Process for removing oil and water from gas and recycling oil by adopting low-temperature methanol

A low-temperature methanol and methanol-water separation tower technology is applied in the purification of liquid scrubbing gas, the purification of condensed non-gaseous material gas, and energy input. , The effect of high gas purification and increasing added value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

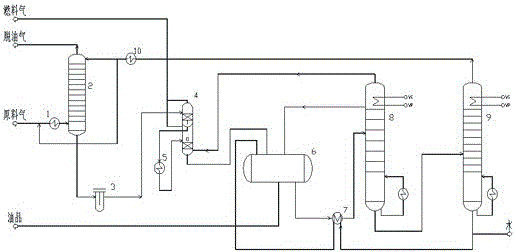

Image

Examples

Embodiment 1

[0037] In this embodiment 1, the crude gas flow rate is 122000Nm 3 / h (111900kg / h), temperature: 25°C, pressure: 30bar, oil content: 0.079wt%, water 0.02wt%.

[0038] The crude gas is sprayed into 400kg / h of methanol first to prevent the water in the feed gas from freezing at low temperature, and then enters the feed cooler 1, and then the crude gas is cooled to -30°C and enters the oil removal tower 2. The temperature of the 3600kg / h methanol sprayed on the top of the tower is -30℃. After deoiling treatment under the pressure of 30bar, the deoiled gas exits the device from the top of the tower, and the low-temperature oily methanol is filtered from the bottom of the deoiling tower 2 through methanol The dirty methanol after dust removal by filter 3 enters the secondary flash washing tower 4.

[0039] In the secondary flash scrubber 4, the operating pressure of the medium-pressure flash section is 9 bar, and the operating temperature is -30°C. The flash liquid is heated to -5...

Embodiment 2

[0042] In this embodiment 2, the crude gas flow rate is 440000Nm 3 / h (420000kg / h), temperature: 25°C, pressure: 45bar, oil content: 0.050wt%, water 0.016wt%

[0043] This embodiment is identical with embodiment 1 step, and concrete operation parameter changes as follows

[0044] Before the crude gas enters the desulfurized gas and enters the feed cooler 1, 1600kg / h of methanol at -27°C is sprayed into the deoiling tower 2, and 11400kg / h of methanol is sprayed at the top of the tower.

[0045] In the secondary flash tower 4, after the first-stage flash, the pressure is reduced to 10 bar, and the temperature is reduced to -25°C. After being heated to -5°C by the flash heater 5, the decompression flash is continued, and the pressure is controlled in the second stage. is 2bar, at this time the flash temperature reaches -20°C,

[0046] The operating temperature of the oil-water extractor 6 is 35° C., and the pressure is maintained at 2 bar.

[0047] The oil separation tower hea...

Embodiment 3

[0052] In this embodiment 3, the crude gas flow rate is 515000Nm 3 / h(495000kg / h), temperature: 20°C, pressure: 60bar, oil content: 0.39wt%, water content: 0.018wt%

[0053] This embodiment is identical with embodiment 1 step, and concrete operation parameter changes as follows

[0054] Before the crude gas enters the desulfurized gas into the feed cooler 1, it is sprayed with 2000kg / h of methanol

[0055] Enter the deoiling tower 2, spray 15000kg / h of methanol at the top of the tower to remove oil.

[0056] In the secondary flash tower 4, after the first stage of flash evaporation, the pressure is reduced to 11bar, and the temperature is reduced to -20°C. After being heated to 0°C by the flash heater 5, the decompression flash is continued. In the second stage, the pressure is controlled to be 3bar, at this time the flash temperature reaches -5°C,

[0057] The operating temperature of the oil-water extractor 6 is 30° C., and the pressure is maintained at 3 bar.

[0058] T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com