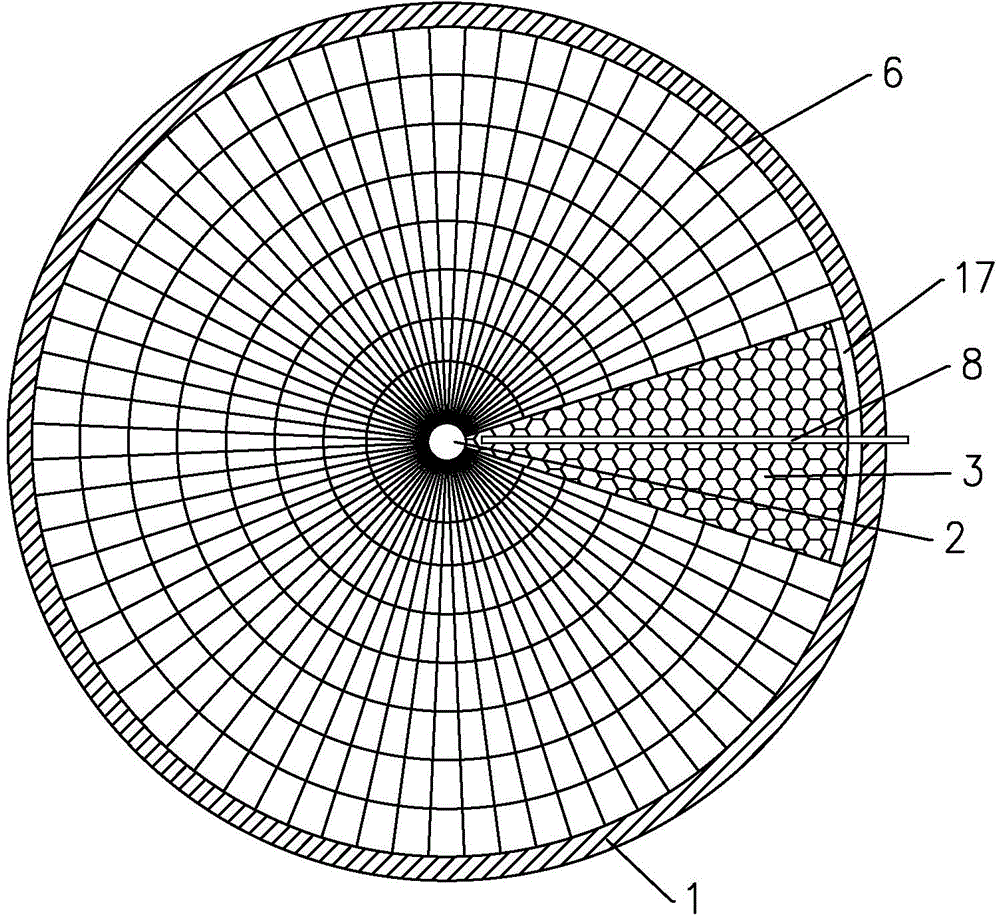

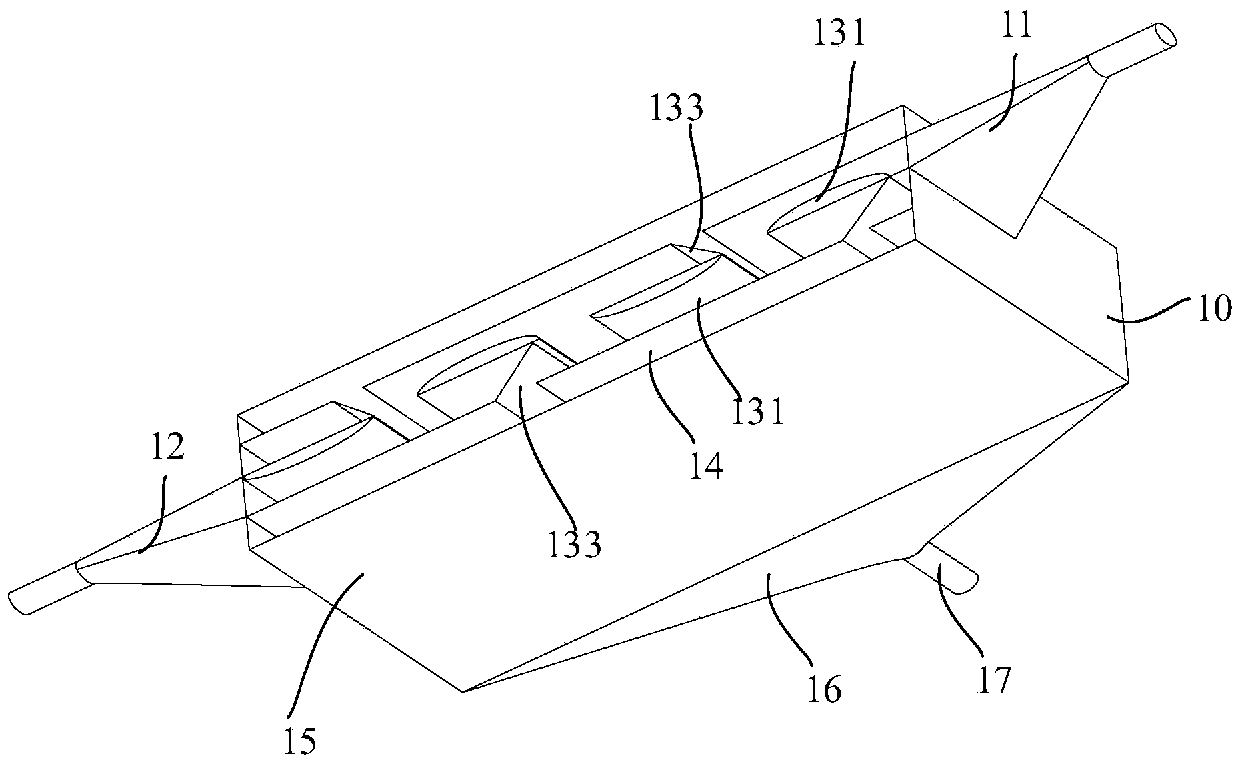

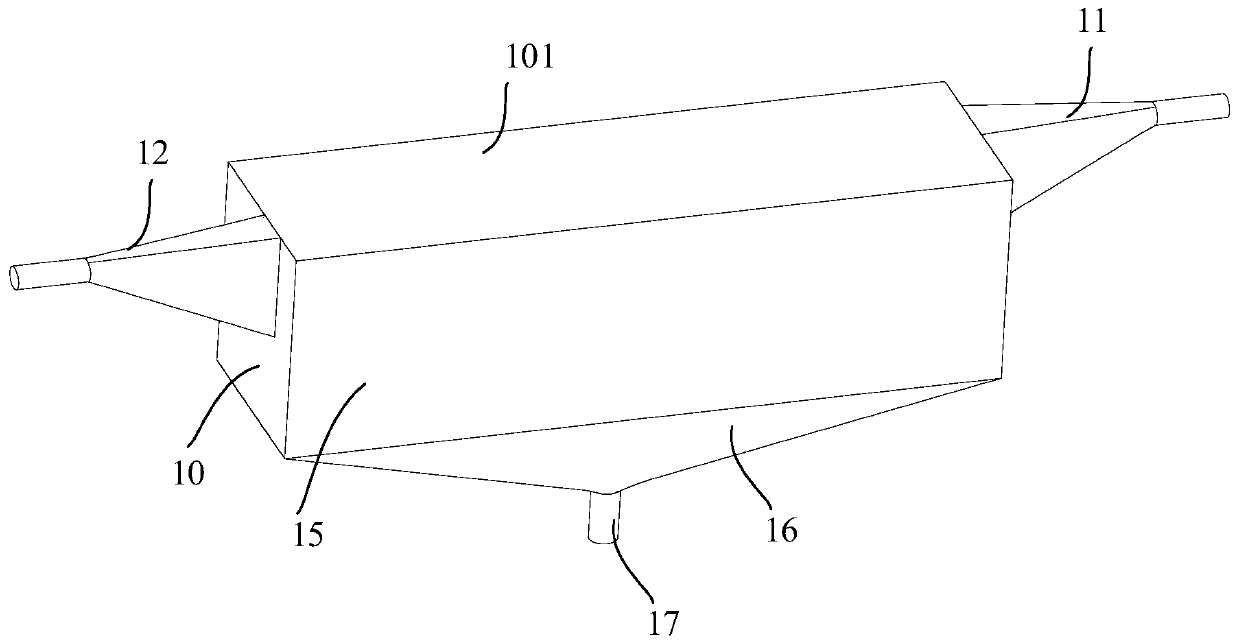

One-tank multi-stage horizontal separator

InactiveCN103585823AReduce volumeLarge gas volumeDispersed particle separationElectrolysisCentrifugation

The present invention discloses a one-tank multi-stage horizontal separator, which comprises a tank, tank bottom feet, fractionation dropping vertical pipes, a drop aggregation pipe and the like. According to the present invention, principles of gravity sedimentation separation, centrifugation separation, collision separation and multiple separation are adopted to increase hydrogen and oxygen purity; a hydrogen and oxygen mixture produced through water electrolysis enters the separator from an inlet, is sprayed on a separation plate to be spread, and a varnish and oxygen dissolved in the liquid are separated due to a diffusion effect; the liquid falls down through self-gravity, and passes through the gap on the lower portion of the separation plate, and the flow direction of the gas carrying small droplets is changed a plurality of times in the separator, such that the small droplets are condensed and fall down; and the liquid on the lower portion of the separator is discharged out of the separator through a liquid discharge valve, the carried trace droplets are condensed and removed again when the separated gas passes through separation umbrella cut holes so as to obtain purified gas, wherein the purified gas is discharged from a gas outlet. The one-tank multi-stage horizontal separator has characteristics of large gas production, excellent separation effect, high gas purity, small occupation space, economy, applicability and the like.

Owner:HARBIN ERQING TECH

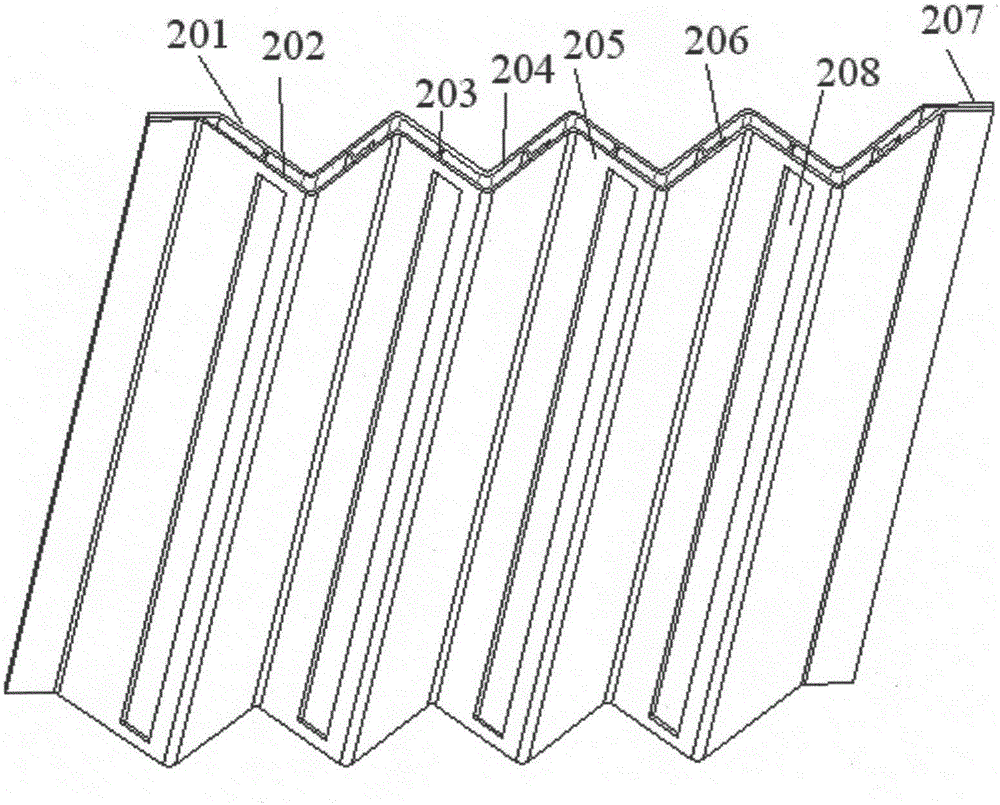

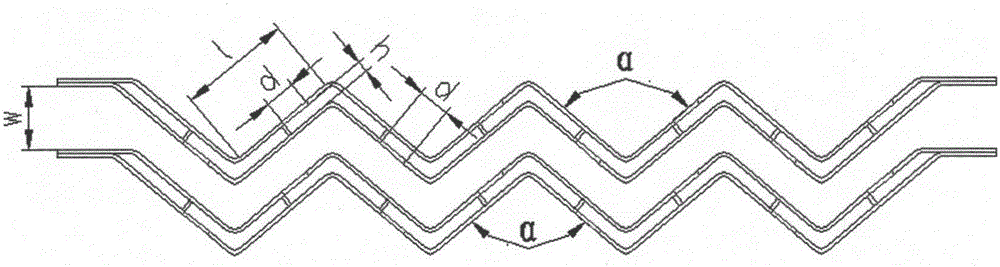

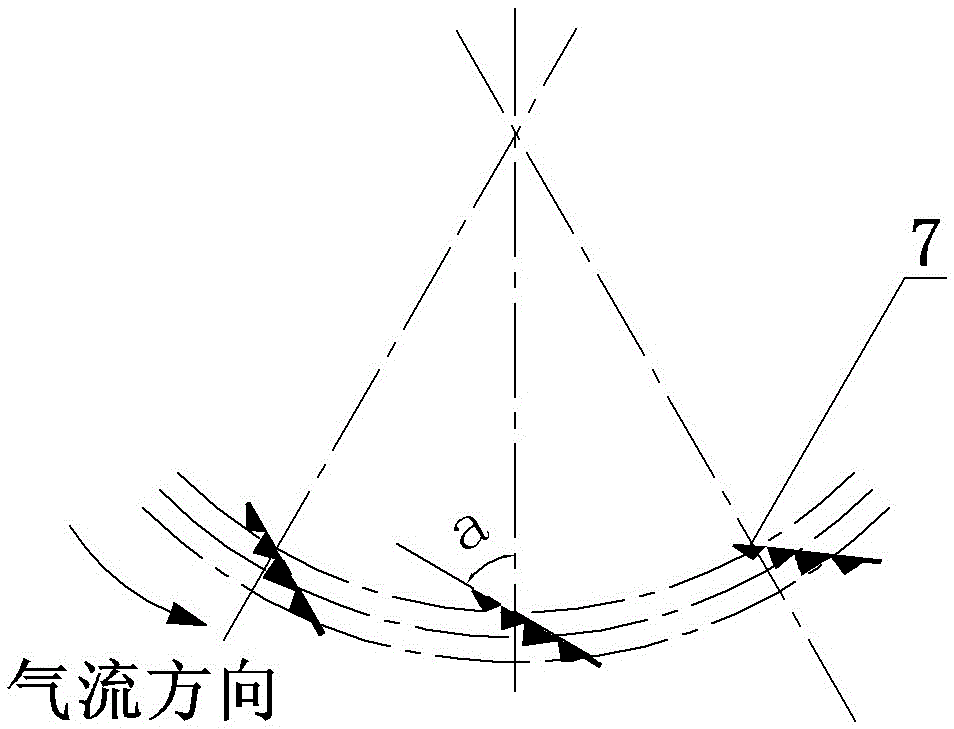

Steam-water separation corrugated plate and separation device

ActiveCN105749628AReduce secondary carryIncrease critical velocityDispersed particle separationEngineeringStraight segment

