Method and device for purifying and recycling emitted argon in preparation process of monocrystalline silicon

A technology of preparation process and recovery method, which is applied in the field of argon gas discharge in the purification and recovery of single crystal silicon preparation process, which can solve the problems of high cost, inability to realize large-scale industrial application, easy deactivation, etc., and achieve convenient operation and maintenance and energy saving Consumption, control simple and reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

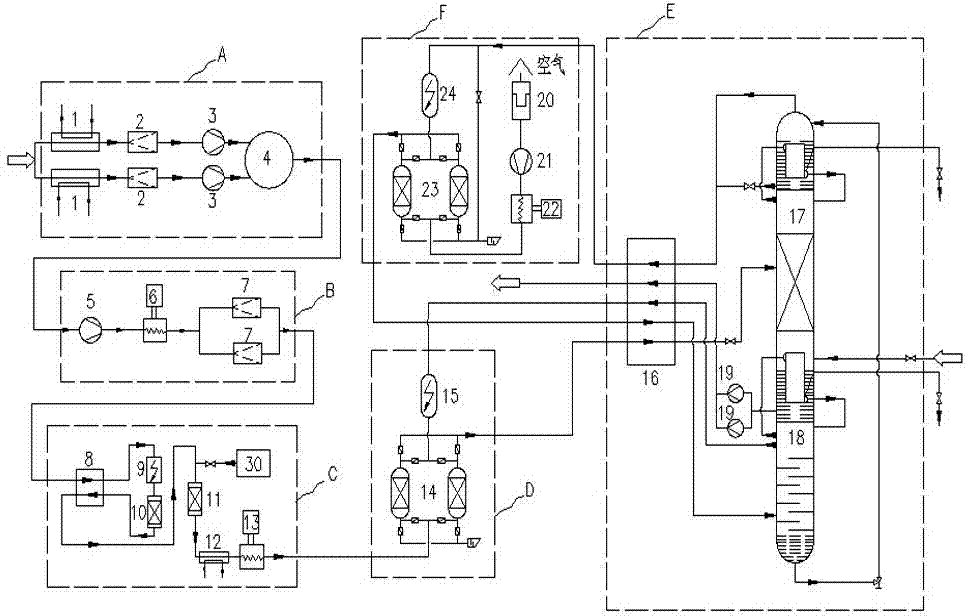

[0040] The present invention will be described in detail below in conjunction with the accompanying drawings and examples: a method for purifying and recovering exhausted argon in a single crystal silicon production process according to the present invention, the method includes the following steps:

[0041] a) Collect the crude argon gas discharged from the monocrystalline silicon furnace and perform compression degreasing treatment,

[0042] b) Use catalytic oxidation to remove carbon monoxide and alkanes in crude argon,

[0043] c) Remove the oxygen in the crude argon by hydrogenation and deoxygenation,

[0044] d) Remove the carbon dioxide and moisture in crude argon and air respectively by adsorption method,

[0045] e) Use high- and low-pressure double-tower cryogenic rectification methods to produce pure nitrogen and high-purity argon respectively.

[0046] In the step a), the crude argon gas discharged from the single crystal silicon furnace is collected and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com