High-efficiency gas purification bioreactor based on complex enzyme immobilization technology and purification method thereof

A bioreactor and gas purification technology, applied in chemical instruments and methods, separation methods, chemical/physical processes, etc., can solve the unsatisfactory problems of biological methods, and achieve simple and reasonable equipment structure, convenient operation, and low investment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

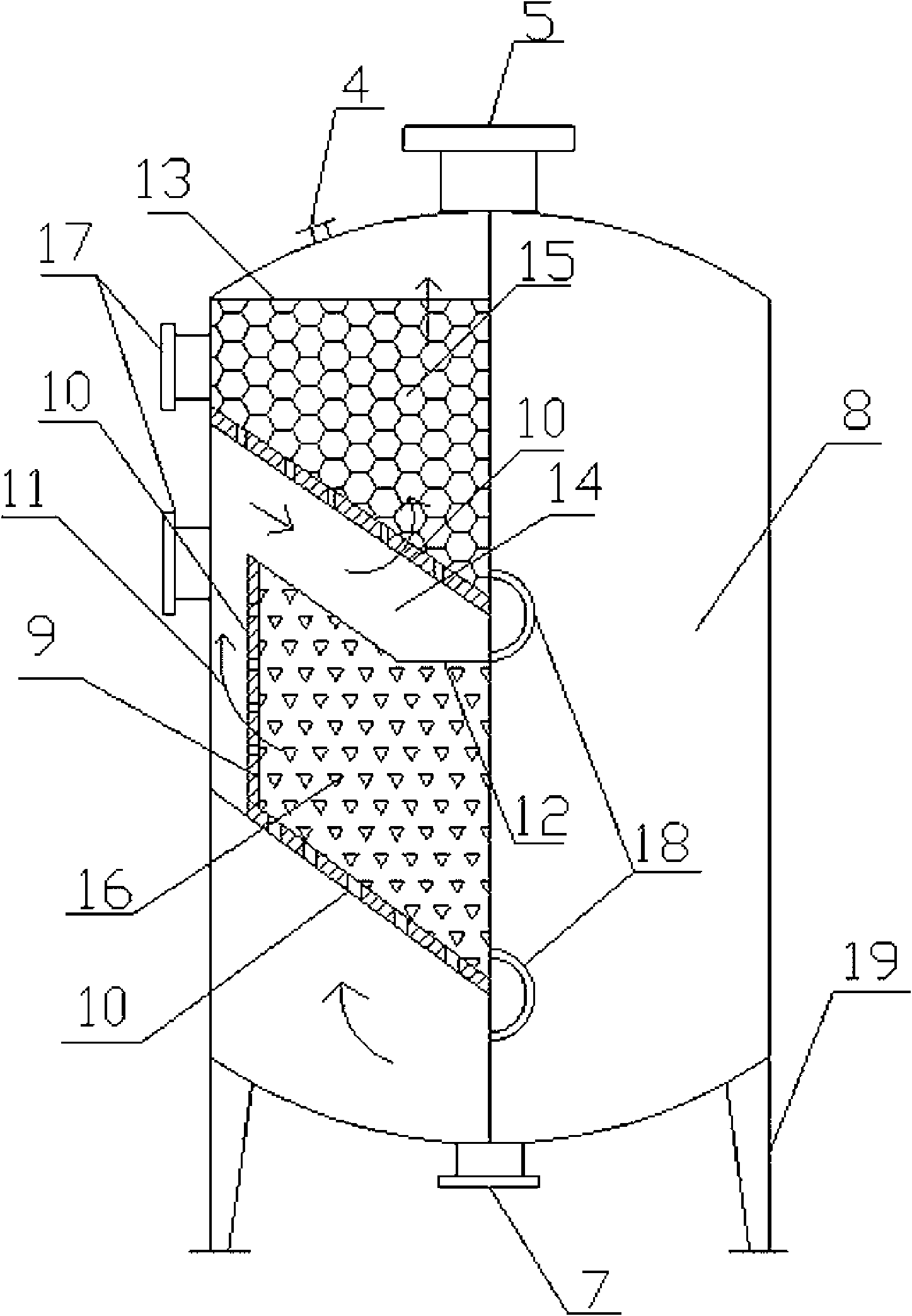

[0024] The working process of the reactor described in Example 2 is: the gas to be purified enters the first filter chamber after entering the air inlet at the bottom, and goes up through the air flow channel on the peripheral wall of the first filter chamber to the point between the top of the first filter chamber and the bottom of the second filter chamber. After entering the conical airflow channel between them, it enters the high-efficiency composite biological enzyme catalytic layer of the second filter chamber, and finally discharges from the top air outlet. Its advantages and effects are reflected in the fact that after the gas to be purified enters the first filter chamber, it needs to go up from the air flow channel on the surrounding wall and then pass through the conical air flow channel. The air flow channel goes up, and the filtered gas can fully contact with the complex biological enzyme catalytic layer of the university, and the dust filtering effect is good.

...

