Patents

Literature

33results about How to "Stable dust removal" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

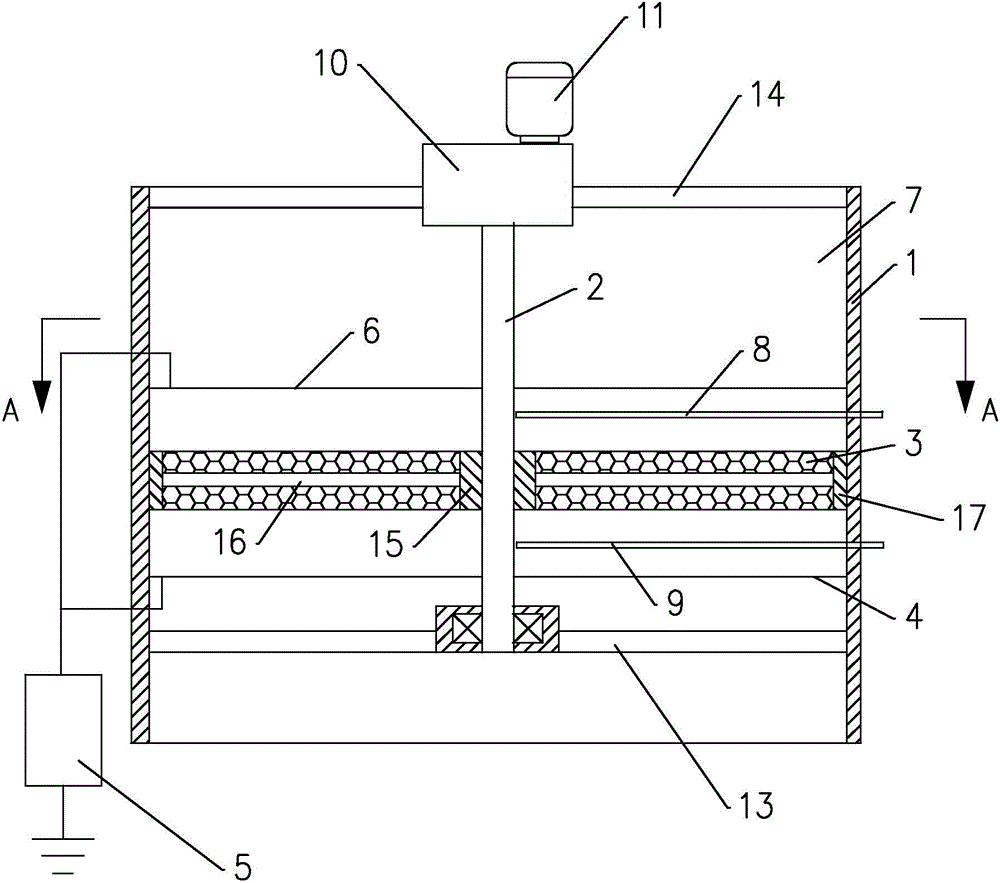

Combined type runoff electric precipitation air purifier

InactiveCN103949345ALarge gas volumeReduce wind resistanceExternal electric electrostatic seperatorElectrode constructionsElectricityPotential difference

The invention discloses a combined type runoff electric precipitation air purifier. The combined type runoff electric precipitation air purifier comprises a shell, wherein an air purification channel is formed in the shell; a front discharging net is arranged in the air purification channel in a direction of the section of the air purification channel; the front discharging net is fixedly connected to the shell; a dust collection electrode net plate is arranged behind the front discharging net in the air purification channel; airflow is capable of flowing through the surface of the dust collection electrode net plate; the dust collection electrode net plate is manufactured by multiple layers of wire nets which are stacked by porous foam metal plates, a plurality of parallel corrugated plates, a plurality of parallel flat plates or honey comb plates, or a plurality of wire net surfaces; a potential difference being 5000-60000V is generated between the front discharging net and the dust collection electrode net plate due to electric connection with a high-voltage direct-current power supply. The invention aims to provide the combined type runoff electric precipitation air purifier. The combined type runoff electric precipitation air purifier is capable of treating a large volume of air in unit of time, low in wind resistance, prominent in effect of removing tiny dust within PM (Particulate Matter) being 2.5, extremely stable in dust collection performance, low in operation cost and long in service life.