Owner:SHANGHAI POWER EQUIP RES INST

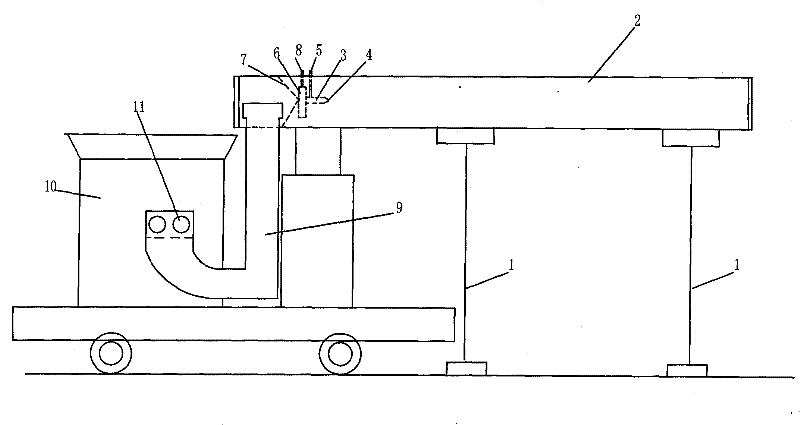

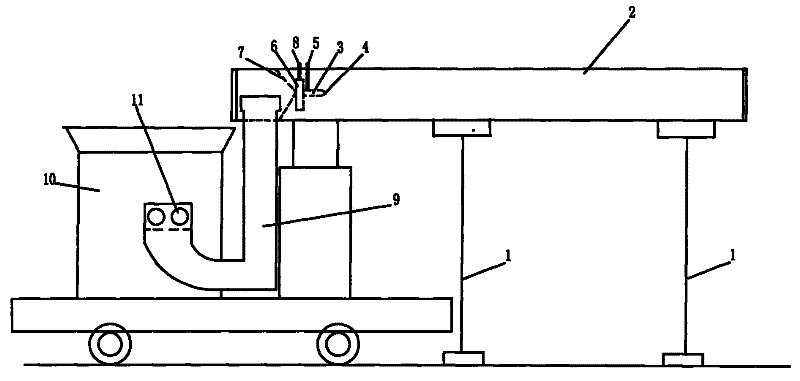

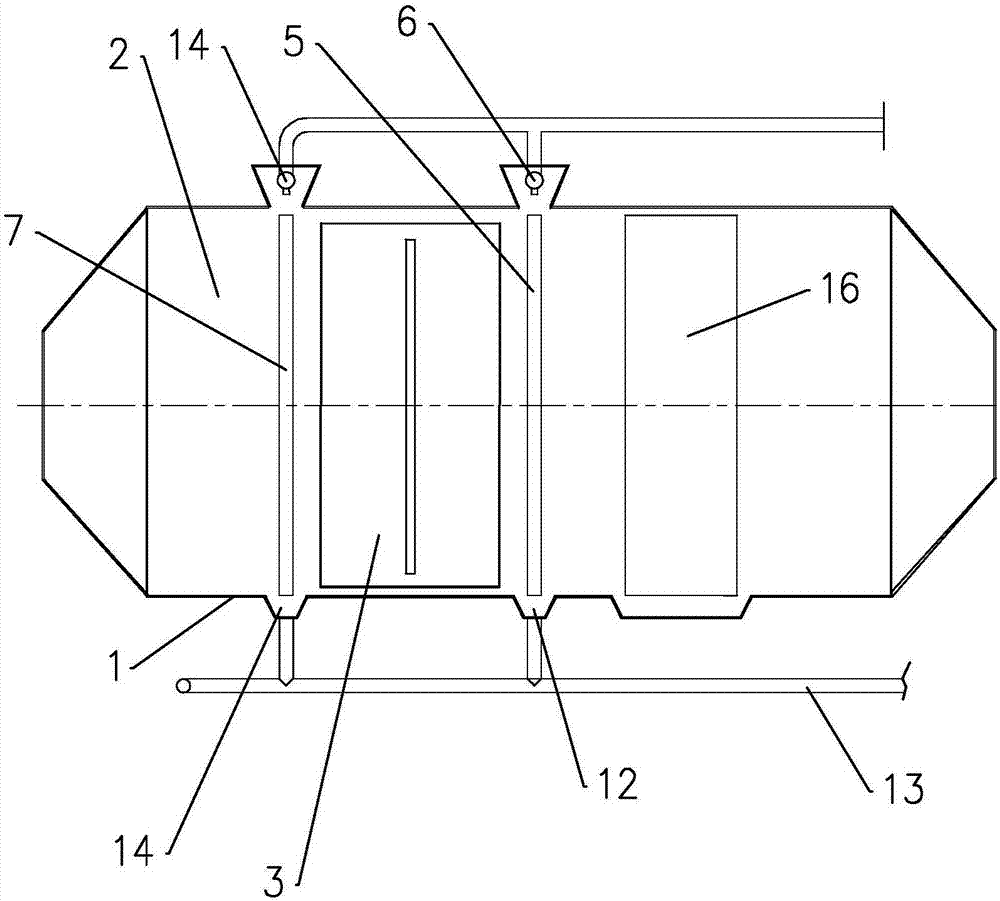

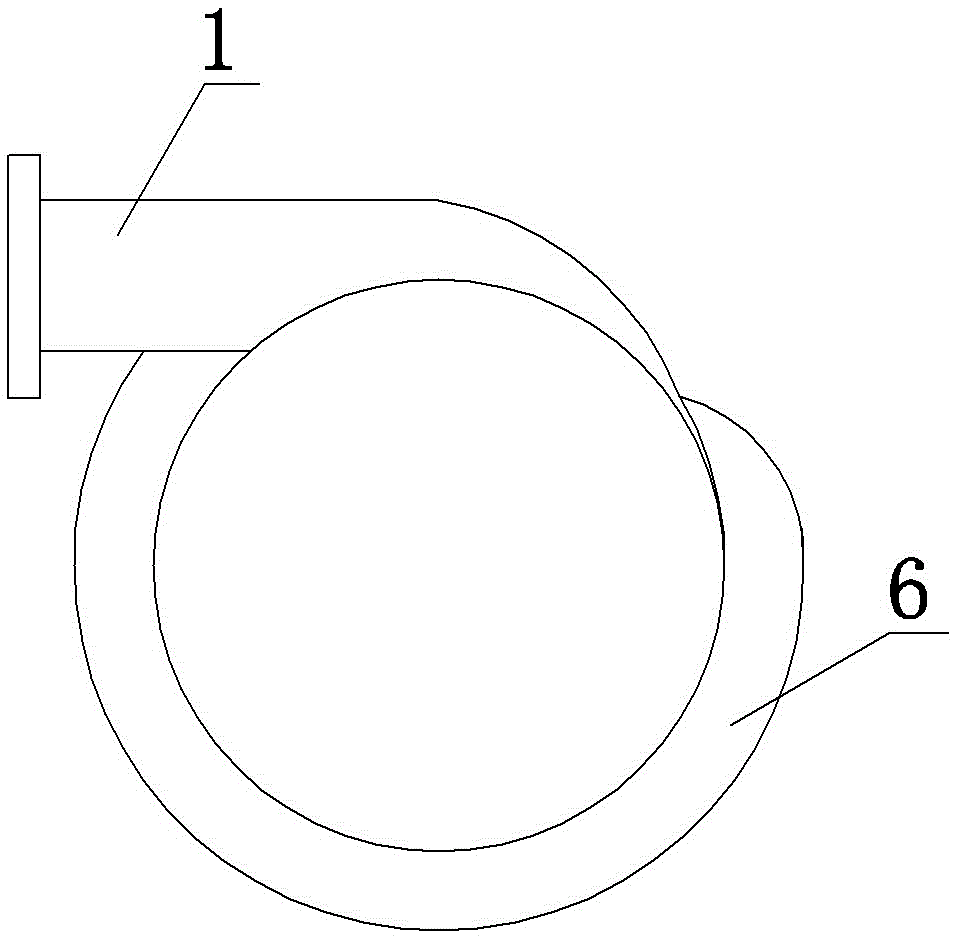

Air-water mixing jet flow dust removing fan

InactiveCN102465710ALess water consumptionHandle a large amount of gasDust removalFire preventionJet flowAir pump

An air-water mixing jet flow dust removing blower comprises a support (1), wherein a wind guide drum (2) is arranged on the support (1), an air-water mixing jet flow device is arranged on the right side of the air inlet of the wind guide drum (2) and inside the wind guide drum (2), the air-water mixing jet flow device comprises an air-water mixing pipe (3), the air-water mixing pipe (3) is axially arranged along the wind guide drum (2), an air-water mixing jet nozzle (4) is arranged at the right end of the air-water mixing pipe (3), a water inlet is formed on the side wall of the air-water mixing pipe (3), the water inlet of the air-water mixing pipe (3) is connected with a water pump through a water transportation pipeline (5), the left end of the air-water mixing pipe (3) is connected with an air-water mixing box (6) positioned inside the wind guide drum (2), the air-water mixing box (6) is connected with an air pump through a gas transportation pipeline (8), and the air inlet of the wind guide drum (2) is connected with the outlet of a negative pressure dust sucking box (9). The invention aims to provide the air-water mixing jet flow dust removing blower which consumes less water, can treat a large amount of gas, and is high in dust removing efficiency.

