Device and process for purifying harmful gas through combining gas-liquid absorption with micro-electrolysis

A harmful gas and process technology, applied in the direction of chemical instruments and methods, dispersed particle separation, separation methods, etc., can solve the problems of micro-electrolysis technology waste gas treatment that have not been seen, and achieve improved absorption effect, large gas volume, and improved absorption capacity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

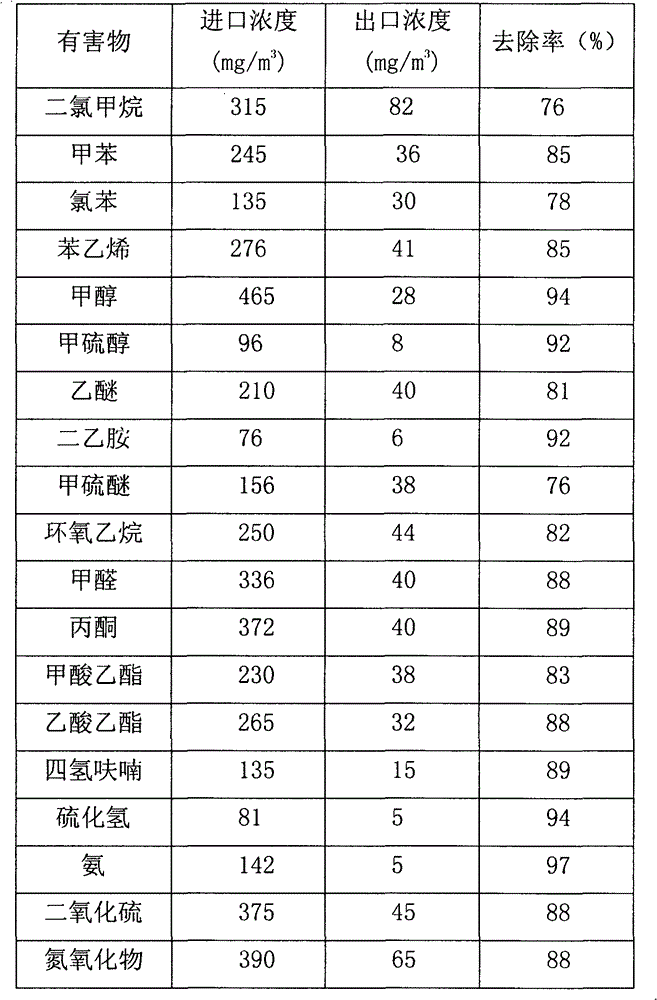

Embodiment 1

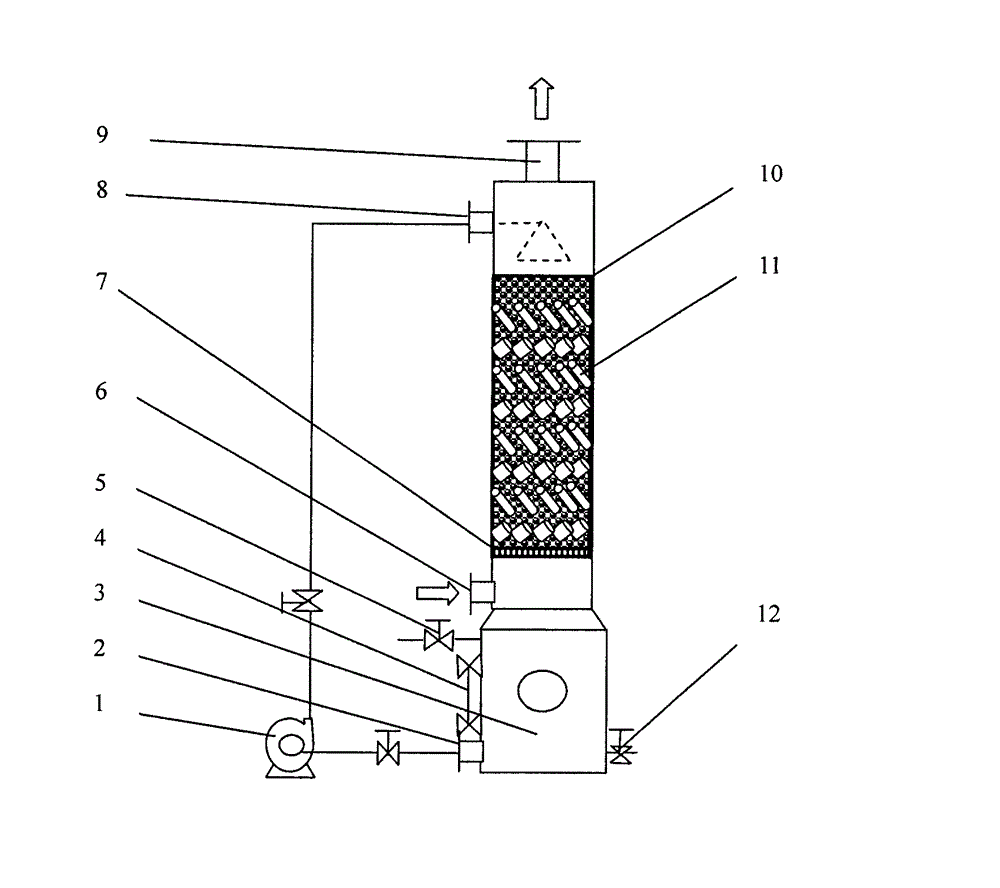

[0015] Example 1: The experimental device system flow is shown in the accompanying drawings. The absorption tower is a packed tower structure, the tower body material is polypropylene, the tower diameter is Ф300mm, and the packing layer height is 2500mm. It is composed of iron Pall rings and activated carbon. Among them, the diameter of the Pall ring is 25mm, and the thickness is 2mm. The diameter of the activated carbon is about 15mm, and