A Cyclone Inertial Dust Collector with Double Isolation Chambers

A technology of double isolation chambers and dust collectors is used in cyclone devices, devices whose axial directions of cyclones can be reversed, etc., which can solve the problems of large resistance, poor separation ability of fine dust and high energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

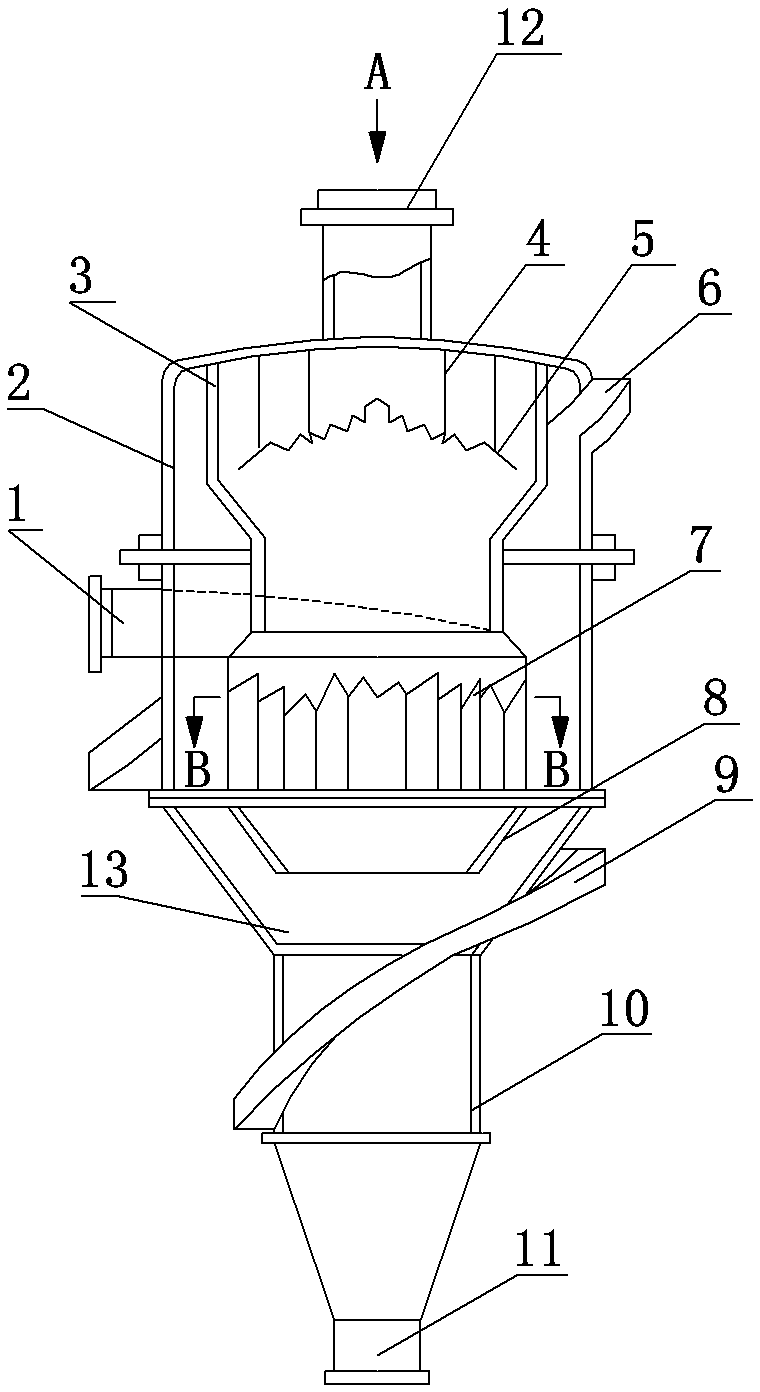

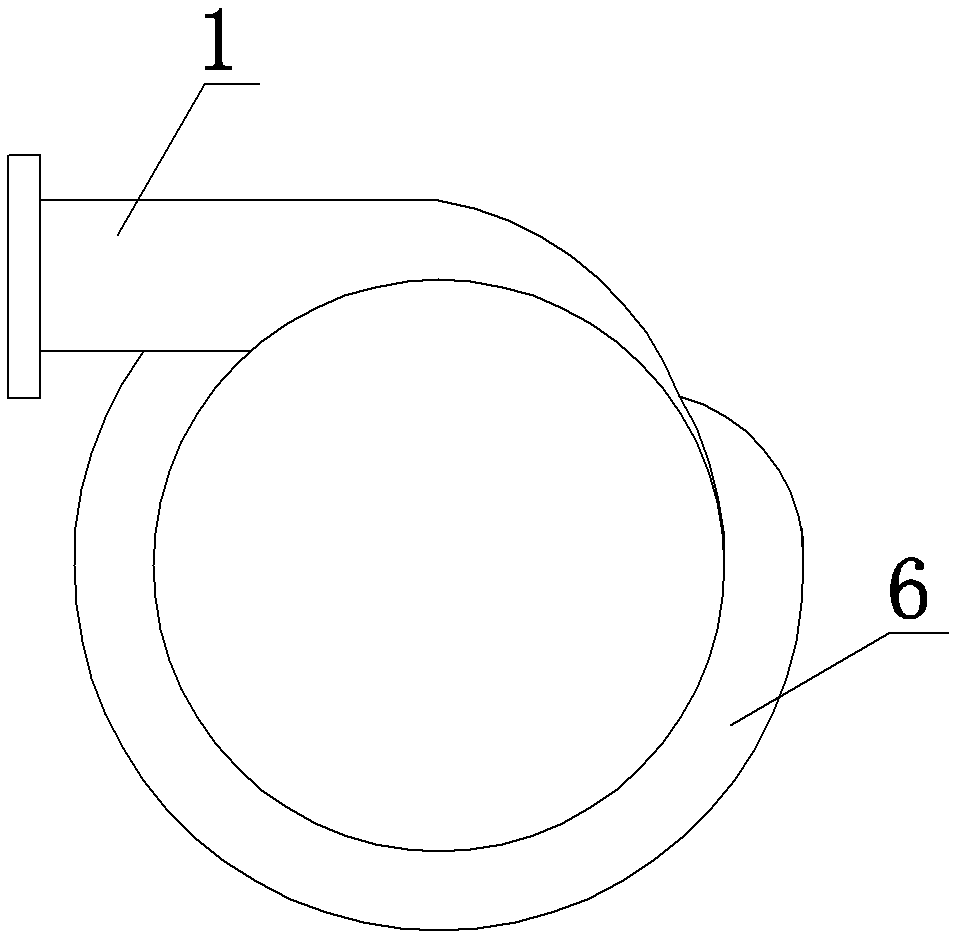

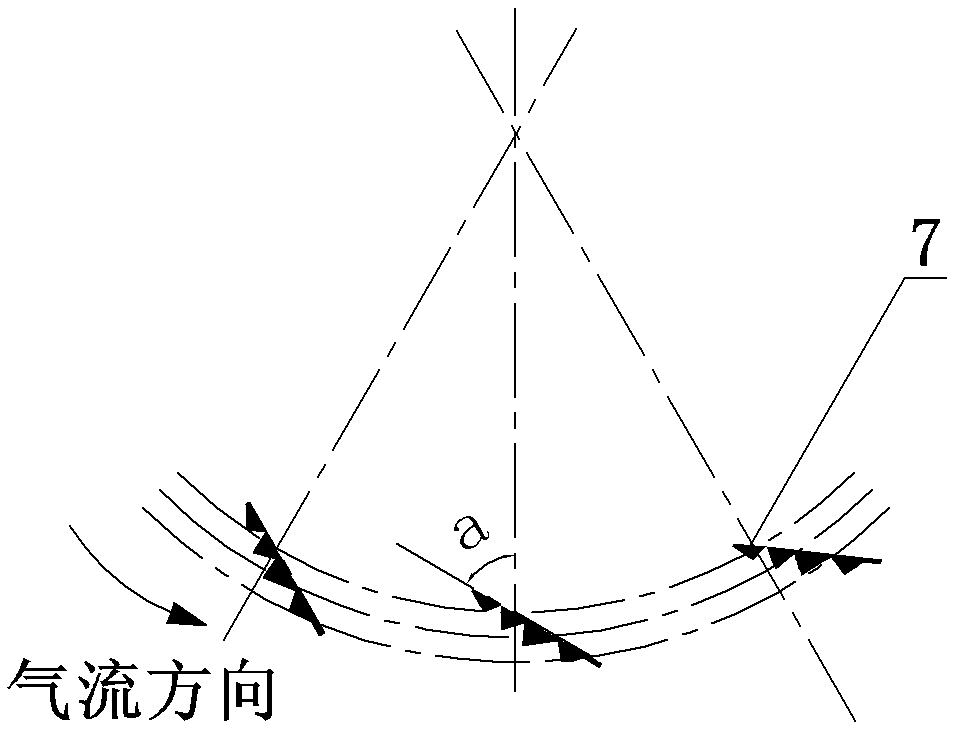

[0012] Such as Figure 1~Figure 3 As shown, the present invention includes a dust removal cylinder, the dust removal cylinder is a closed cylinder composed of an upper cylinder 2 and a lower cylinder 10, an air inlet 1 is arranged on the upper cylinder 2, and The air port 1 is connected tangentially to the upper cylinder 2, and an exhaust pipe 12 is arranged on the top of the upper cylinder 2, and the exhaust pipe 12 extends into the interior of the upper cylinder 2, and the exhaust pipe 12 is provided with an exhaust pipe. The position of the air inlet 1 is lower than that of the exhaust port, and a spiral bypass chamber 6 communicating with it is provided on the upper cylinder 2, and a bypass chamber 6 communicating with it is provided on the lower cylinder 10. The spiral bypass chamber two 9, that is, bypass chamber one 6, bypass chamber two 9 are spiral isolation chambers; the top of the upper cylinder 2 near the exhaust pipe 12 is provided with a core pipe 3, and the core...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com