Owner:LONGKOU MINING GRP

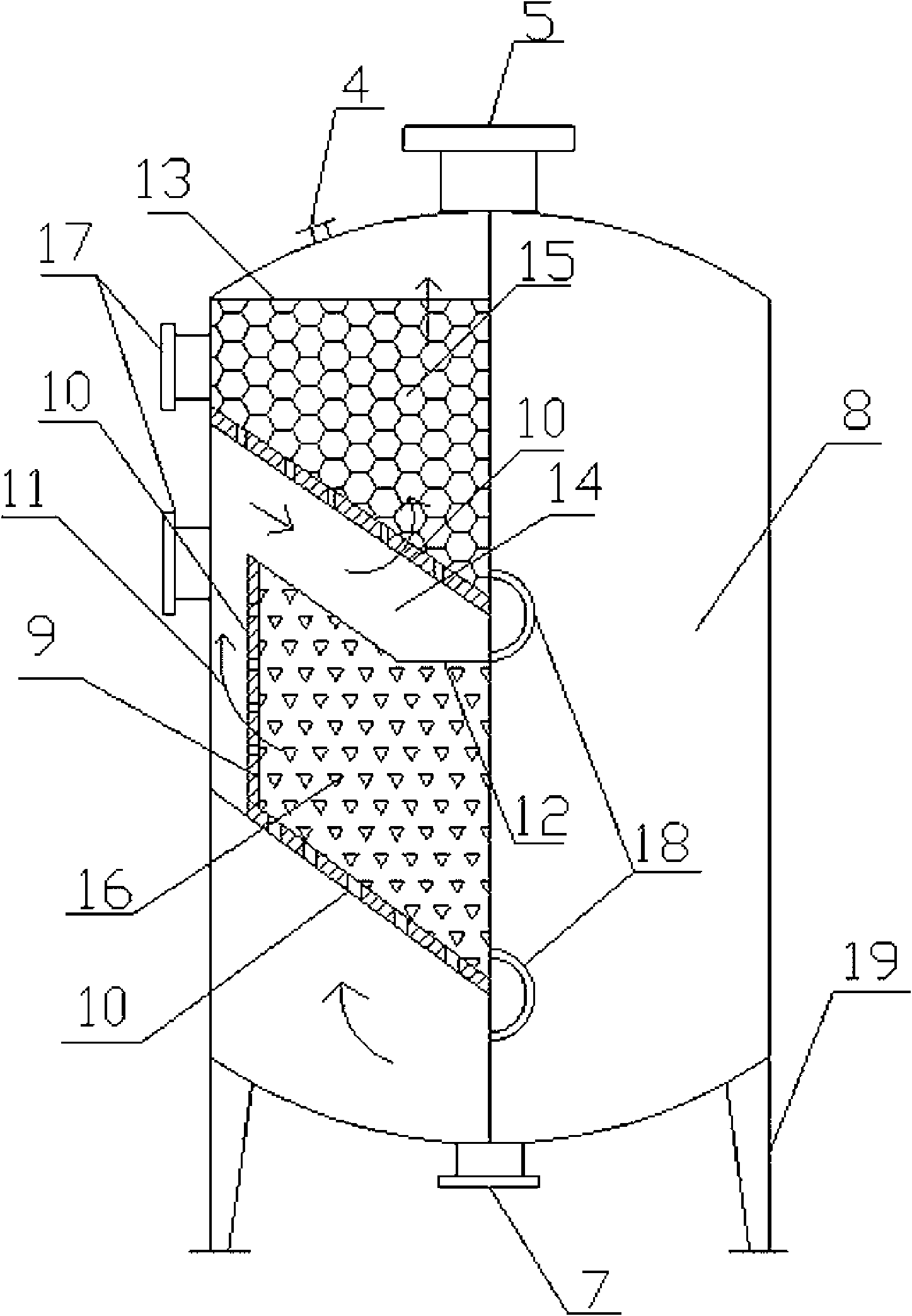

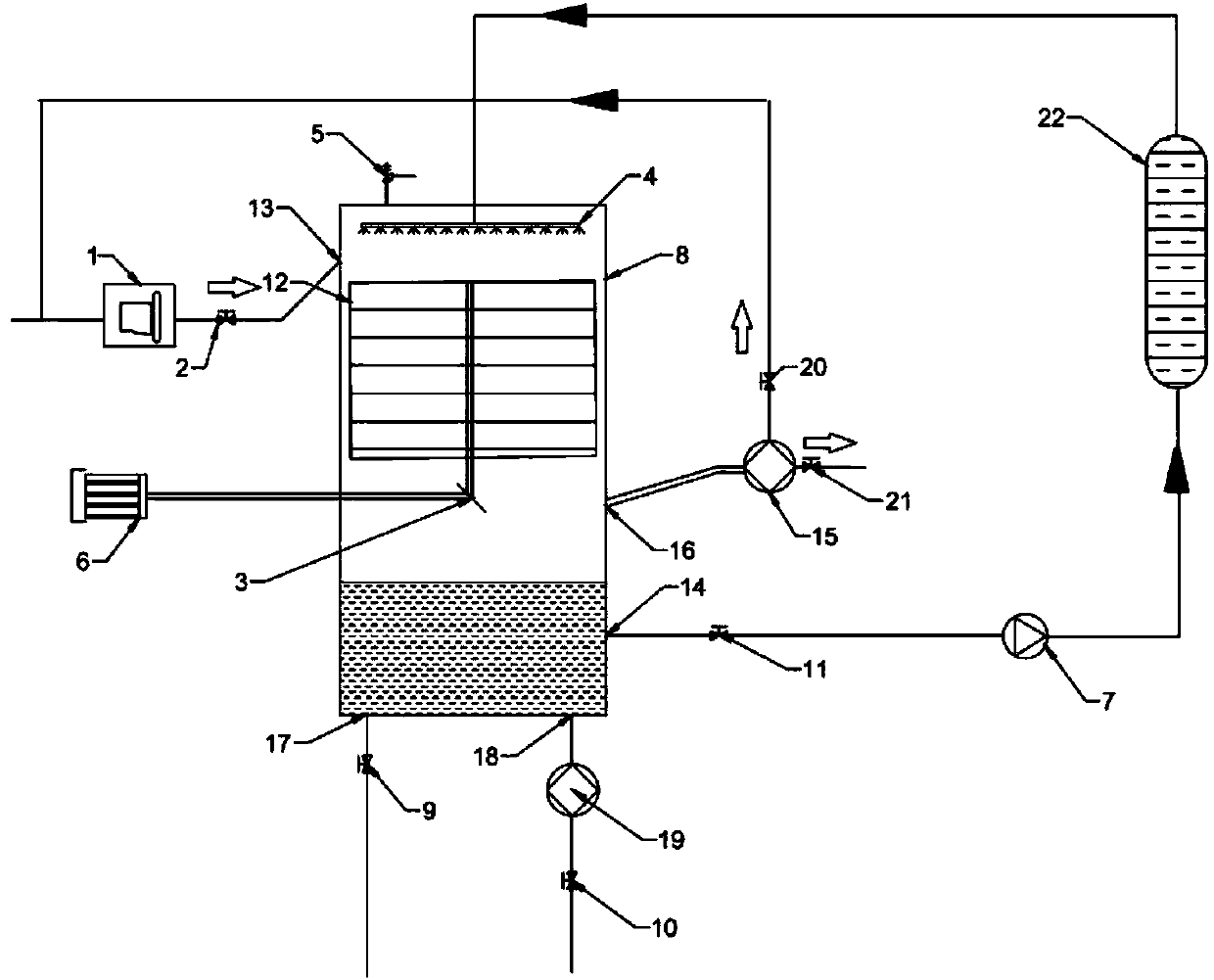

Super-gravity ammonia removal device and ammonia removal method

PendingCN107694293AImprove recycling ratesHigh speedGas treatmentDispersed particle separationMicroscopic scaleCapital cost

The invention discloses a super-gravity ammonia removal device, comprising a box body, an explosion-proof motor, a liquid circulation loop and a gas circulation loop. The super-gravity ammonia removaldevice provided by the invention utilizes a strong centrifugal force generated by high-speed rotation to enlarge a contact area by means of a liquid film formed by a plastic net, so that gas-liquid relative movement speed is increased, an interphase contact boundary area is greatly increased and is rapidly updated, the mass transfer efficiency of the device is 1 to 3 orders of magnitude greater than that of spray tower equipment, and ammonia gas can be more fully dissolved in water accordingly. The water is recycled, so that the energy consumption of the water is reduced, and the recycling rate of ammonia is increased; furthermore, the super-gravity ammonia removal device has the characteristics of small volume, simple structure, short retention time, uniform micromixing, high mass transfer efficiency and low investment and operating costs. The invention also discloses an ammonia removal method of the super-gravity ammonia removal device.

Owner:JIANGSU UNIV OF SCI & TECH

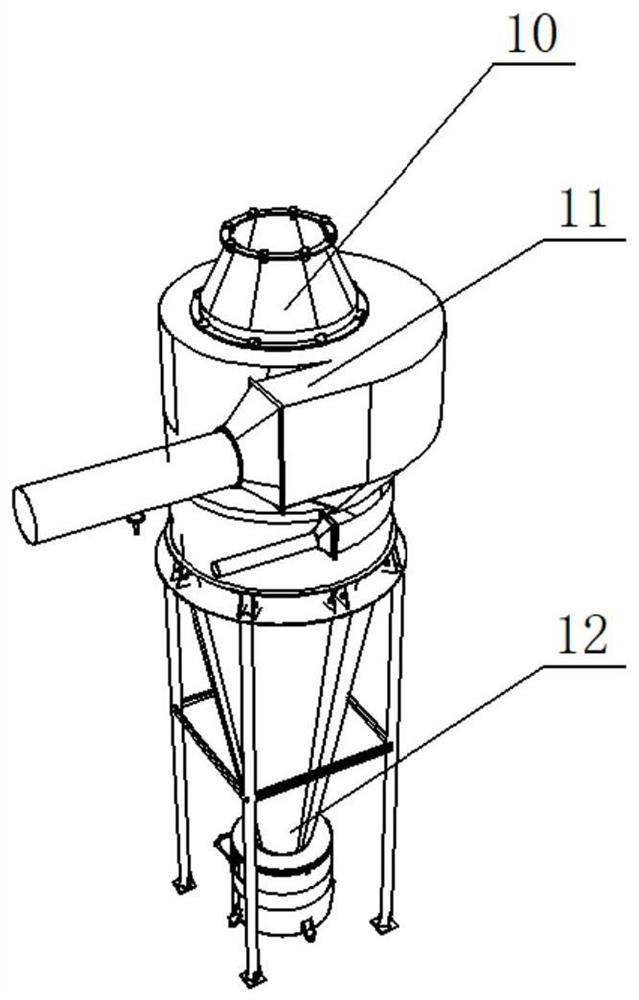

Cyclone separating gas oil separator

InactiveCN101185919AGood effectReduce resistanceReversed direction vortexDispersed particle separationCyclonic separationProduct gas

The invention discloses an oil-gas separator used in an oil-sealing type rotating mechanical vacuum pump. The conventional oil-gas separators which are all internally provided with filter screens and absorption fillers, have the disadvantages of complex structure, inconvenient maintenance, big airflow resistance and small treatment capacity. The invention comprises a shell body and a catheter which is connected with the upper part of the shell body, the invention is characterized in that the top part of the shell body is provided with a coping which is connected with a central exhaust pipe arranged in the center of the shell body; the bottom of the shell body is opened with an oil exit pore positioned below the central exhaust pipe; the air outlet of the catheter is tangent to the inner wall on the upper part of the shell body. The invention leads the air in the separator to have longer path and has the advantages of good separation effect, small airflow resistance, large treatment capacity and convenient maintenance.

Owner:蔡海涛 +1

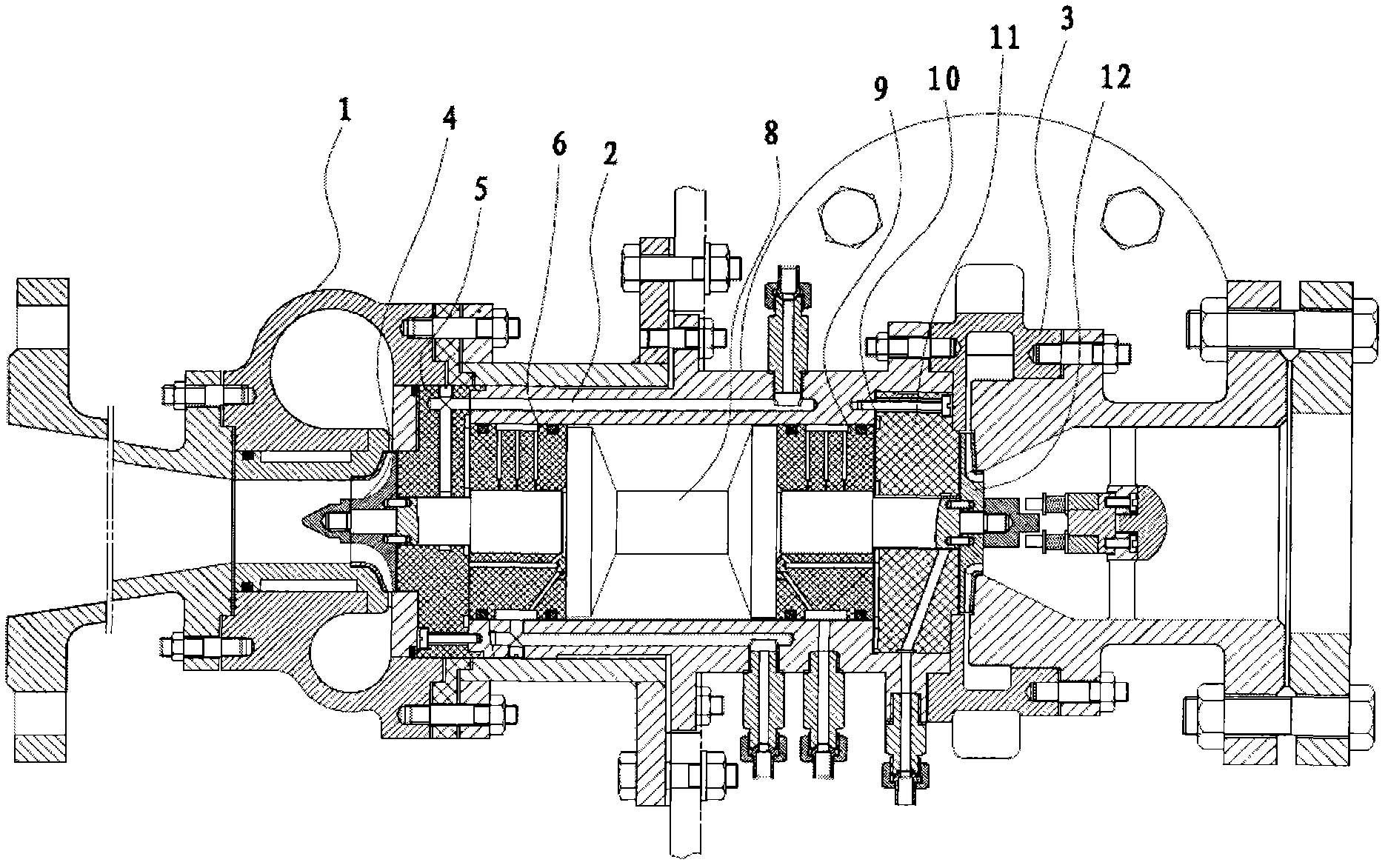

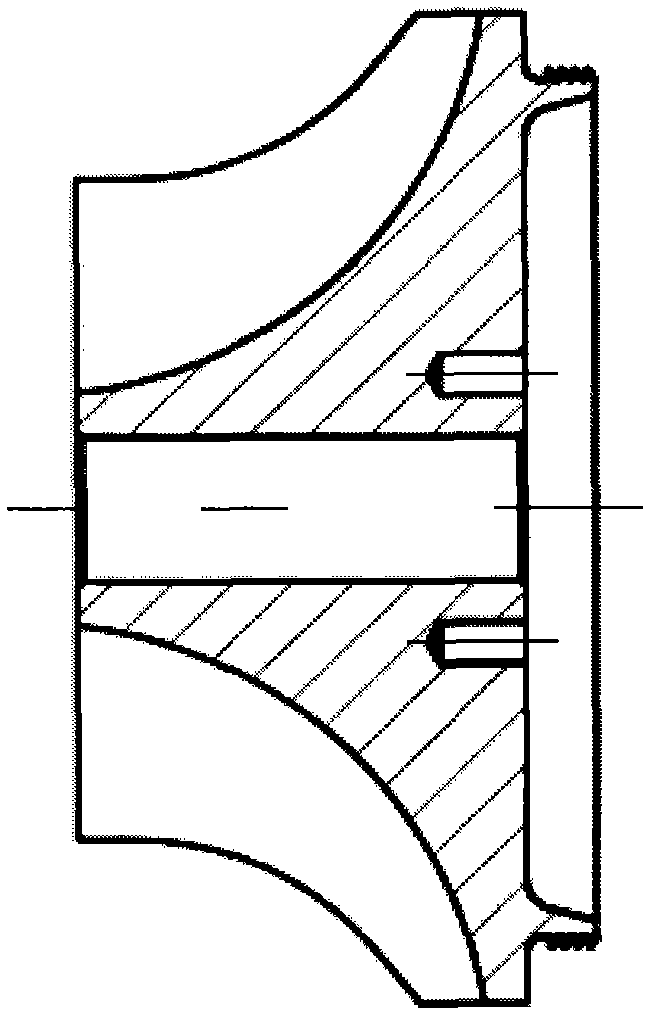

After-boosted turbo expander for gas bearing

InactiveCN102003221ALarge gas volumeImprove reliabilityBlade accessoriesLeakage preventionAir volume

The invention provides an after-boosted turbo expander for a gas bearing. The after-boosted turbo expander comprises a middle case. The left end of the middle case is provided with a turbo volute and the right end of the middle case is provided with a booster volute. A rotor is rotationally arranged in the middle case. Two ends of the rotor are respectively provided with an expansion wheel and a boosted wheel which are respectively arranged in the turbo volute and the booster volute. A left gas bearing and a right gas bearing are sleeved on the rotor. The left gas bearing is used for supporting the expansion wheel and the right gas bearing is used for supporting the boosted wheel. A bearing stop collar is arranged between the left gas bearing and the right gas bearing. The bearing stop collar is sleeved outside the rotor, and fixed with the middle case, wherein the expansion wheel is a radial axial flow centripetal reactionary expansion wheel, and the boosted wheel is a front tilting rear bending type ternary flow closed wheel type boosted wheel. The after-boosted turbo expander for the gas bearing has the advantages of large processed air volume, high efficiency and high reliability.

