Cyclone separating gas oil separator

An oil and gas separator and cyclone separation technology, applied in separation methods, dispersed particle separation, cyclone devices, etc., can solve the problems of pump oil splashing, large airflow resistance, oil-line spraying, etc., and achieve good oil and gas separation effect, Reasonable structure design and small airflow resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

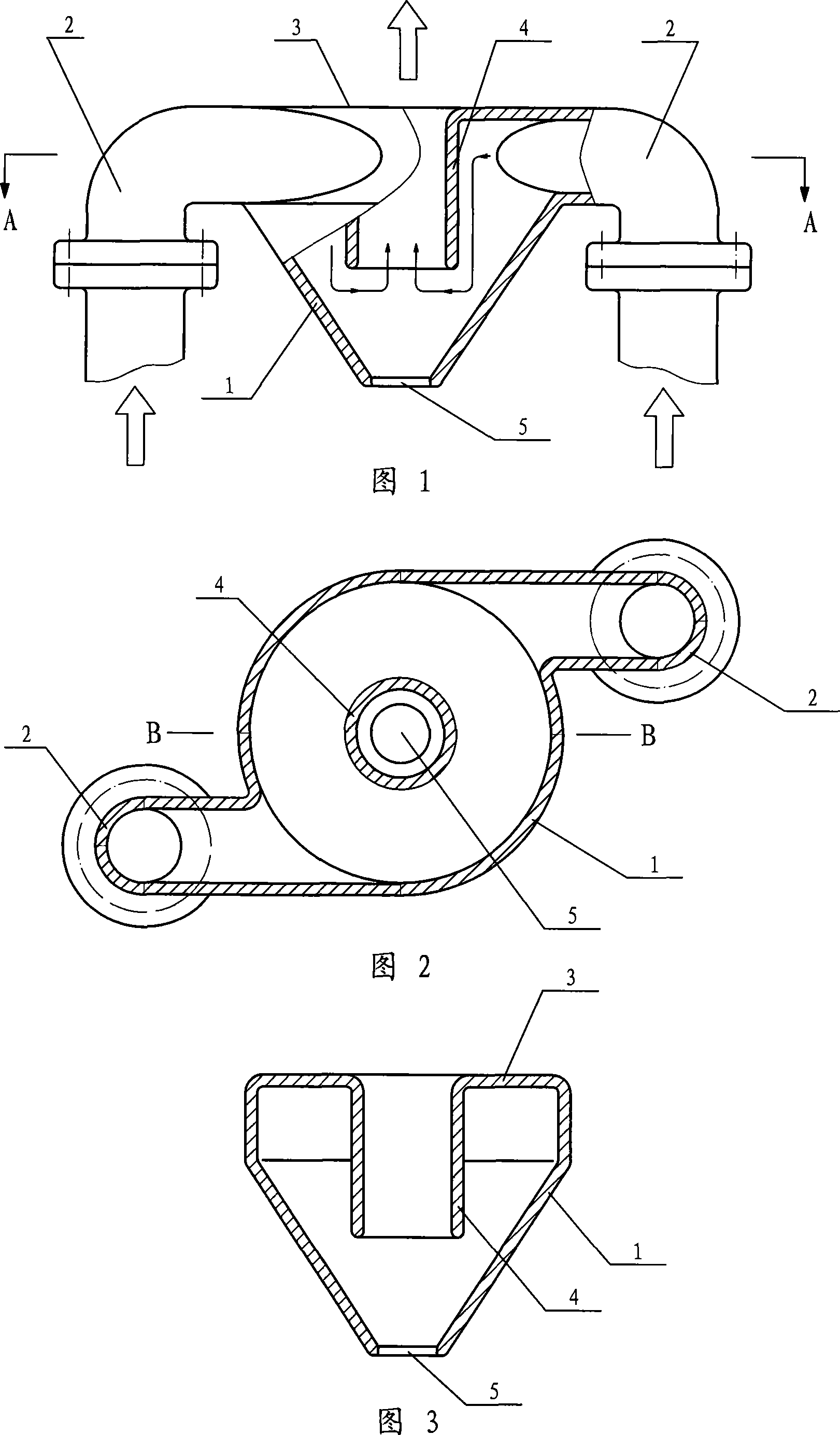

[0016] As shown in the figure, the cyclone oil-gas separator is composed of a shell 1, a top cover 3 connected to the top of the shell, and a conduit 2 connected to the upper part of the shell. The conduit 2 is a 90-degree elbow, with Two, symmetrically installed on the housing 1, the housing 1 is in the shape of a truncated cone, the upper part is larger and the lower part is smaller. The center of the top cover 3 is connected with a central exhaust pipe 4 which is integrated with it. The central exhaust pipe 4 is located at the center of the housing 1, and the bottom of the housing 1 has an oil outlet 5 located below the central exhaust pipe. , the air outlet of the transverse part of the duct 2 is tangent to the inner wall of the upper part of the housing, the air inlet of the central exhaust pipe 4 is lower than the air outlet of the duct 2, and the air outlet of the central exhaust pipe 4 is flush with the outer wall of the top cover 3 . The vertical part of the conduit ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com