Double-filter-element contra-rotation super-gravity wet-process dust remover

A counter-rotation, super-gravity technology, applied in separation methods, chemical instruments and methods, separation of dispersed particles, etc., can solve the problem of low removal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

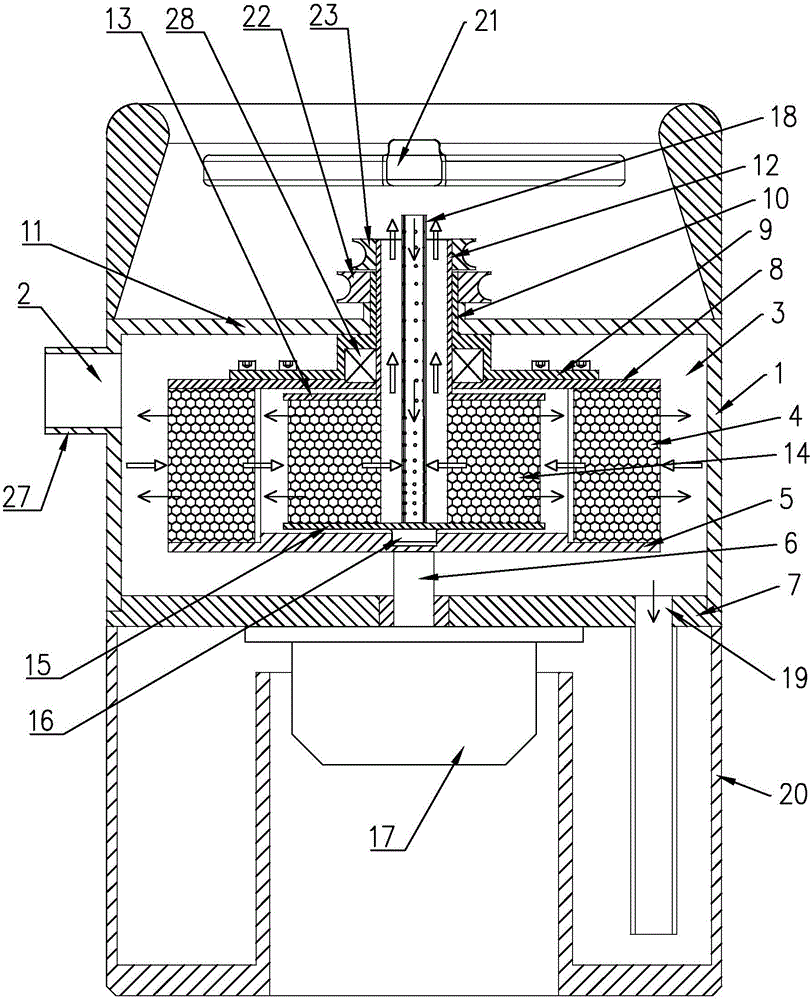

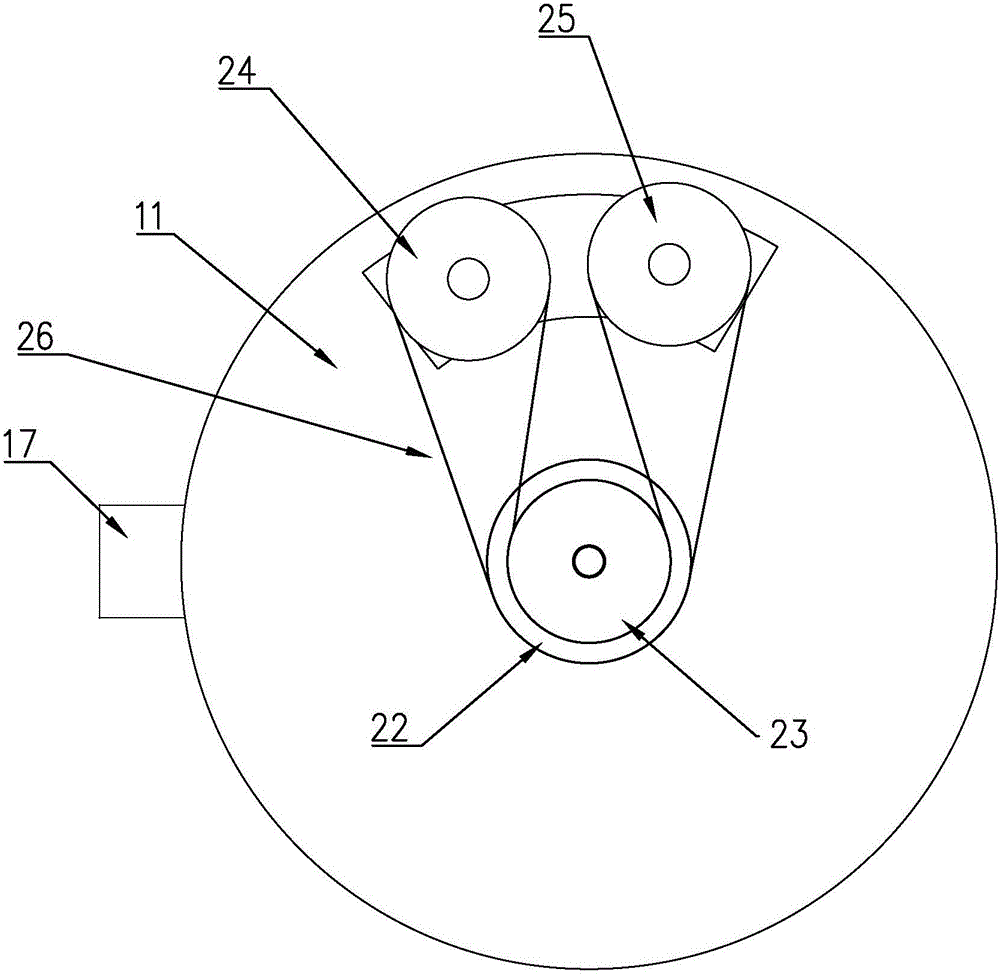

[0018] Such as figure 1 with figure 2 As shown, the dual-filter reverse-rotating supergravity wet dust collector of the present invention includes a casing 1, more than one air inlet 2 is provided on the side wall of the casing 1, and a dust removal chamber is provided in the middle of the casing 1. 3. There is an outer ring filter element 4 in the middle of the dust removal chamber 3. The cross section of the outer ring filter element 4 along the horizontal direction is circular, the axis of the outer ring filter element 4 is in the vertical direction, and the bottom end of the outer ring filter element 4 is fixed on the On the turntable 5, the disk surface of the turntable 5 is located in the horizontal direction, the middle part of the turntable 5 is connected to the top of the vertical shaft 6 made of steel, the axis of the vertical shaft 6 is located in the vertical direction, and the vertical shaft 6 extends downward through the bottom plate 7 of the casing 1 , the bot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com