Owner:孟金来

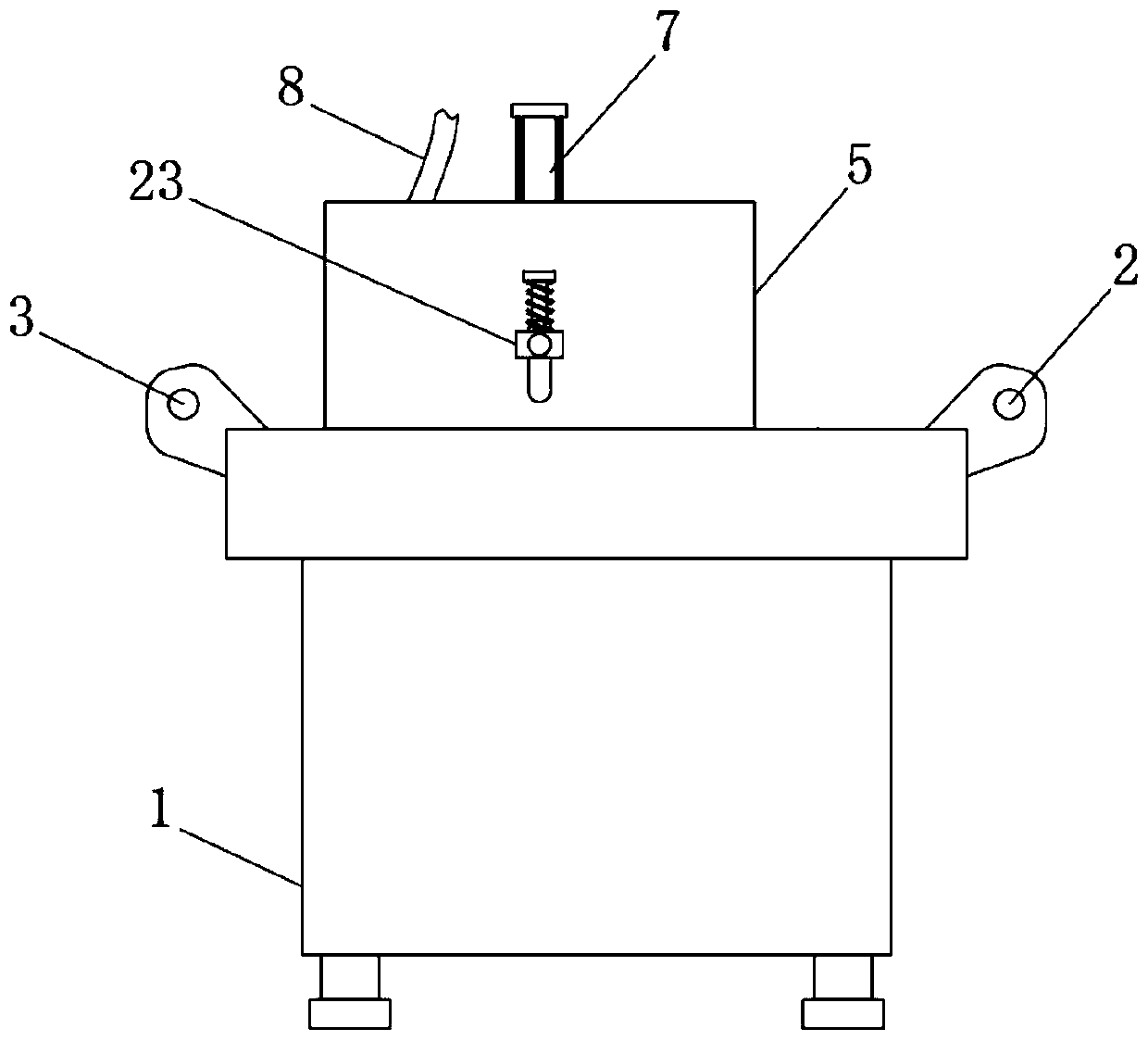

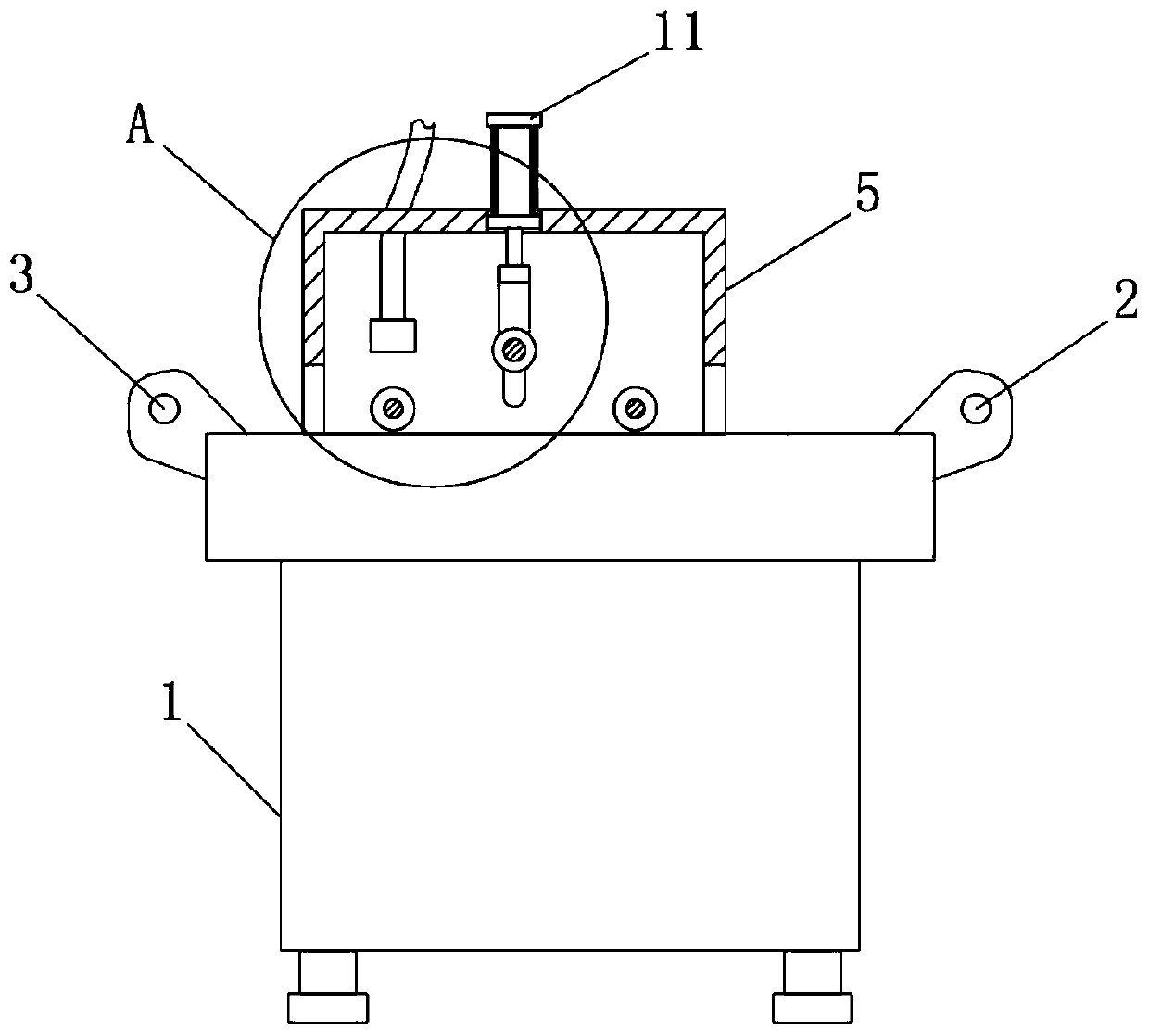

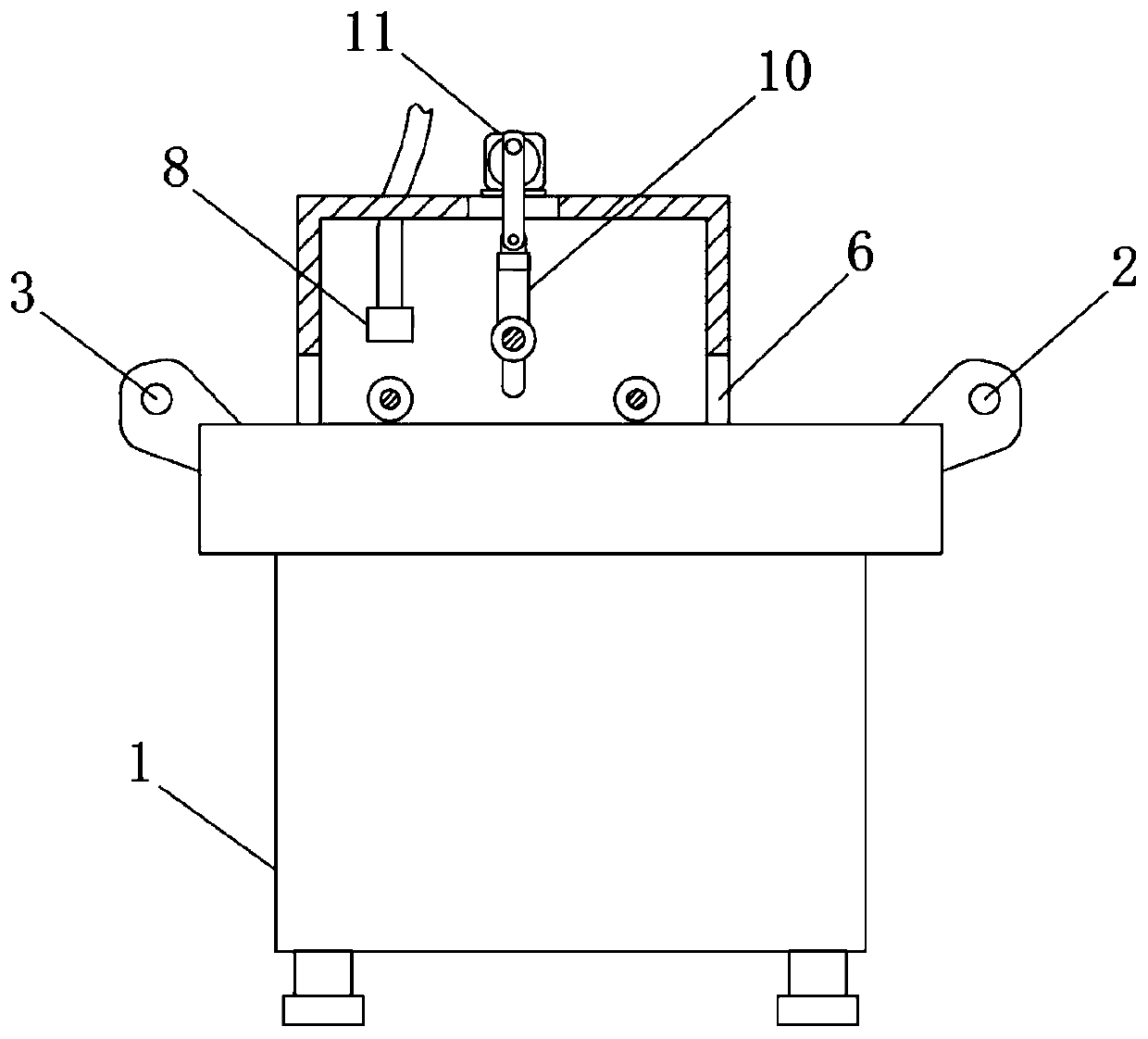

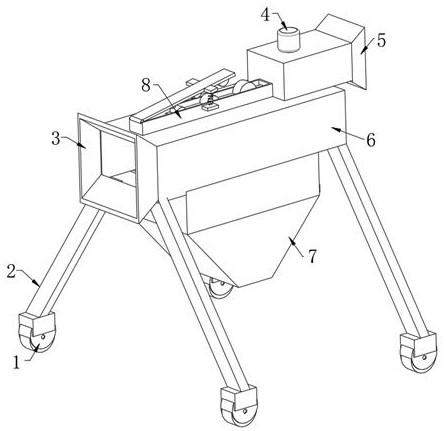

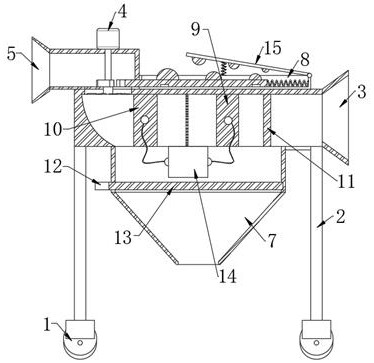

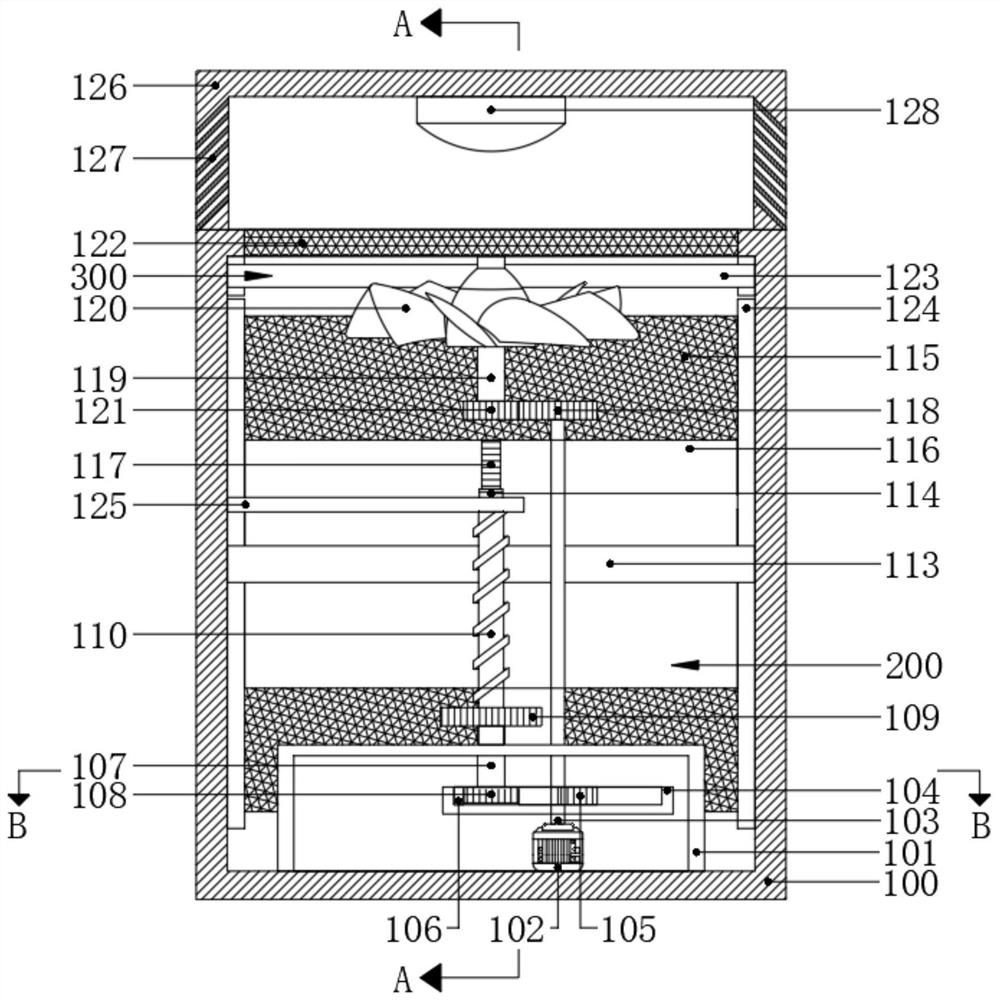

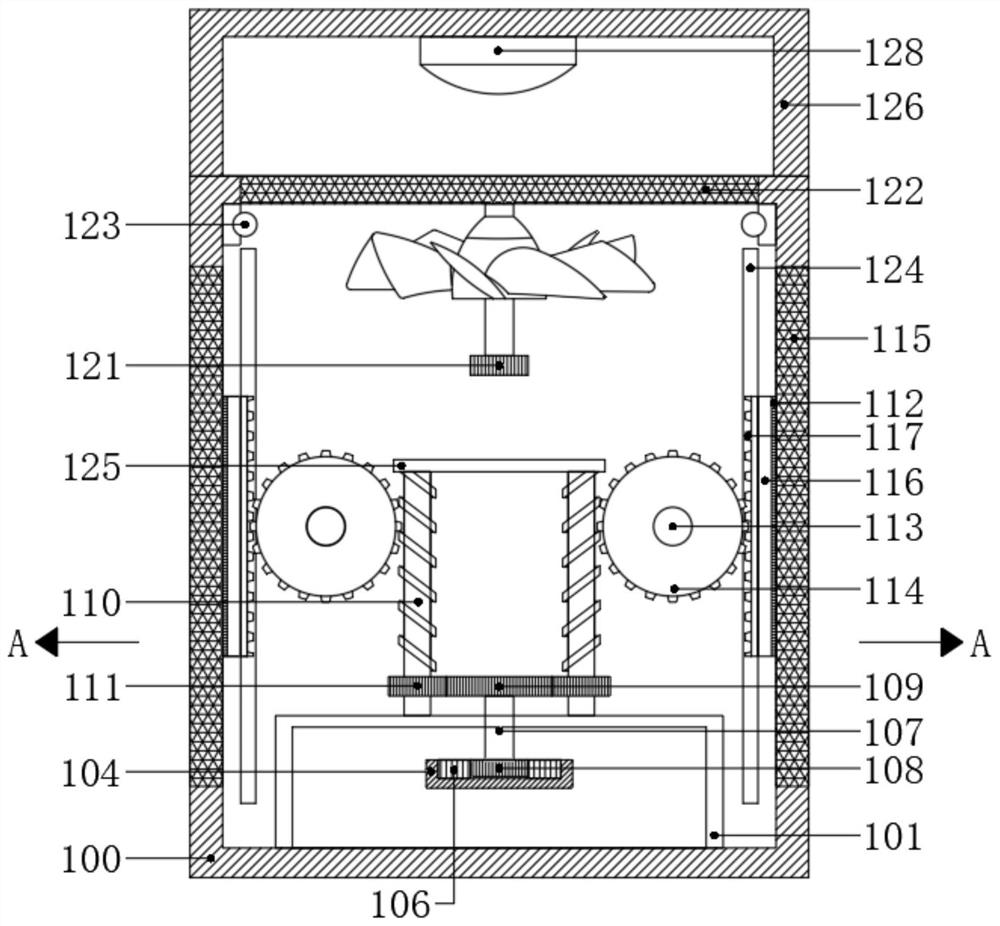

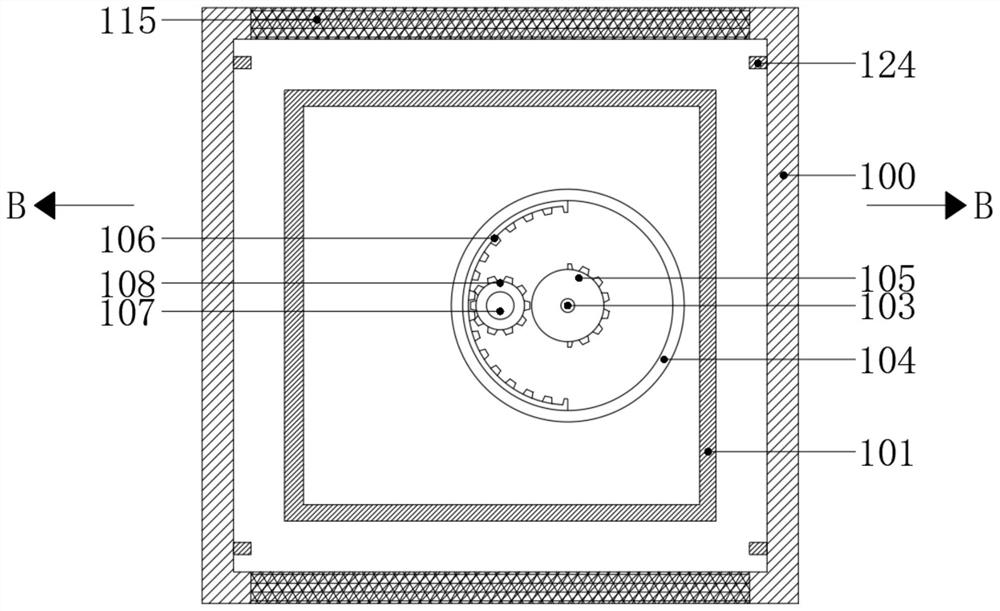

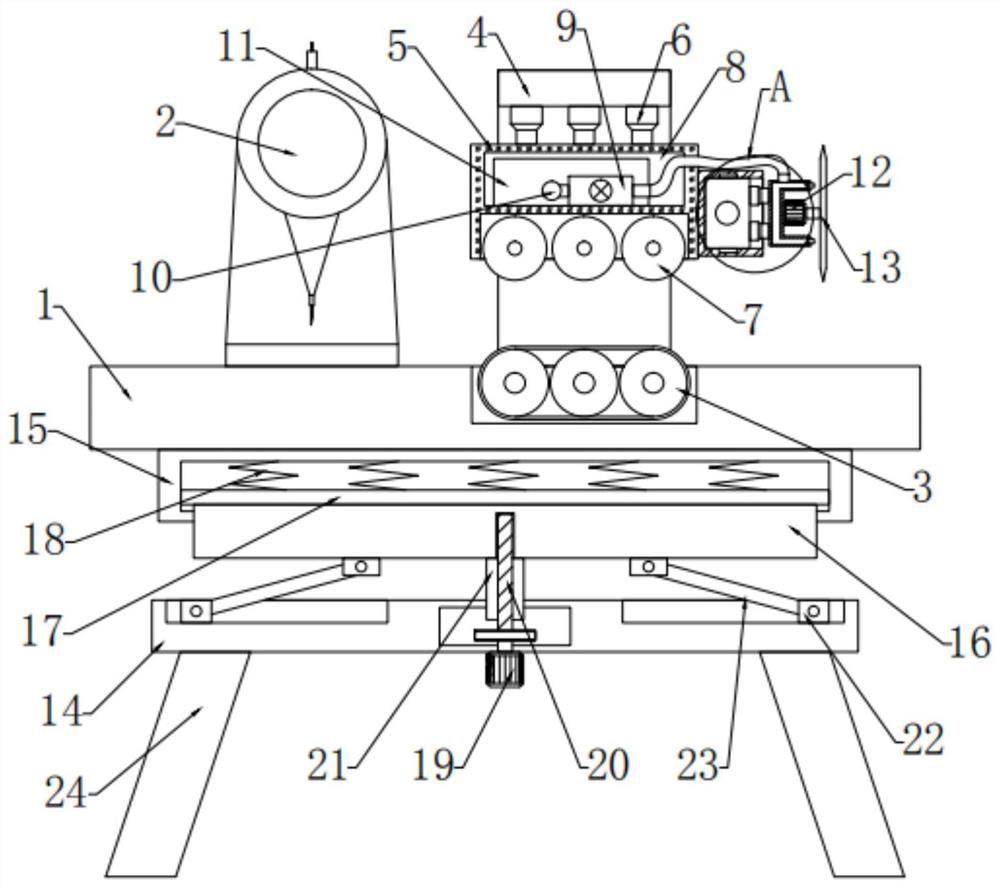

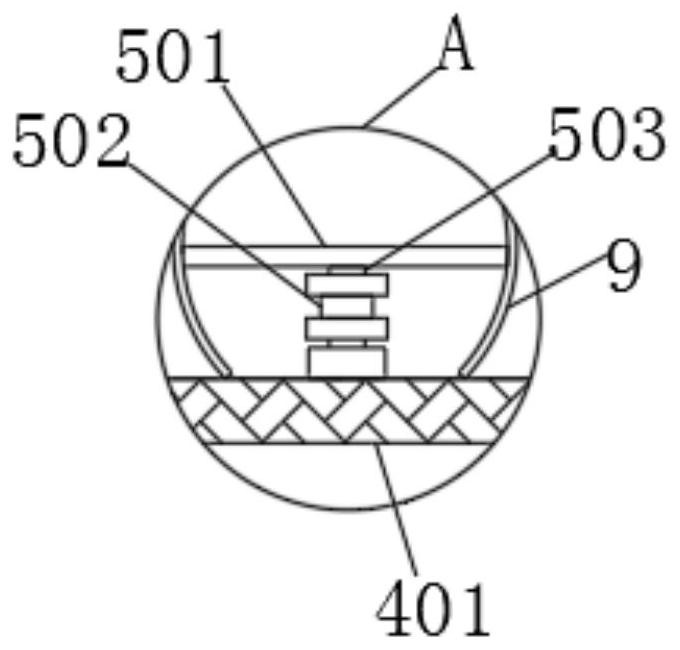

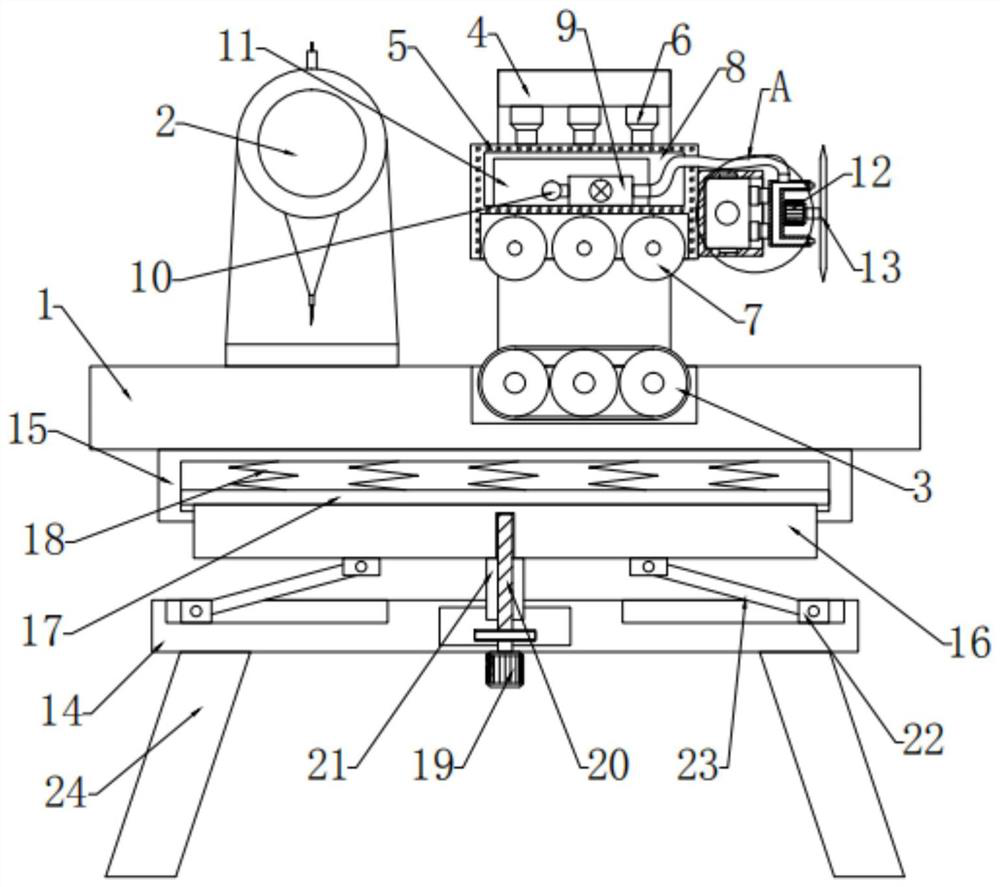

Efficient dust removing device for lithium battery

InactiveCN108672341AAvoid leaningStable dust removalCleaning using toolsCleaning using gasesEngineeringLithium battery

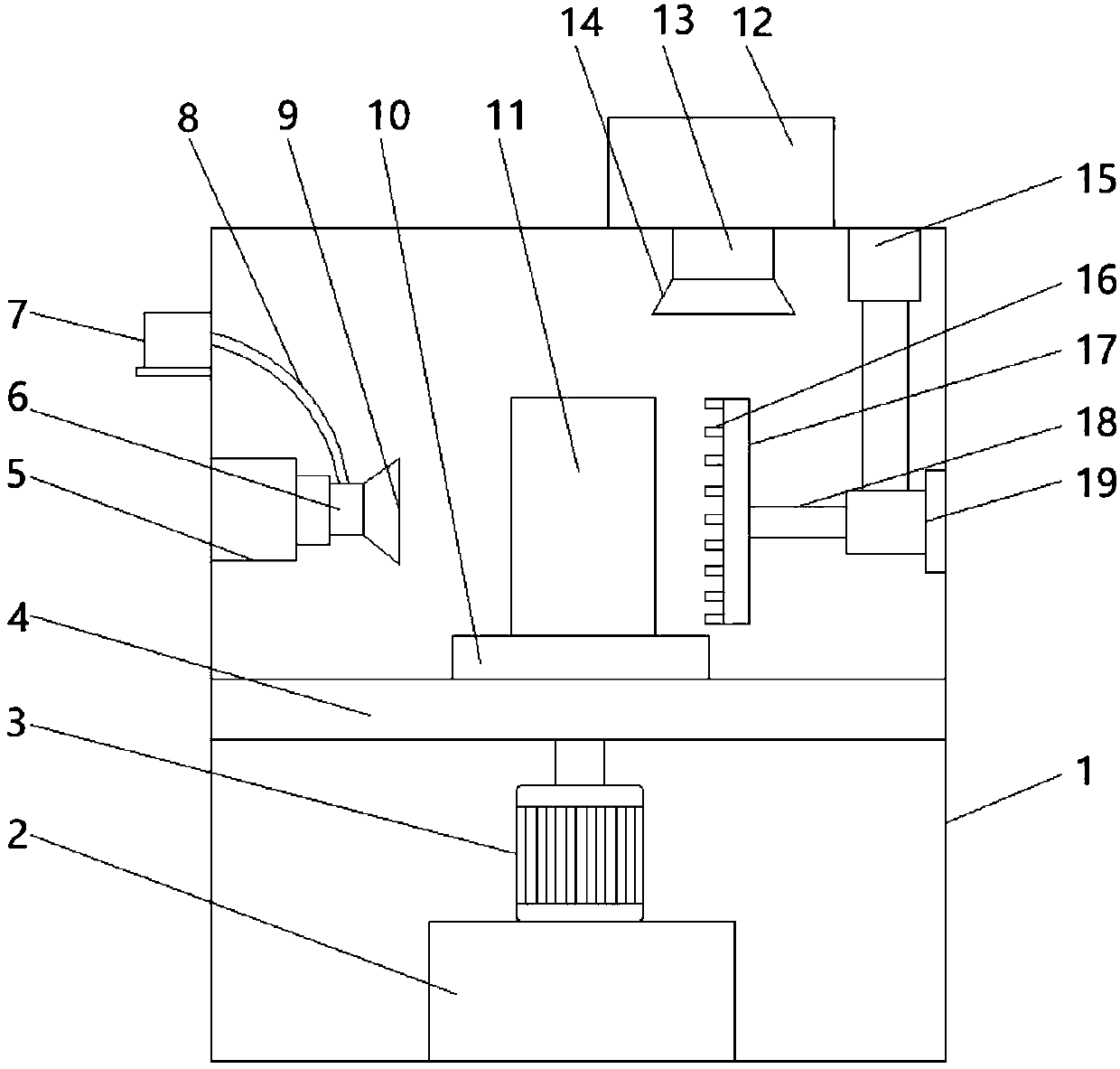

The invention discloses an efficient dust removing device for a lithium battery. The efficient dust removing device comprises a dust removing box body, a supporting plate, a lithium battery body, a gas jetting machine, a dust sucking machine, a first electric telescoping rod, a second electric telescoping rod and a third electric telescoping rod. A rotating motor is installed on the middle portionof the bottom face of the dust removing box through a motor base. The motor base is fixed in the dust removing box body. The bottom end of the rotating motor is arranged on the motor base. A transmission shaft at the top end of the rotating motor is fixedly connected with a bearing base through the supporting plate. The supporting plate is arranged in the dust removing box body. The side edge ofthe supporting plate is fixedly connected with the inner wall of the dust removing box body. The bearing base is arranged in the middle of the upper end face of the supporting plate and is connected with the supporting plate in a rotating manner. The lithium battery body is fixed to the bearing base. According to the efficient dust removing device for the lithium battery, dust can be removed fastand thoroughly, the dust removing speed is increased, the dust removing efficiency is improved, and meanwhile the stability of the lithium battery in the dust removing process is ensured.

Owner:庄毅超

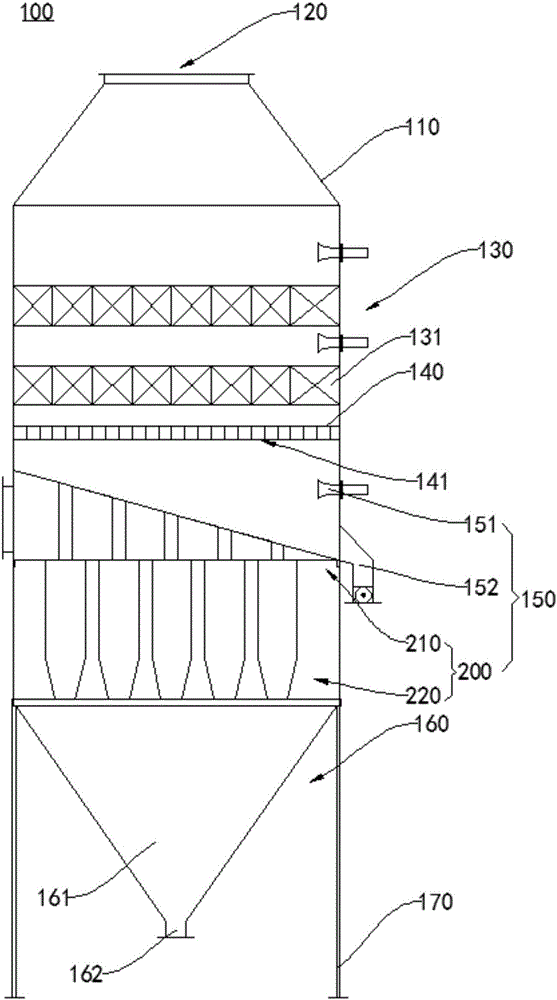

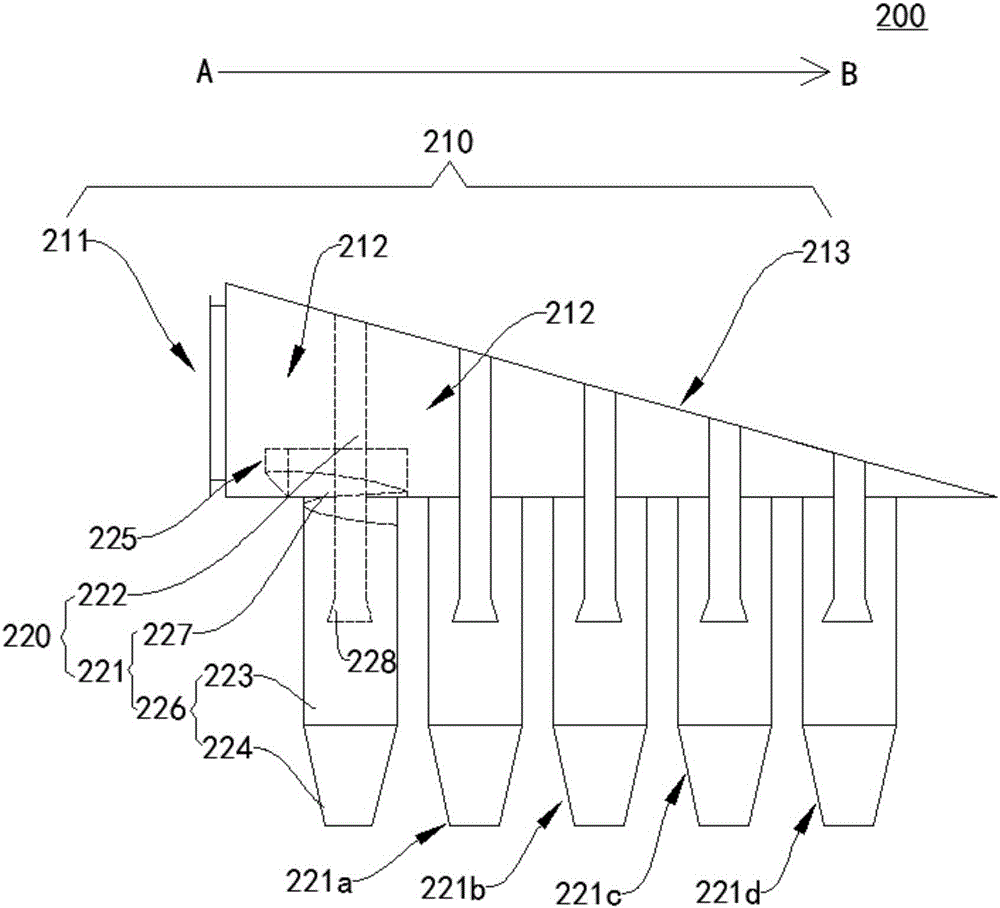

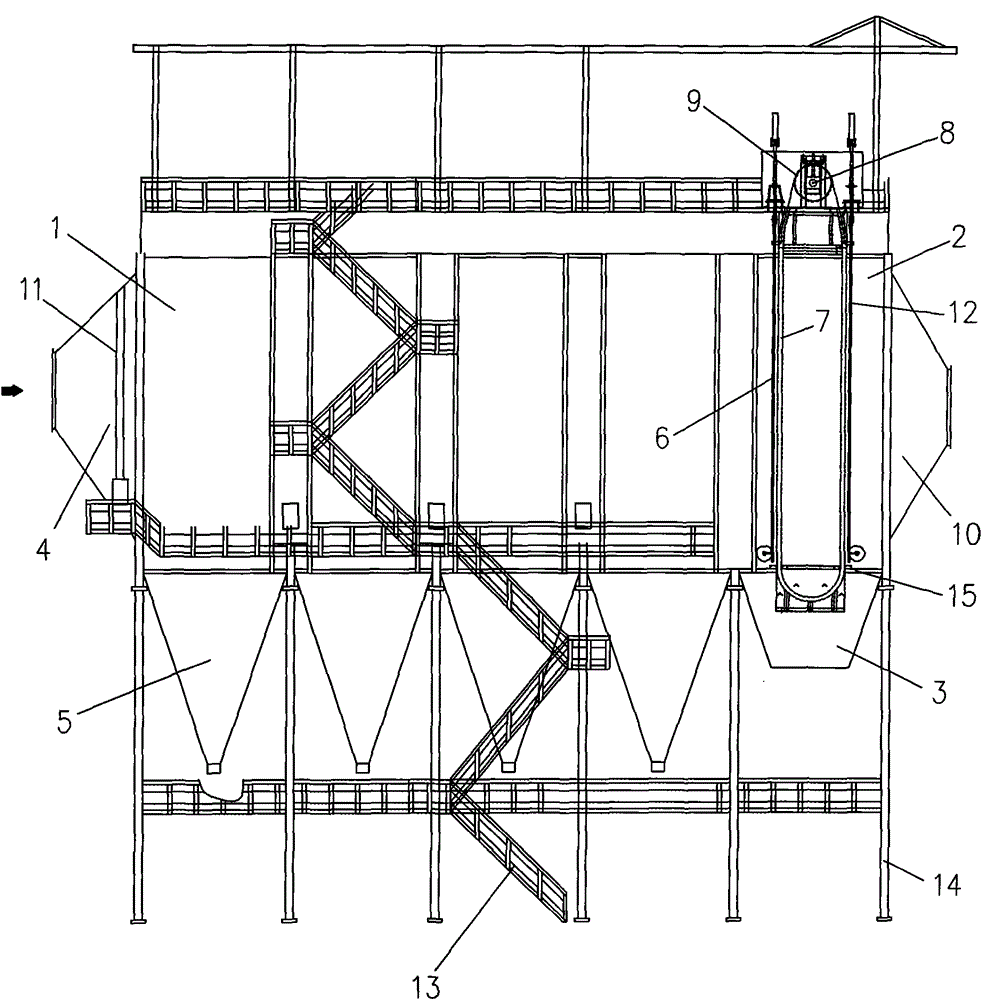

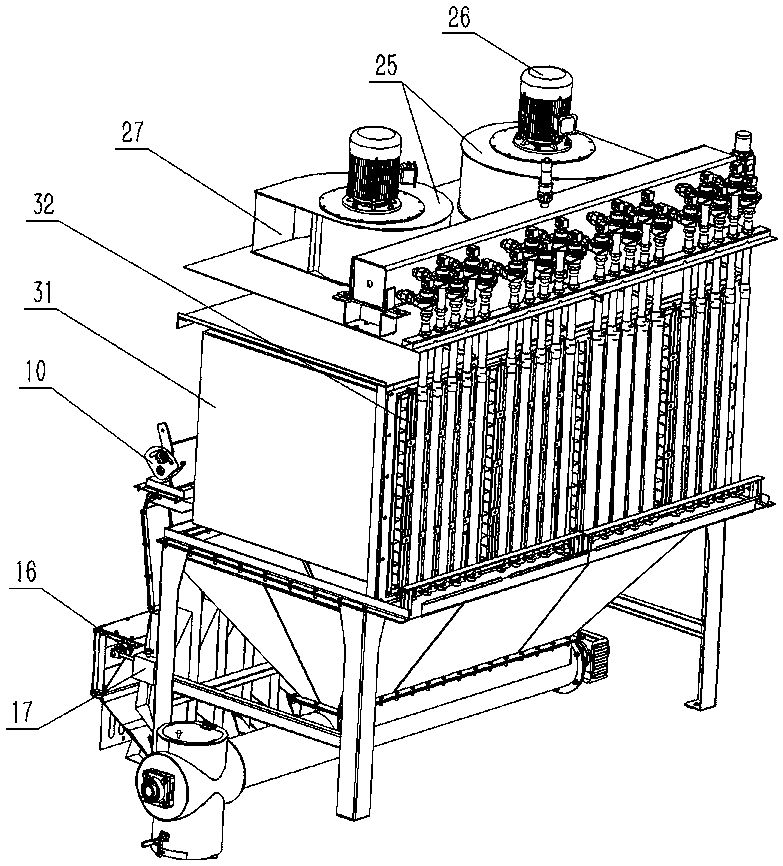

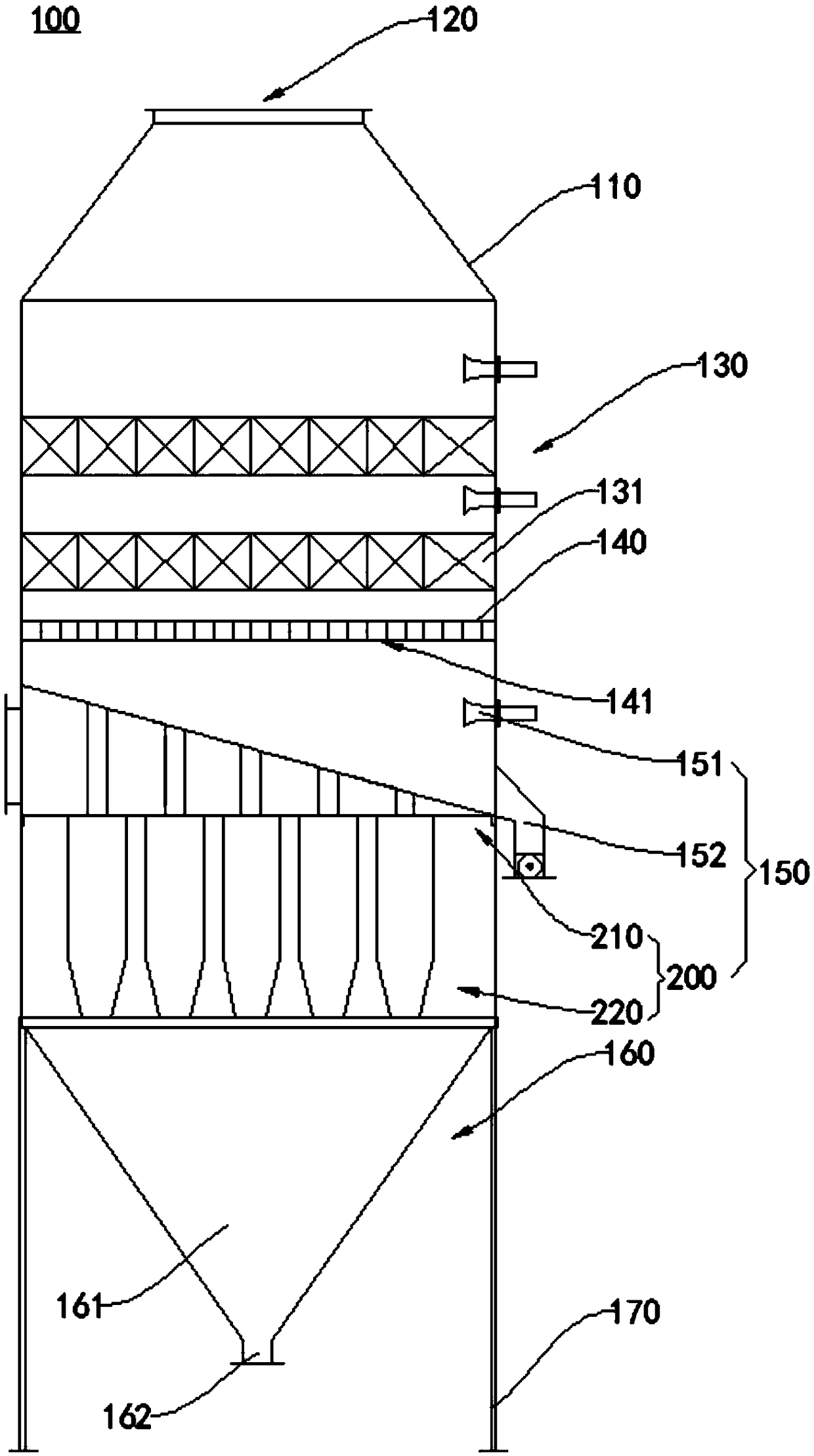

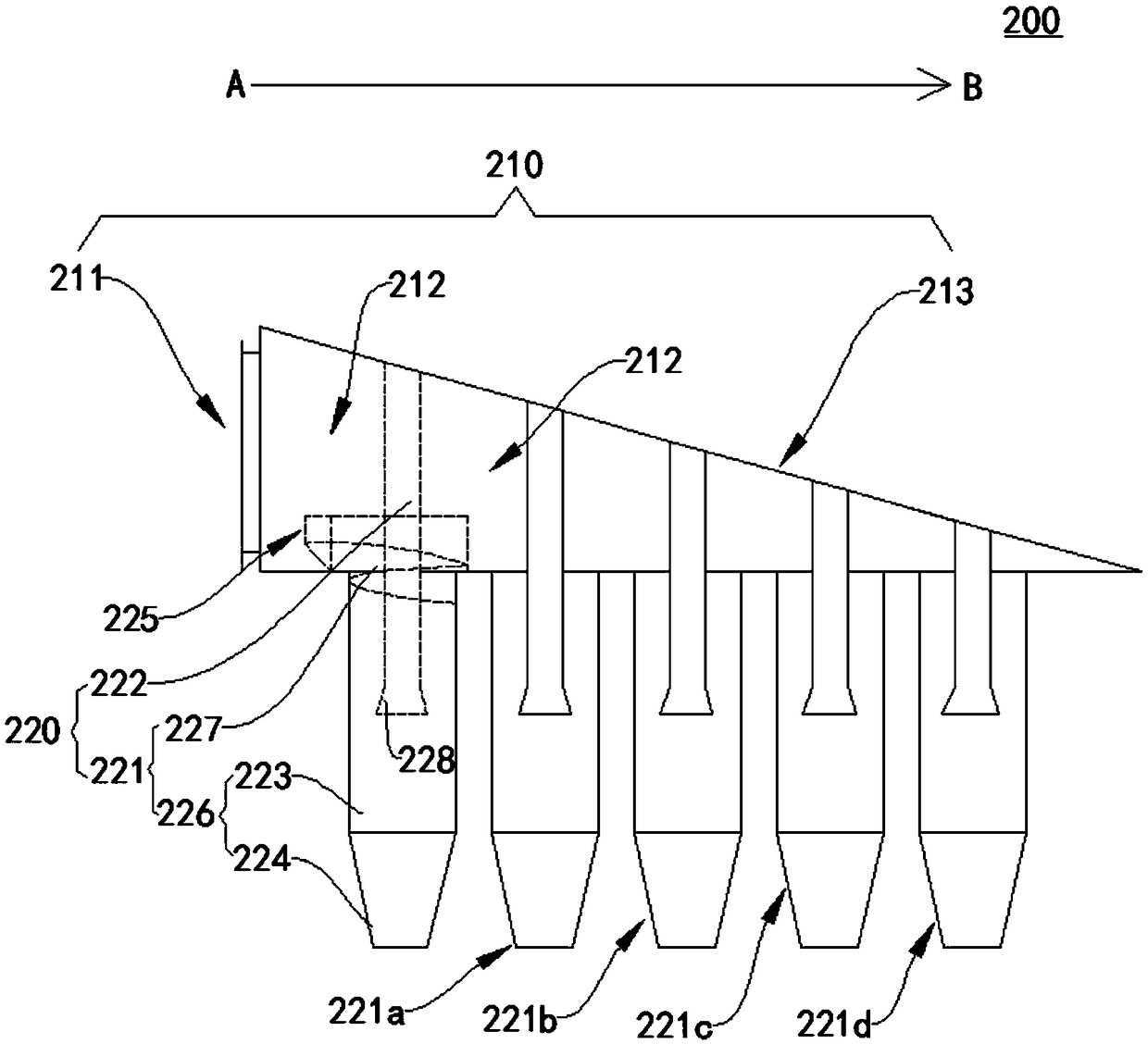

Gas-solid separator, as well as denitration and dust-removing device

ActiveCN106422543AIncrease flow speedIncrease throughputGas treatmentDispersed particle separationProcess engineeringCyclonic separation

The invention relates to environmental protection equipment and a denitration and dust-removing device, in particular to a gas-solid separator, as well as a denitration and dust-removing device. The gas-solid separator comprises a smoke gas distribution chamber. The smoke gas distribution chamber is provided with a smoke gas inlet for introducing a to-be-separated gas in a first direction; a plurality of gas cavities which are communicated mutually are distributed in the smoke gas distribution chamber in the first direction; and the volume of the plurality of the gas cavities is gradually reduced in the first direction. The smoke gas distribution chamber is connected with a plurality of cyclone separation assemblies which are in one-to-one correspondence with the plurality of gas cavities; each separation assembly comprises a cyclone cylinder and a gas discharge pipe which are matched mutually; the cyclone cylinder is provided with a gas inlet and flow guide end which is used for input gas and positioned in the gas cavities; and the gas discharge pipe partially stretches into the cyclone cylinder and penetrates through the smoke gas separation chamber. The denitration and dust-removing device comprises a shell and the gas-solid separator. The gas-solid separator, as well as the denitration and dust-removing device, protects a catalyst and prolongs the service life of the catalyst to finally realize the technical effects of improving the denitration effect and reducing the cost.

