One-tank multi-stage horizontal separator

A horizontal separator and tank technology, which is applied in the field of separators, can solve the problems of limited separation gas volume, large equipment space, and many auxiliary accessories, and achieve the effects of improving hydrogen and oxygen purity, good separation effect, and reducing connection points

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

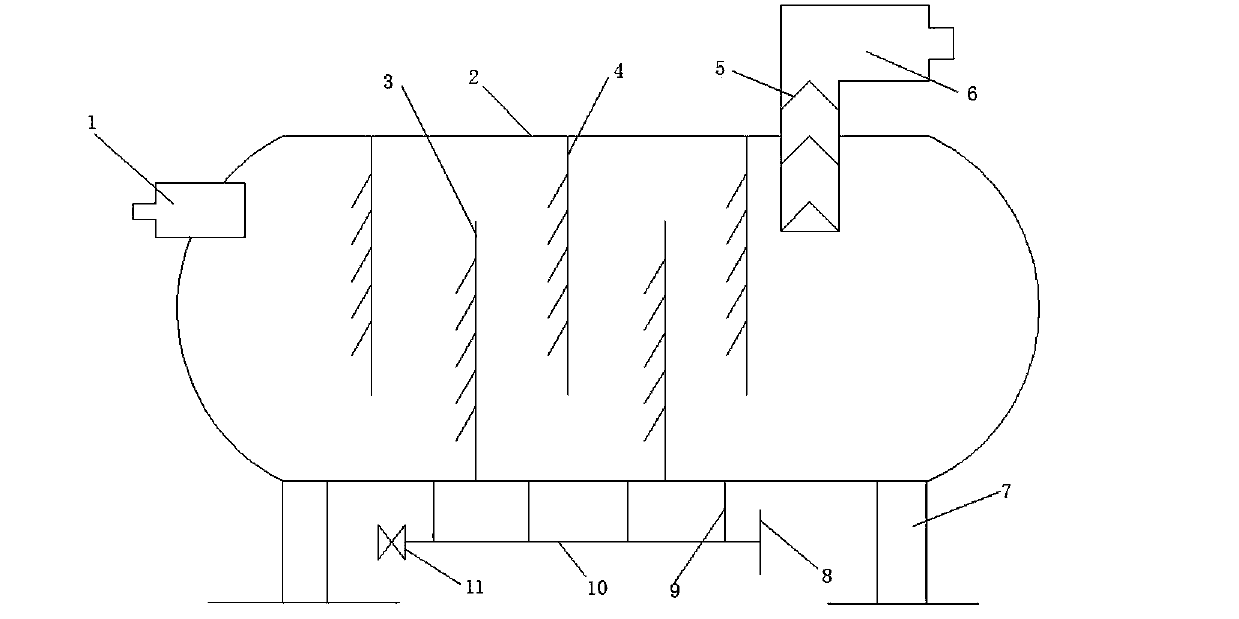

[0016] A tank multi-stage horizontal separator, comprising a tank body 2, a tank foot 7, a graded drip standpipe 9, a drip converging pipe 10, etc., and is characterized in that: both sides of the bottom of the tank body 2 are connected to the tank foot 7 The bottom of the tank body 2 is connected with a plurality of grading drop pipes 9 , and the other end of the grading drop pipe 9 is connected with a drip converging pipe 10 .

Embodiment 2

[0018] One side of the tank body 2 is provided with an air inlet 1 on the upper part, and the other side is provided with an air outlet 6 , and a plurality of upper isolation plates 4 and lower isolation plates 3 are arranged inside the tank body.

Embodiment 3

[0020] One end of the drip converging pipe 10 is provided with a discharge valve 11 , and the other end is provided with a blind plate 8 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com