the porosity of the filler layer is about 25%. The simulated exhaust gas is introduced from the air inlet at the bottom of the tower, and is discharged from the upper part after passing through the gas-solid-liquid three-phase reaction zone.

[0016] The experimental conditions are: the absorption liquid is 2% sodium chloride aqueous solution + hydrochloric acid. Solution pH=3±0.5.

[0017] Gas flow: 200m 3 / h, gas temperature: 25°C.

[0018] The types of exhaust gas are volatilized with common and representative hydrocarbons, alcohols, ...

Embodiment 2

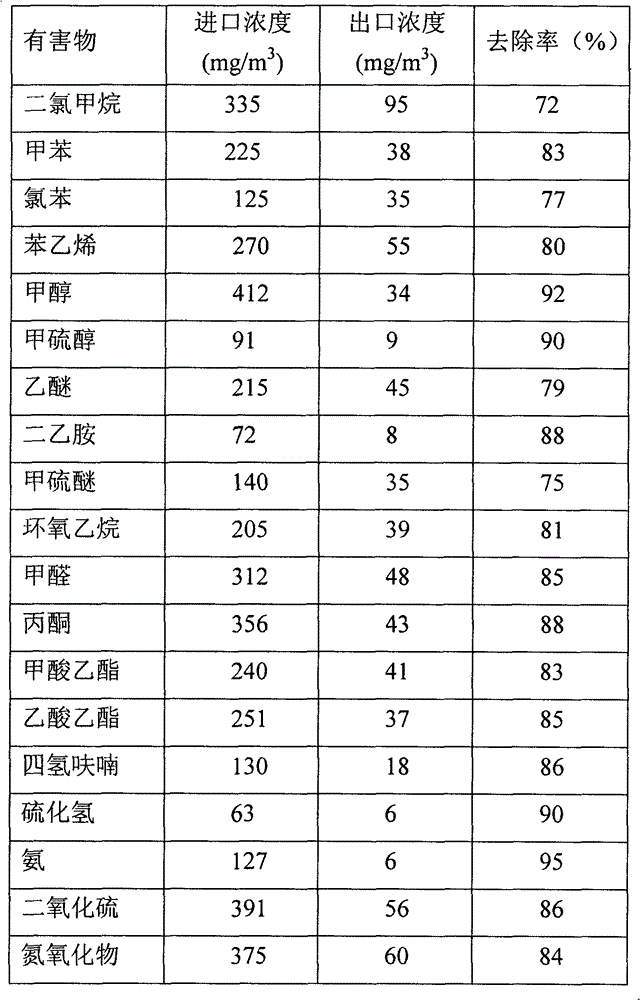

[0025] Embodiment 2: Experimental device The system flow diagram is shown in the accompanying drawing.

[0026] The experimental conditions are: the absorption liquid is 2% sodium sulfate aqueous solution+sulfuric acid. Solution pH=5±0.5.

[0027] Other conditions are with embodiment 1.

[0028] Experimental results: as shown in Table 2.

[0029] Table 2 Harmful substance removal effect

[0030]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com