Owner:SHANDONG TIANLI ENERGY SAVING ENG

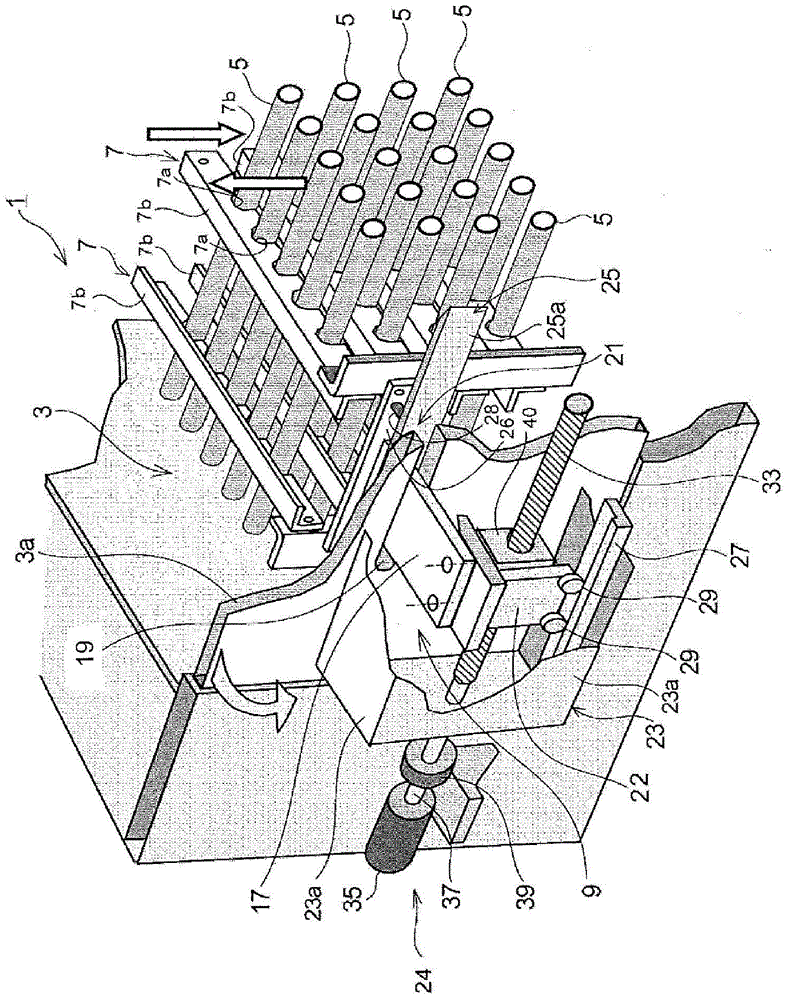

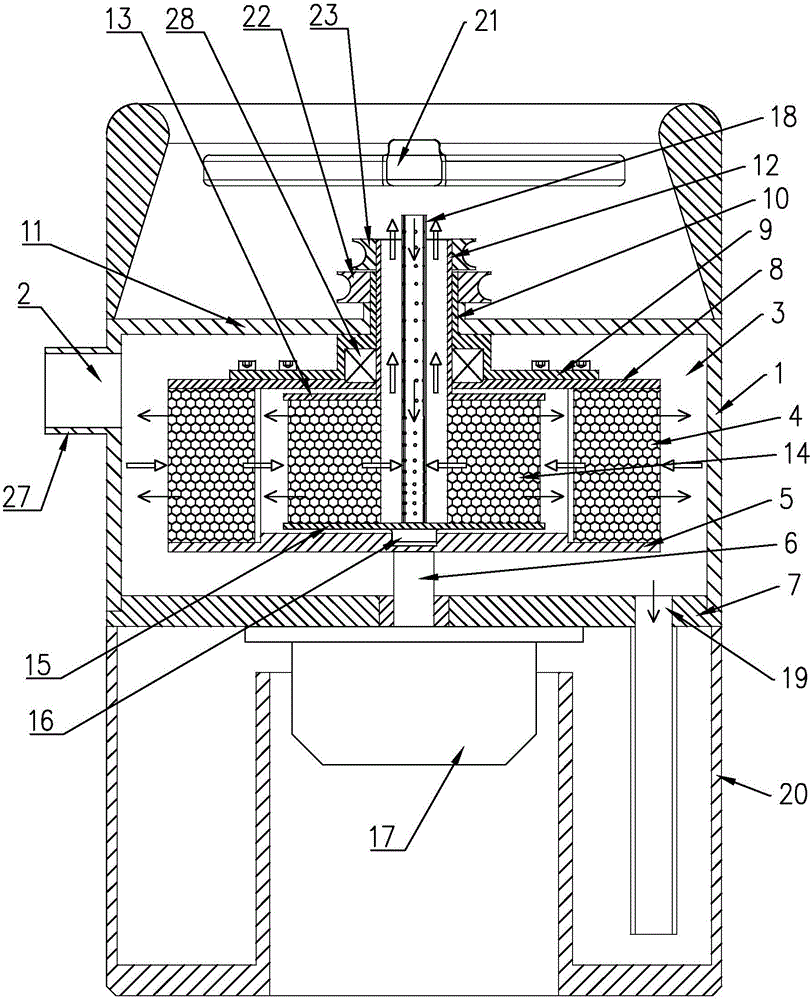

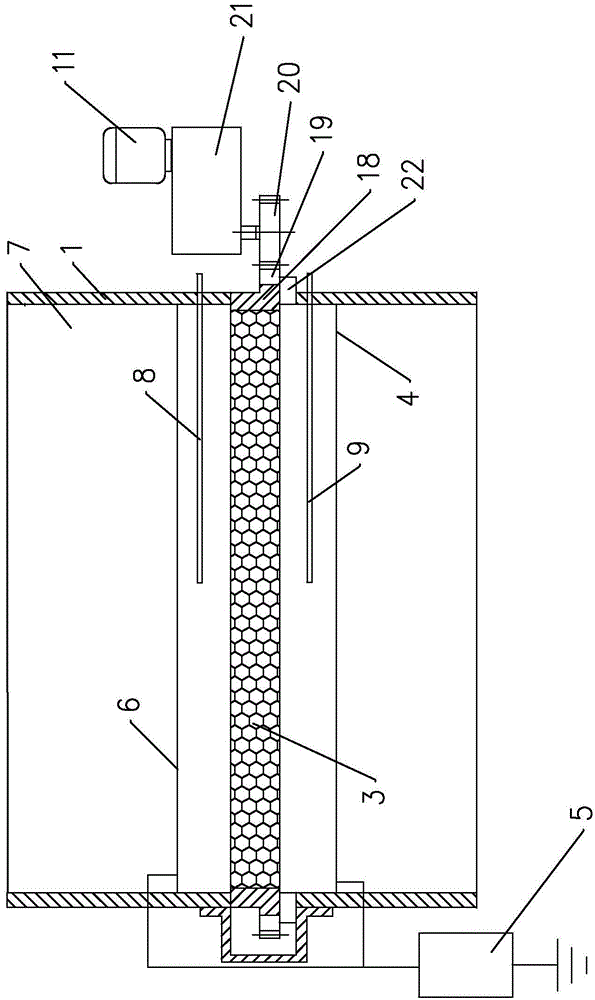

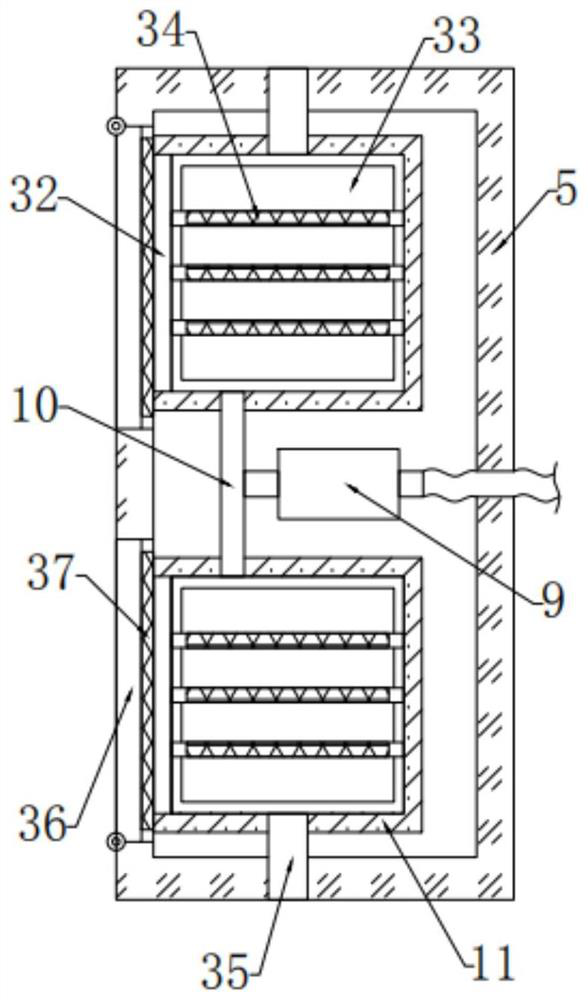

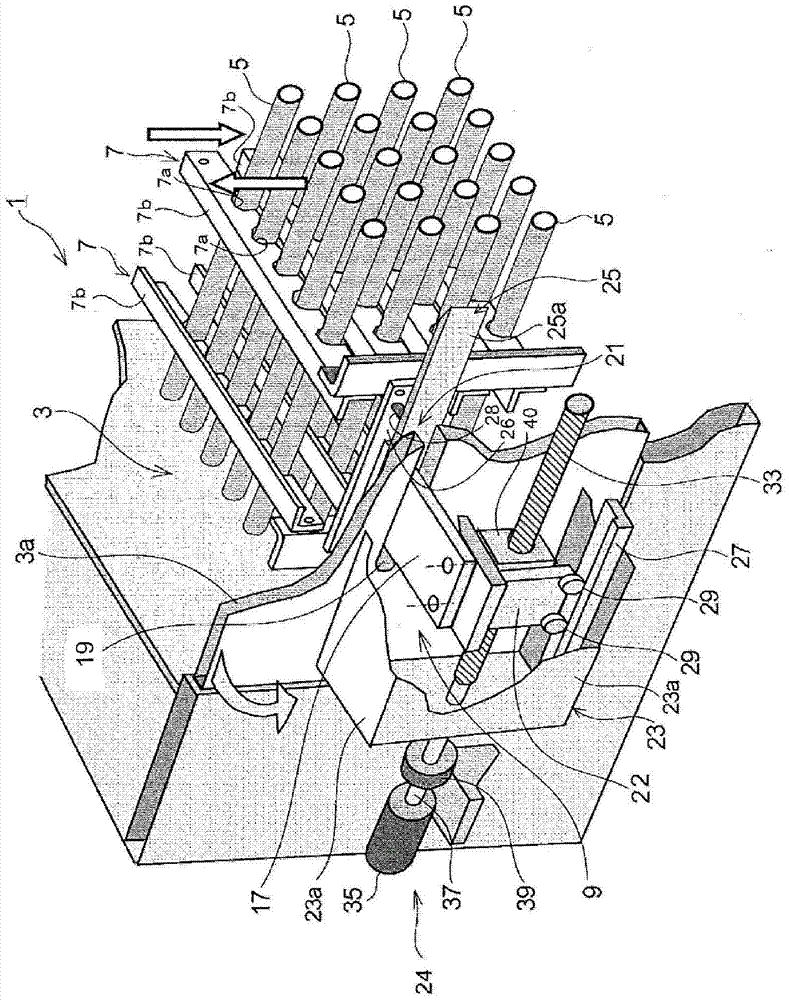

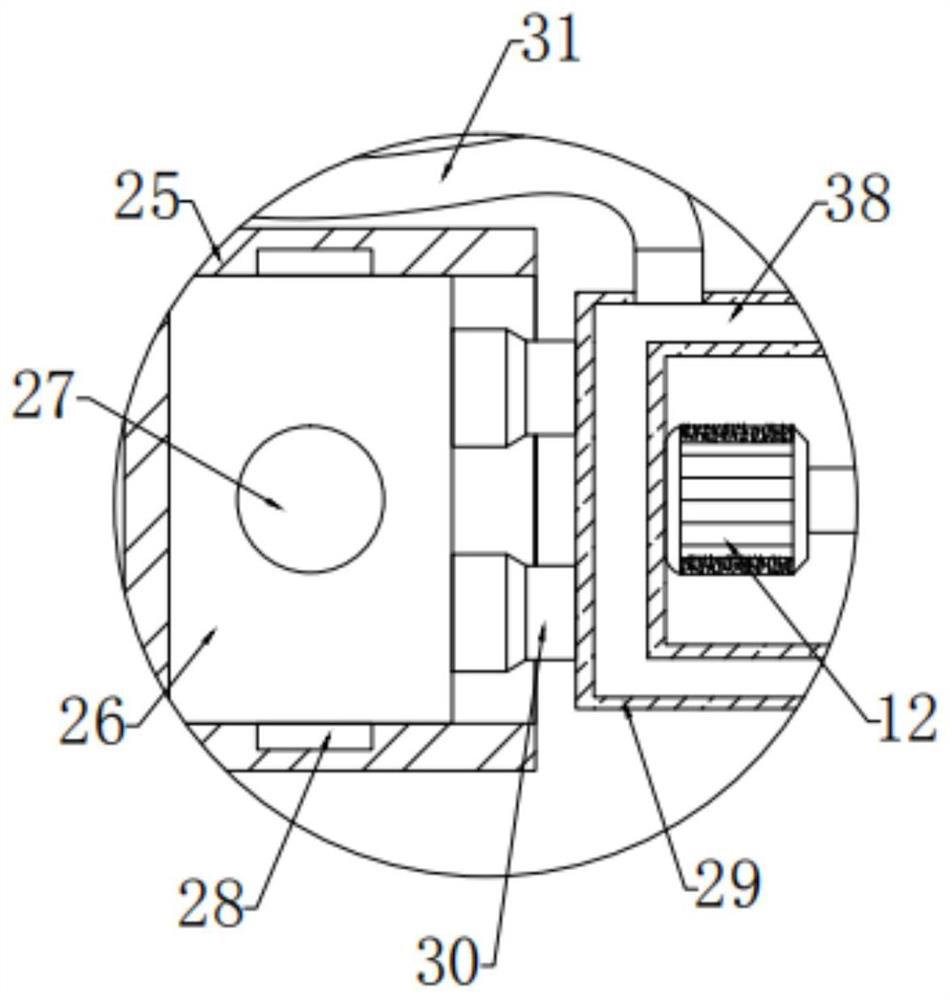

Gas cooler

ActiveCN105026874APrevent leakageMiniaturizationHollow article cleaningCleaning using toolsCooling chamberGas cooler

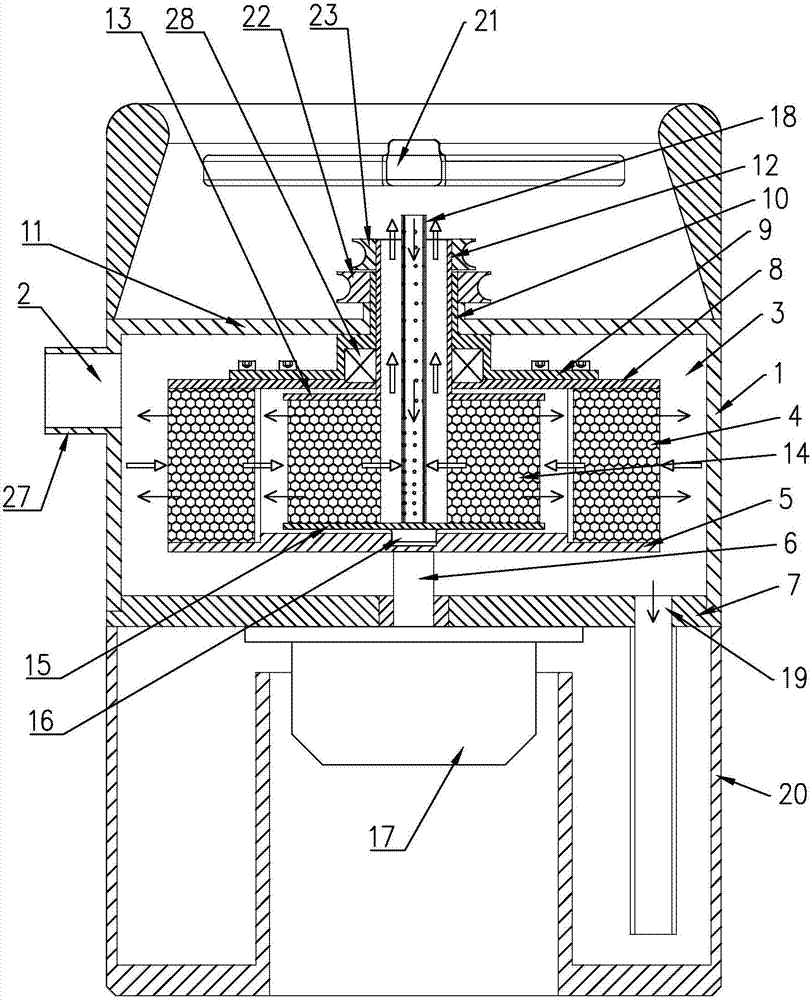

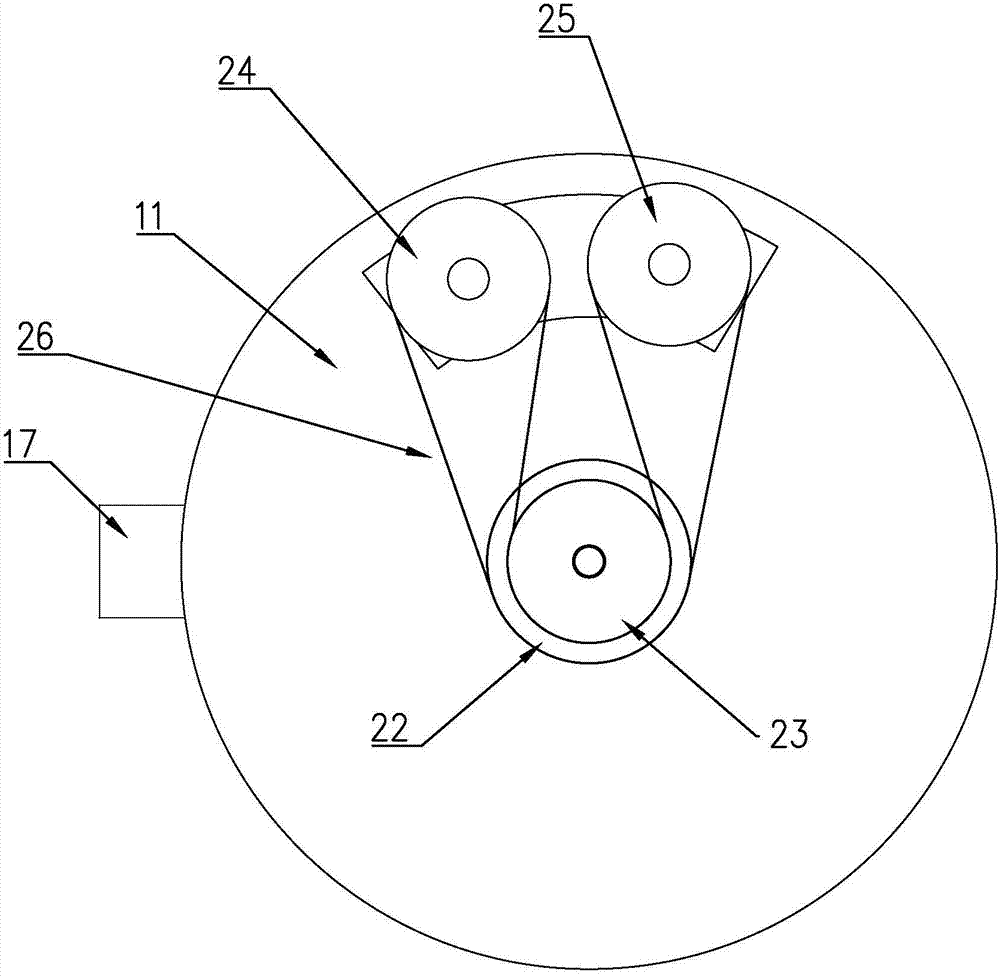

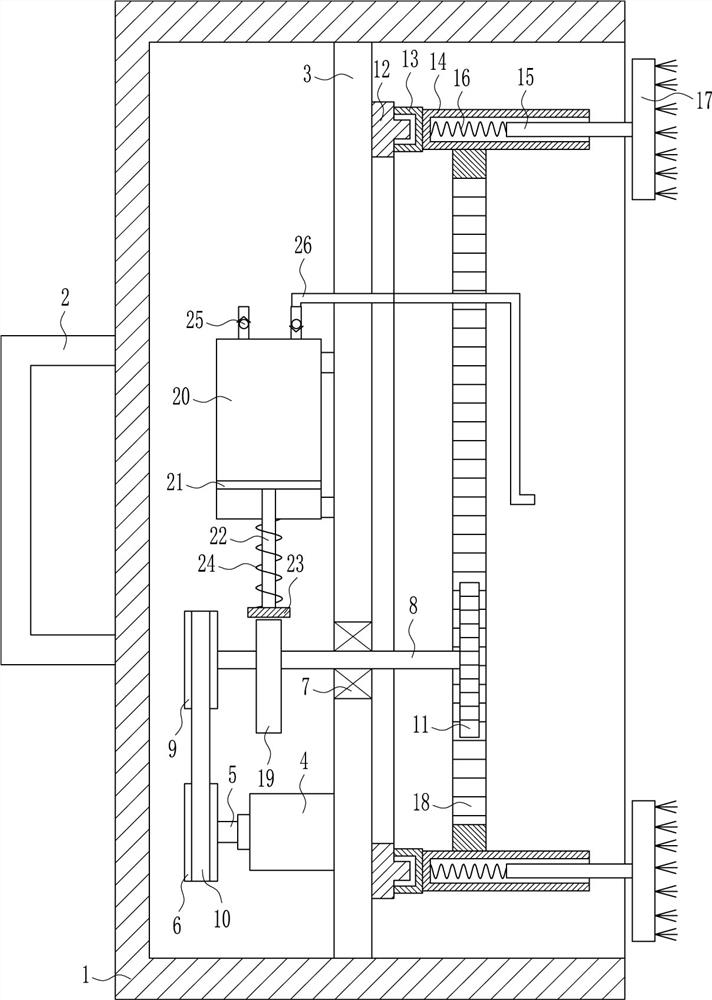

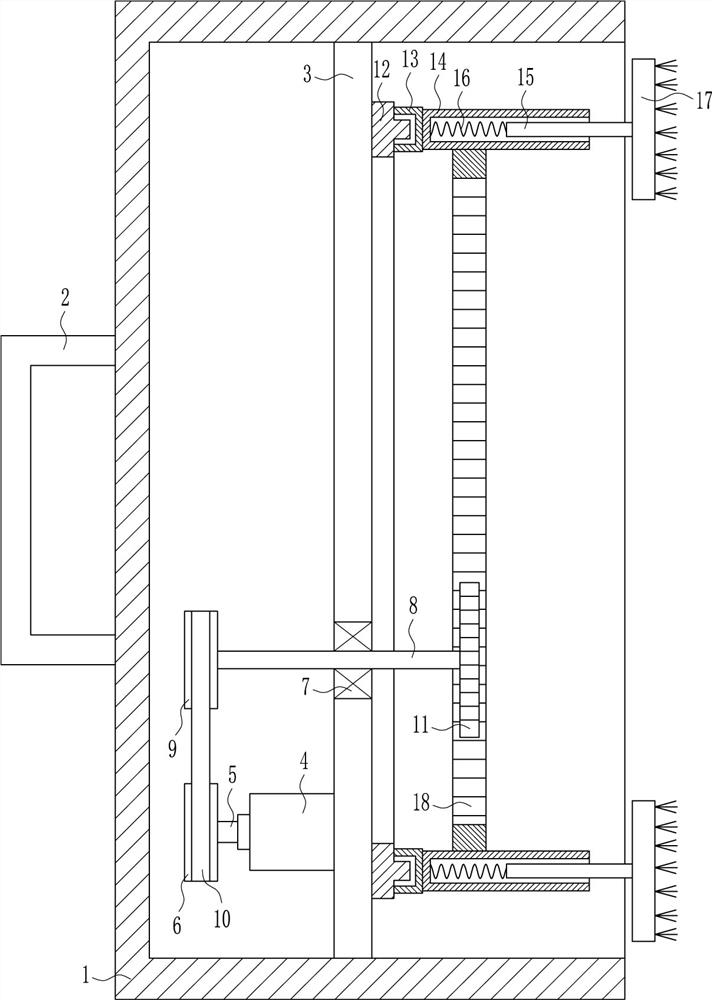

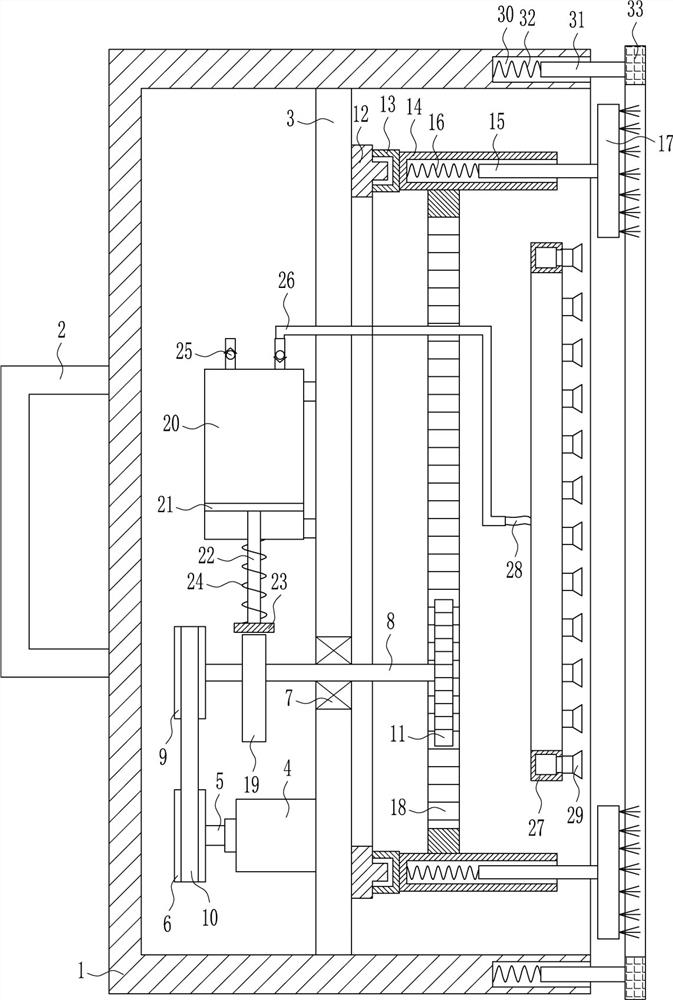

Provided is a gas cooler which is reduced in size, is configured so as to prevent discharge gas from leaking to the outside, and enables dust to be consistently brushed off. This gas cooler (1) has: cooling pipes (5) which are arranged within a cooling chamber (3); a dust brush-off member (7) which is provided in a slidable manner on the peripheral surfaces of the cooling pipes; and a reciprocation mechanism (9) which is capable of reciprocating the dust brush-off member in the axial direction of the cooling pipes. The reciprocation mechanism is provided with: a holding member (17) which holds the dust brush-off member so that the dust brush-off member is capable of reciprocating and which extends in the direction intersecting the axial direction of the cooling pipes; an opening (19) which is provided in a side wall (3a) of the cooling chamber and which enables the holding member to extend out of the cooling chamber and reciprocate; a seal mechanism (21) which prevents gas within the cooling chamber from leaking to the outside; a movement body (22) which supports the holding member extending out of the opening and which is capable of reciprocating; and a drive means (24) which reciprocates the movement body.