Owner:苏州制氧机股份有限公司

Method and device for purifying and recycling emitted argon in preparation process of monocrystalline silicon

ActiveCN103373716BHigh recovery rateImprove reliabilityNitrogen purification/separationNoble gas compoundsAlkaneAutomatic control

The invention relates to a method and device for purifying and recycling emitted argon in a preparation process of monocrystalline silicon. The method comprises the following steps of: collecting crude argon emitted by a monocrystalline silicon furnace and then carrying out compression oil removal treatment, removing carbon monoxide and alkane by adopting a catalytic oxidation method, removing oxygen by adopting a hydrogenation oxygen removing method, removing carbon dioxide and water by adopting an adsorption method, and removing nitrogen and hydrogen by adopting a high-low pressure dual-tower low-temperature distillation method to finally obtain pure compressed argon which can be directly conveyed to the monocrystalline silicon furnace for being recycled. The device comprises a crude argon collecting and pretreating system for carrying out crude oil filtration on the crude argon emitted by the monocrystalline silicon furnace, a compression oil removing system for filtering refine oil, a catalytic reaction system for removing carbon monoxide, alkane and oxygen components, a crude argon purifying system for removing the carbon dioxide and the water, a low-temperature distillation system for removing the nitrogen and hydrogen components, an air treating system for providing a raw material air source for a process of preparing the nitrogen by the low-temperature distillation system, and an automatic control system for controlling the whole set of device. The method and device can realize that a large quantity of protection argon in the monocrystalline silicon industry is recovered and recycled.

Owner:HANGZHOU HANGYANG

Combined type purification device for low-concentration vulcanization waste gas

InactiveCN105664686AEffectively decompose fissionEffectively achieve decomposition and fissionNitrous oxide captureGas treatmentVulcanizationWork performance

The invention belongs to the field of technologies for treating low-concentration vulcanization waste gas, and particularly relates to a combined type purification device for low-concentration vulcanization waste gas. The combined type purification device comprises a photolysis oxidation equipment body and waste gas purification spraying equipment. The waste gas purification spraying equipment is divided into a left portion and a right portion, flow guide plates are arranged between the photolysis oxidation equipment body and the left portion of the waste gas purification spraying equipment, a primary spraying component is arranged on the top of the left side of the waste gas purification spraying equipment, and secondary spraying components are arranged on the right side of the waste gas purification spraying equipment; a cooling circulating water tank is arranged at the bottom of the waste gas purification spraying equipment, the primary spraying component and the secondary spraying components are sequentially connected with a circulating water pump and the cooling circulating water tank by a spraying pipe, a demister is arranged on the top of the waste gas purification spraying equipment, and a waste gas outlet is sequentially formed in the top of the waste gas purification spraying equipment. The combined type purification device for the low-concentration vulcanization waste gas has the advantages that the combined type purification device is stable in work performance and convenient to maintain, and a large quantity of low-concentration vulcanization waste gas generated in rubber product vulcanization procedures can be thoroughly and effectively treated by the aid of the combined type purification device.

Owner:HANGZHOU HENGYU ENVIRONMENTAL PROTECTION TECH

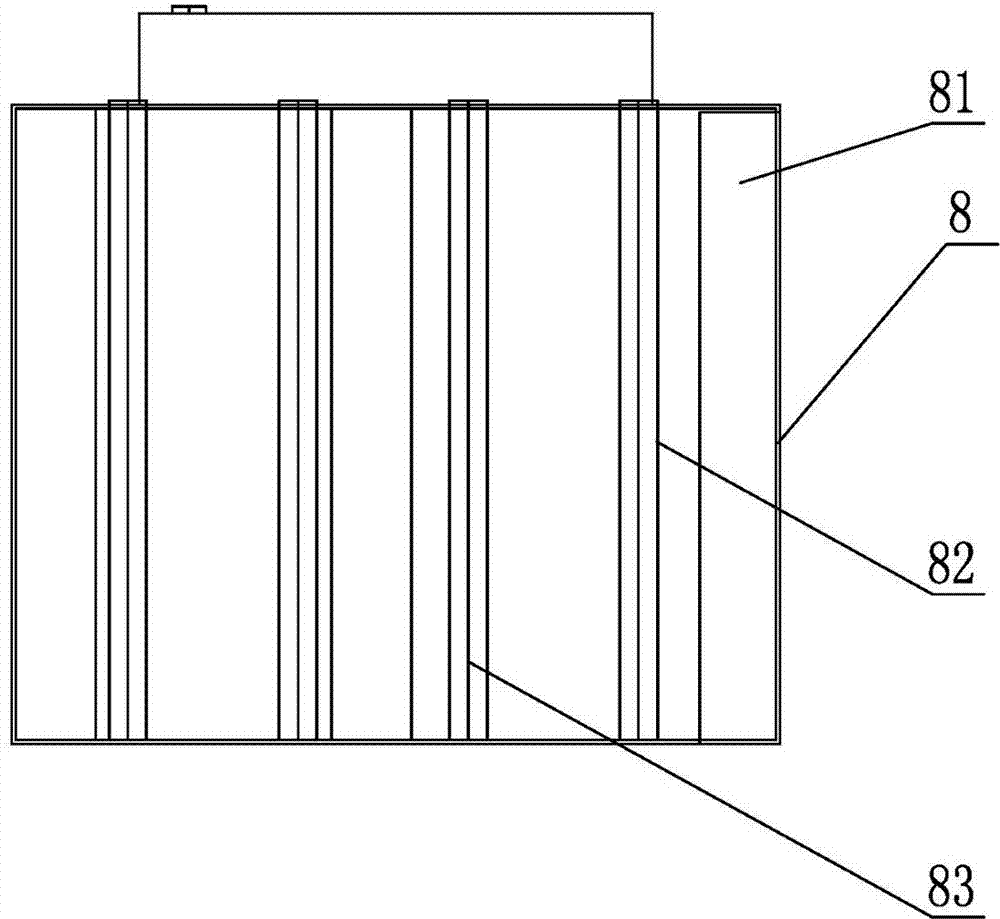

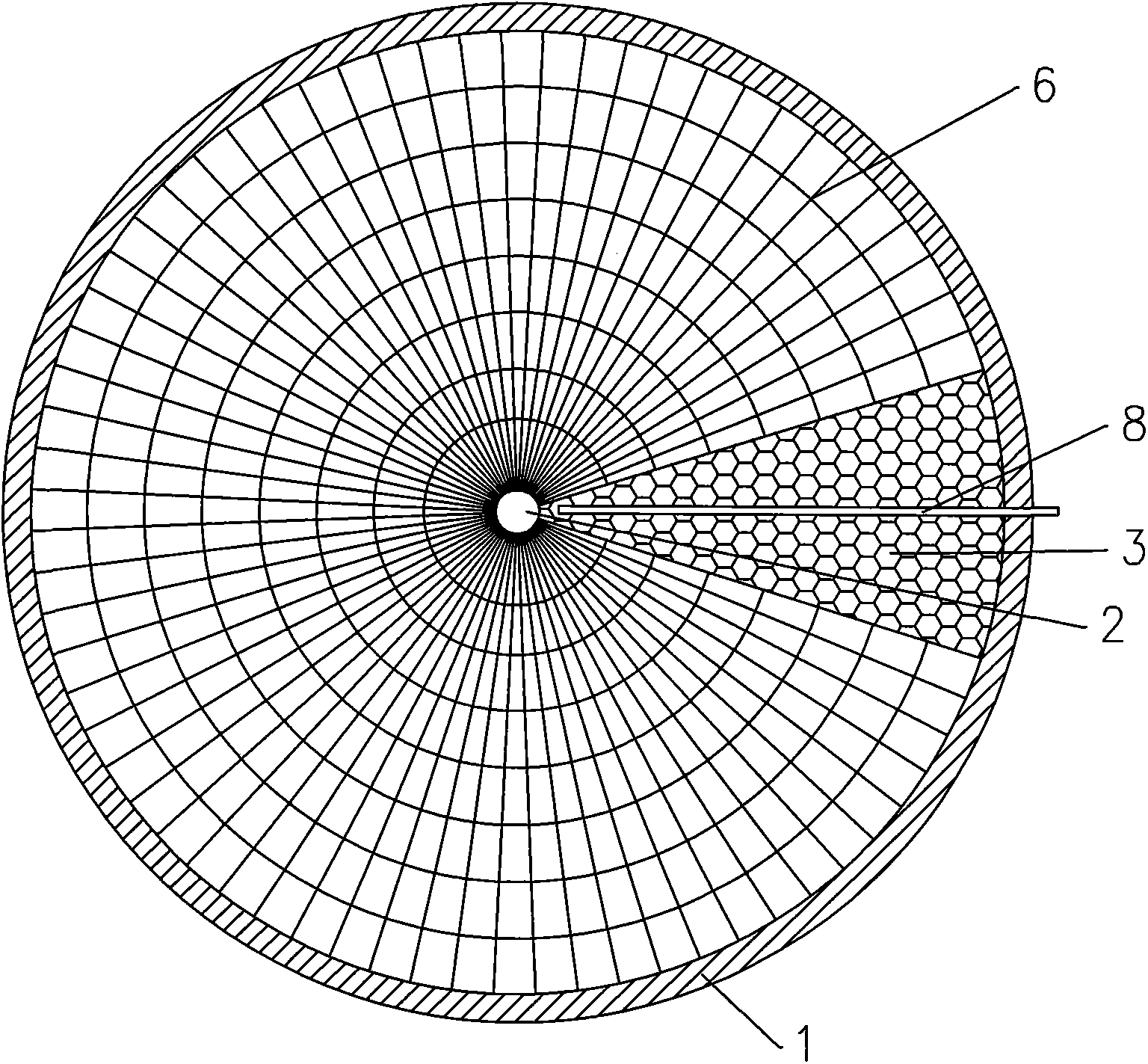

Rotating disc type runoff lightning shield dust remover

InactiveCN103506219AStable dust removalLow running costExternal electric electrostatic seperatorElectrode constructionsHoneycombElectricity

The invention discloses a rotating disc type runoff lightning shield dust remover. The dust remover comprises a casing, wherein a dust air pipe is arranged in the casing; a disc-shaped lightning shield is arranged inside the dust air pipe; the disc surface of the lightning shield can rotate around the section of the dust air pipe; the circumferential surface of the lightning shield is in clearance fit with the inner wall of the dust air pipe; a front discharging net is arranged in front of the lightning shield towards the inlet end of the dust air pipe; the end surface of the lightning shield towards the front discharging net is parallel to the front discharging net; the lightning shield is made of porous foam metal plates, a plurality of parallel corrugated plates, honeycomb plates or silk nets; a potential difference is generated between the front discharging net and the lightning shield through the electric connection with a high-voltage direct-current power supply; a dust blowing pipe is arranged in the dust air pipe; the dust blowing opening of the dust blowing pipe is towards the disc surface of the lightning shield. The invention aims to provide the rotating disc type runoff lightning shield dust remover which has greater treated air quantity in the unit time and a prominent effect of removing fine dust comprising PM 2.5, is stable in dust removing performance, low in operation cost and long in service life.

