A clean and environmentally friendly dust collector for grain storage and cleaning centers

A clean and environmentally friendly dust collector technology, which is applied in the field of grain dust collectors and clean and environmentally friendly dust collectors, can solve the problems of serious dust in the working environment, polluted environment, and unsatisfactory dust collection effect of the suction duct, and achieves fast, stable and good dust removal. , cleaning uniformity and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in further detail below in conjunction with the accompanying drawings.

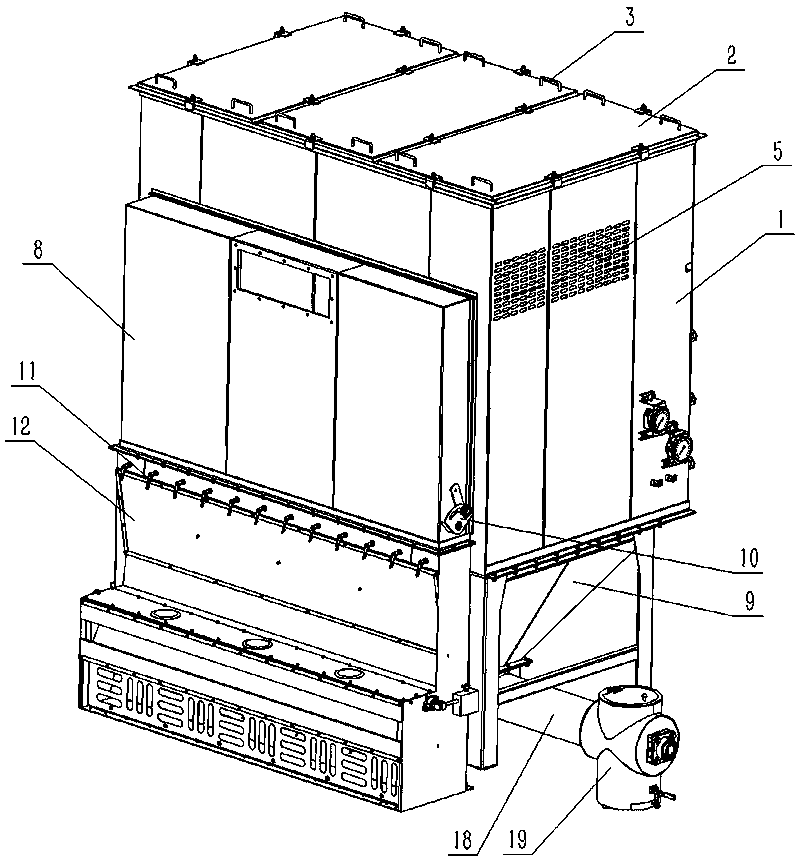

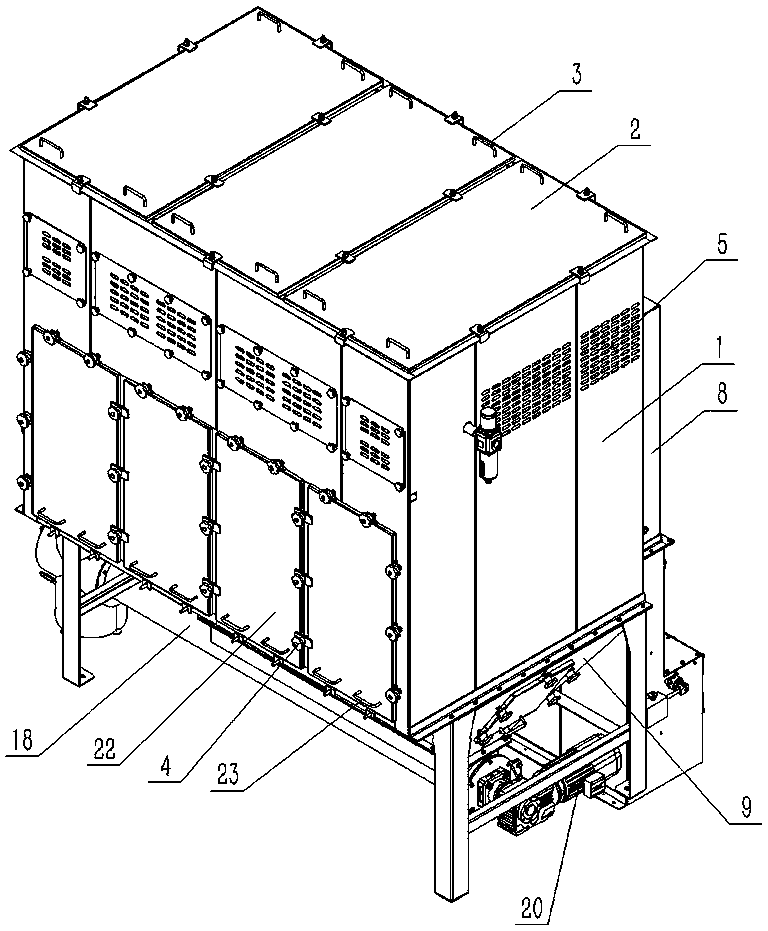

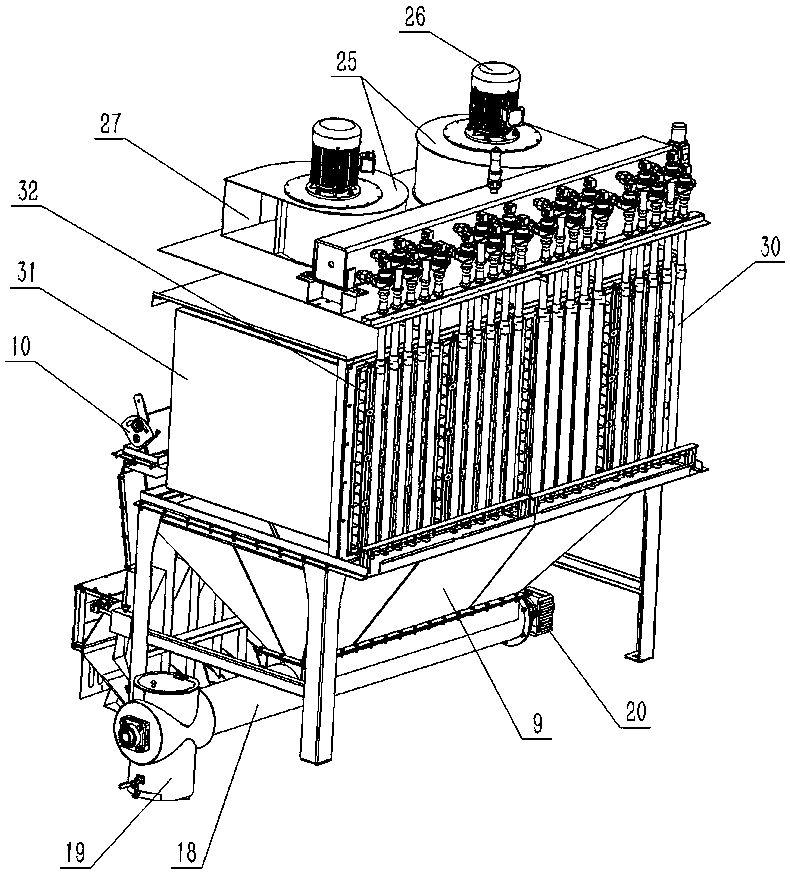

[0036] as attached Figure 1-12As shown in the figure, a clean and environmentally friendly dust collector for a grain storage and cleaning center includes a casing 1, a suction and dust chamber arranged in the casing 1, a dust filter chamber communicated with the suction and dust chamber, and a filter for dust removal. The room provides a centrifugal fan 25 with suction negative pressure and a dust collection and processing system arranged below the dust filter chamber. The wind centrifugal fan 25 is driven by an explosion-proof motor 26 to work. The dust collection and treatment system includes a dust collection hopper 9 communicated with the dust collection filter chamber, an auger conveyor 18 communicated with the dust collection ash hopper 9, a deceleration motor 20 that drives the auger conveyor 18 to convey, and a The closed air outlet 19 at one end o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com