Owner:JFE STEEL CORP

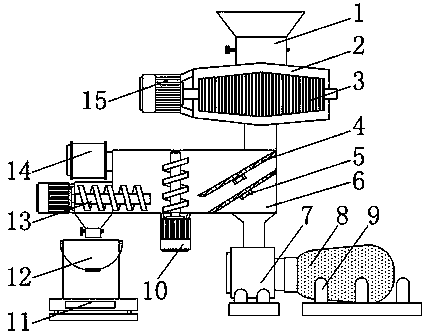

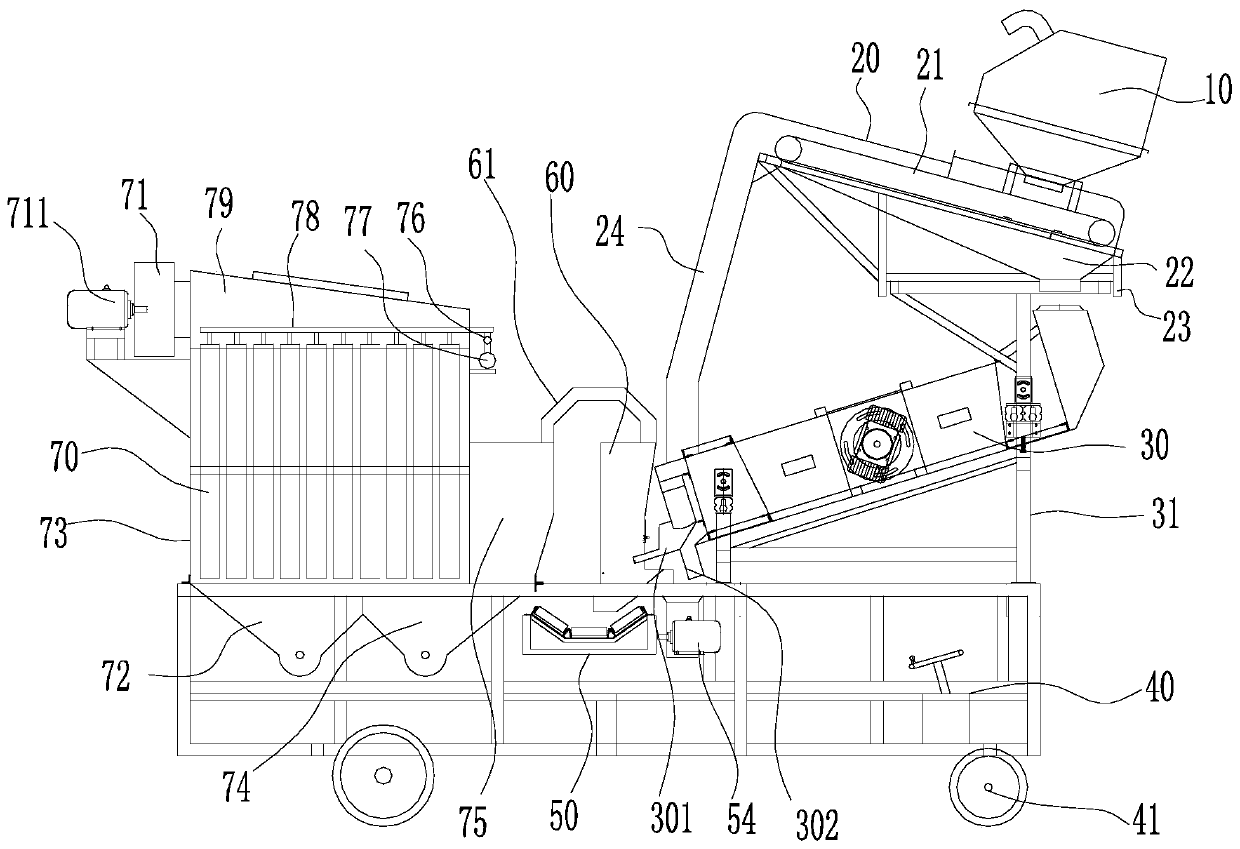

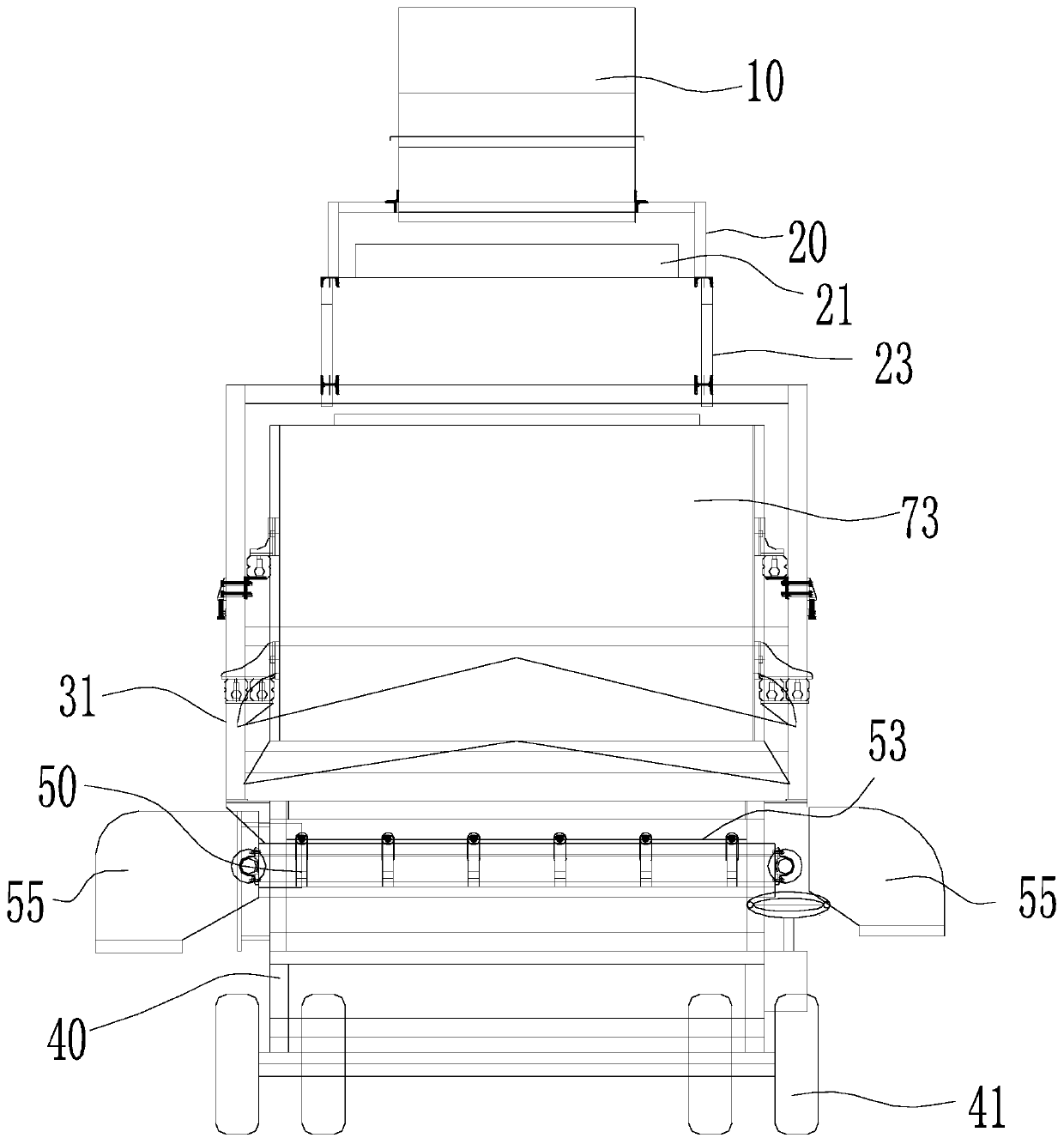

Rice mill

The invention discloses a rice mill, which aims to provide a rice mill with more thorough separation of rice bran, more accurate weighing of rice grain and more convenient use. The rice mill comprisesa feeding hopper, a rice milling device, a rice bran separation device, a rice grain holding device and a bran powder holding device; the rice bran separation device comprises a rice bran separationbox, a rice sieve, a blower, a spiral discharging machine, a spiral mixer and an exhaust fan; the rice sieve is obliquely arranged in the rice bran separation box; the blower is arranged at the blowernozzle of the rice bran separation box and the blowing direction faces to the rice bran separation box; the spiral discharging machine is arranged at the rice grain outlet; the spiral mixer is arranged at the mixing opening; the exhaust fan is arranged at the bran powder outlet; the rice grain holding device comprises a rice barrel and an electronic scale; the inlet of the bran powder filtering cloth bag is communicated with the air outlet of the exhaust fan.

Owner:ANREN COUNTY SHENGPING RICE IND

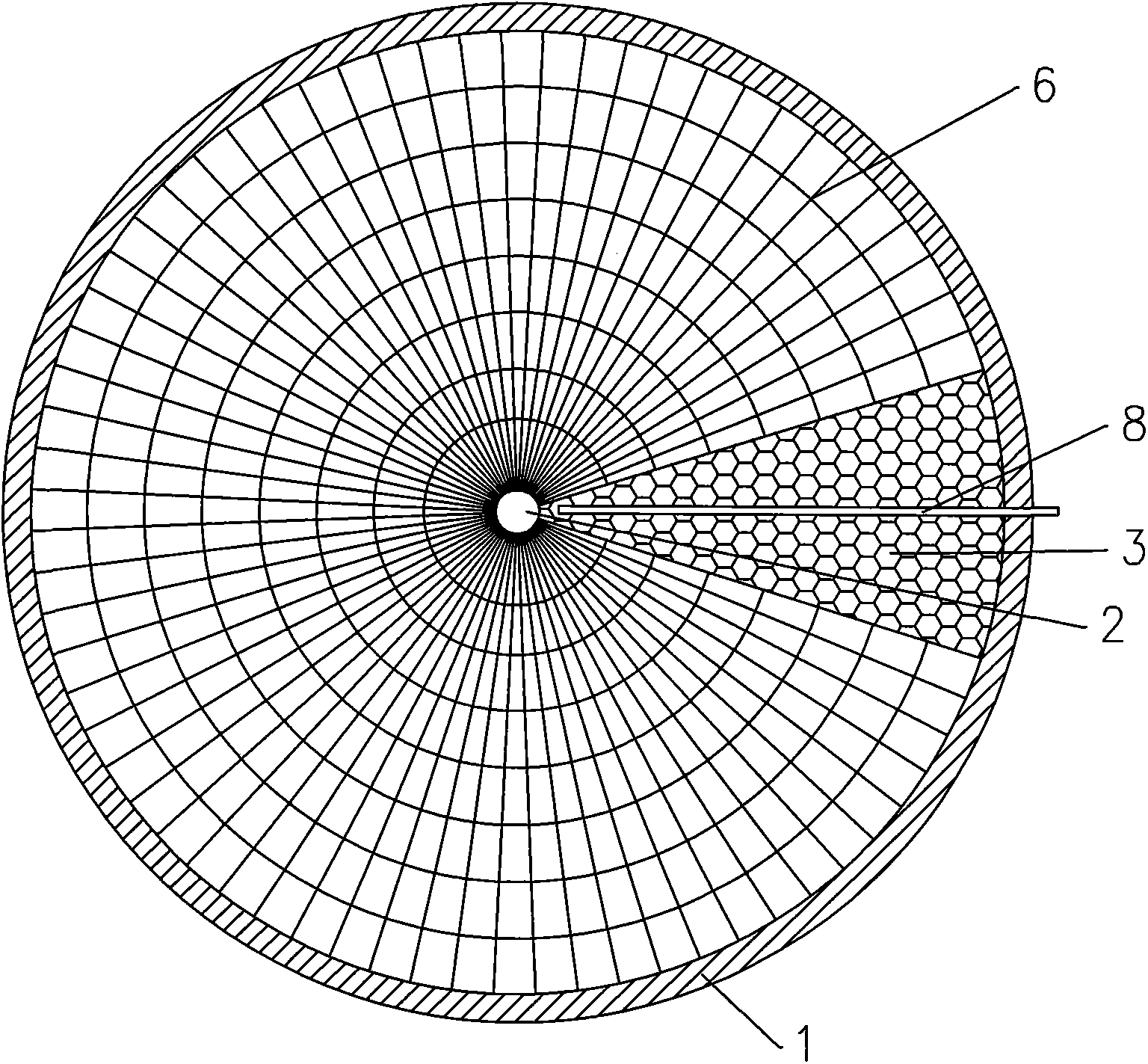

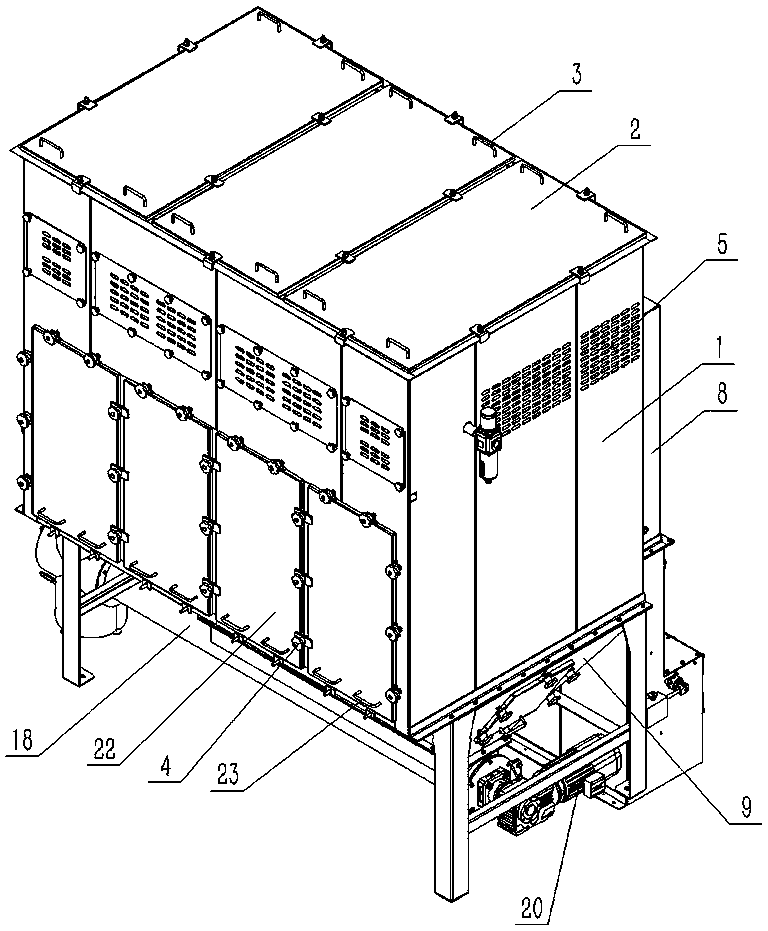

Rotating disc type runoff lightning shield dust remover

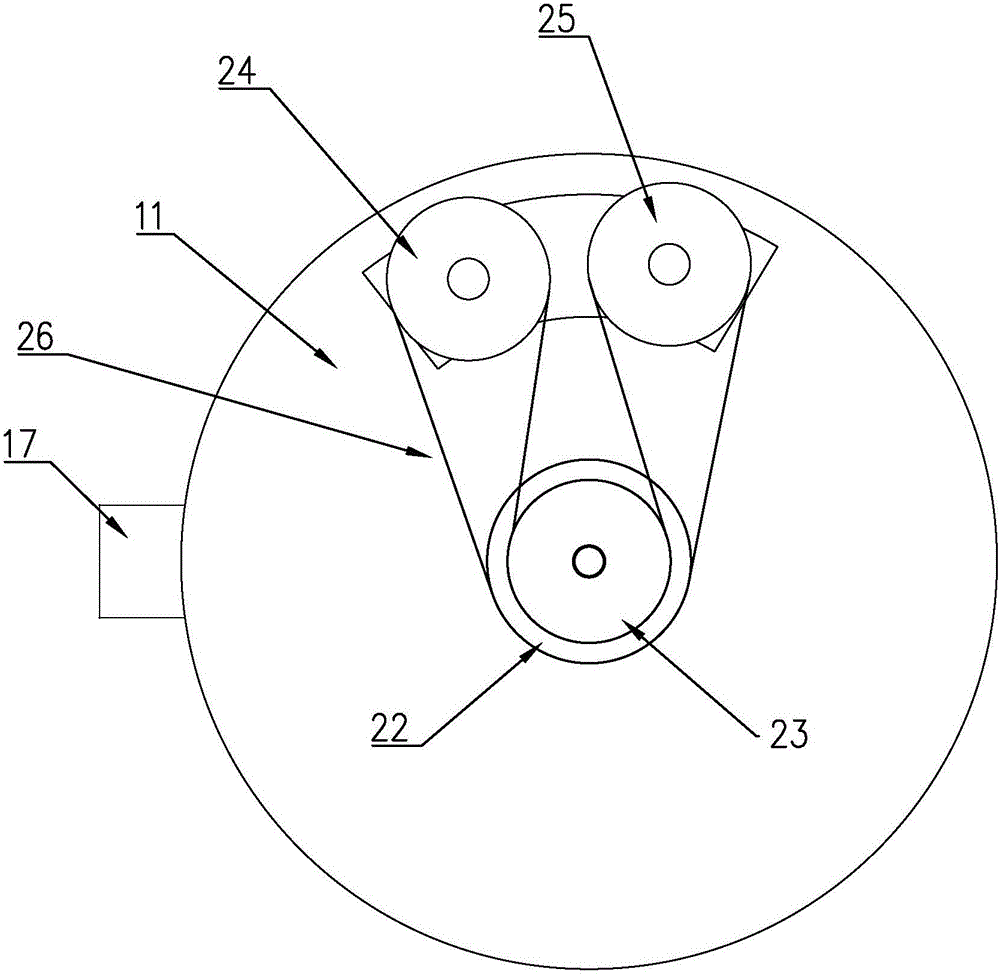

InactiveCN103506219AStable dust removalLow running costExternal electric electrostatic seperatorElectrode constructionsHoneycombElectricity

The invention discloses a rotating disc type runoff lightning shield dust remover. The dust remover comprises a casing, wherein a dust air pipe is arranged in the casing; a disc-shaped lightning shield is arranged inside the dust air pipe; the disc surface of the lightning shield can rotate around the section of the dust air pipe; the circumferential surface of the lightning shield is in clearance fit with the inner wall of the dust air pipe; a front discharging net is arranged in front of the lightning shield towards the inlet end of the dust air pipe; the end surface of the lightning shield towards the front discharging net is parallel to the front discharging net; the lightning shield is made of porous foam metal plates, a plurality of parallel corrugated plates, honeycomb plates or silk nets; a potential difference is generated between the front discharging net and the lightning shield through the electric connection with a high-voltage direct-current power supply; a dust blowing pipe is arranged in the dust air pipe; the dust blowing opening of the dust blowing pipe is towards the disc surface of the lightning shield. The invention aims to provide the rotating disc type runoff lightning shield dust remover which has greater treated air quantity in the unit time and a prominent effect of removing fine dust comprising PM 2.5, is stable in dust removing performance, low in operation cost and long in service life.