Owner:孟金来

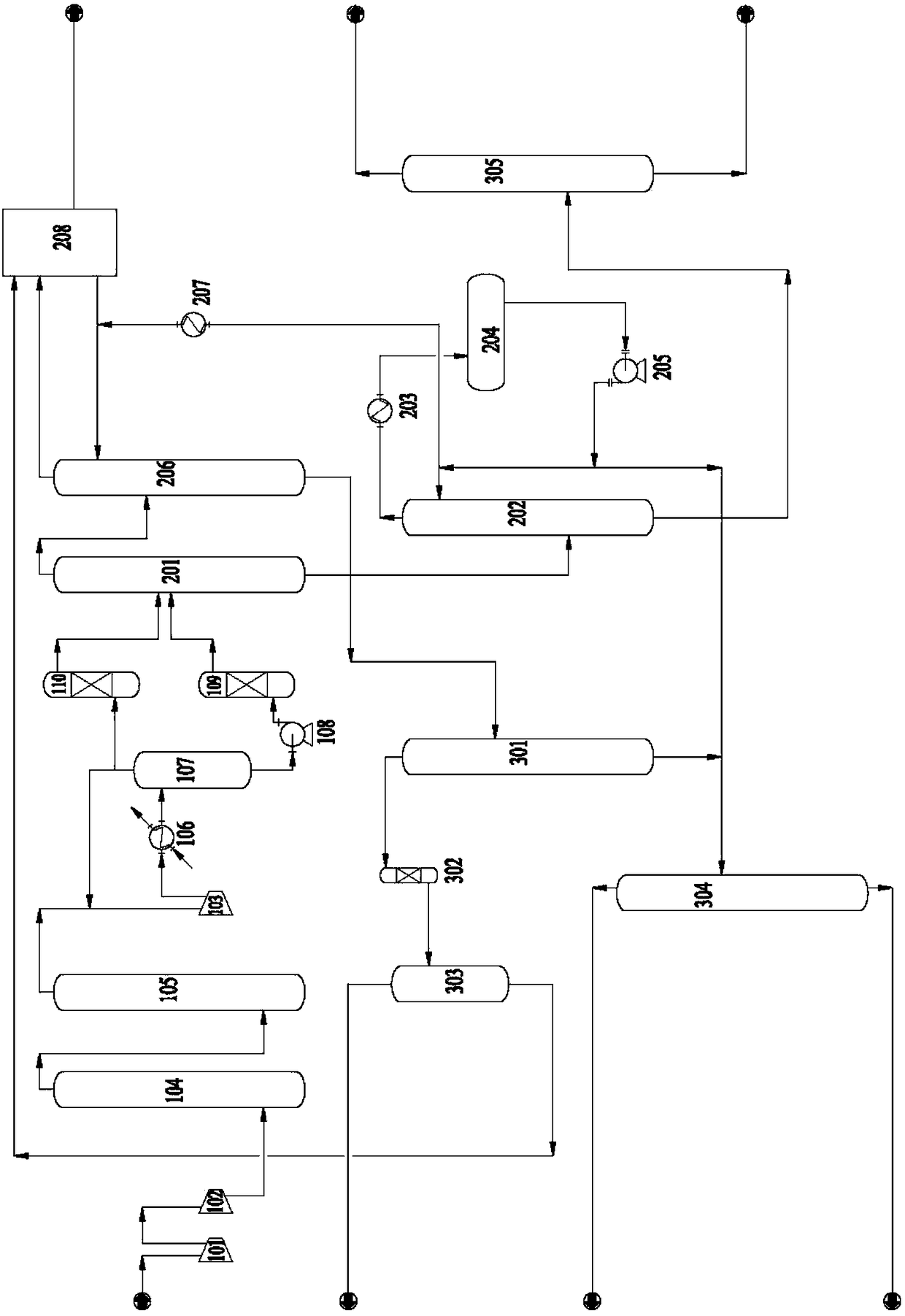

Separating process and system of low-energy-consumption MTO product gas

ActiveCN108586180ASmall sizeLow investment costDistillation purification/separationHydrocarbon from oxygen organic compoundsProduct gasTower

The invention discloses a separating process and system of low-energy-consumption MTO product gas. Valuable hydrocarbon such as ethylene in the methanol to olefin (MTO) product gas (demethanizer tailgas) is recovered through a powerless copious cooling technology, the operation pressure of a first carbon and second carbon separation system is reduced, the grade of a product gas centrifugal compression machine is reduced, and process energy consumption is reduced; by means of the powerless copious cooling technology, the temperature of first carbon tail gas can be reduced, mixed propane or even pure propylene is used as the first carbon and second carbon separation washing absorber, and the loss of propylene carried in the first carbon tail gas is quite low; the washing absorption materialfor first carbon and second carbon separation is sent into the system from the upstream of a first carbon removal tower, the circulation of lots of materials returning from the downstream of the device to the upstream in an existing process is avoided, and energy loss is caused. The product gas is dried behind the outlet of a three-section compression unit, and water in the product gas can be effectively removed.

Owner:北京恒泰洁能科技有限公司

Wet process corona desulfurization, denitrification and dust removal smoke gas purification device and use method

PendingCN106861403AEfficient removalLarge gas volumeCombination devicesGas treatmentProcess engineeringAirflow

The invention relates to a wet process corona desulfurization, denitrification and dust removal smoke gas purification device and a use method. The device comprises a machine case, wherein a smoke gas purification gas passage is arranged in the machine case in the forward and backward direction; a plurality of anode plates are arranged in the smoke gas purification gas passage in parallel; the upper part of each anode plate is provided with an anode spraying pipe in the forward and backward direction; a water outlet of each anode spraying pipe faces to the corresponding anode plate respectively; a cathode is arranged at one side of the anode plate; a gas filtering anode plate with the plate surface in which gas flow can pass through is arranged in the smoke gas purification gas passage and is positioned behind the plurality of anode plates; the plate surface of the gas filtering anode plate is arranged along the cross section direction of the smoke gas purification gas passage; a gas filtering anode plate spraying pipe is arranged above the gas filtering anode plate along the cross section direction of the smoke gas purification gas passage. The invention aims at providing the wet process corona desulfurization, denitrification and dust removal smoke gas purification device and the use method with the advantages that the gas treatment quantity in unit time is great; the effect for removing oxynitride, sulfur dioxide, sulfur trioxide and tiny dust including PM2.5 (Particulate Matter2.5) is very obvious; the desulfurization, denitrification and dust removal performance is very stable.

Owner:孟金来

Turntable-type runoff electrode plate dust collector

ActiveCN104437859AStable dust removalLow running costExternal electric electrostatic seperatorElectrodes cleaningElectricityPotential difference

The invention discloses a rotating disc type runoff lightning shield dust remover. The dust remover comprises a casing, wherein a dust air pipe is arranged in the casing; a disc-shaped lightning shield is arranged inside the dust air pipe; the disc surface of the lightning shield can rotate around the section of the dust air pipe; the circumferential surface of the lightning shield is in clearance fit with the inner wall of the dust air pipe; a front discharging net is arranged in front of the lightning shield towards the inlet end of the dust air pipe; the end surface of the lightning shield towards the front discharging net is parallel to the front discharging net; the lightning shield is made of porous foam metal plates, a plurality of parallel corrugated plates, honeycomb plates or silk nets; a potential difference is generated between the front discharging net and the lightning shield through the electric connection with a high-voltage direct-current power supply; a dust blowing pipe is arranged in the dust air pipe; the dust blowing opening of the dust blowing pipe is towards the disc surface of the lightning shield. The invention aims to provide the rotating disc type runoff lightning shield dust remover which has greater treated air quantity in the unit time and a prominent effect of removing fine dust comprising PM 2.5, is stable in dust removing performance, low in operation cost and long in service life.

Owner:孟金来

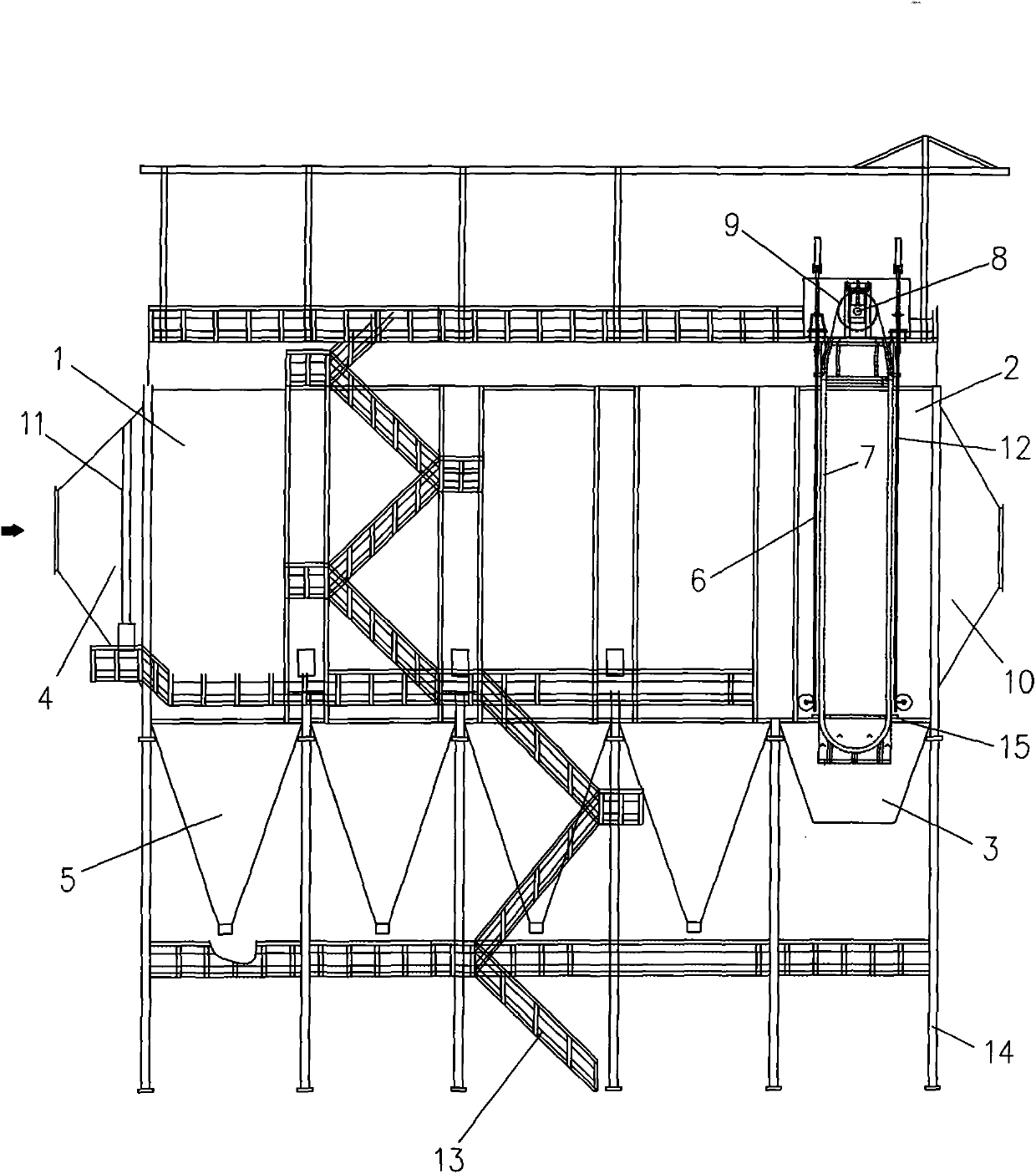

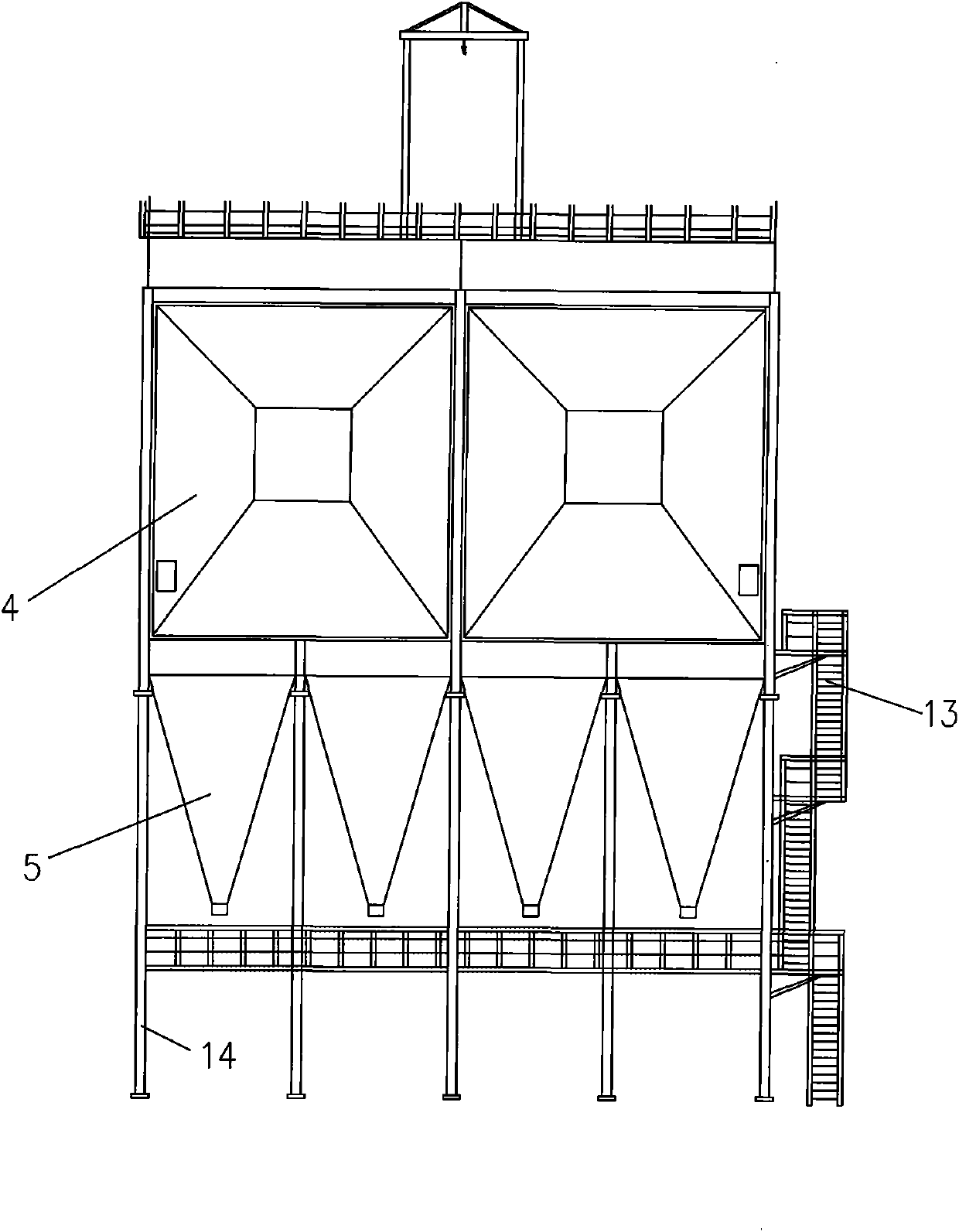

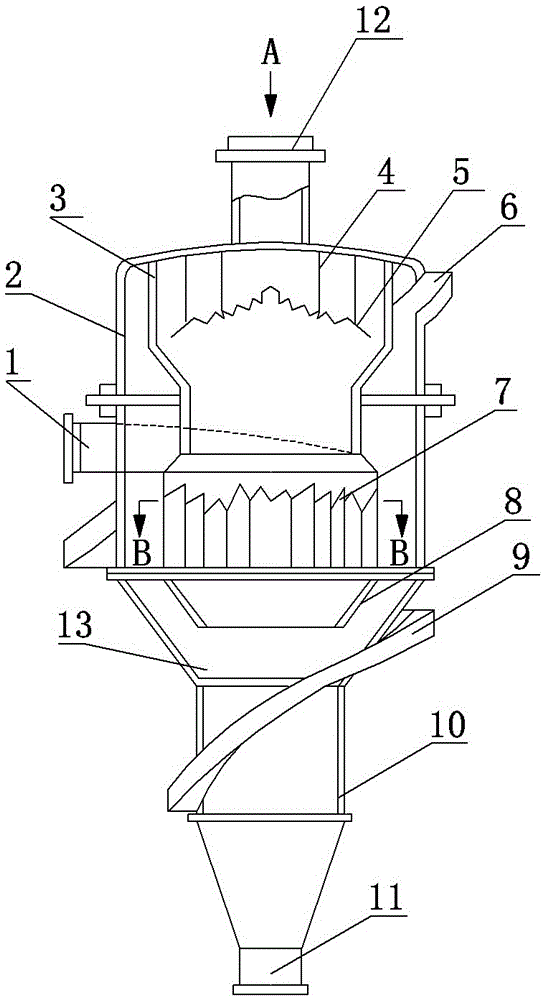

Horizontal electric dust collector with frame corona electrode and template collector

