Air box type pulse dedusting device

A technology of pulse dust collector and gas box, which is applied in gas treatment, chemical instruments and methods, and separation of dispersed particles. It is not easy to stick the bag and reduce the effect of static electricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

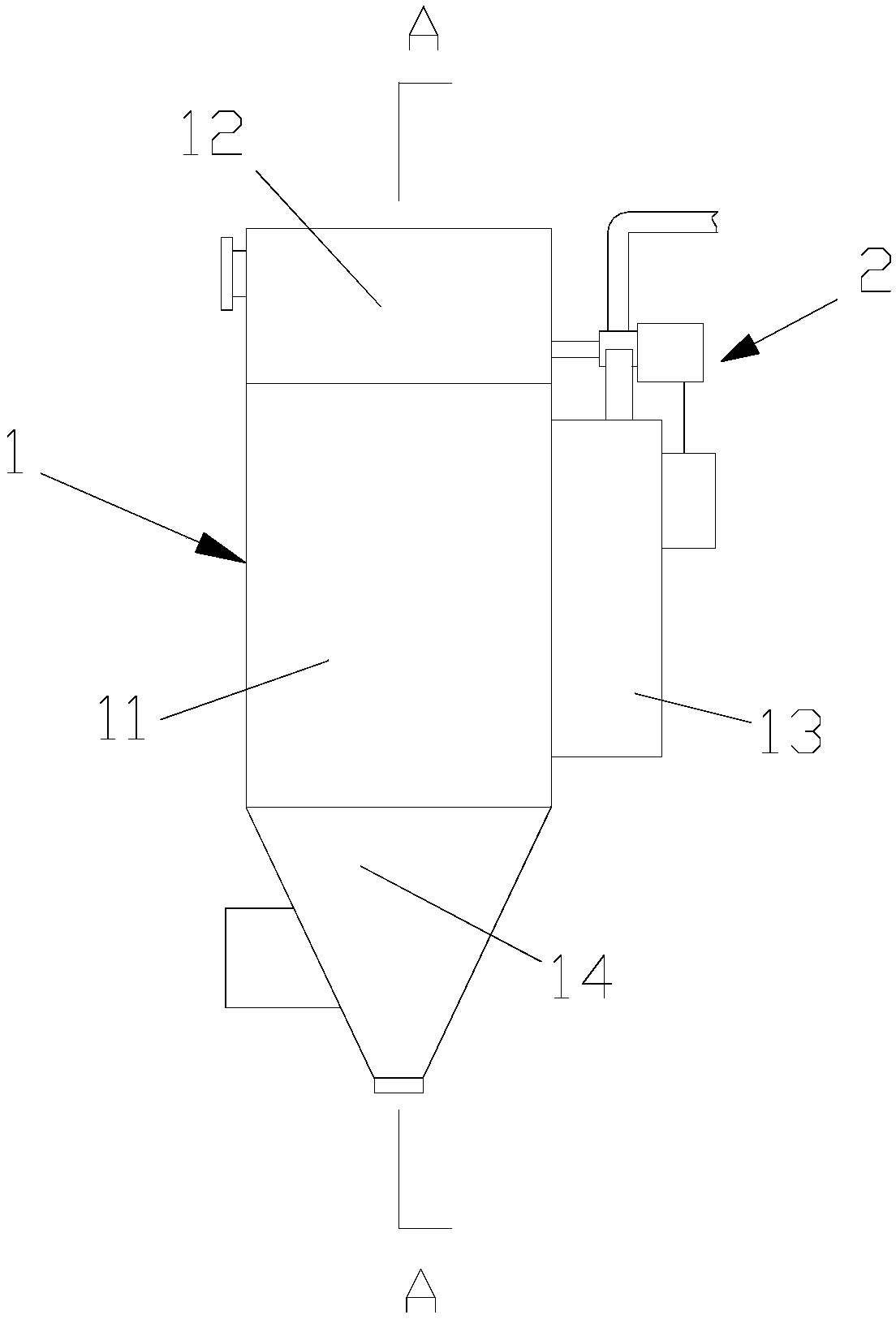

[0021] A gas box type pulse dust collector, such as figure 1 As shown, it includes a dust-collecting gas box 1, and a pulse device 2 arranged on one side of the dust-collecting gas box 1 and used in conjunction with the dust-collecting gas box 1;