Owner:孟金来

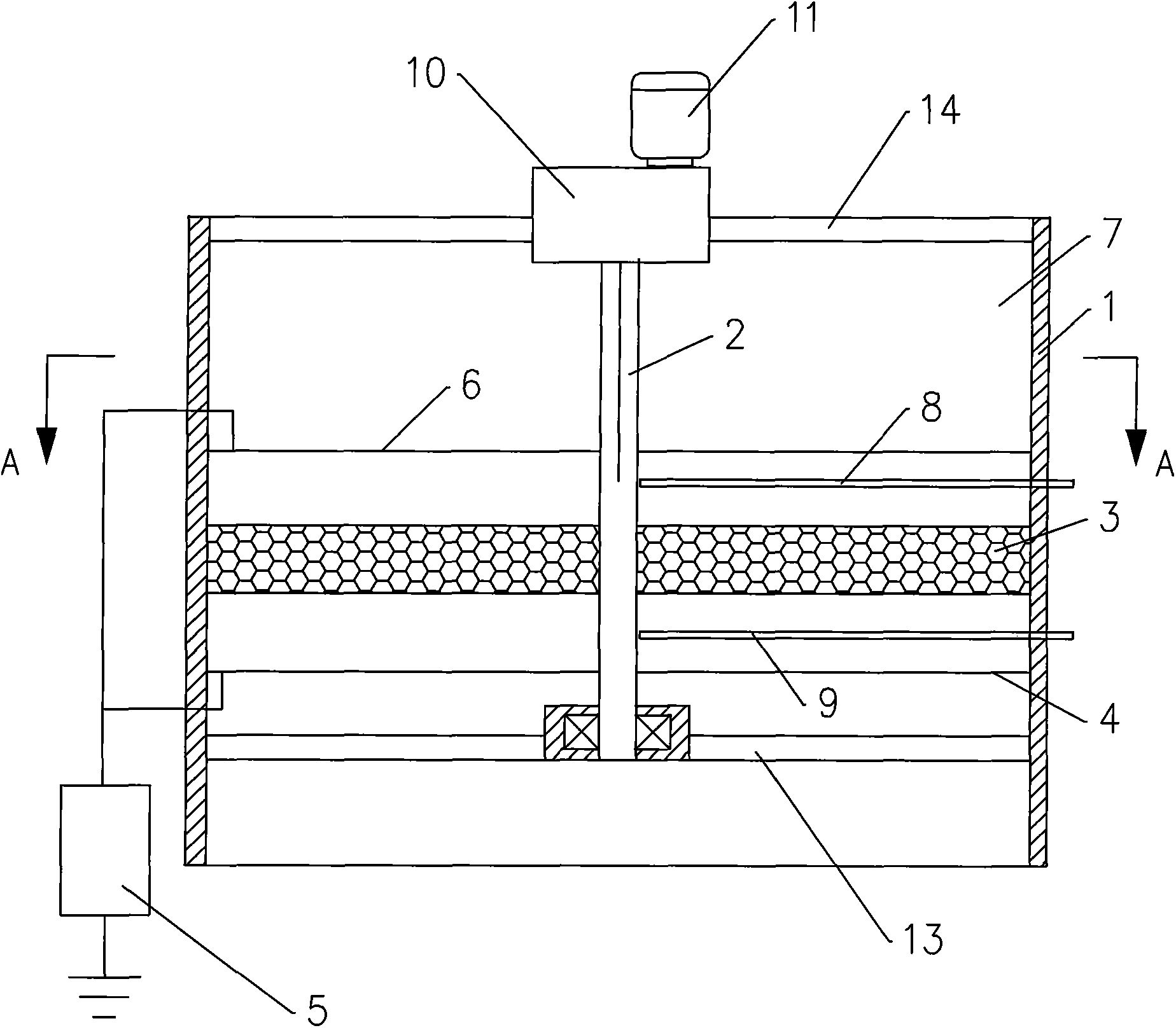

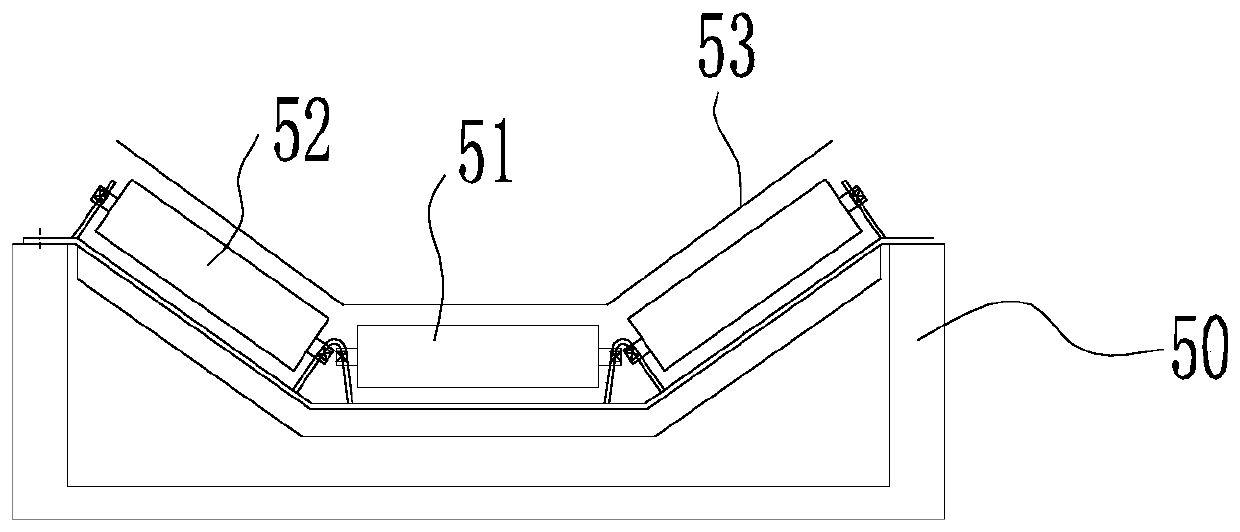

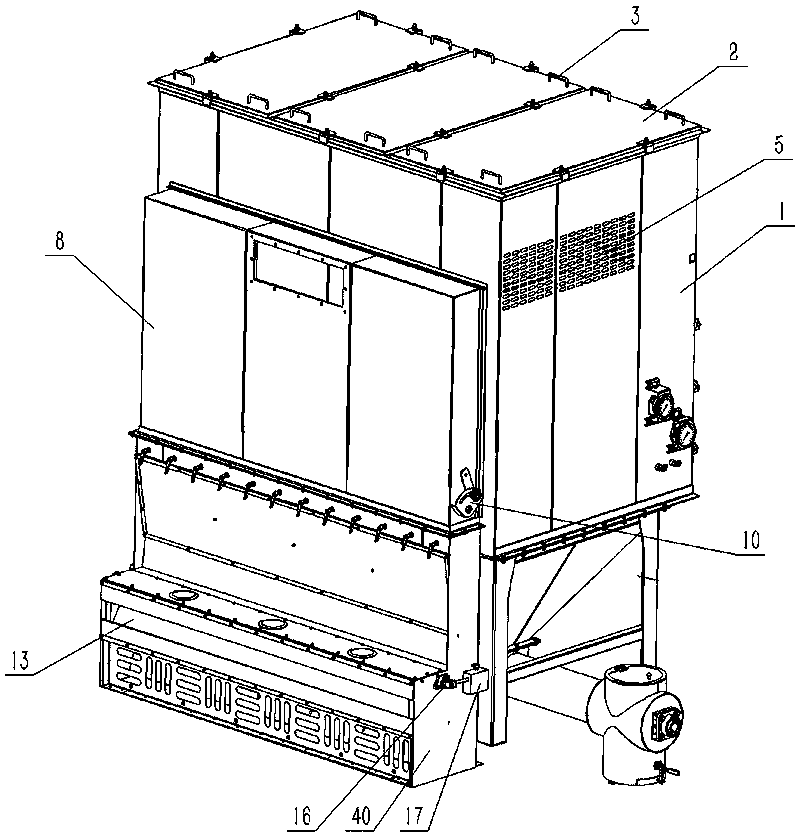

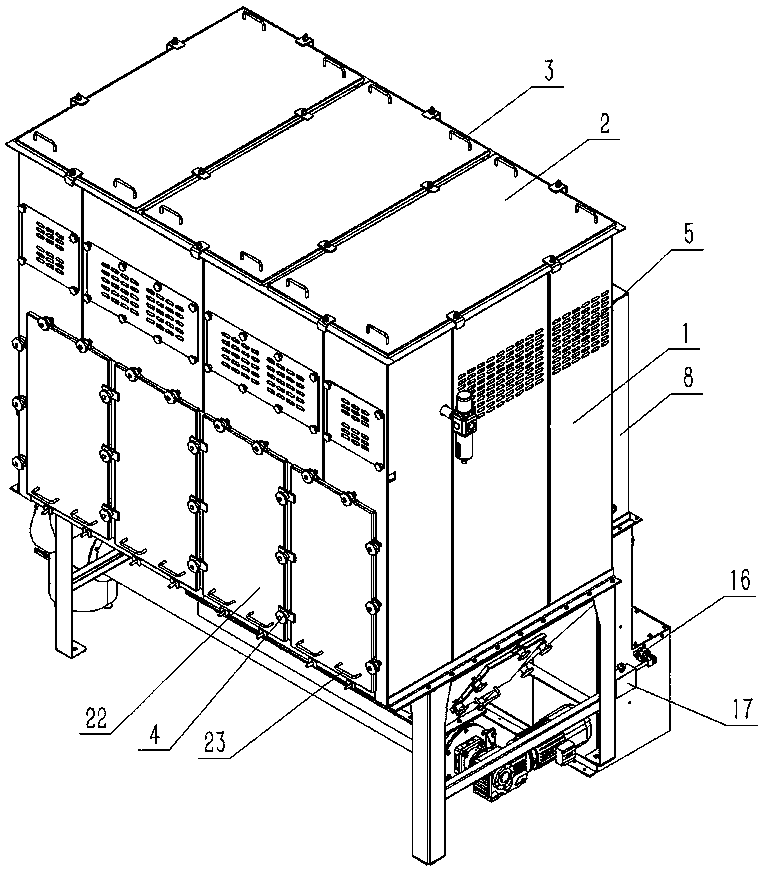

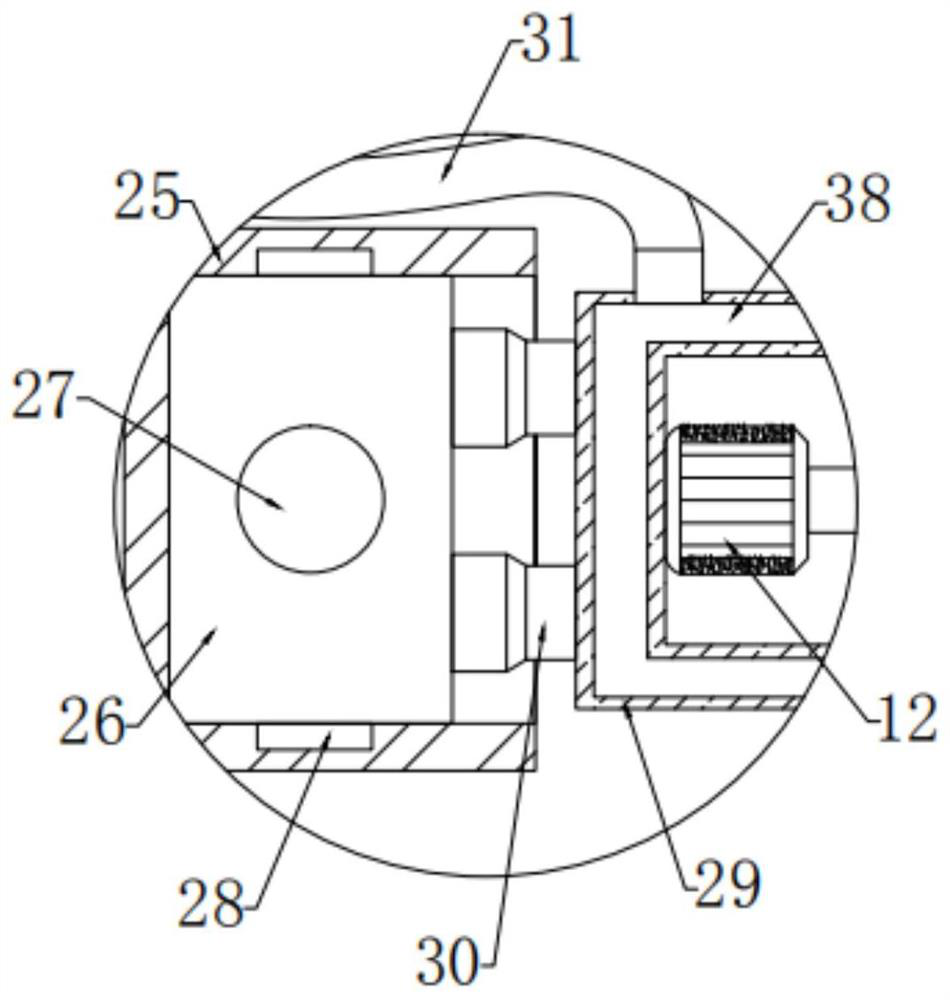

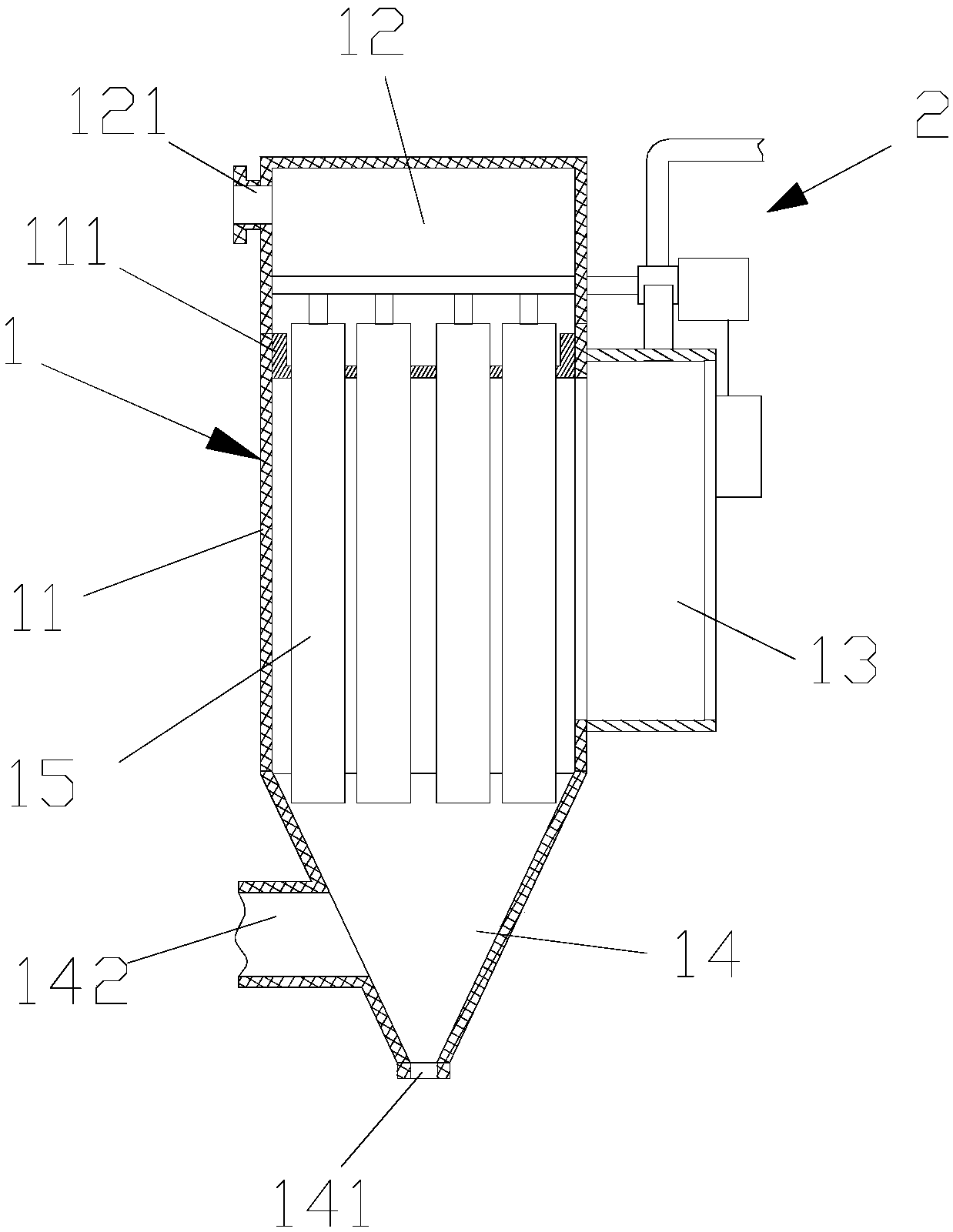

Double-filter-element contra-rotation super-gravity wet-process dust remover

ActiveCN105833641AImprove dust removal efficiencyStable dust removalCombination devicesEngineeringMotor shaft

The invention relates to a double-filter-element contra-rotation super-gravity wet-process dust remover which comprises a shell, wherein a gas inlet is formed on a side wall of the shell; a dust-removing chamber is arranged on the middle part in the shell; an external ring filter element is arranged on the middle part in the dust-removing chamber; the cross section of the external ring filter element along the horizontal direction is of a circular shape; the axis of the external ring filter element is located along the vertical direction; the bottom end of the external ring filter element is fixed on a turntable; the middle part of the turntable is connected with the top end of a vertical shaft; the vertical shaft downward extends and passes through a base plate of the shell; the bottom end of the vertical shaft is coaxially connected with a motor shaft of a motor; the motor is fixedly arranged on the base plate; an upper separating plate is fixedly arranged at the top end of the external ring filter element; an upper end face of the upper separating plate is glued with a lower end face of a driving connecting plate; and the middle part of the upper end face of the driving connecting plate is fixedly connected with the bottom end of a hollow driving sleeve. The invention aims to provide the double-filter-element contra-rotation super-gravity wet-process dust remover with higher dust-removing efficiency, more stable dust-removing property and capability of more thoroughly removing various fine grains.

Owner:贾克

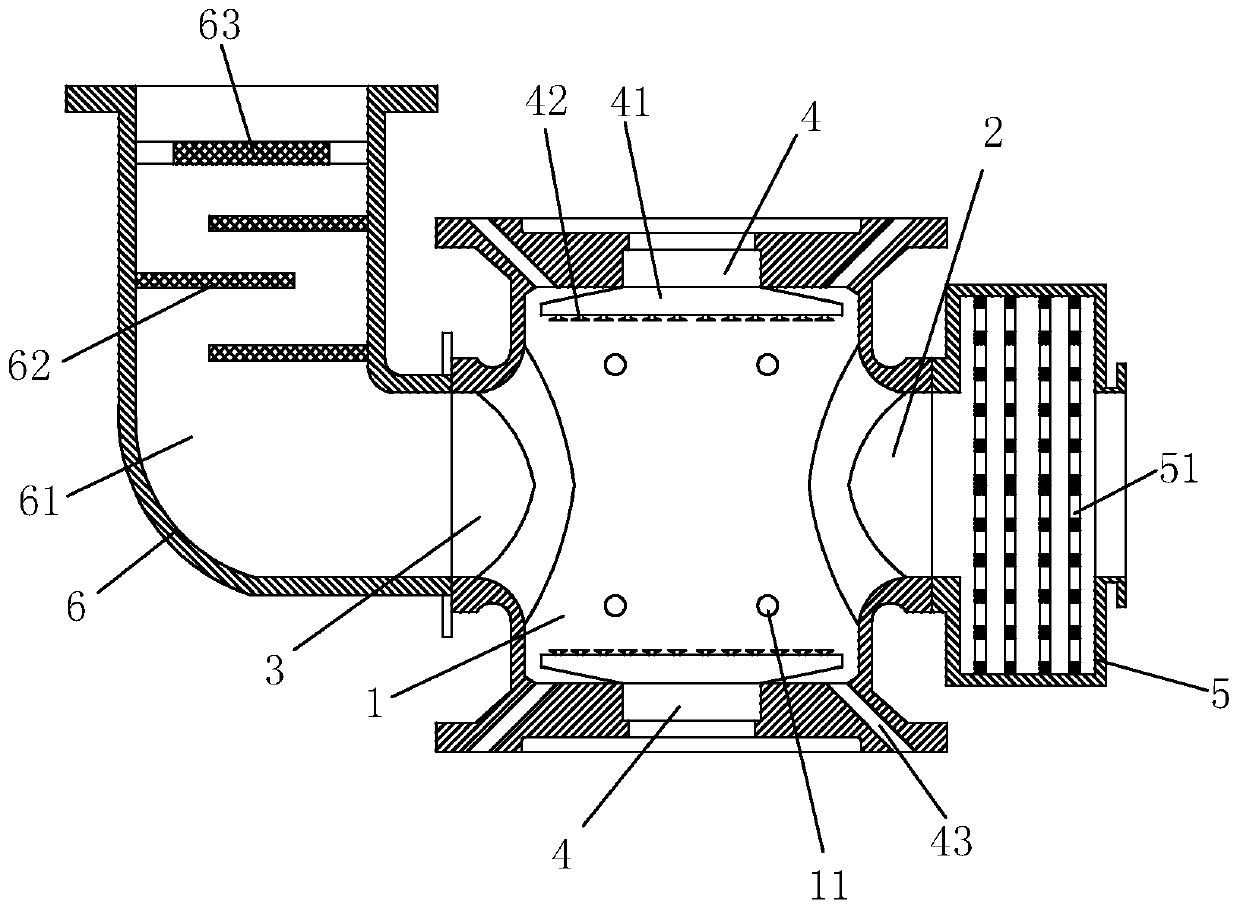

Turntable-type runoff electrode plate dust collector

ActiveCN104437859AStable dust removalLow running costExternal electric electrostatic seperatorElectrodes cleaningElectricityPotential difference

The invention discloses a rotating disc type runoff lightning shield dust remover. The dust remover comprises a casing, wherein a dust air pipe is arranged in the casing; a disc-shaped lightning shield is arranged inside the dust air pipe; the disc surface of the lightning shield can rotate around the section of the dust air pipe; the circumferential surface of the lightning shield is in clearance fit with the inner wall of the dust air pipe; a front discharging net is arranged in front of the lightning shield towards the inlet end of the dust air pipe; the end surface of the lightning shield towards the front discharging net is parallel to the front discharging net; the lightning shield is made of porous foam metal plates, a plurality of parallel corrugated plates, honeycomb plates or silk nets; a potential difference is generated between the front discharging net and the lightning shield through the electric connection with a high-voltage direct-current power supply; a dust blowing pipe is arranged in the dust air pipe; the dust blowing opening of the dust blowing pipe is towards the disc surface of the lightning shield. The invention aims to provide the rotating disc type runoff lightning shield dust remover which has greater treated air quantity in the unit time and a prominent effect of removing fine dust comprising PM 2.5, is stable in dust removing performance, low in operation cost and long in service life.

Owner:孟金来

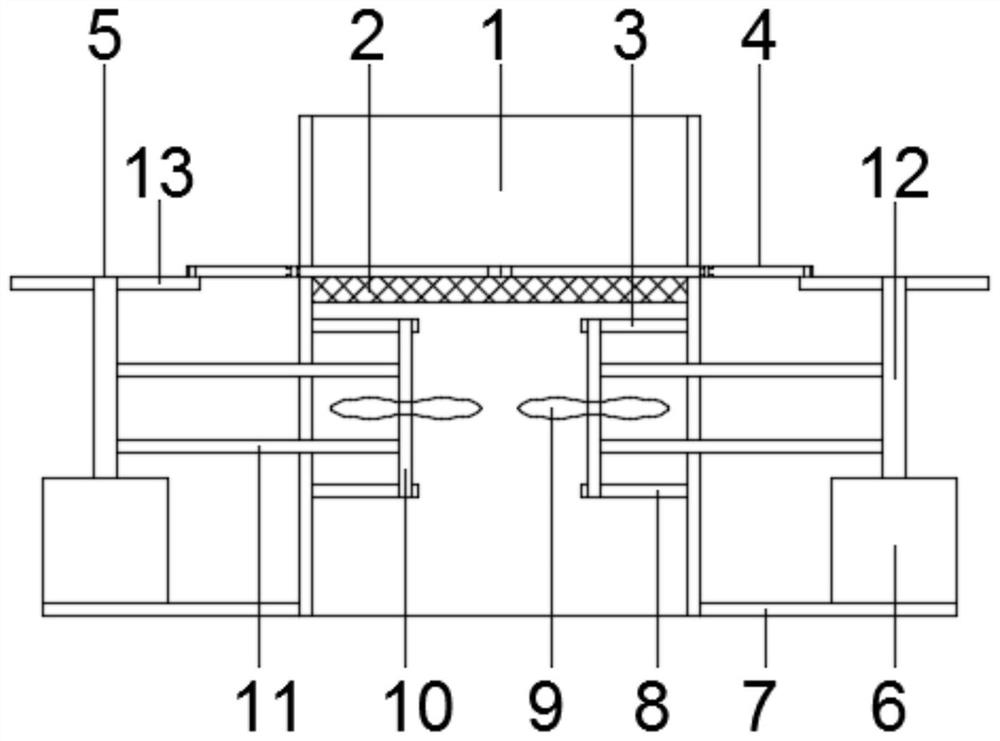

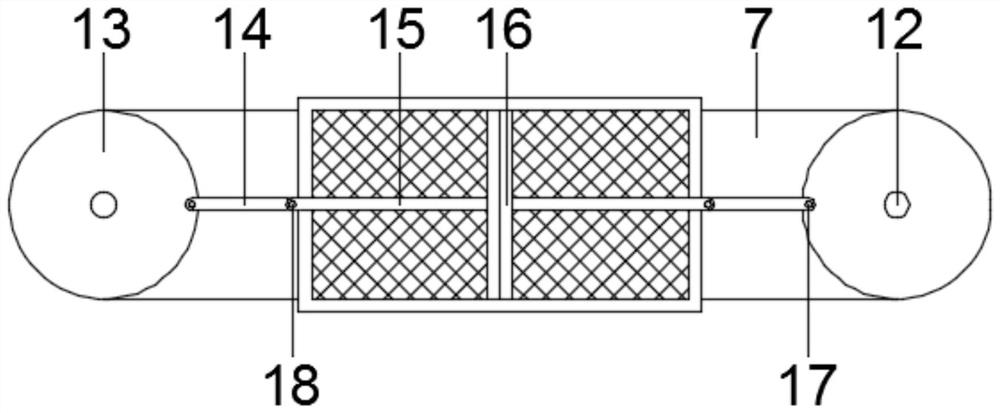

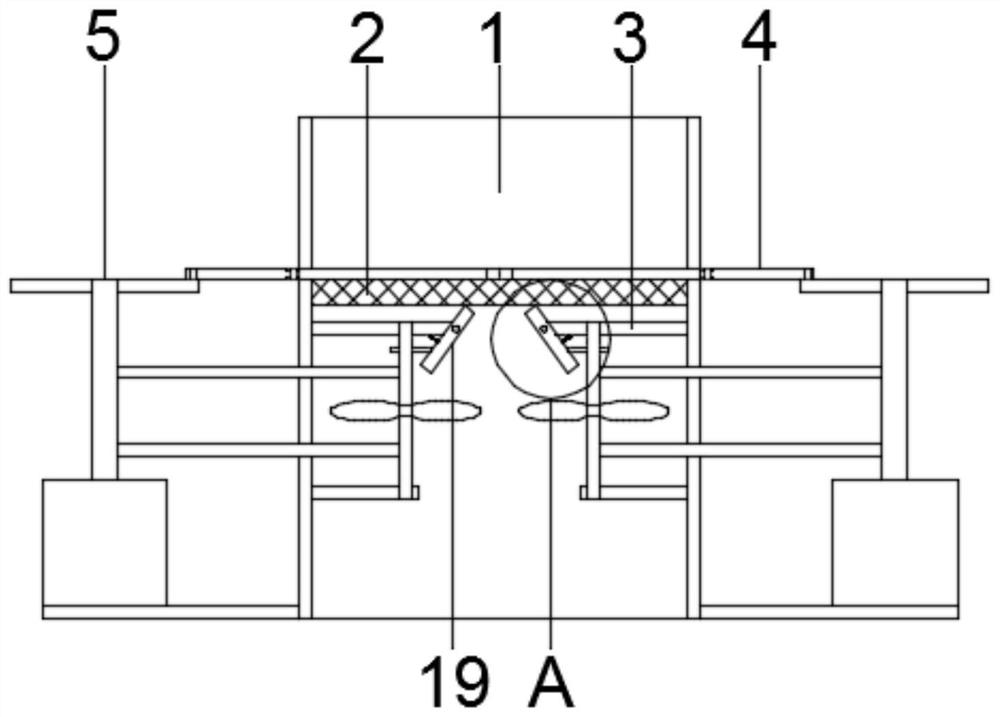

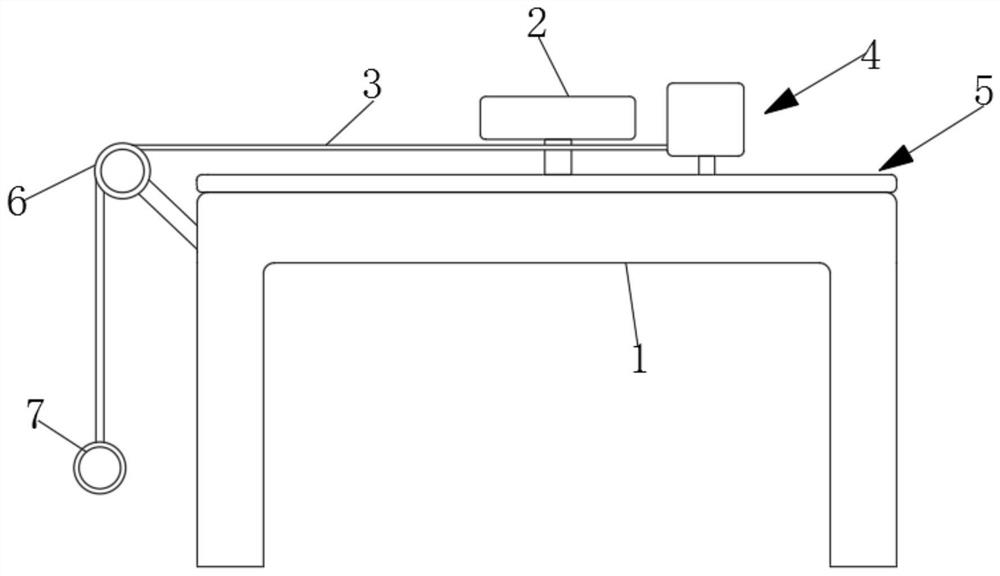

Material rolling equipment for garment material processing

InactiveCN111017608AEfficient suctionStable dust removalWebs handlingDust controlStructural engineering

The invention discloses material rolling equipment for garment material processing. The material rolling equipment comprises a supporting base and a feeding guide roller and a discharging guide roller, which are movably arranged at the two ends of the top of the supporting base. A dustproof cover is arranged at the top of the supporting base; coil stock through grooves are formed in the two sidesof the dustproof cover; a vibration dust removal mechanism is arranged on one side, close to the feeding guide roller, in the dust cover; and a dust suction mechanism is arranged on the side, close tothe discharging guide roller, in the dustproof cover. Compared with the prior art, the material rolling equipment for garment material processing has the advantages that dust-free rolling of cloth inthe garment material processing process is guaranteed through a vibration dust removal mode, and adverse effects on the surface quality of the cloth are avoided while efficient dust removal is guaranteed, so that high-quality dust-free rolling of garment material processing is guaranteed.

