A flat cloth cylinder dust collector with good dust collection and dust removal effect

A technology of dust collection and dust removal and flat cloth tube, which is applied in chemical instruments and methods, separation of dispersed particles, filtration of dispersed particles, etc., and can solve problems such as respiratory health hazards of operators, flying dust and light impurities, dust in the working environment, etc. To achieve the effect of clean and environmentally friendly working environment, improve efficiency, and complete dust collection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

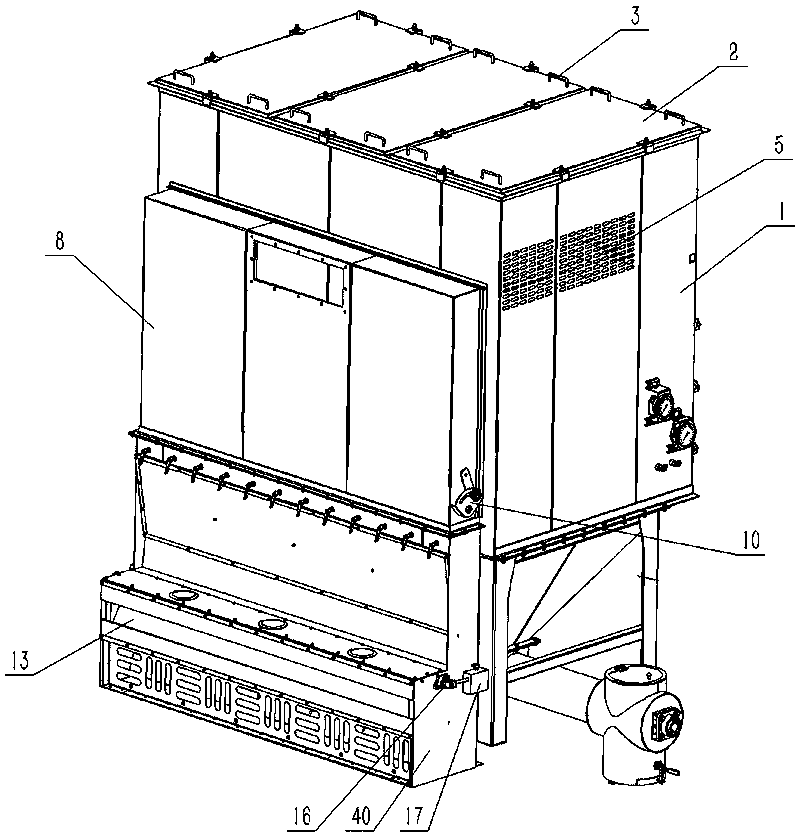

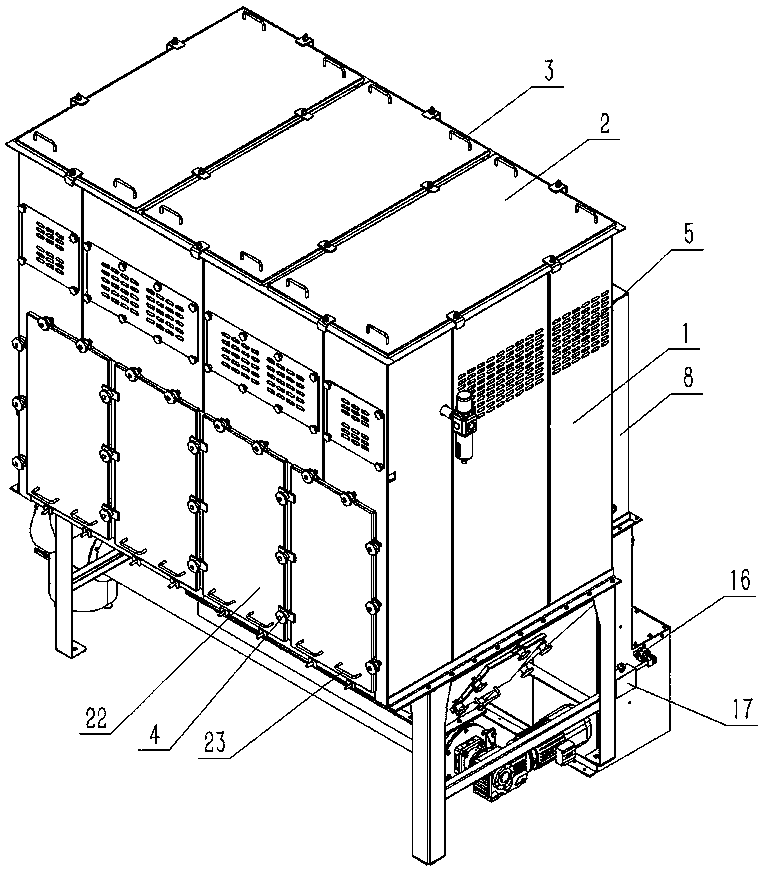

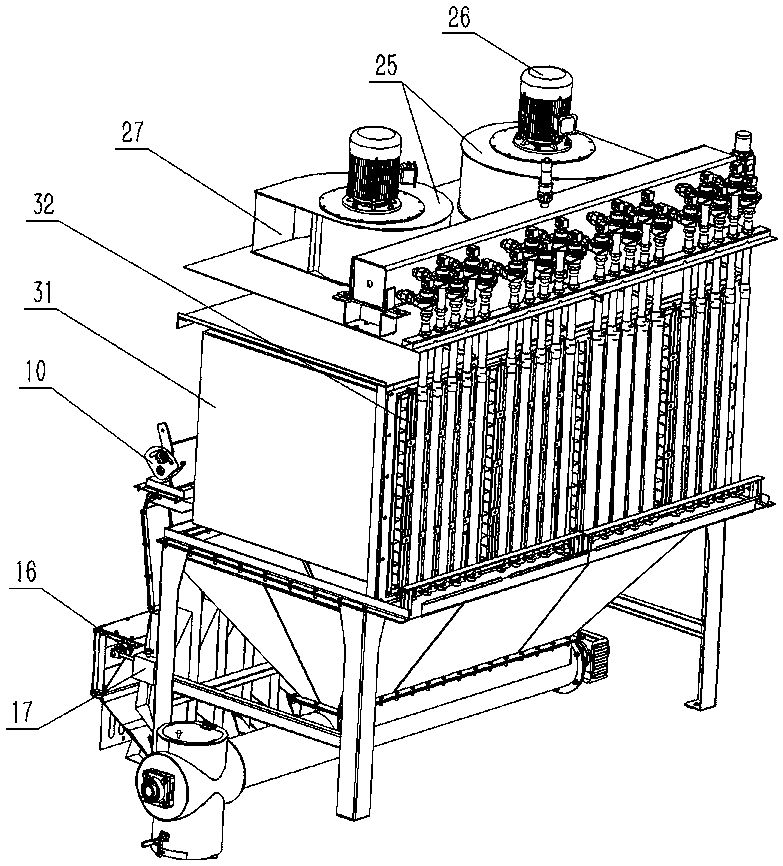

[0029] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0030] as attached Figure 1-9As shown, a flat cloth cylinder dust collector with good dust absorption and dust removal effect includes a casing 1, a suction dust chamber arranged in the casing 1, a storage material passage communicated with the suction dust chamber, and a suction chamber. The dust removal filter room connected to the dust removal filter room and the centrifugal fan 25 that provides suction and negative pressure to the dust removal filter room. The wind centrifugal fan 25 is driven by an explosion-proof motor 26. When the grain flows through the storage material channel, the dust in the grain is light Impurities fly or float on the grain, and the suction negative pressure generated by the centrifugal fan 25 passes through the dust removal filter room and the suction room successively, and then sucks the dust in the storage material channel co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com