InactiveCN104923401AStable and accurate pole distanceImprove discharge performanceExternal electric electrostatic seperatorElectric supply techniquesAutomatic controlLow voltage

The invention provides a horizontal electric dust collector with a frame corona electrode and a template collector, and belongs to the field of particle pollutant purifying equipment. According to the technical scheme, the frame type corona electrode and a template type dust collector are installed in a shell of the electric dust collector in a spaced mode; rectangular pyramids at the two ends of the shell are both provided with an intake air flow distribution plate and an exhaust air flow distribution plate, an ash bucket is fixed to the lower side of the shell, and the lower portion of the ash bucket is connected with a spiral conveyer; and a dust collecting electrode dust cleaning device is installed at the bottom of the shell, a corona electrode dust cleaning device is installed on the top of the shell, and a low-voltage power supply control cabinet, a high-voltage power supply control cabinet and a power transformer are fixed to one side of the shell. The dust collector has the beneficial effects that the polar distance of the frame type corona electrode is stable and accurate, the distance between polar plates of the template type dust collector is wide, and the corona electrode dust cleaning device is installed on the top of the shell; the structure is compact, running is safe, pressure loss is small, dust removal efficiency is high, the gas treatment amount is large, and automatic control can be achieved; and design is novel, the structure is reasonable, operation is easy and convenient, maintenance is easy, and safety and reliability are achieved.

Owner:河南省汤阴县华兴机械制造有限公司

Boundary separation dust collection equipment

PendingCN110585806ASimple structureDust removal speed is fastDispersed particle separationEngineeringAirflow

The invention provides boundary separation dust collection equipment and belongs to the technical field of dust collection. The boundary separation dust collection equipment comprises a tank body, wherein a gas inlet and a gas outlet are respectively formed in the tank body; the gas outlet communicates with exhaust equipment; a gas flow channel is formed in the tank body; a curved surface bulge isarranged on one side wall of the gas flow channel; a baffle plate is arranged on another side wall of the gas flow channel; and a first opening is formed between the baffle plate and the gas flow channel so that gas flows flowing through the curved surface bulge impact the surface of the baffle plate and flow out from the first opening. The boundary separation dust collection equipment provided by the invention is simple in structure, short in gas flow route, thus rapid in dust collection speed, large in gas treatment capacity, in addition, small in floor space and simple and convenient to maintain.

Owner:兰州云式环境科技有限公司

Process for removing oil and water from gas and recycling oil by adopting low-temperature methanol

InactiveCN106318473AAchieve recyclingIncrease added valueEnergy inputGas purification by non-gaseous materials condensationThermal energyOil phase

The invention discloses a process for removing oil and water from a gas and recycling oil by adopting low-temperature methanol. According to the process, an oil-containing and water-containing feed gas enters an oil removal tower to remove the oil from the oil-containing and water-containing feed gas through the low-temperature methanol; low-temperature oil-containing methanol from the oil removal tower enters a secondary flash evaporation washing tower and is subjected to intermediate pressure flash evaporation and low-pressure flash evaporation; a liquid phase which is subjected to the flash evaporation enters an oil and water extractor for extracting; an oil phase serves as a product; after the water into which a small amount of the oil is dissolved is treated through an oil separating tower, a non-condensable gas at the top of the tower enters the a secondary flash evaporation tower; the oil at the upper part of the tower enters the oil and water extractor; water-containing methanol is obtained at the bottom of the tower and enters a methanol separating tower for separating; the methanol returns to the oil removal tower; part of the water at the bottom of the tower is recycled as an extracting agent, and the other part of the water is delivered outside as superfluous water. The process has the advantages that washing gas water is not produced, coal gas waste heat energy can be recycled and utilized in grades, and meanwhile, different grades of steam can be generated.

Owner:SEDIN ENG

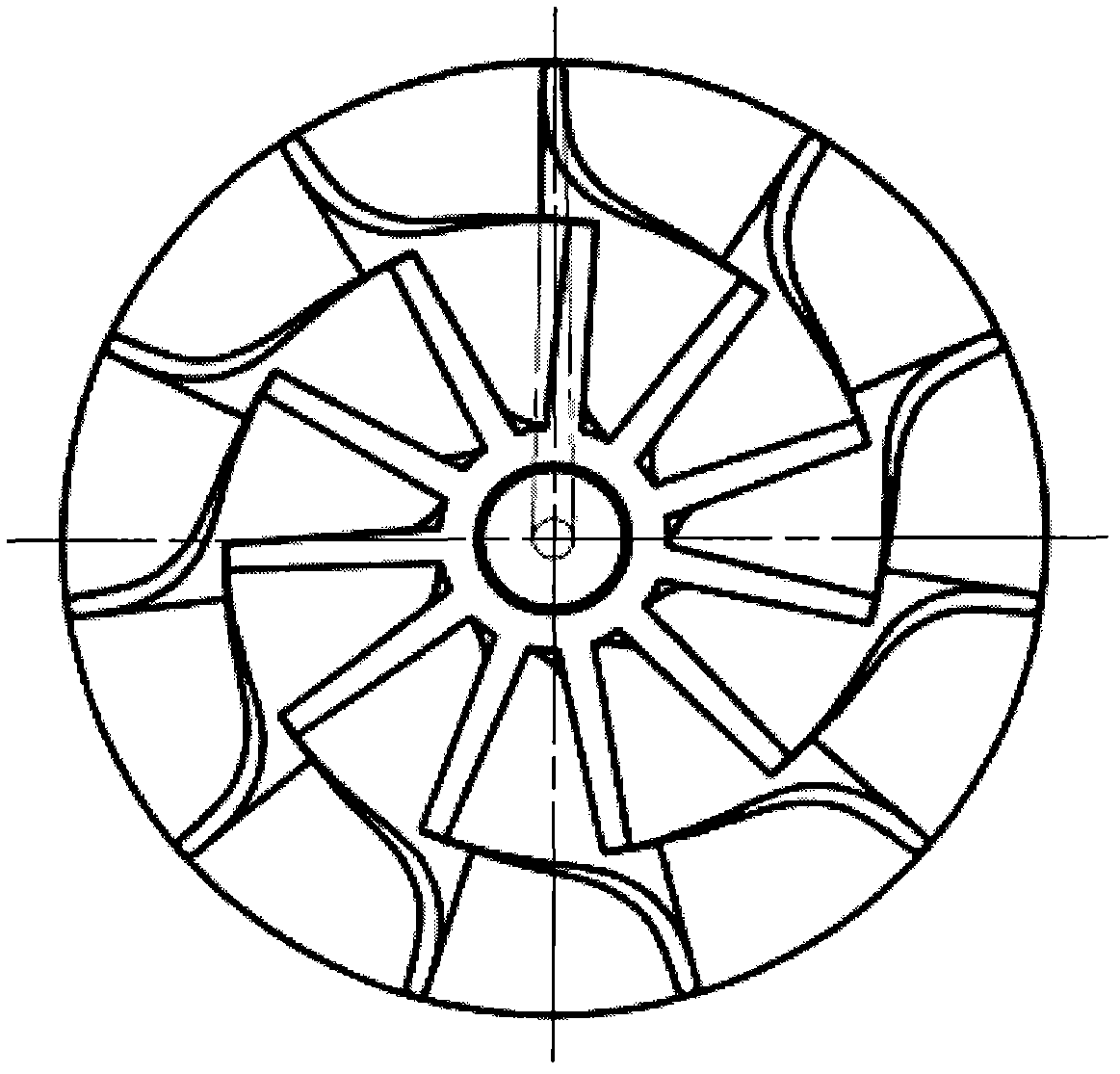

Energy-saving dusting machine

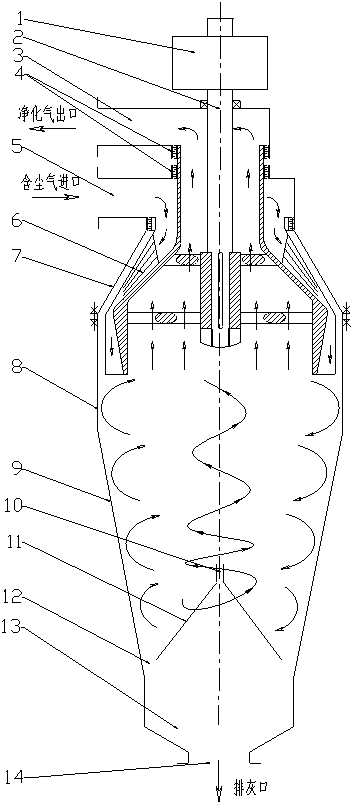

ActiveCN102950064BIncrease centrifugal forceParticle size reductionReversed direction vortexImpellerRotational axis

The invention relates to the technical field of gas-solid separation, and in particular relates to an energy-saving dusting machine. The energy-saving dusting machine is characterized by comprising a rotor system and a stator shell, wherein the rotor system comprises an impeller assembly; the impeller assembly is arranged on a rotating shaft and is positioned on the upper part of the stator shell; the impeller assembly rotates in the stator shell through the rotating shaft perpendicular to the horizontal plane; the impeller assembly comprises a conical cylinder wheel disc; the conical cylinder wheel disc comprises a rotating disc body and supporting rib plates positioned on the inner side of the disc body; the upper end of the rotating disc body is fixed with a purified air ascending pipe; a gap channel between the supporting rib plates and the purified air ascending pipe form a purified air ascending channel; the periphery of the upper part of the disc body of the conical cylinder wheel disc is a conical surface of which the upper end has large diameter and the lower end has small diameter; an upper seal head of the stator shell is in a conical cylinder shape which is matched with the upper part of the disc body of the conical cylinder wheel disc; and an outer side face of the conical surface of the conical cylinder wheel disc is provided with a plurality of discs which are stacked along the axial direction of the rotating shaft. According to the energy-saving dusting machine, the separation efficiency of superfine particles is improved, the separation energy consumption is reduced, and the equipment investment and occupied area are effectively reduced.

Owner:武汉宝鼎节能环保技术开发有限公司

Combined type radial current electric dust collector

ActiveCN103721849ARotary motion stabilityFreedom of rotationElectrode constructionsElectrodes cleaningElectricityCurrent electric

The invention discloses a combined type radial current electric dust collector. According to the dust collector, a radial current type electric dust collecting power discharge net is arranged behind a dust collecting electrode inside a dust collecting airway; an annular dust collecting chain row is arranged behind the radial current type electric dust collecting power discharge net; the front annular part of the dust collecting chain row is parallel to the surface of the radial current type electric dust collecting power discharge net; a left guide rail is arranged on the left side of the dust collecting chain row; the side part of the left end of the dust collecting chain row is guided and positioned through the left guide rail; a right guide rail is arranged on the right side of the dust collecting chain row; the side part of the right end of the dust collecting chain row is guided and positioned through a right guide rail; the lower part of the dust collecting chain row is positioned inside a dust cleaning chamber; a sealing partitioning plate is arranged between the dust cleaning chamber and the dust collecting airway; the dust collecting chain row penetrates through the sealing partitioning plate downwards and enters the dust cleaning chamber; a dust blowing tube is arranged along the left and right direction near the dust collecting chain row inside the dust cleaning chamber. The invention aims at providing the combined type radial current electric dust collector which is large in gas treatment capability in unit time, outstanding in effect in collecting fine dust including PM2.5, very stable in dust collection performance, low in operation cost and long in service life.

Owner:北京华能达电力技术应用有限责任公司

Cyclone inertia dust remover with double separating chambers

ActiveCN105964425AEfficient separationIncrease gas volumeReversed direction vortexCycloneEngineering

The invention provides a cyclone inertia dust remover with double separating chambers which is simple in structure, capable of promoting an effective separation of dust and high in dust removing efficiency. A dust removing cylinder body is a sealed type cylinder body which consists of an upper cylinder body and a lower cylinder body; an air inlet port is circularly arranged on the upper cylinder body and tangentially connected with the upper cylinder body; an exhaust pipe is arranged at the top of the upper cylinder body and extends into the upper cylinder body; an exhaust port is arranged on the exhaust pipe and the position of the air inlet port is lower than the position of the exhaust port; the lower part of the lower cylinder body is connected with a dust collector; a spiral-shaped by-pass chamber I is arranged on the upper cylinder body and a spiral-shaped by-pass chamber II is arranged on the lower cylinder body; the top of the interior of the upper cylinder body near the exhaust pipe is provided with a core tube; a blocking plate is mounted in the core tube and a fixed plate is mounted under the blocking plate; guide vanes are mounted at the lower end of the core tube at intervals and an air outlet necked short pipe is mounted at the lower ends of the guide vanes; a cone cylinder body is connected between the upper cylinder body and the lower cylinder body.