Owner:宁波市鄞州佳旭服饰有限公司

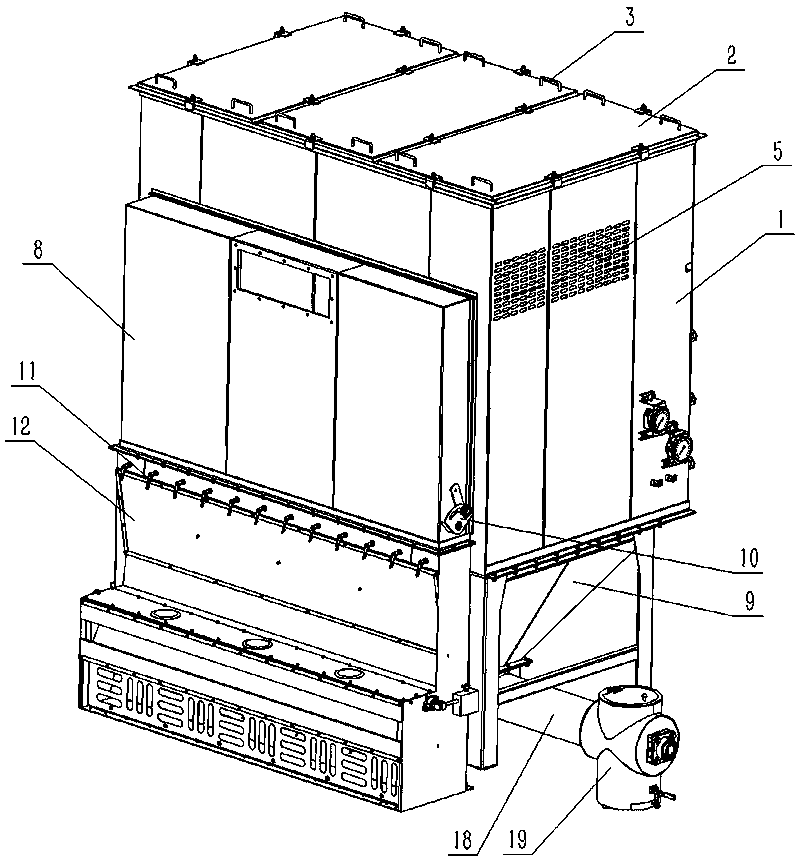

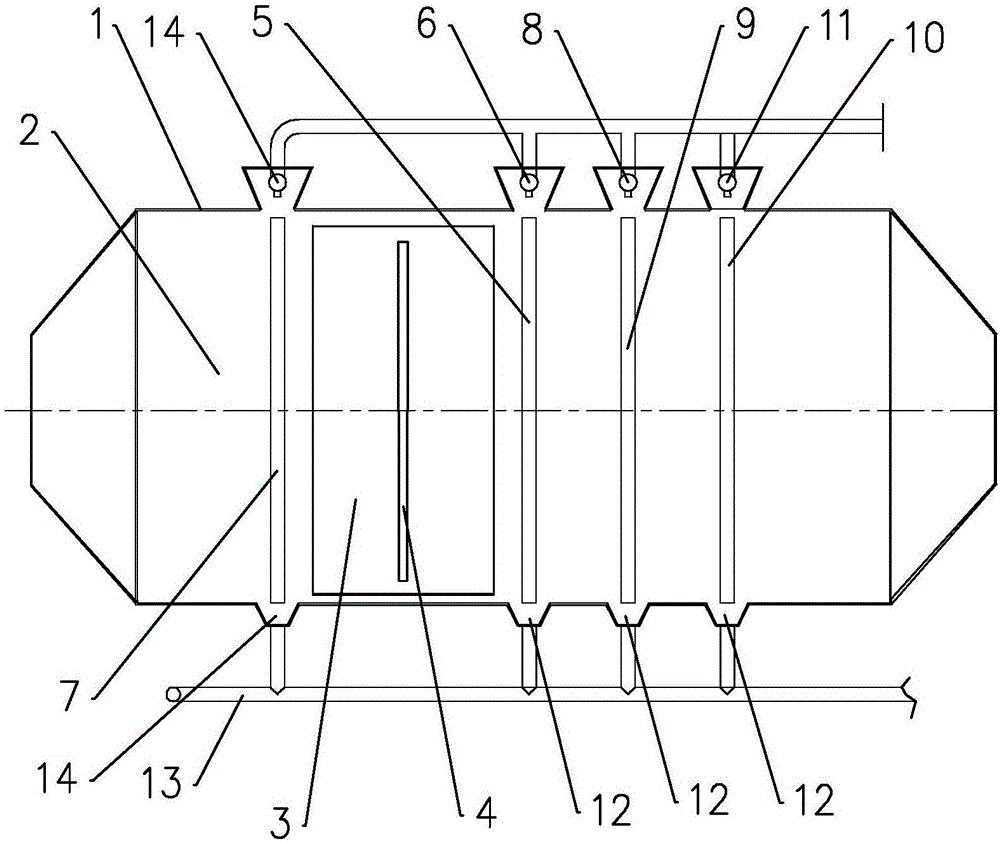

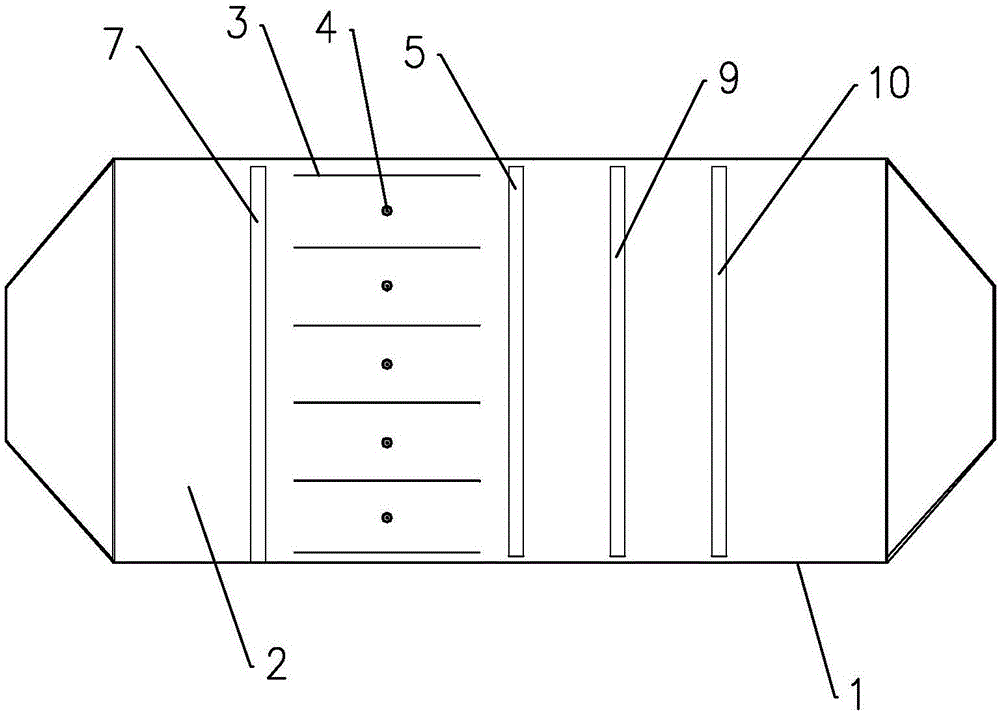

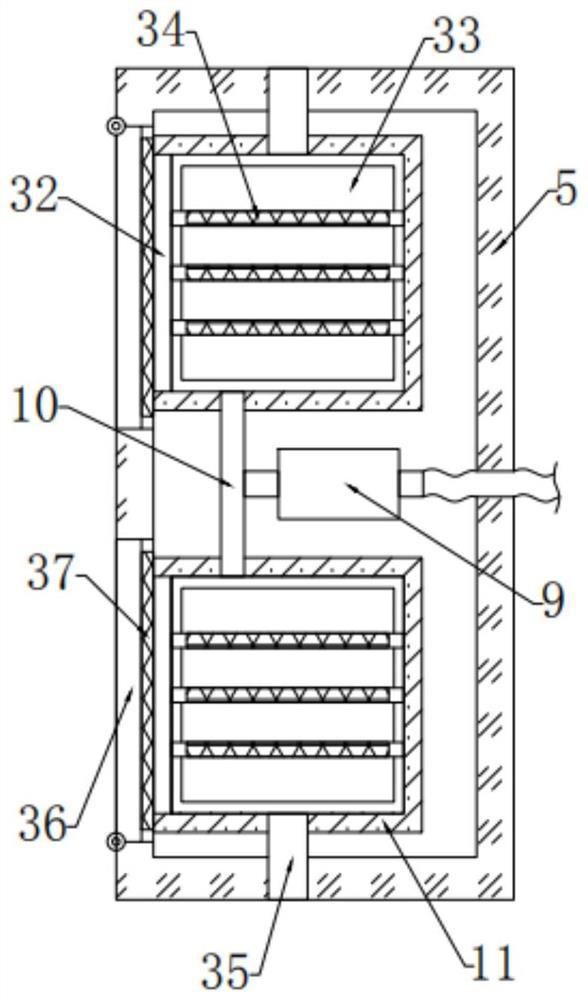

Combined type radial current electric dust collector

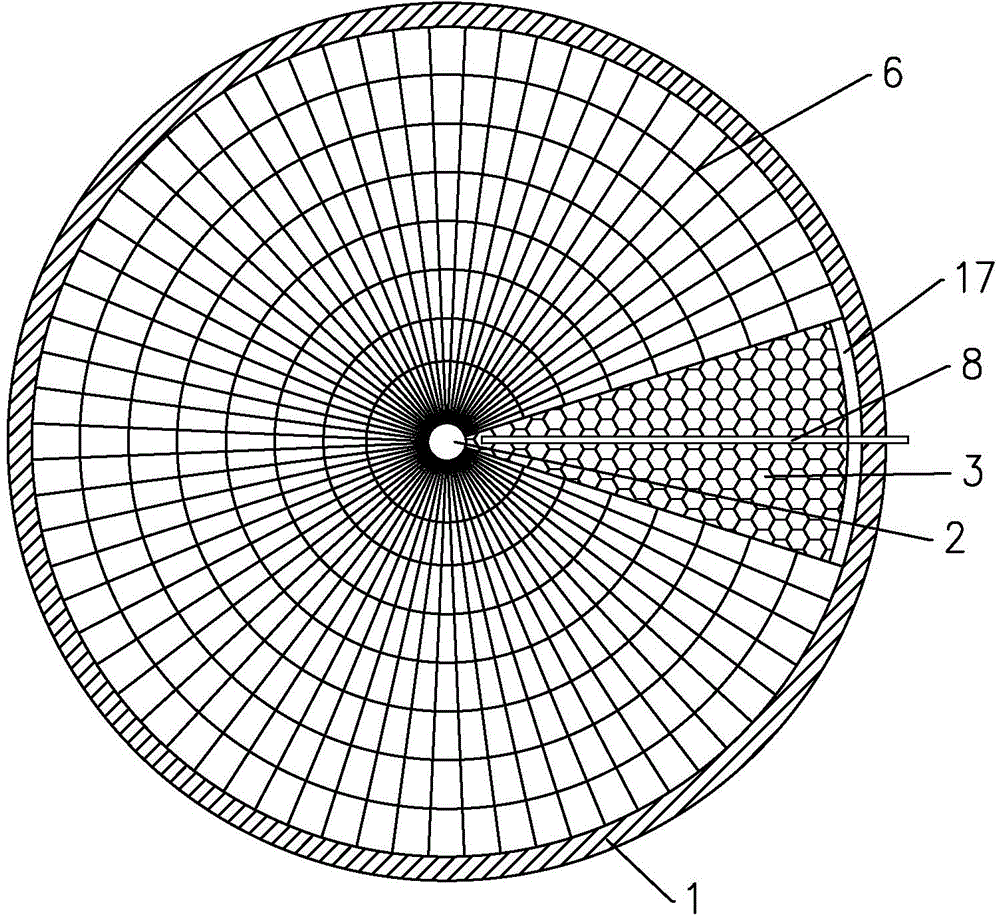

ActiveCN103721849ARotary motion stabilityFreedom of rotationElectrode constructionsElectrodes cleaningElectricityCurrent electric

The invention discloses a combined type radial current electric dust collector. According to the dust collector, a radial current type electric dust collecting power discharge net is arranged behind a dust collecting electrode inside a dust collecting airway; an annular dust collecting chain row is arranged behind the radial current type electric dust collecting power discharge net; the front annular part of the dust collecting chain row is parallel to the surface of the radial current type electric dust collecting power discharge net; a left guide rail is arranged on the left side of the dust collecting chain row; the side part of the left end of the dust collecting chain row is guided and positioned through the left guide rail; a right guide rail is arranged on the right side of the dust collecting chain row; the side part of the right end of the dust collecting chain row is guided and positioned through a right guide rail; the lower part of the dust collecting chain row is positioned inside a dust cleaning chamber; a sealing partitioning plate is arranged between the dust cleaning chamber and the dust collecting airway; the dust collecting chain row penetrates through the sealing partitioning plate downwards and enters the dust cleaning chamber; a dust blowing tube is arranged along the left and right direction near the dust collecting chain row inside the dust cleaning chamber. The invention aims at providing the combined type radial current electric dust collector which is large in gas treatment capability in unit time, outstanding in effect in collecting fine dust including PM2.5, very stable in dust collection performance, low in operation cost and long in service life.

Owner:北京华能达电力技术应用有限责任公司

Double filter reverse rotation super gravity wet dust collector

ActiveCN105833641BImprove dust removal efficiencyStable dust removalCombination devicesArchitectural engineeringMotor shaft

Owner:贾克

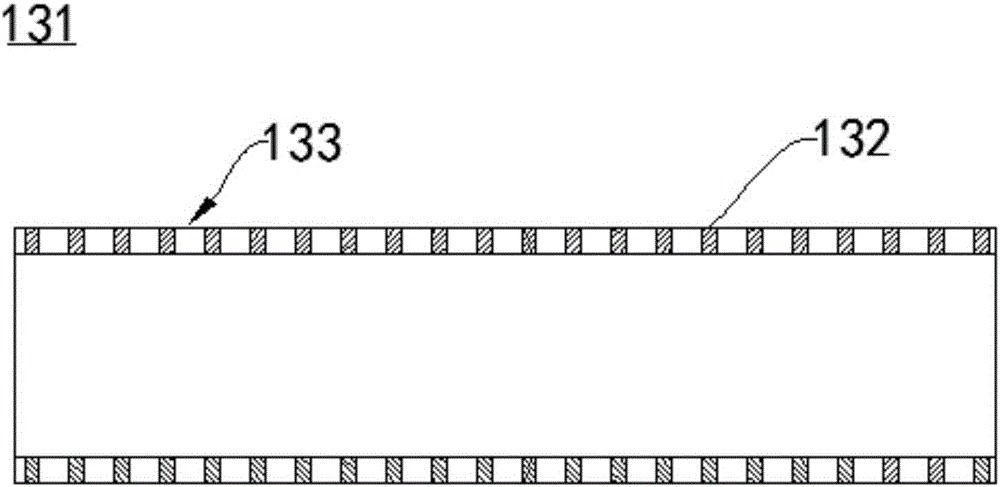

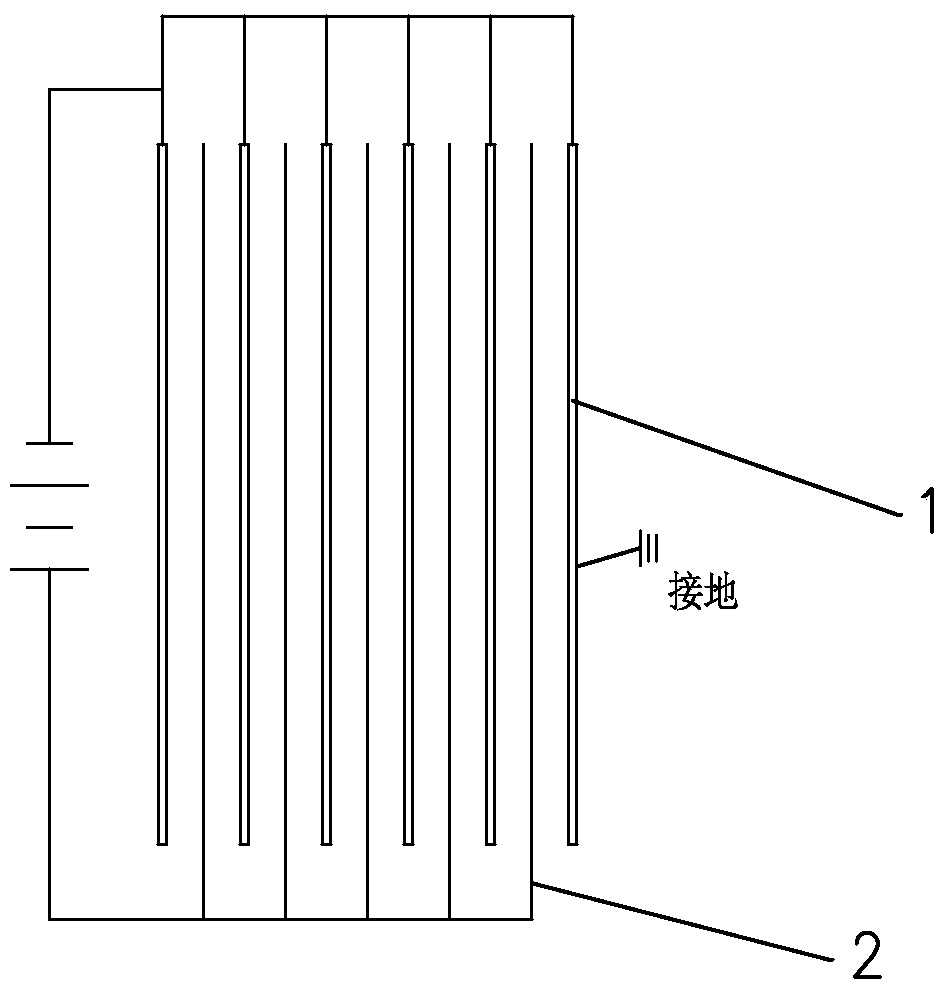

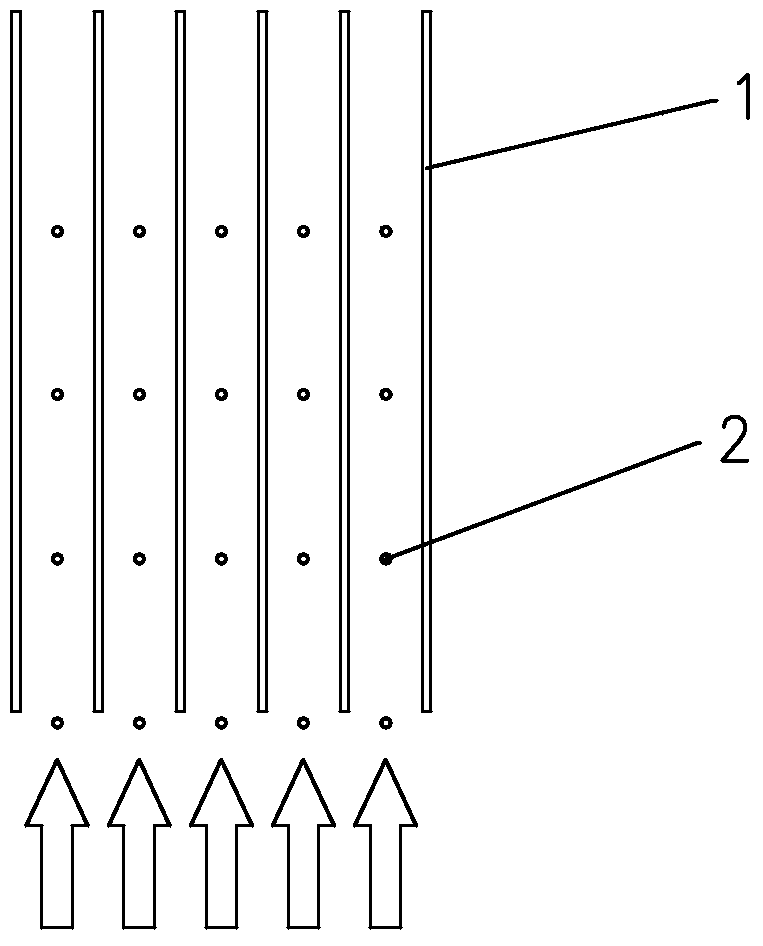

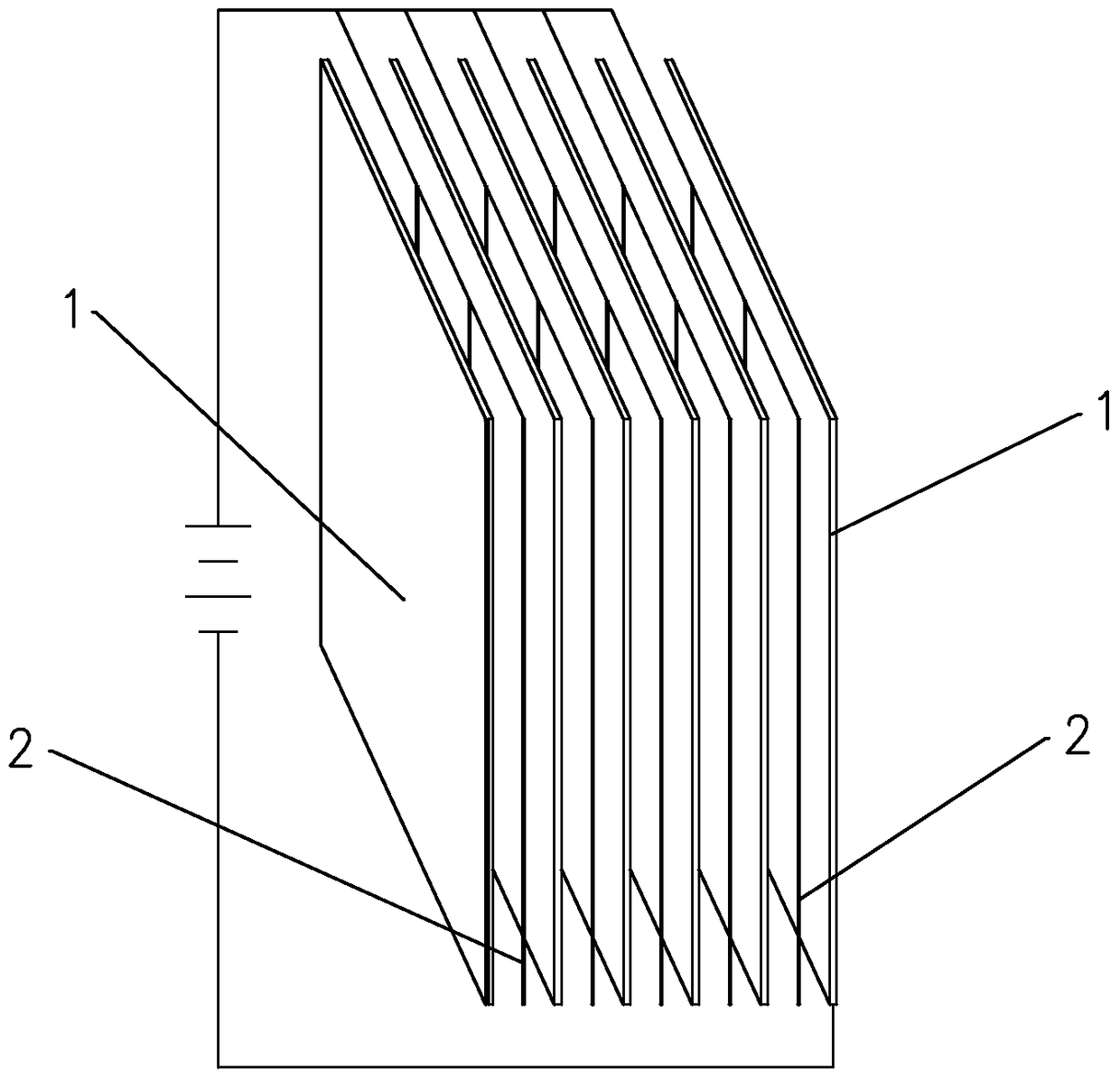

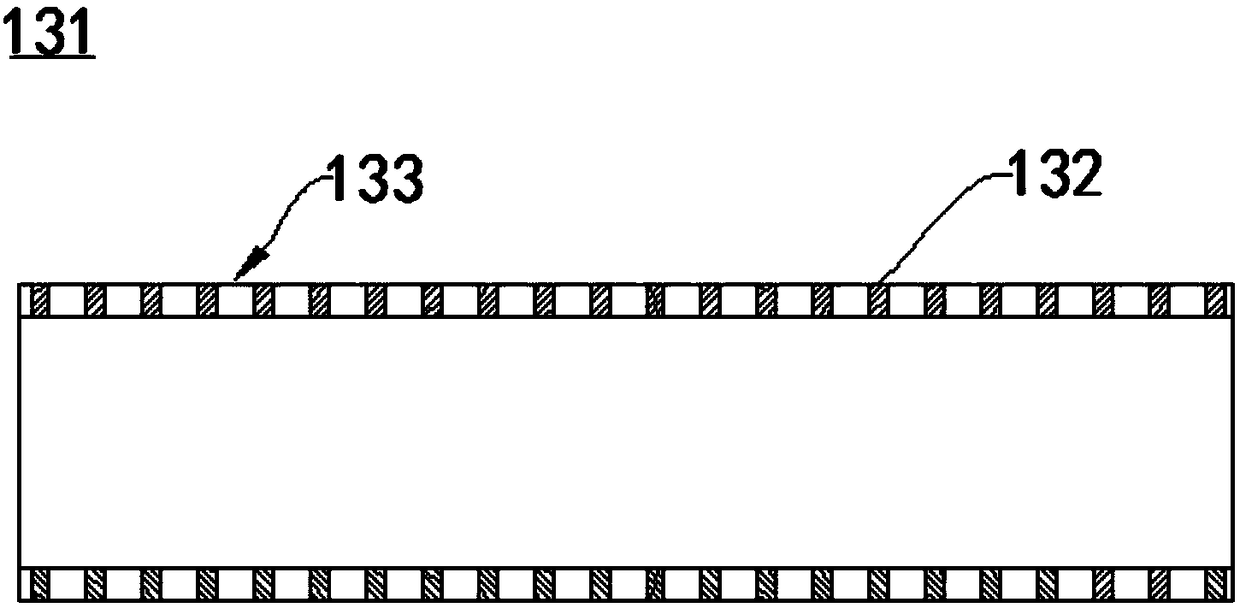

Composite dust collection plate for electrostatic dust removal

ActiveCN105344481BImproved ability to hold dustStable dust removalElectrode constructionsMetal layered productsParticulatesMicrometer

Owner:北京中和锦程科技有限公司

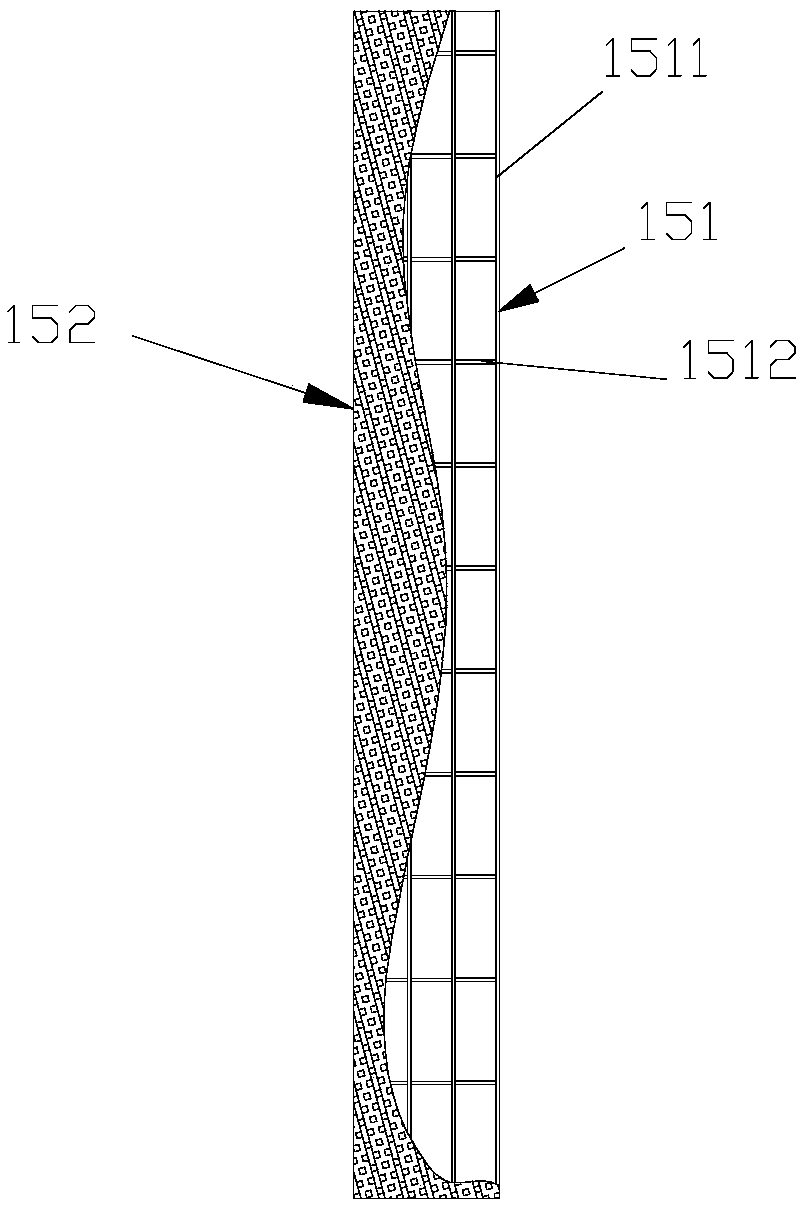

Composite dust collecting plate for electrostatic dust removal

ActiveCN105344481AGreat capacity to hold dustStable dust removalElectrode constructionsMetal layered productsParticulatesMicrometer