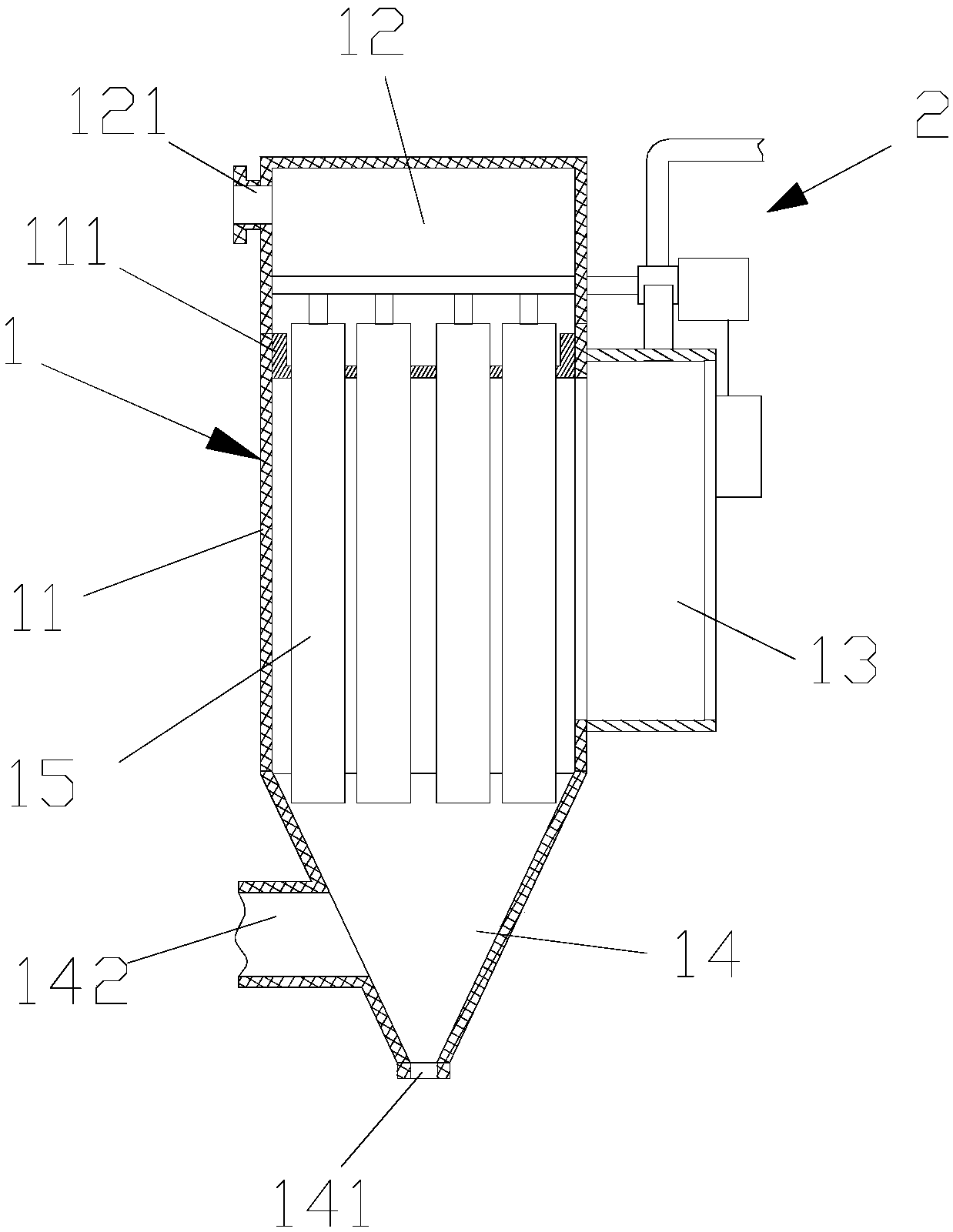

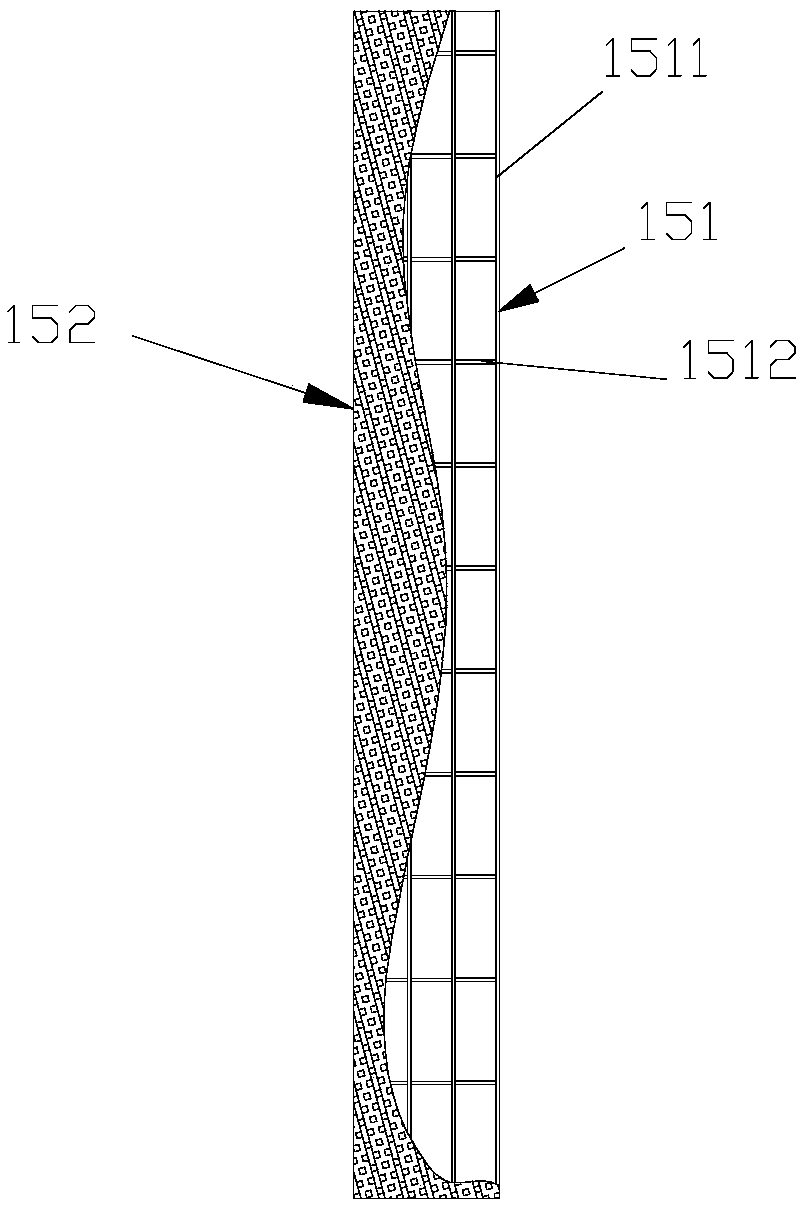

[0022] Such as figure 2 As shown, the dust-collecting air box 1 includes a main box body 11 with an accommodating space inside, and an air outlet cavity 12 arranged above the main box body 11 and fixed to the main box body 11, and arranged on the main box body The inspection door 13 on the side of 11 and communicated with the main box body 11, the dust hopper 14 arranged under the main box body 11, and the bag tube 15 for dust collection arranged in the main box body 11; The upper end of the inside of the main box 11 is provided with a fixing plate 111, and the fixing plate 111 and the main box 11 are fixed by screws, and the bag tube 15 is fixed by the fixing plate 111, so that the bag tube 15 is suspended by the fixing plate 111...

Embodiment 2

[0034] A gas box type pulse dust collector, such as figure 1 As shown, it includes a dust-collecting gas box 1, and a pulse device 2 arranged on one side of the dust-collecting gas box 1 and used in conjunction with the dust-collecting gas box 1;

[0035] Such as figure 2 As shown, the dust-collecting air box 1 includes a main box body 11 with an accommodating space inside, and an air outlet cavity 12 arranged above the main box body 11 and fixed to the main box body 11, and arranged on the main box body The inspection door 13 on the side of 11 and communicated with the main box body 11, the dust hopper 14 arranged under the main box body 11, and the bag tube 15 for dust collection arranged in the main box body 11; The upper end of the inside of the main box 11 is provided with a fixing plate 111, and the fixing plate 111 and the main box 11 are fixed by screws, and the bag tube 15 is fixed by the fixing plate 111, so that the bag tube 15 is suspended by the fixing plate 111...

Embodiment 3

[0047] A gas box type pulse dust collector, such as figure 1 As shown, it includes a dust-collecting gas box 1, and a pulse device 2 arranged on one side of the dust-collecting gas box 1 and used in conjunction with the dust-collecting gas box 1;

[0048] Such as figure 2 As shown, the dust-collecting air box 1 includes a main box body 11 with an accommodating space inside, and an air outlet cavity 12 arranged above the main box body 11 and fixed to the main box body 11, and arranged on the main box body The inspection door 13 on the side of 11 and communicated with the main box body 11, the dust hopper 14 arranged under the main box body 11, and the bag tube 15 for dust collection arranged in the main box body 11; The upper end of the inside of the main box 11 is provided with a fixing plate 111, and the fixing plate 111 and the main box 11 are fixed by screws, and the bag tube 15 is fixed by the fixing plate 111, so that the bag tube 15 is suspended by the fixing plate 111...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com