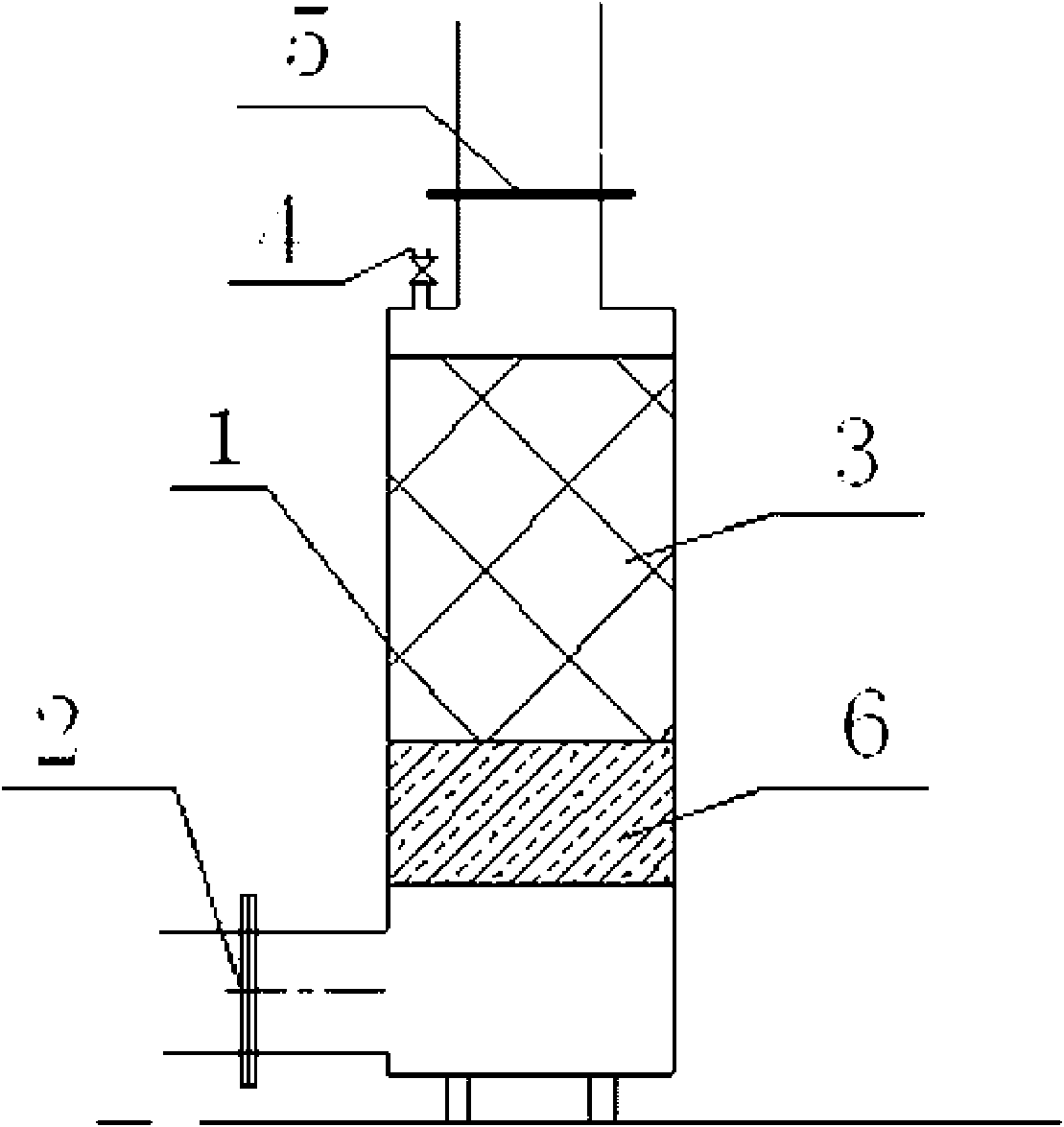

specific Embodiment 1

[0030] Product of the present invention sees in the description of the accompanying drawings figure 2 , comprising a glass fiber reinforced plastic tank body 8, characterized in that: the bottom of the tank body is provided with

[0031] The air inlet 7 is provided with a high-efficiency composite biological enzyme catalytic packing layer 15 on the upper part, and the packing is surrounded by a mesh partition 10. The top of the tank body is connected with the air outlet 5, and the lower part of the inner cavity of the tank is provided with an abalone Filling layer 16 such as Erhuan, the top of the tank body is provided with a safety valve 4, the side wall of the tank body is provided with a feed port 17 and a discharge port 18, and the tank body is supported by feet 19.

[0032] The above-mentioned high-efficiency composite biological enzyme catalytic packing layer is composed of a mesh separator and a high-efficiency immobilized composite biological enzyme composite filler C...

specific Embodiment 2

[0037] According to specific embodiment 1 purification treatment 5000m 3 / h of organic waste gas from painting workshops, in which the content of xylene in the organic waste gas is 16mg / m 3 .

[0038] The organic waste gas containing xylene in the painting workshop enters the gas purification high-efficiency bioreactor through the air inlet at the bottom of the tank, and flows through the high-efficiency composite biological enzyme catalytic packing layer set in the inner cavity of the tank. The high-efficiency composite biological enzyme catalytic packing layer adopts high-efficiency Immobilized composite biological enzyme combination packing CX-TE, high-efficiency composite biological enzyme is composed of one or more enzymes that have a unique catalytic degradation effect on xylene and other organic waste gases, such as peroxidase, etc., through biological enzymes to open xylene pollution The more complex chemical chain in the substance will quickly degrade it into small m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com