Separating process and system of low-energy-consumption MTO product gas

A technology of product gas and low energy consumption, which is applied in the separation process and system field of the main product and low energy consumption MTO product gas, which can solve the problems of ineffective separation of carbon 2 and carbon 1 tail gas, increased investment and operating costs, and reduce investment Effects of capital and operating costs, capital and operating cost reductions, pipeline and valve size reductions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

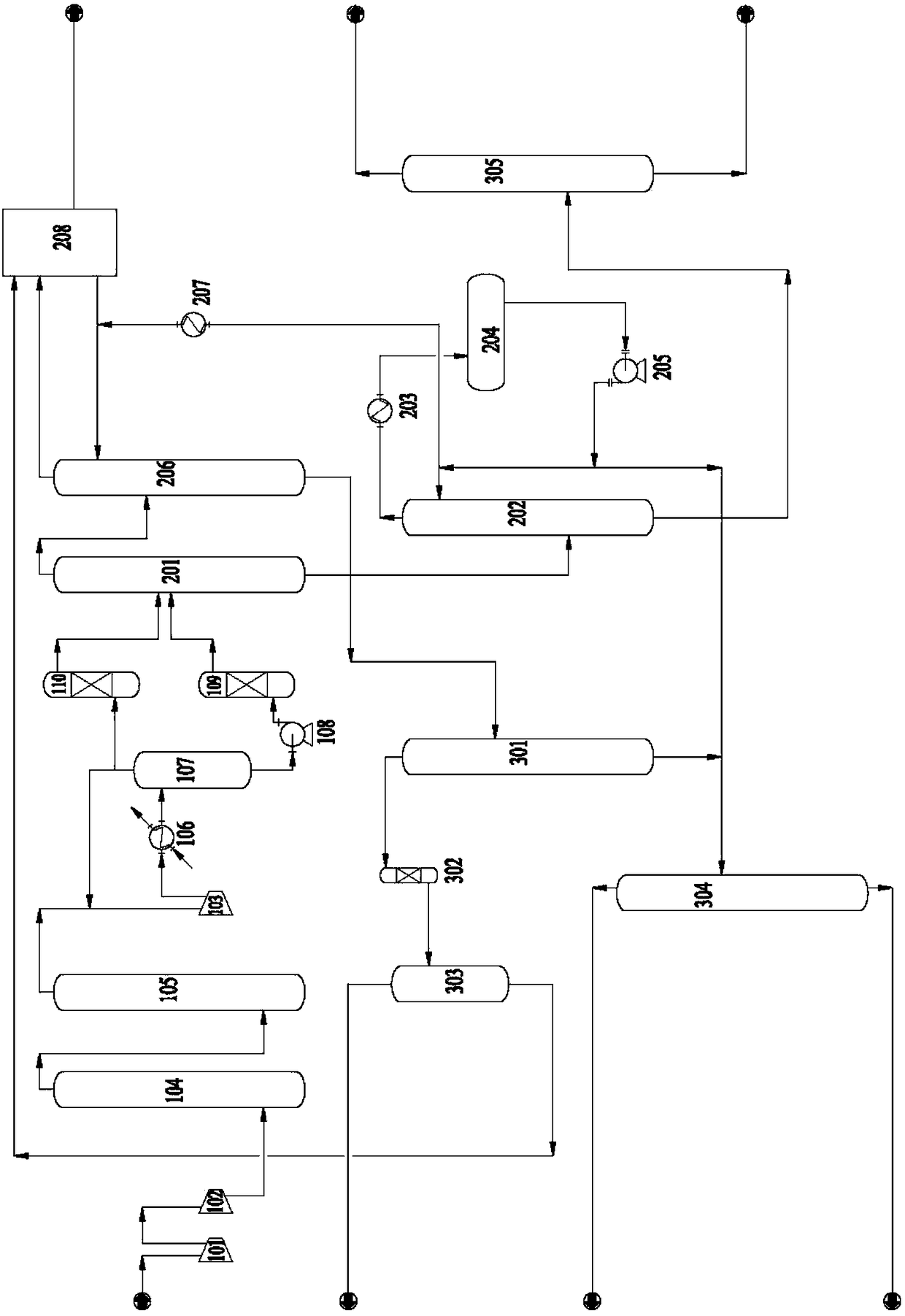

[0054] Such as figure 1 As shown, the present embodiment provides a separation process of low-energy MTO product gas, which includes the following steps in turn:

[0055] 1) The product gas from the methanol-to-olefins reactor (including hydrogen, nitrogen, carbon monoxide, carbon dioxide, and hydrocarbons from C1 to C5) is cooled to 38°C to 42°C by quenching water washing, and then enters the first-stage compression unit of the olefin separation device 101 is compressed to 0.2Mpa ~ 0.4Mpa, and then enters the second stage compression unit 102 to compress to 0.8Mpa ~ 1.3Mpa;

[0056] 2) After the product gas is compressed by the compressor in step 1), it enters the oxide removal tower 104 and the alkali washing tower 105 respectively, and carries out the organic oxidation of oxides (aldehydes, ketones, alcohols, ethers, etc.) substances) and acid gases (mainly carbon dioxide and hydrogen sulfide) removal;

[0057] 3) The compressed gas purified in step 2) is compressed by th...

Embodiment 2

[0070] Such as figure 1 As shown, the present embodiment provides a separation system for low-energy MTO product gas, including a compression unit 101, a compression unit 102, an oxide removal tower 104, an alkali washing tower 105, and a three-stage compression unit sequentially connected by pipelines. Compression unit 103, cooler 106 and drier feed liquid separator tank 107; The top of described drier feed liquid separator tank 107 is connected with gas phase drier 110, and the bottom of described drier feed liquid separator tank 107 is conveyed The pump 108 is connected with a liquid phase drier 109, a liquid phase product gas coalescer is connected between the delivery pump 108 and the liquid phase drier 109, and the gas phase drier 110 and the liquid phase drier 109 are respectively connected with a high pressure degasser. Carbon three towers 201, the high-pressure decarburization three towers 201 are connected with a decarburization first tower 206, and the decarbonizati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com