Owner:WUXI PROFESSIONAL COLLEGE OF SCI & TECH

A Cyclone Inertial Dust Collector with Double Isolation Chambers

ActiveCN105964425BEfficient separationIncrease gas volumeReversed direction vortexEngineeringExhaust pipe

The invention provides a cyclone inertial dust collector with double isolation chambers, which has a simple structure, can promote effective separation of dust, and has high dust removal efficiency; the dust removal cylinder is a closed cylinder composed of an upper cylinder and a lower cylinder. Type cylinder, with an air inlet on the upper ring of the upper cylinder, and the air inlet is connected tangentially to the upper cylinder, and an exhaust pipe is arranged on the top of the upper cylinder, and the exhaust pipe extends into the upper cylinder Inside the cylinder, there is an exhaust port on the exhaust pipe, the position of the air inlet is lower than that of the exhaust port, the lower part of the lower cylinder is connected with the dust collector, and the upper cylinder is provided with a spiral side Road chamber 1, there is a spiral bypass chamber 2 on the lower cylinder, a core tube is installed on the top of the upper cylinder near the exhaust pipe, a baffle is installed in the core tube, and a fixing plate is installed at the lower end of the baffle , the lower end of the core tube is provided with guide vanes at intervals, the lower end of the guide vanes is equipped with a short pipe with an air outlet shrinkage, and a cone cylinder is connected between the upper cylinder and the lower cylinder.

Owner:WUXI PROFESSIONAL COLLEGE OF SCI & TECH

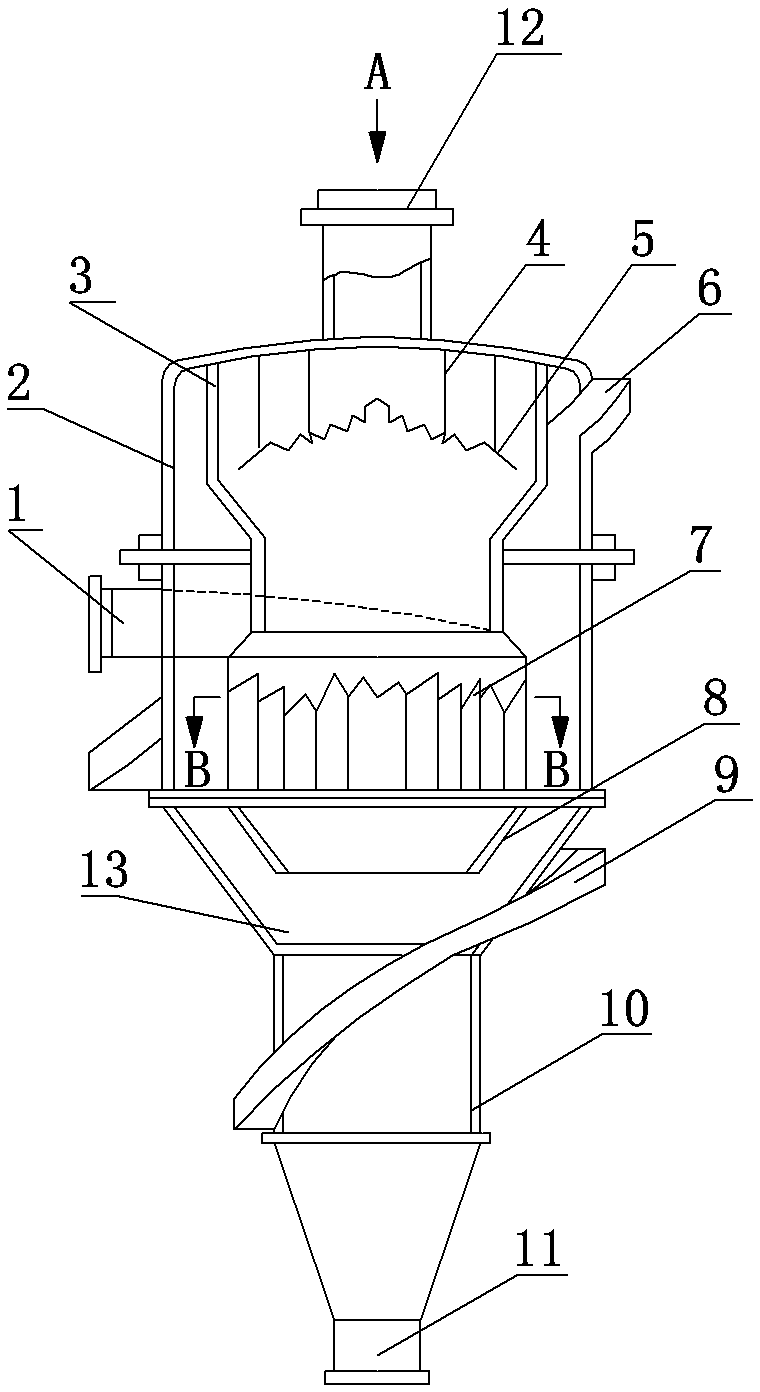

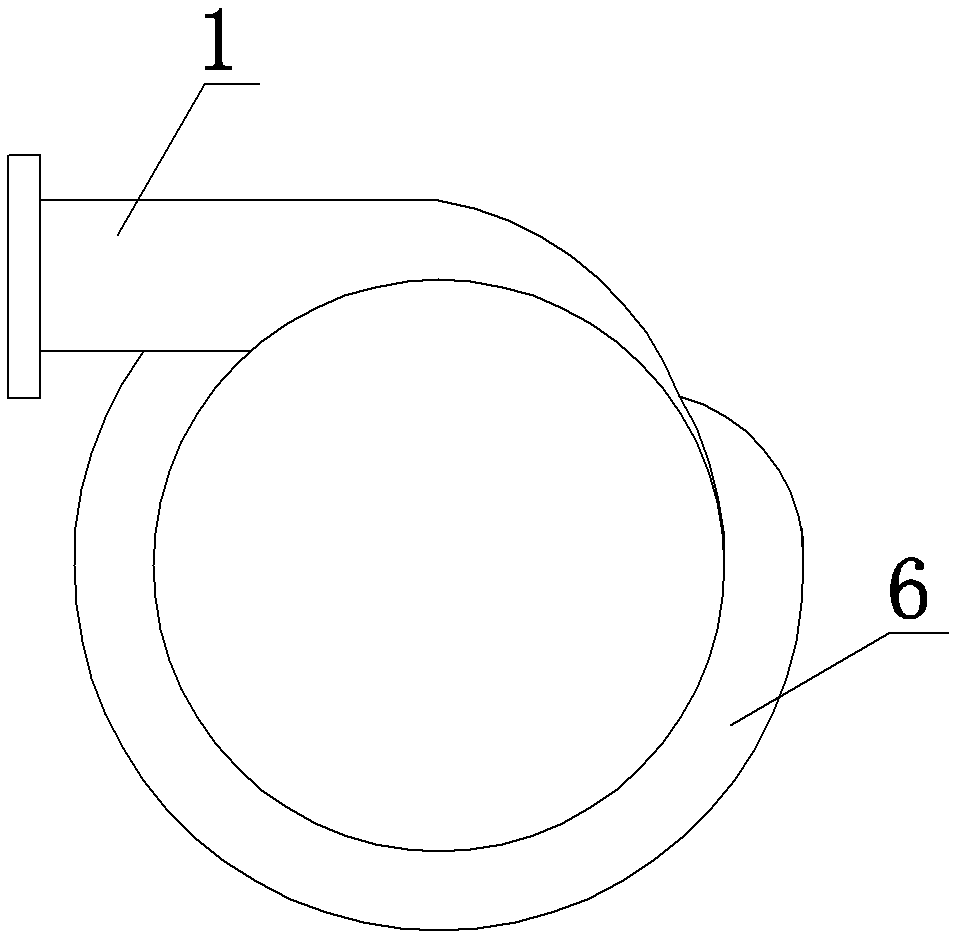

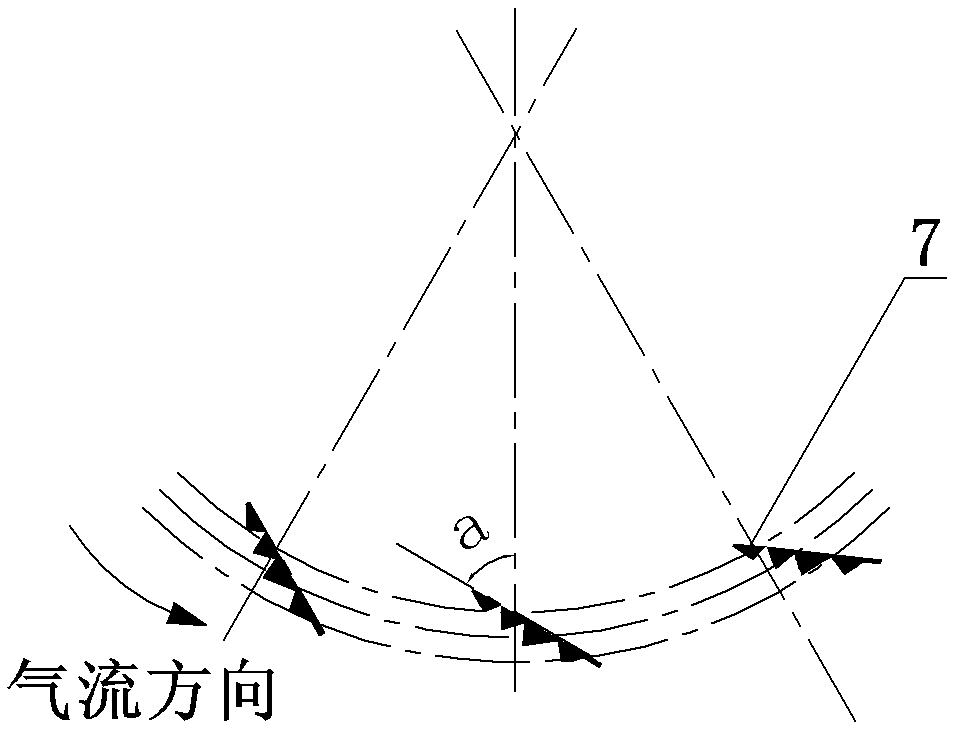

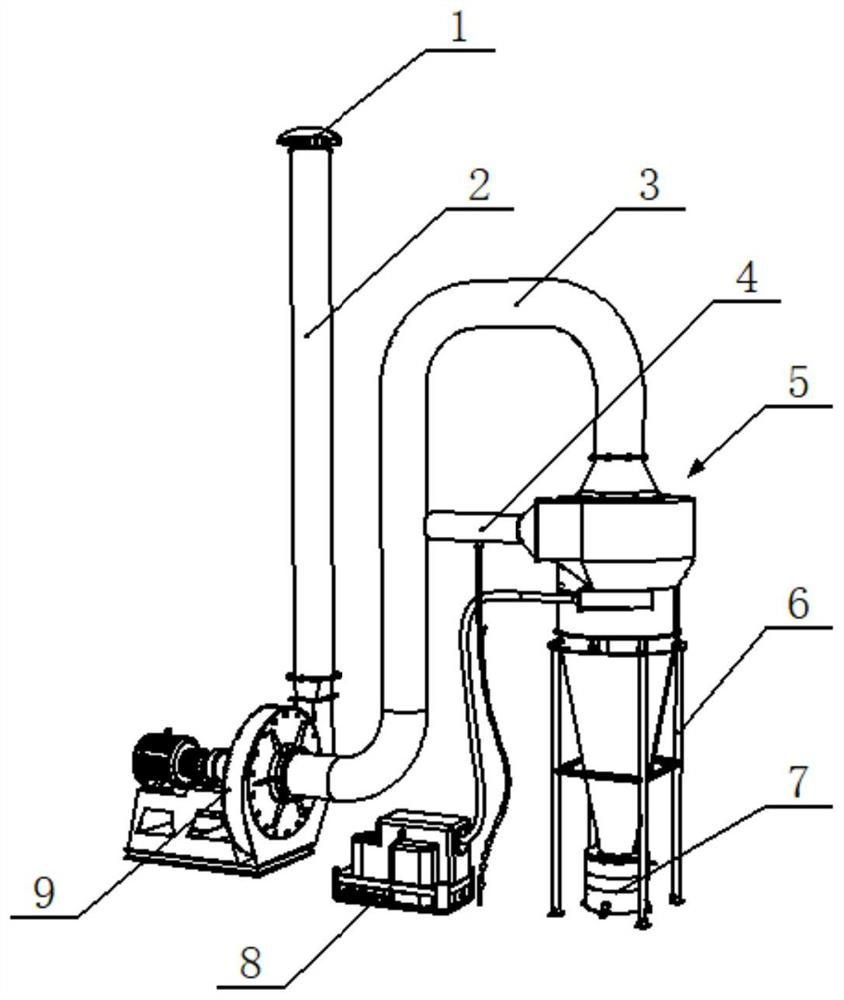

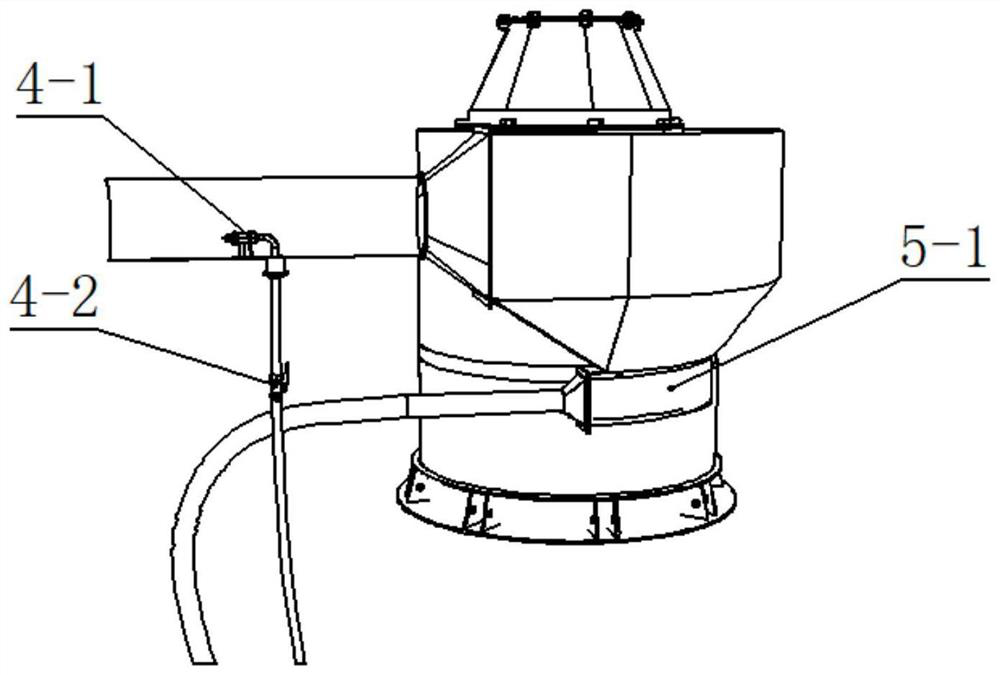

Nested multi-rotor cyclone dust removal device

ActiveCN113750654ARealize multi-stage dust removalRealize the effect of degreasingHuman health protectionCombination devicesThermodynamicsEngineering

The invention provides a nested multi-rotor cyclone dust removal device. A tangential emulsifier mist inlet pipeline, a guide plate and a multi-pipe cyclone separator are arranged in a nested cyclone dust remover, so that the multi-stage dust removal and oil removal effects of the nested cyclone dust remover are realized; a volute type air inlet and a tangential emulsifier mist inlet pipeline are tangentially arranged on a shell body of the nested cyclone dust collector, the linear speed of waste gas entering the dust collector is effectively increased by adopting volute type air inlet, cyclone enters the multi-pipe cyclone separator through a flow guide plate to realize secondary dust collection, and the dust collection efficiency is effectively improved; and the tangential emulsifier mist inlet pipeline is connected with an oil removal emulsifier atomization device, waste gas enters the nested cyclone dust collector and then does high-speed centrifugal motion to provide negative pressure for the tangential emulsifier mist inlet pipeline, and an atomized oil removal emulsifier in the oil removal emulsifier atomization device enters the nested cyclone dust collector and does high-speed centrifugal motion along with the waste gas, so that the atomized oil removal emulsifier is fused with waste gas components, and oil stains in the waste gas are effectively removed.

