Method for purifying harmful waste gas by combination of absorption and microelectrolysis and special device thereof

A harmful gas, micro-electrolysis technology, applied in chemical instruments and methods, separation methods, dispersed particle separation, etc., can solve the problems of waste gas treatment that have not been seen in micro-electrolysis technology, improve absorption effect, avoid secondary volatilization, operation simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

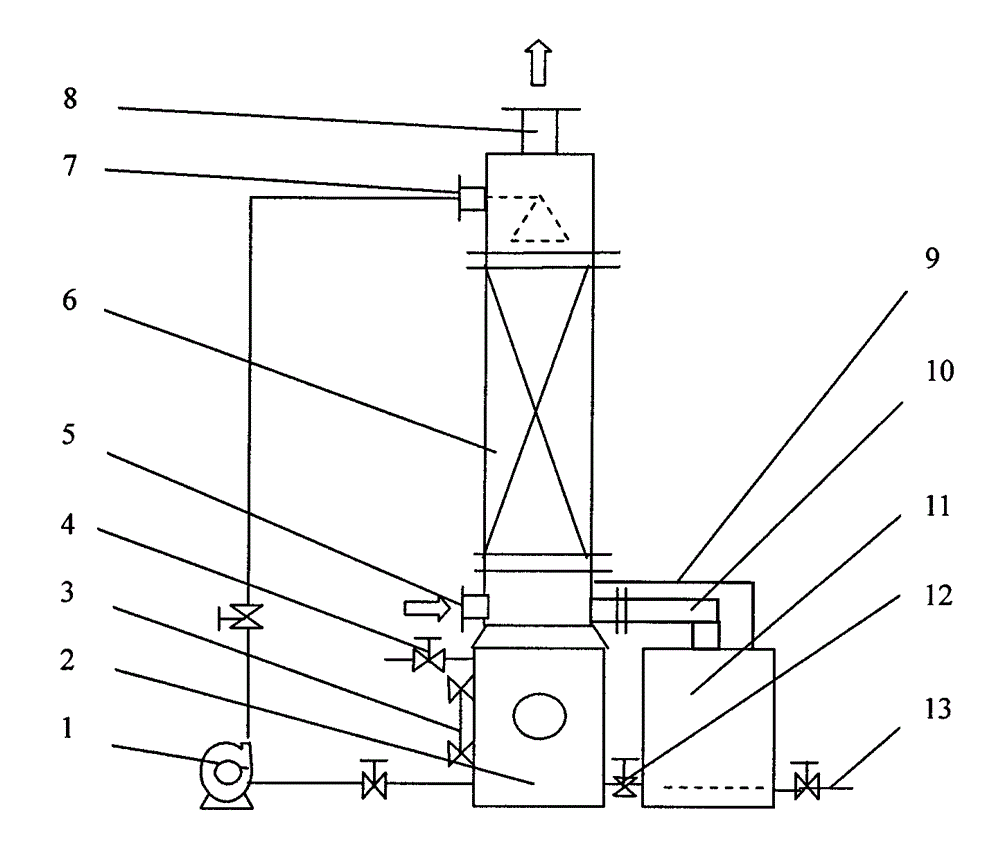

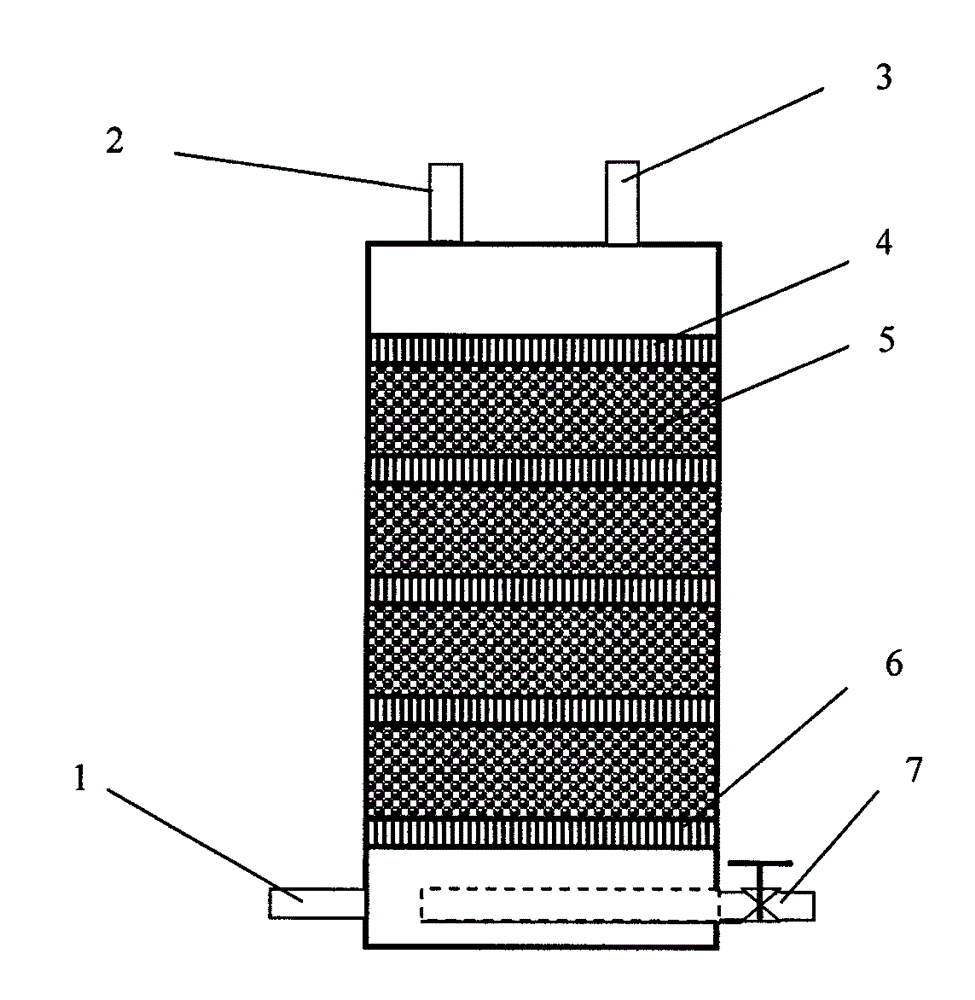

[0021] Embodiment 1: Experimental device system flow such as figure 1 As shown, the micro-electrolysis reactor adopts figure 2 structure shown. The material of the outer body of the reactor is polypropylene, the size is 400mm×400mm×1200mm, the distance between adjacent iron nets is 50mm, the thickness of the iron net is 2mm, and the mesh size is 5mm×5mm. The active carbon particles used as the mobile electrode have an average geometric diameter of about 1 mm and a filling rate of about 15% in the liquid phase. The absorption tower is a packed tower, the tower diameter is Ф300mm, the height of the packing layer is 2500mm, and the packing is polypropylene ladder ring. The simulated exhaust gas enters through the air inlet at the bottom of the tower, passes through the absorption reaction zone, and is discharged from the upper part.