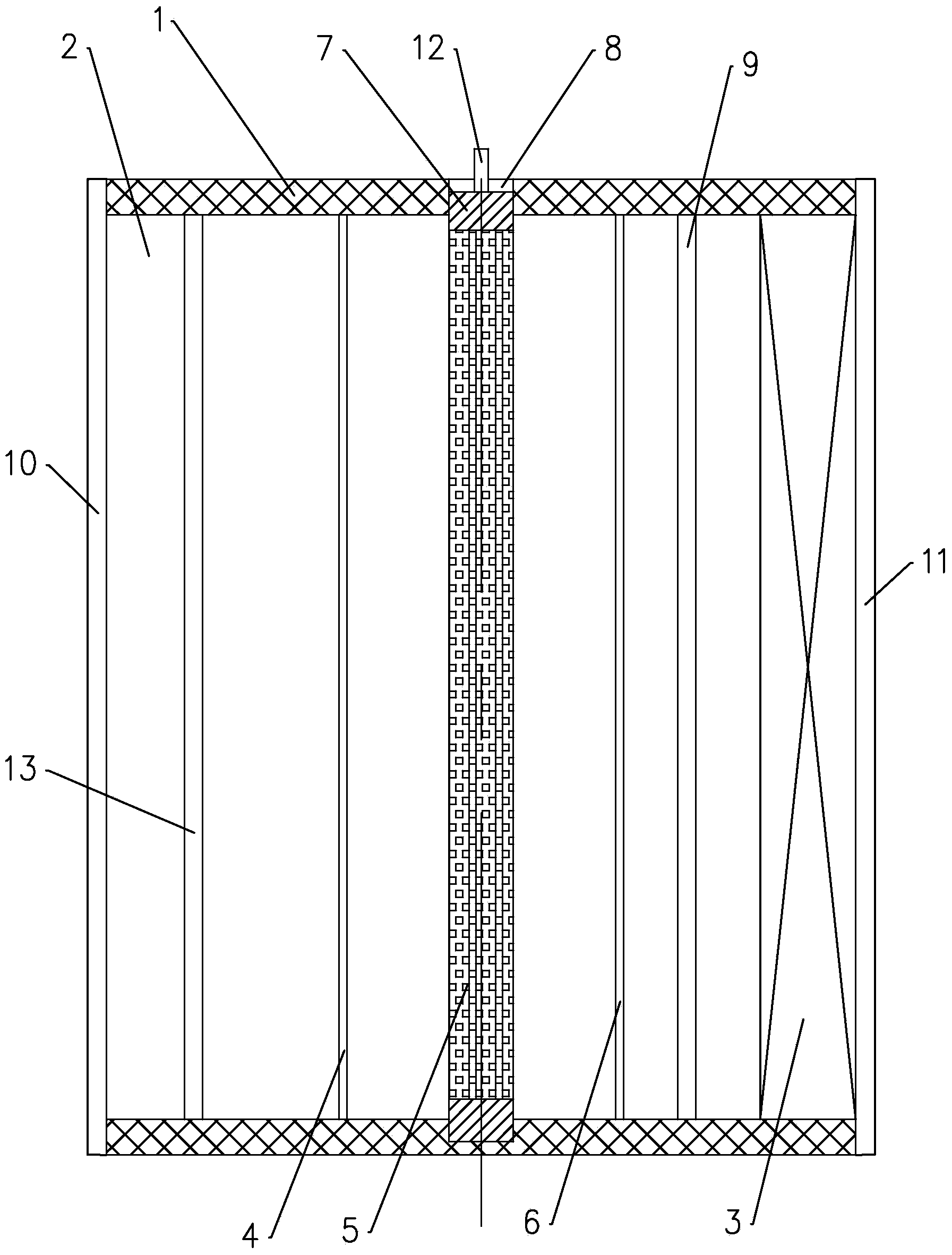

A composite dust collecting plate for electrostatic dust collection comprises a dust collecting electrode (1) made of conductive materials, and a dust suction layer (2) made of silk-shaped or porous materials is arranged on the surface of the dust collecting electrode (1); and the conductivity of the silk-shaped or porous materials for forming the dust suction layer (2) is 1*10<-8>S / m to 1*10<-5>S / m. According to the composite dust collecting plate for electrostatic dust removal, the dust containing capacity is high, the time period needing by dust cleaning is long, the efficiency of cleaning particles with the equivalent diameter smaller than or equal to 2.5 micrometers is high, and the dust removal performance is very stable.

Owner:北京中和锦程科技有限公司

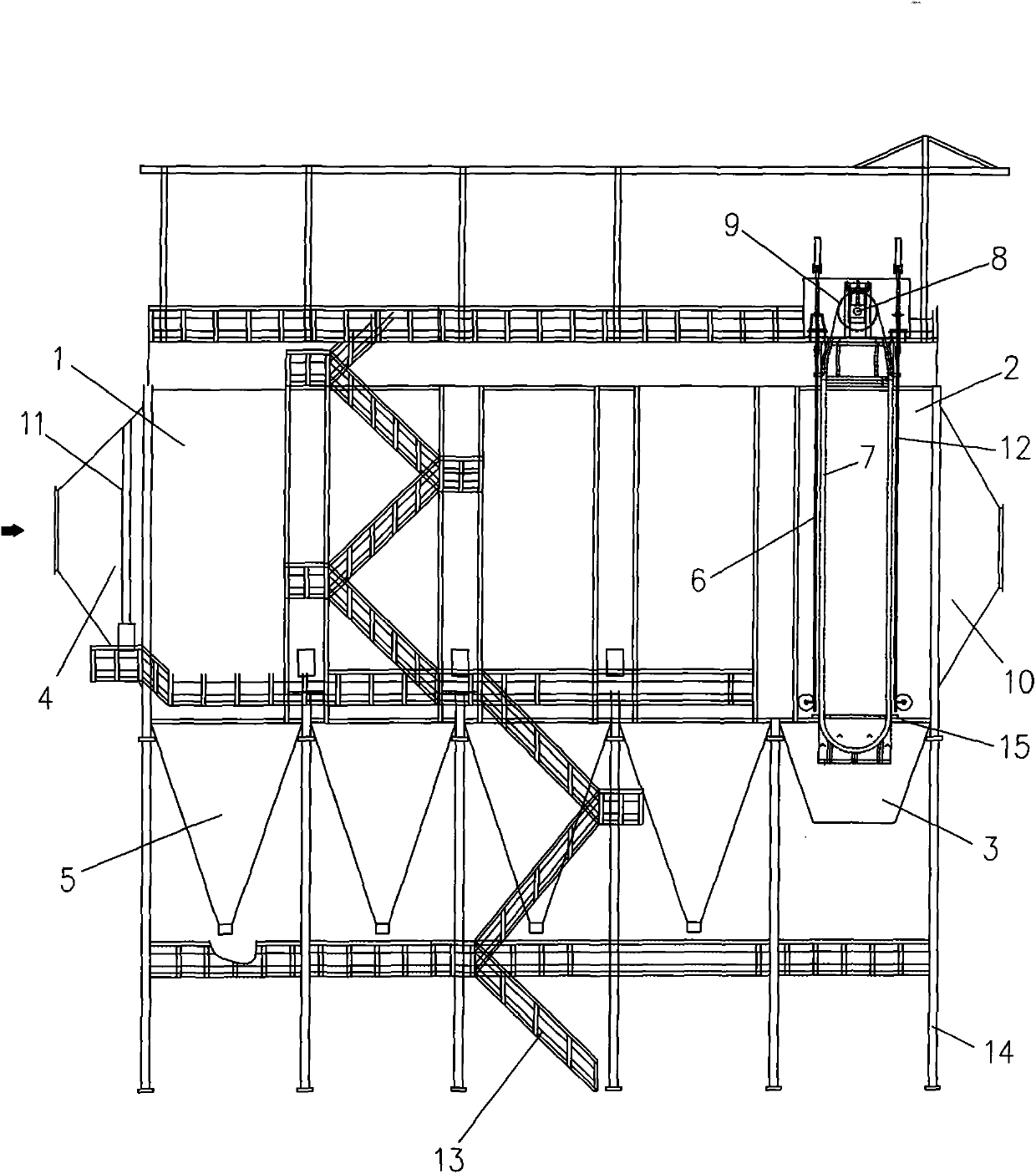

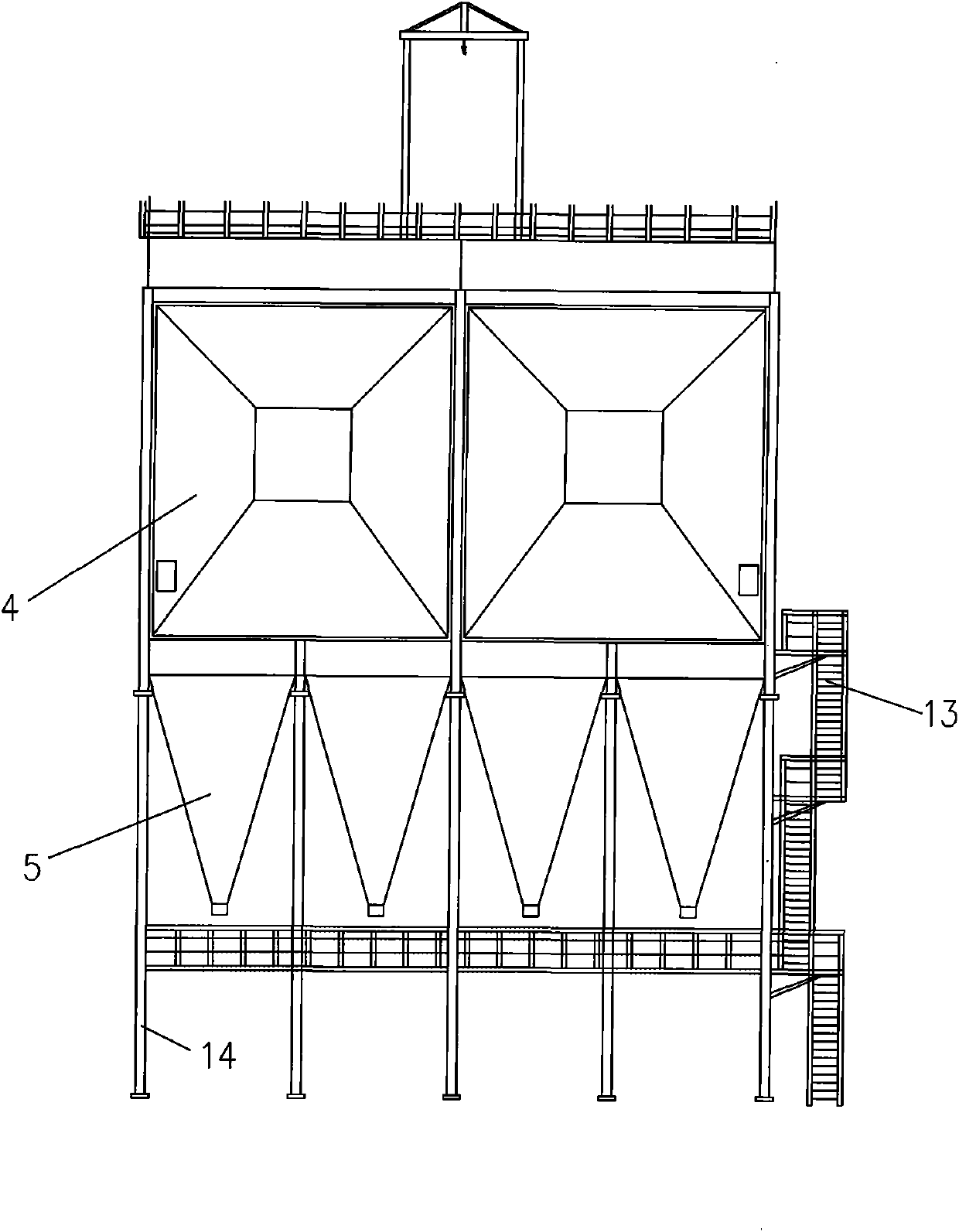

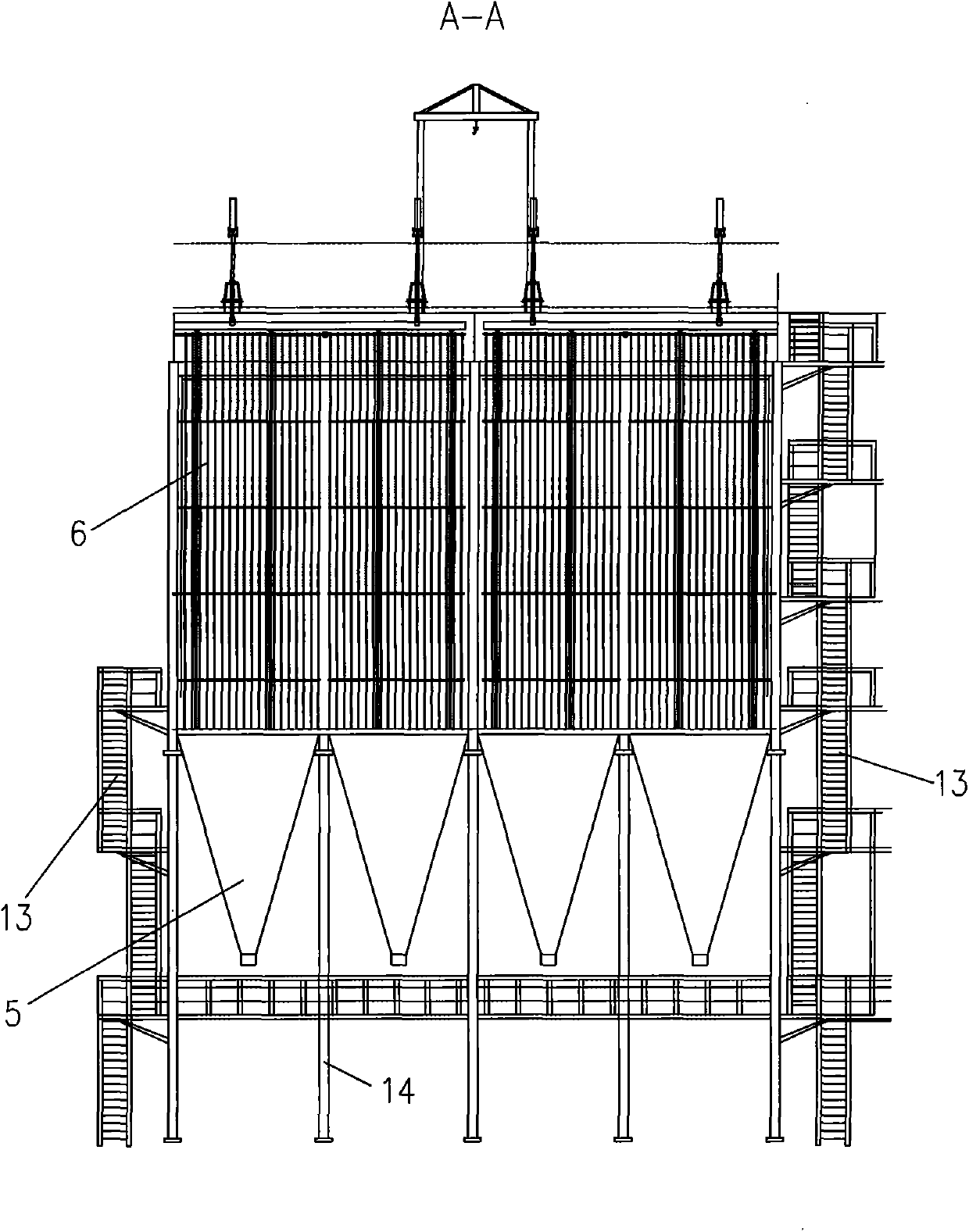

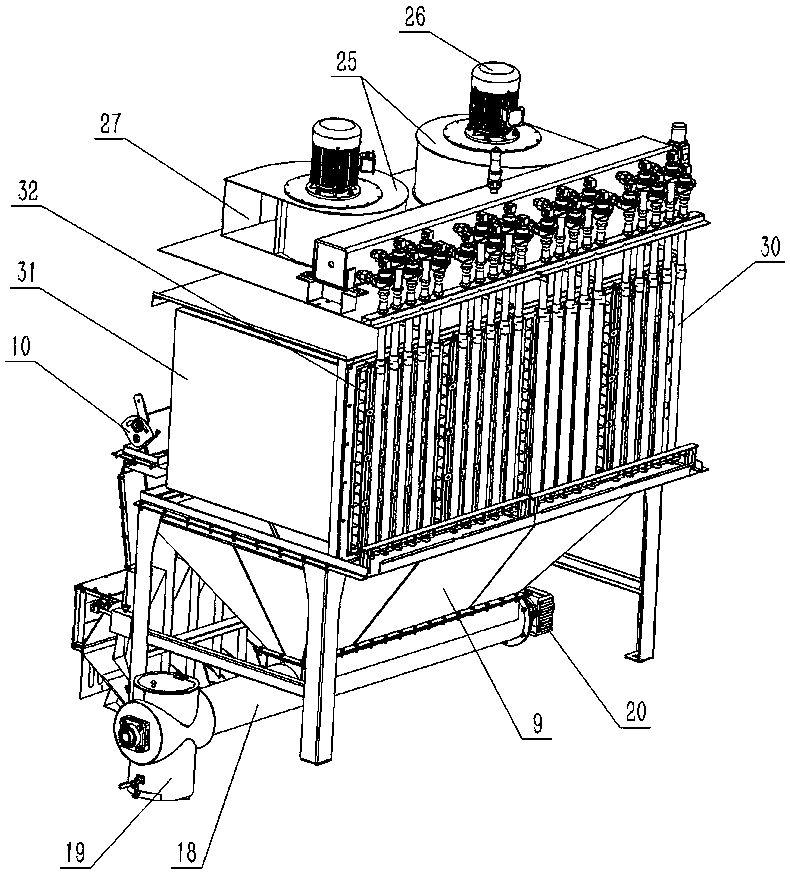

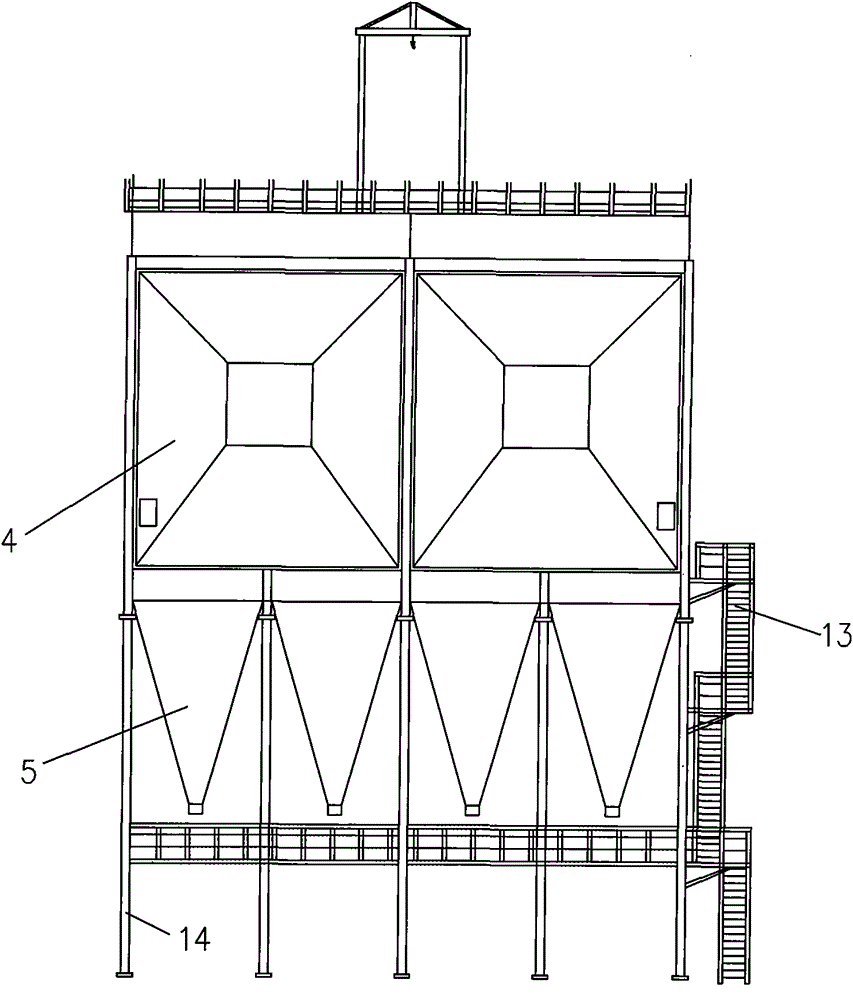

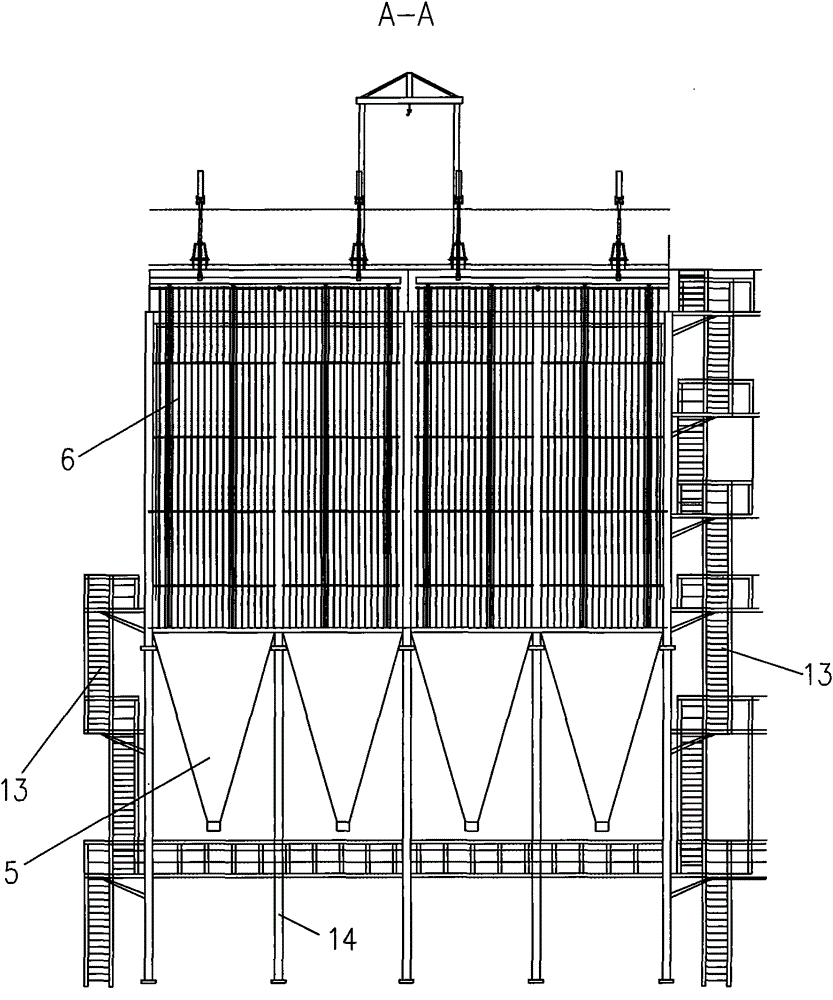

A clean and environmentally friendly dust collector for grain storage and cleaning centers

ActiveCN105944464BEasy to collectSave time and effort to collectDispersed particle filtrationGrain storageEngineering

Owner:HEBEI PINGLE FLOUR MACHINERY GROUP

Combined radial flow electrostatic precipitator

ActiveCN103721849BRotary motion stabilityFreedom of rotationElectrode constructionsElectrodes cleaningElectricityCurrent electric

The invention discloses a combined type radial current electric dust collector. According to the dust collector, a radial current type electric dust collecting power discharge net is arranged behind a dust collecting electrode inside a dust collecting airway; an annular dust collecting chain row is arranged behind the radial current type electric dust collecting power discharge net; the front annular part of the dust collecting chain row is parallel to the surface of the radial current type electric dust collecting power discharge net; a left guide rail is arranged on the left side of the dust collecting chain row; the side part of the left end of the dust collecting chain row is guided and positioned through the left guide rail; a right guide rail is arranged on the right side of the dust collecting chain row; the side part of the right end of the dust collecting chain row is guided and positioned through a right guide rail; the lower part of the dust collecting chain row is positioned inside a dust cleaning chamber; a sealing partitioning plate is arranged between the dust cleaning chamber and the dust collecting airway; the dust collecting chain row penetrates through the sealing partitioning plate downwards and enters the dust cleaning chamber; a dust blowing tube is arranged along the left and right direction near the dust collecting chain row inside the dust cleaning chamber. The invention aims at providing the combined type radial current electric dust collector which is large in gas treatment capability in unit time, outstanding in effect in collecting fine dust including PM2.5, very stable in dust collection performance, low in operation cost and long in service life.

Owner:北京华能达电力技术应用有限责任公司

Environment-protecting grain cleaning and dust removing device

InactiveCN110420851ASimple structurePractical and convenientSievingGas current separationBaghouseEngineering

The invention discloses an environment-protecting grain vibration dust removing device. The device comprises a base and a dust removing device body, wherein a screen body support is arranged at the right end of the base, a double-layer vibration screen is obliquely arranged on the screen body support, a grain outlet and an impurity outlet are formed in the lower end of the double-layer vibration screen, the dust removing device body is arranged on the left side of the double-layer vibration screen, the dust removing device body comprises a bag-type dust remover arranged at the left end of thebase and an air inlet cylinder arranged above the grain outlet, the upper end of the air inlet cylinder is connected with an air suction pipe, and the air suction pipe communicates with an air inlet of the bag-type dust remover. The device has the advantages of being simple in structure, practical and convenient, suitable for grain cleaning and impurity removal equipment, rapid and stable in dustremoval, good in dust removal effect, and clean and environment-protecting in dust removal process.

Owner:ANHUI JIESHOUSHI YUNLONG FOOD MACHINE ENG

Corona wet desulfurization and denitrification dust removal flue gas purification device and using method thereof

PendingCN106823709ALarge gas volumeOutstanding fine dust effectCombination devicesGas treatmentFlue gasAir filter

The invention discloses a corona wet desulfurization and denitrification dust removal flue gas purification device and a using method thereof. The device comprises an enclosure, wherein a flue gas purification duct is formed in the enclosure along the forward and backward direction; multiple anode plates are arranged in parallel in the flue gas purification duct; an anode spray pipe is arranged above each anode plate along the forward and backward direction; a water outlet of each anode spray pipe faces a corresponding anode plate; a cathode is arranged on one side of each anode plate; an air filtering anode plate through the plate surface of which airflow can pass is arranged in the flue gas purification duct and positioned in the rear of the multiple anode plates; the plate surface of the air filtering anode plate is arranged along a section direction of the flue gas purification duct; and an air filtering anode plate spray pipe is arranged above the air filtering anode plate along the section direction of the flue gas purification duct. The invention aims to provide a corona wet desulfurization and denitrification dust removal flue gas purification device which is large in amount of treated gases in unit time, outstanding in effect of removing nitric oxides, sulfur dioxide, sulfur trioxide and fine dust including PM2.5 and extremely stable in desulfurization, denitrification and dust removal performances, and a using method of the device.