Owner:XINGTAI TIANYUANXING FOOD EQUIP

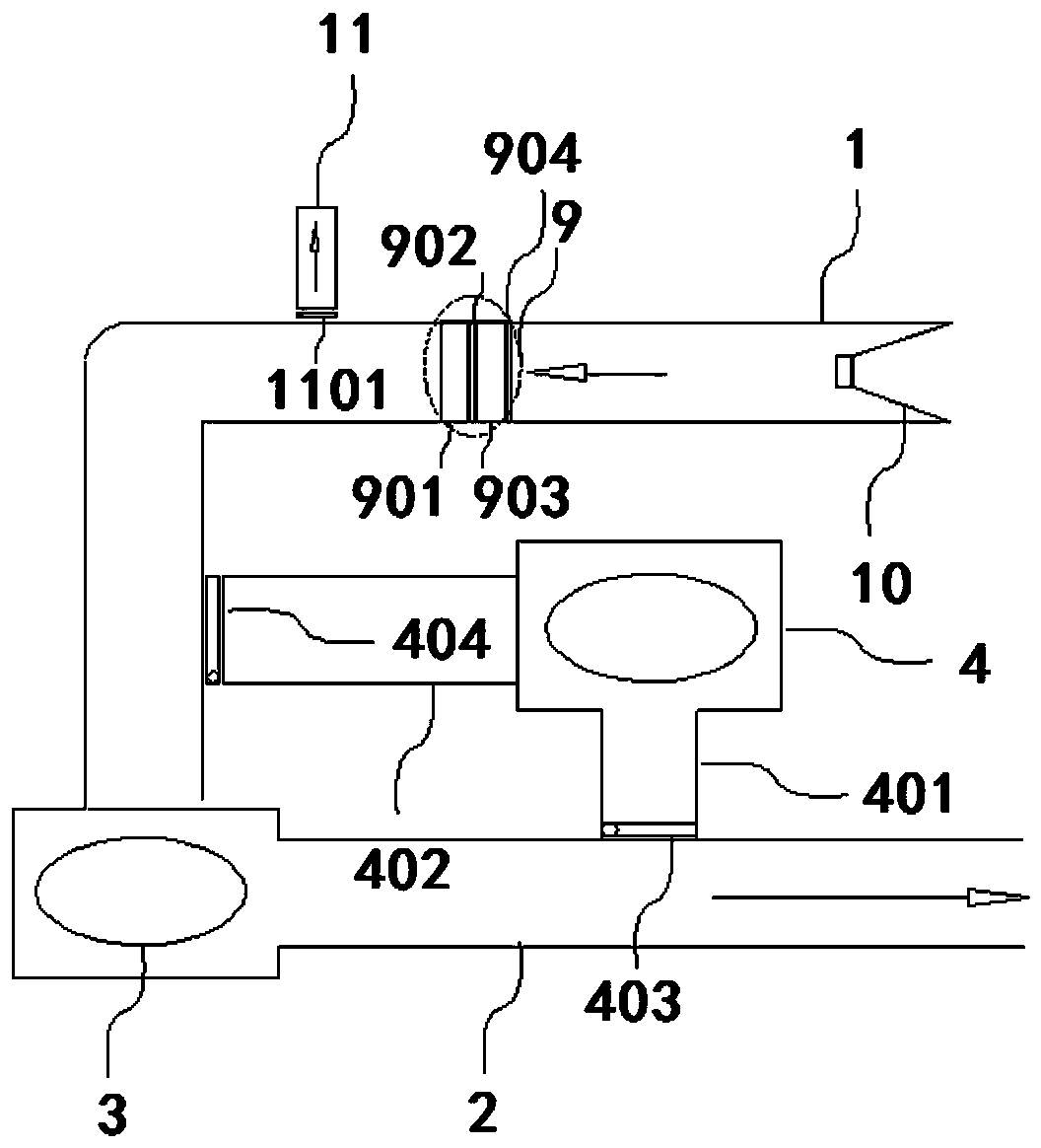

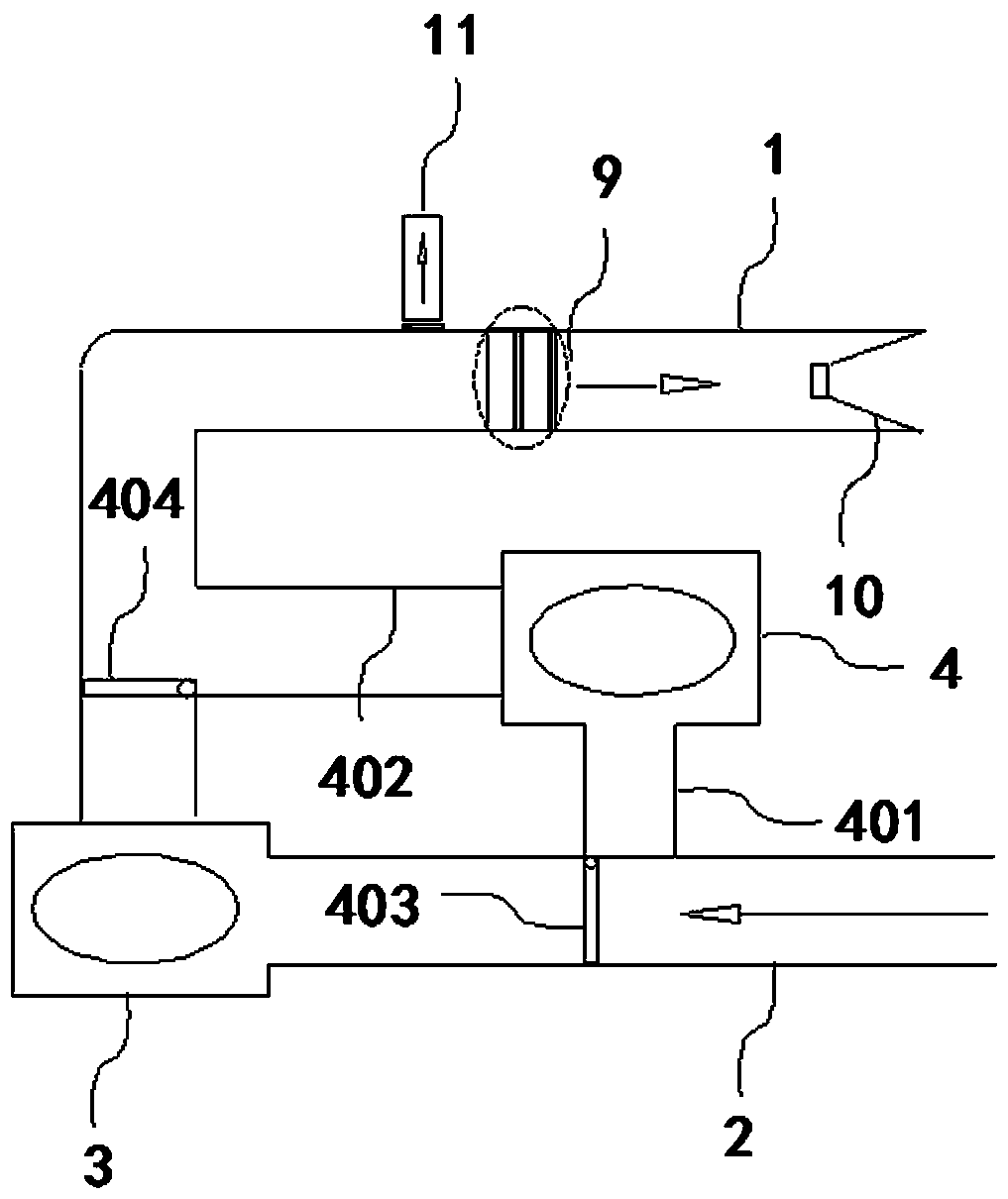

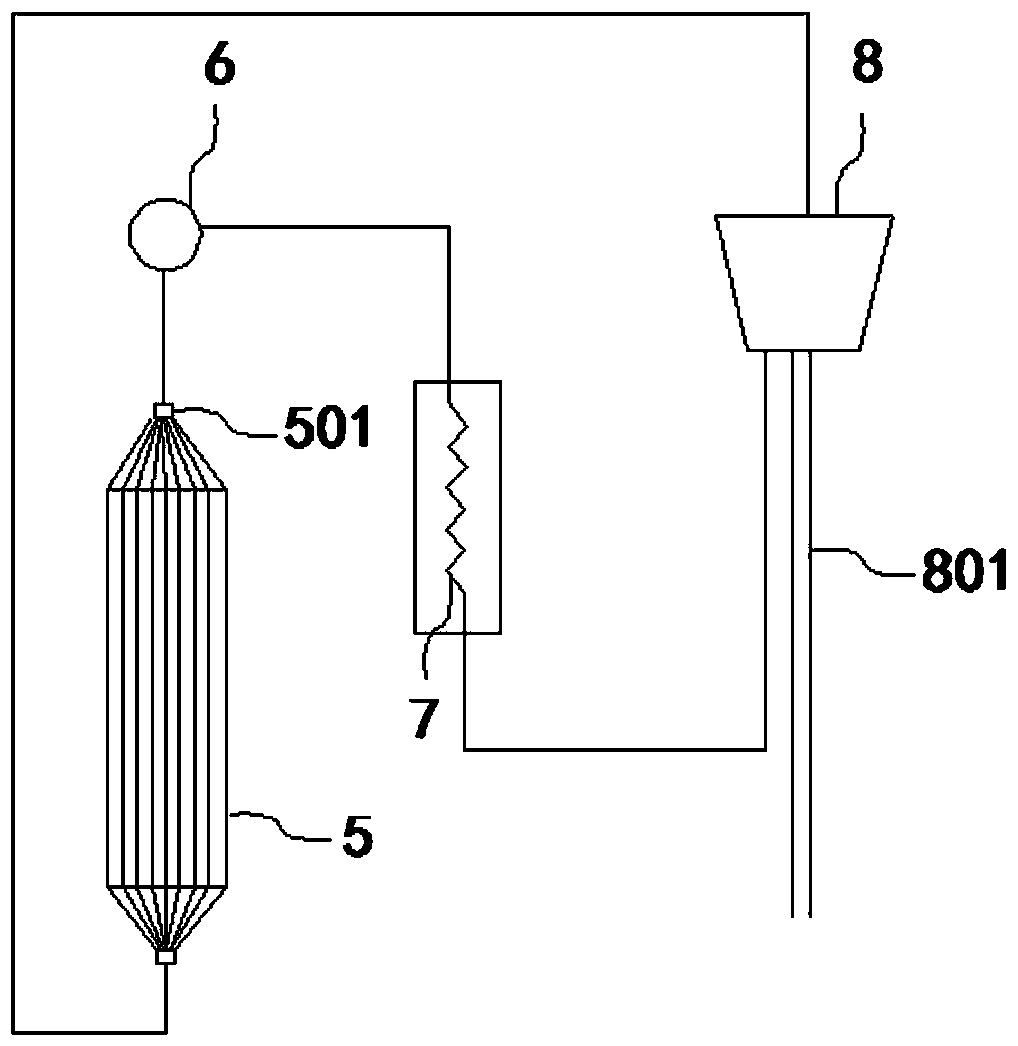

Vehicle air conditioning system with waste heat recovery function

InactiveCN108583218AHigh heat conversion efficiencyReduce manufacturing costs and energy consumptionAir-treating devicesVehicle heating/cooling devicesAutomotive engineeringRefrigerant

The invention belongs to the field of vehicle air conditioners, in particular to a vehicle air conditioning system with a waste heat recovery function. The vehicle air conditioning system comprises atwo-way ventilation module and a waste heat recovery module, wherein the two-way ventilation module comprises an external air passage of a vehicle body (1), an air exchange passage in a vehicle (2), aone-way air inlet fan (3), a one-way air outlet fan (4), an air-out loading channel (401) and an air-out feeding channel (402), and the waste heat recovery module includes a refrigerant heat exchangeassembly (5), a hydraulic pump (6), a heat exchange assembly (7) and a power turbine (8); the end port of a liquid distributor of the refrigerant heat exchange assembly (5) is connected to the heat exchange input end port of the heat exchange assembly (7) through the hydraulic pump (6); and the heat exchange output end port of the heat exchange assembly (7) is connected to an entrance of the power turbine (8). The vehicle air conditioning system with the waste heat recovery function has high heat conversion efficiency, low manufacturing cost and low energy consumption, high heat exchange speed, and can realize air supply from the outside of a vehicle compartment to the interior of the vehicle compartment and air discharge from the inside of the vehicle compartment to the outside of the vehicle compartment.

Owner:北京远大天益生态建筑设计院有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com