[0022] The experimental conditions are: the absorption liquid is 2% sodium chloride aqueous solution + hydrochloric acid. Solution pH=3±0.5. ...

Embodiment 2

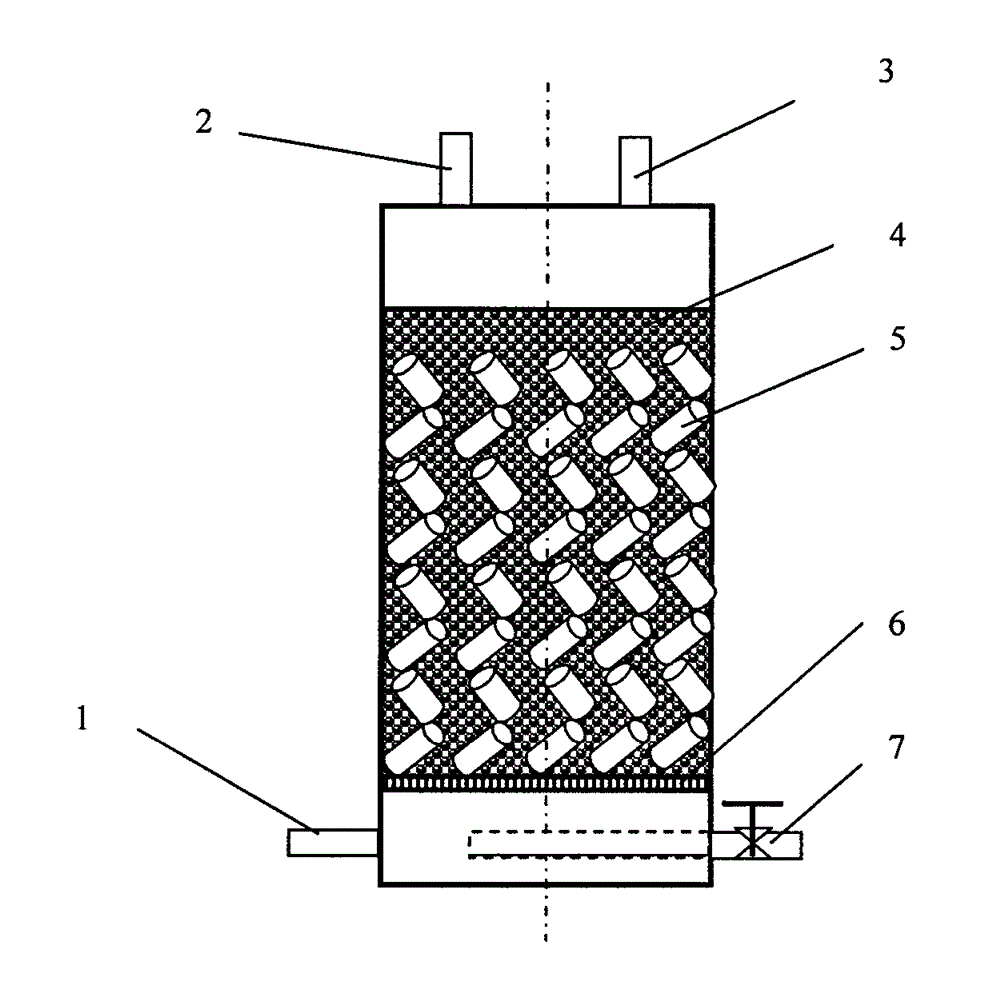

[0031] Embodiment 2: experimental device system flow such asfigure 1 As shown, the micro-electrolysis reactor adopts image 3 structure shown. The micro-electrolysis reactor adopts a cylindrical structure, the cylinder material is polypropylene, the diameter is 150mm, the effective height is 800mm, the diameter of the iron Pall ring is 25mm, and the thickness is 2mm. The active carbon particles used as the mobile electrode have an average geometric diameter of about 1 mm and a filling rate of about 15% in the liquid phase. The absorption tower is a packed tower, the tower diameter is Ф300mm, the height of the packing layer is 2500mm, and the packing is polypropylene ladder ring. . The simulated exhaust gas enters through the air inlet at the bottom of the tower, passes through the absorption reaction zone, and is discharged from the upper part.

[0032] The experimental conditions are: the absorption liquid is 2% sodium sulfate aqueous solution+sulfuric acid. Solution pH=5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com