Owner:孟金来

High-frequency power supply control system of electrostatic dust collector

PendingCN114082533AEffective Shake CollectionGuaranteed cleaning efficiencyElectric supply techniquesElectrodes cleaningThermodynamicsControl system

The invention belongs to the technical field of electrostatic dust collectors, particularly relates to a high-frequency power supply control system of an electrostatic dust collector, and aims to solve the problems that a small part of collected dust can be adhered to a dust collection assembly and the inner wall of dust collector equipment, and electrodes of the dust collection assembly cannot discharge smoothly along with the increasing and increasing use times. According to the invention, the system comprises a control unit and an electrostatic dust collector, the control unit is connected with the electrostatic dust collector, the electrostatic dust collector is provided with a power supply module, the control unit is connected with a parallel shunt module, the parallel shunt module is connected with the power supply module, and the electrostatic dust collector is provided with a discharge unit and a dust collection unit. A driving module is further arranged on the electrostatic dust collector. The collision operation on the vibration frame can be repeated, excessive dust can be effectively shaken off and collected from the collection hopper, and the cleaning and dust removal efficiency of the dust removal equipment is guaranteed.

Owner:中电国核(北京)节能环保科技有限公司

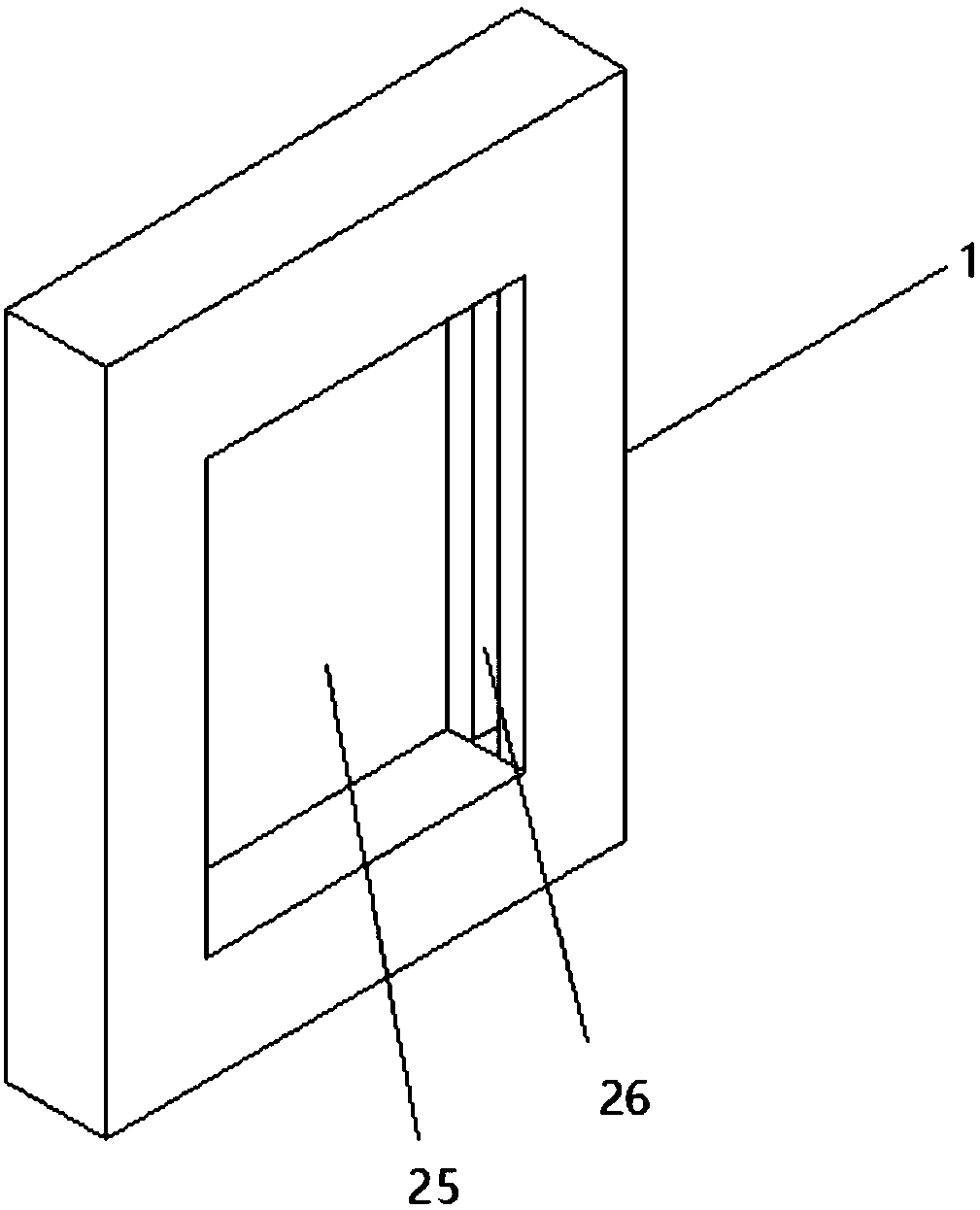

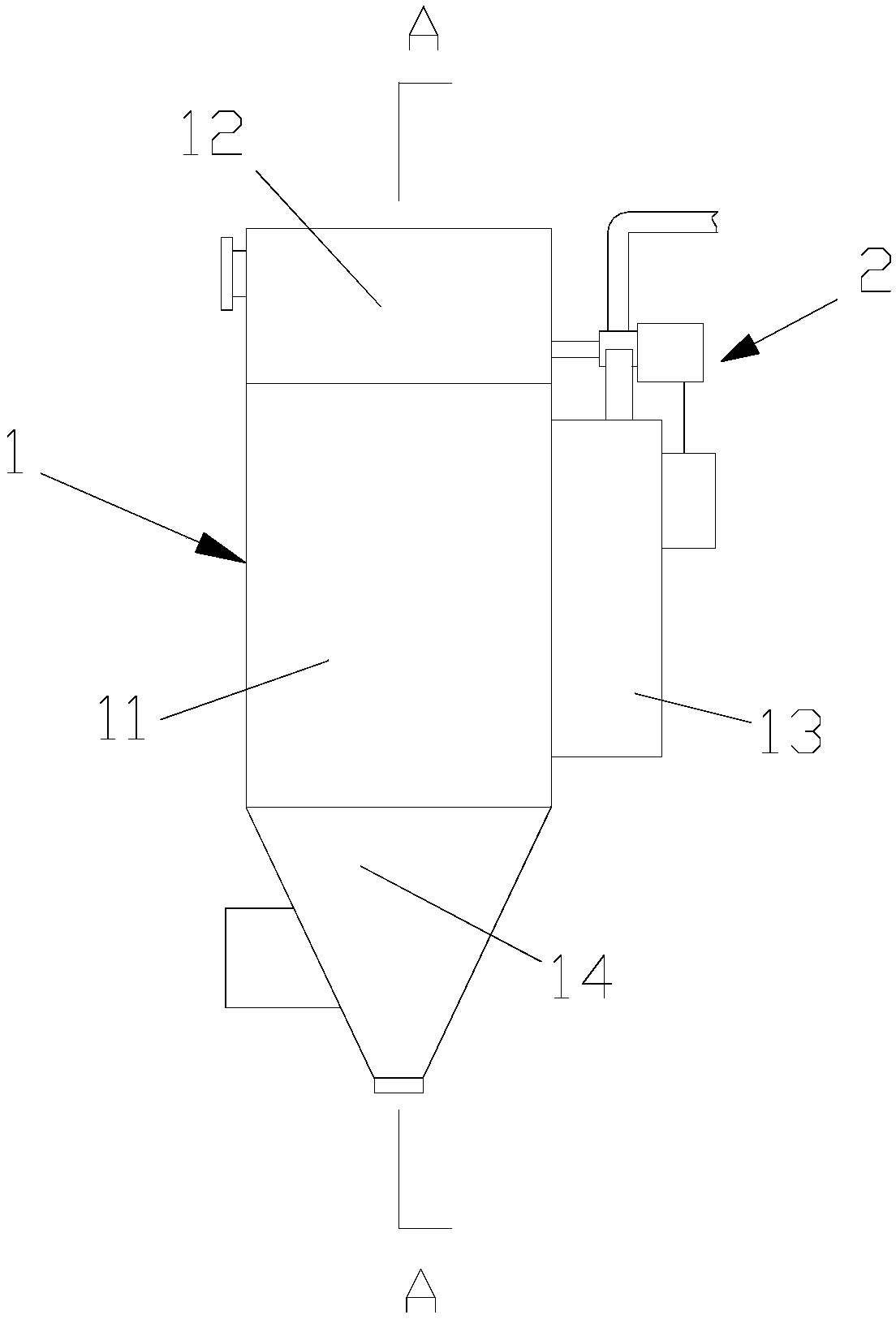

Dust removal equipment for feed processing

PendingCN112675629AAvoid cloggingStable dust removalDispersed particle filtrationFeed processingDust control

The invention relates to dust removal equipment for feed processing, and belongs to the technical field of feed processing equipment. The dust removal equipment comprises a dust removal cylinder, a filter plate is fixedly mounted in the dust removal cylinder, an air blowing mechanism is mounted on one side of the filter plate, and a filter plate cleaning mechanism is mounted on the other side of the filter plate; and a driving mechanism for driving the air blowing mechanism and the filter plate cleaning mechanism to work is fixedly mounted on the outer side of the dust removal cylinder. The driving mechanism is arranged to drive the air blowing mechanism and the filter plate cleaning mechanism to work at the same time, blockage of the filter plate is effectively avoided while stable dust removal is achieved, and efficient and stable dust removal operation is guaranteed; meanwhile, the vibration mechanism is mounted on the air blowing mechanism, and the filter plate is continuously beaten in the blowing process, so filter plate clogging is further avoided, the dust removal effect is good, the dust removal efficiency is high, and the dust removal equipment is more convenient and practical.

Owner:无锡市昌顺科技有限公司

A dust removal equipment for the production of coated sand

ActiveCN108187432BIncrease contact areaSolve the real problemCombination devicesPunchingIndustrial equipment

The invention relates to the technical field of industrial equipment, in particular to a dust removal device applied to the production of coated sand. Compared with the prior art, the dust removal device for the production of coated sand is provided with a filter screen on the air inlet filter device. The upper and lower ends of the cylindrical cylinder are equipped with nozzles, which spray water and remove dust through convection. At the same time, high-pressure air is passed through the four high-pressure punching holes to make the air in the cylindrical cylinder turbulent, so as to increase air and water. In order to increase the dust removal effect, a water baffle and a wind baffle are installed at the air outlet. On the one hand, it can trap water droplets in the air, and on the other hand, it also solves the problem of direct current wind. Through these layers of filtration, It can completely dissolve the dust in the air into the water. The most important thing is that its structure is simple and the design is reasonable. It is almost impossible to cause clogging, dust removal failure and other failures. It has the advantages of reasonable structure, good use effect, low failure rate and stable dust removal.

Owner:漳州垚鑫新材料科技有限公司

Vehicle-mounted air filtering electric sterilizer

InactiveCN112549917AAvoid affecting intake air filtrationGuaranteed uptimeGas treatmentAir-treating devicesAir filtrationBacterial virus

The invention relates to the technical field of air filtering electric disinfectors, and discloses a vehicle-mounted air filtering electric disinfector. The vehicle-mounted air filtering electric sterilizer comprises a self-cleaning mechanism and a sterilizing mechanism, and the sterilizing mechanism is fixedly connected to the upper side of an inner cavity of the self-cleaning mechanism; the self-cleaning mechanism comprises a plate box, a mounting box is fixedly connected to the bottom wall of an inner cavity of the plate box, and a motor is fixedly mounted on the bottom wall of an inner cavity of the mounting box. According to the vehicle-mounted air filtering electric disinfector, through matching of the plate box, the mounting box, the motor and the like, the device can perform dedusting operation on the inner chamber. Dust is prevented from blocking a filter screen due to long-time air filtration to influence inlet air filtration of the device, and long-time stable operation of the device is facilitated; and through cooperation of a fan rod, fan blades, a fifth gear and other devices, the device can disinfect filtered air, invasion of harmful bacteria and viruses in the air is effectively reduced, and body health of users is facilitated.

Owner:杭州展虹科技有限公司

A flat cloth cylinder dust collector with good dust collection and dust removal effect

The invention discloses a flat cloth barrel type deduster with good dust collection and dust removal effects. The deduster comprises a casing, an air suction and dust collection chamber arranged in the casing, a storage material channel communicating with the air suction and dust collection chamber, a dedusting filtering chamber communicating with the air suction and dust collection chamber and a centrifugal fan providing air suction negative pressure for the dedusting filtering chamber. The flat cloth barrel type deduster with the good dust collection and dust removal effects is designed for grain storage, when grain flows and passes through the storage material channel, dust and light impurities in the grain fly around or float above the grain, air suction negative pressure generated by the centrifugal fan passes through the dedusting filtering chamber and the air suction and dust collection chamber sequentially and sucks the dust in the storage material channel communicating with the air suction and dust collection chamber into the air suction and dust collection chamber and the dedusting filtering chamber for dust removal and filtering, the dust in the grain can be completely sucked away in the flowing process of the grain, the dust suction and dust removal effects are improved, the dust removal effect is better, and the grain is cleaner.

Owner:HEBEI PINGLE FLOUR MACHINERY GROUP

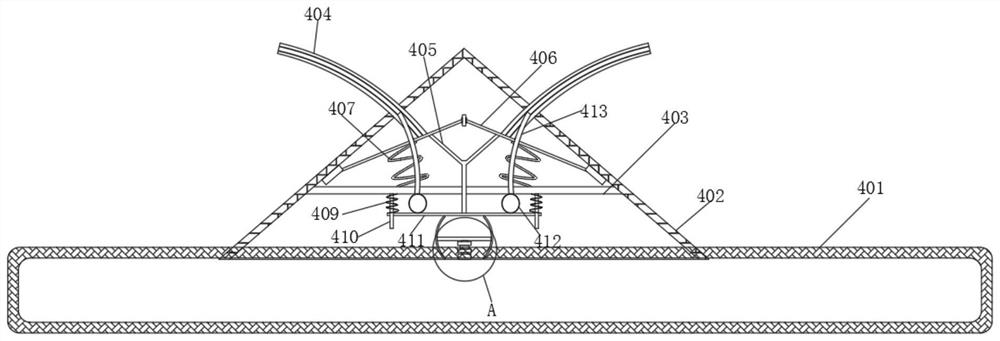

Sewing machine cutting device with dust collecting function

ActiveCN112481846AAvoid accumulationGuaranteed stabilityNeedle severing devicesSewing-machine control devicesWorking environmentProcess engineering

The invention relates to the technical field of textile production, in particular to a sewing machine cutting device with a dust collecting function. The device comprises an operating table; a machinebody is arranged at the top of the operating table; a cutting mechanism used for cutting sewing threads is arranged on the right side of the machine body; a conveying mechanism is arranged between the cutting mechanism and the machine body; the conveying mechanism is connected with the cutting mechanism through a supporting mechanism; and a dust suction mechanism is arranged on the inner side ofthe conveying mechanism. According to the device, the conveying mechanism is arranged, and sewn cloth can be transferred through a conveying belt, so that it is avoided that the cloth is accumulated on the operating table; meanwhile, sewing threads are cut in the conveying process, so that the processing time is shortened, and the production efficiency is improved; and the dust suction mechanism is arranged, a dust suction pump is provided with a dust suction pipe for sucking dust generated in the sewing thread cutting process, and the dust is collected through a filter frame and a dust collection box which are arranged on the inner side of a filter box, so that the pollution to the environment when the device runs can be avoided, and meanwhile a comfortable working environment is providedfor operators.

Owner:SUZHOU KAICHENG SEWING EQUIP

Urban road height limiting rod with dust removal function

InactiveCN113172010AEasy to useGood dust effectCleaning using toolsCleaning using gasesDisplay boardClassical mechanics

The invention relates to the technical field of height limiting rods, and discloses an urban road height limiting rod with a dust removal function. The urban road height limiting rod comprises a height limiting frame main body, wherein the top of the height limiting frame main body is provided with a display board, a dust removal mechanism and a moving mechanism; a fixed pulley is mounted on the side wall of the height limiting frame main body; one end of the moving mechanism is provided with a pull rope; the other end of the pull rope penetrates through the fixed pulley to be connected with a pull ring; and the dust removal mechanism is movably arranged above the height limiting frame main body through the moving mechanism. According to the urban road height limiting rod, the dust removal mechanism is arranged, a supporting rod in the dust removal mechanism is in the shape of a circular truncated cone, and an annularly-arranged bristle assembly can be unfolded by the supporting rod in the shape of the circular truncated cone when a Y-shaped rope pulls a movable plate to move front and back, so that the dust wiping range is larger, and use is more convenient.

Owner:蒋全喜

A device for cleaning dust on the surface of an instrument

ActiveCN109047079BImprove dust removal effectLarge spray rangeCleaning using toolsCleaning using gasesGear wheelDust control

The invention relates to a cleaning device, in particular to a dust cleaning device on the surface of an instrument. The technical problem to be solved is to provide a device for cleaning dust on the surface of an instrument that saves time and cleans up enough and thoroughly. The technical solution of the present invention is: a dust cleaning device on the surface of an instrument, including a frame body, a handle, a vertical plate, a first motor, etc.; A first motor is installed on the lower part of the left side. In the present invention, the first motor is used as the drive, and the inner ring gear is driven to rotate through the first gear, so that the brush can be driven to clean the dust on the surface of the instrument. A compression cylinder is also provided, and the cam drives the compression cylinder to extract air, and then sprays it to the The surface of the instrument, under the action of the second slide bar and the third spring, can make the rubber frame always contact with the surface of the shell of the instrument, so that the brush can be more stable during dust removal, and can be cleaned more thoroughly.

Owner:江苏良玉激光新材料有限公司

Short distance electrostatic precipitator

ActiveCN105435961BImprove efficiencyStable dust removalExternal electric electrostatic seperatorElectric supply techniquesElectricityParticulates

The invention discloses a short-interval electric dust remover. The short-interval electric dust remover comprises direct current power sources and a plurality of tabulate dust collection electrodes made from a metal materials. The plate faces of the multiple dust collection electrodes are located in the left-right vertical direction and mutually parallel to one other. An air channel in the left-right direction is formed between the two adjacent dust collection electrodes. Each air channel is internally provided with a plurality of corona wires. The axes of the corona wires are parallel to the plate faces of the dust collection electrodes. The positive pole of the direct current power sources are connected with the corona wires. The corona wires are arranged in the vertical direction. The voltage between the dust collection electrodes and the corona wires is 10000 V-18000 V. The distance between the two adjacent dust collection electrodes is 40 mm-80 mm. The length of each dust collection electrode in the air channel direction is five to ten times the distance between the two adjacent dust collection electrodes. The short-interval electric dust remover is great in dust collection capacity; the time period for dust removing is long; the efficiency for removing particulate matter with the equivalent diameter less than or equal to 2.5 micrometers from dust collection plates is high.

Owner:北京中和锦程科技有限公司

A gas-solid separator and its denitrification and dust removal device

ActiveCN106422543BStable dust removalSpeed up the flowGas treatmentDispersed particle separationGas solidCyclonic separation

The invention relates to environmental protection equipment and a denitration and dust-removing device, in particular to a gas-solid separator, as well as a denitration and dust-removing device. The gas-solid separator comprises a smoke gas distribution chamber. The smoke gas distribution chamber is provided with a smoke gas inlet for introducing a to-be-separated gas in a first direction; a plurality of gas cavities which are communicated mutually are distributed in the smoke gas distribution chamber in the first direction; and the volume of the plurality of the gas cavities is gradually reduced in the first direction. The smoke gas distribution chamber is connected with a plurality of cyclone separation assemblies which are in one-to-one correspondence with the plurality of gas cavities; each separation assembly comprises a cyclone cylinder and a gas discharge pipe which are matched mutually; the cyclone cylinder is provided with a gas inlet and flow guide end which is used for input gas and positioned in the gas cavities; and the gas discharge pipe partially stretches into the cyclone cylinder and penetrates through the smoke gas separation chamber. The denitration and dust-removing device comprises a shell and the gas-solid separator. The gas-solid separator, as well as the denitration and dust-removing device, protects a catalyst and prolongs the service life of the catalyst to finally realize the technical effects of improving the denitration effect and reducing the cost.

Owner:SHANDONG TIANLI ENERGY SAVING ENG

gas cooler

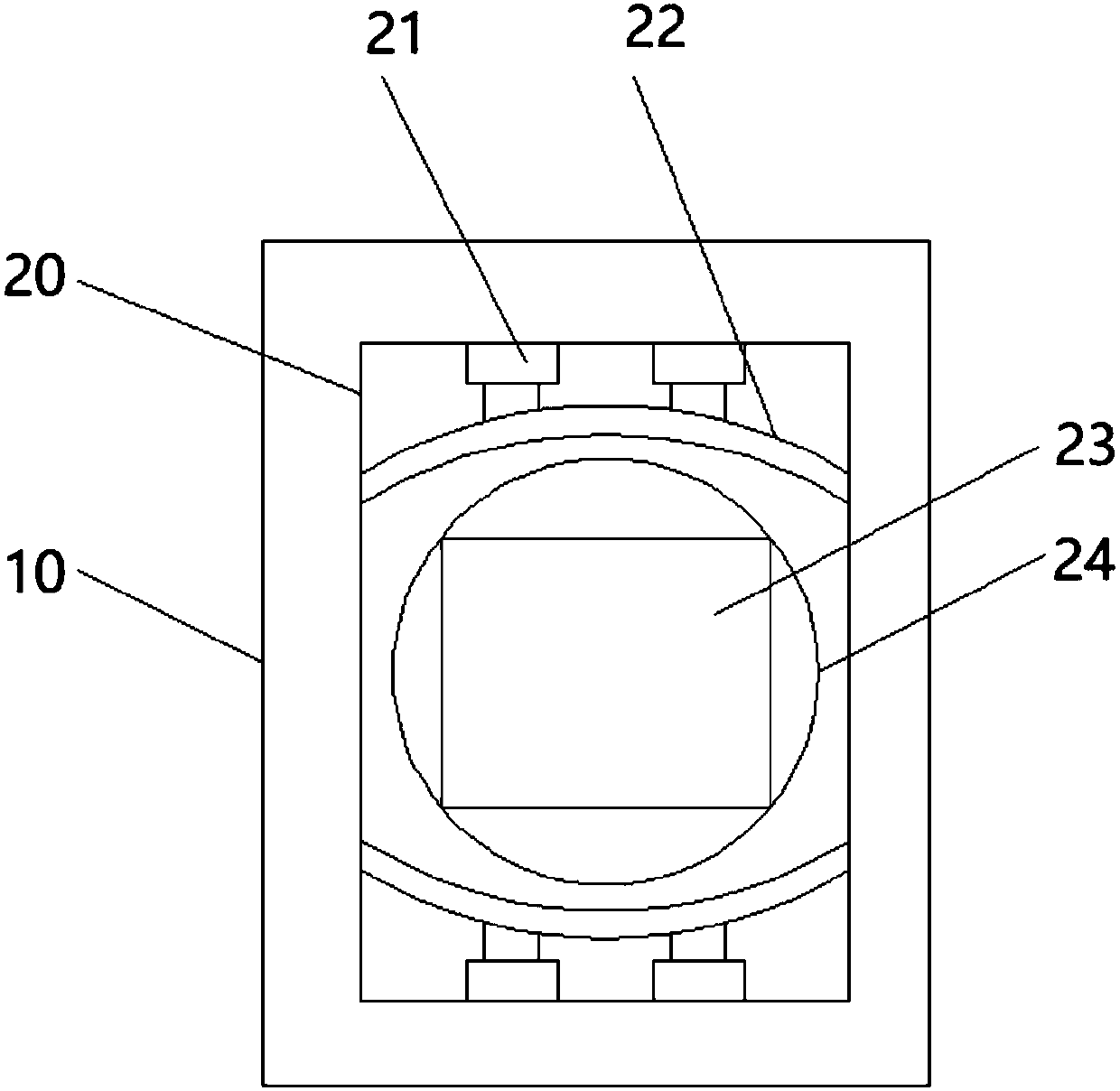

ActiveCN105026874BPrevent leakageMiniaturizationHollow article cleaningCleaning using toolsCooling chamberEngineering

The present invention provides a gas cooler capable of being reduced in size, capable of preventing exhaust gas from leaking to the outside, and capable of stably removing dust. The gas cooler (1) of the present invention has: a plurality of cooling pipes (5), which are arranged in the cooling chamber (3); dust removal parts (7), which are slidably arranged on the peripheral surface of the cooling pipes; reciprocating A moving mechanism (9), which makes the dust removal component reciprocate along the axial direction of the cooling pipe. The reciprocating mechanism is provided with: a holding member (17), which holds the dust removal member reciprocally movable and protrudes in a direction intersecting with the axial direction of the cooling pipe; an opening (19), which is provided on the side wall (3a) of the cooling chamber ), which enables the holding member to protrude from the side of the cooling chamber and reciprocates; a sealing mechanism (21), which prevents the gas in the cooling chamber from leaking to the outside; a moving body (22), which supports the holding member protruding from the opening and capable of reciprocating movement; and a drive mechanism (24) that reciprocates the moving body.

Owner:JFE STEEL CORP

Air box type pulse dedusting device

InactiveCN109351074AAvoid bondingEasy to break awayGas treatmentDispersed particle filtrationEngineeringMaterials processing

The invention discloses an air box type pulse dedusting device. The device includes a dust collecting air box and a pulse apparatus arranged on one side of the dust collecting air box; the dust collecting air box comprises a main box body internally provided with a containing space, a gas outlet chamber formed above the main box body, a checking door arranged on one side of the main box body, a dust outlet hopper arranged below the main box body and a bag drum which is arranged in the main box body and used for collecting dust. The bag drum includes a cylindrical support framework and a clothbag arranged on the support framework. The bag drum in the device supports the cloth bag through the support framework to prevent the cloth bag from being bonded during use; meanwhile, the cloth bag is also tightened by the support framework and thus can vibrate during pulse blowing for dedusting, and therefore the dust is more likely to detach from the cloth bag, so that the effects of maintaining stability during dedusting and preventing the bag from being burnt are achieved. Meanwhile, a novel environment-friendly material is adopted for processing and preparing the cloth bag, not only is the cost reduced, but also the generation possibility of static electricity is lowered, and improvement of the safety performance of the device is facilitated.

Owner:冯嘉豪

A sewing machine cutting device with dust collection function

ActiveCN112481846BAvoid accumulationGuaranteed stabilityNeedle severing devicesSewing-machine control devicesWorking environmentProcess engineering

The invention relates to the technical field of textile production, in particular to a sewing machine cutting device with a dust collection function, comprising an operating table, an organic body is arranged on the top of the operating table, and a shearing mechanism for cutting sewing threads is arranged on the right side of the machine body, the shearing mechanism and the machine body There is a conveying mechanism between them, and the conveying mechanism and the shearing mechanism are connected by a support mechanism, and a dust suction mechanism is arranged inside the conveying mechanism. In the present invention, by setting the conveying mechanism, the cloth that has been sewn can be transferred by using the conveyor belt, avoiding the accumulation of cloth On the operating table, the cutting of the sewing thread is completed during the conveying process, thereby shortening the processing time and improving the production efficiency. By setting the dust suction mechanism, the dust suction pump absorbs the dust generated during the sewing thread cutting process through the dust suction tube. , and use the filter frame and dust box set inside the filter box to collect the dust, which can avoid environmental pollution during the operation of the device and provide a comfortable working environment for the operator.

Owner:SUZHOU KAICHENG SEWING EQUIP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com