Super-gravity ammonia removal device and ammonia removal method

A hypergravity, ammonia concentration technology, applied in separation methods, chemical instruments and methods, gas treatment, etc., can solve the problems of low absorption efficiency, small reaction contact area, uneven distribution of gas and liquid, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to make the above objects, features and advantages of the present invention more comprehensible, specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

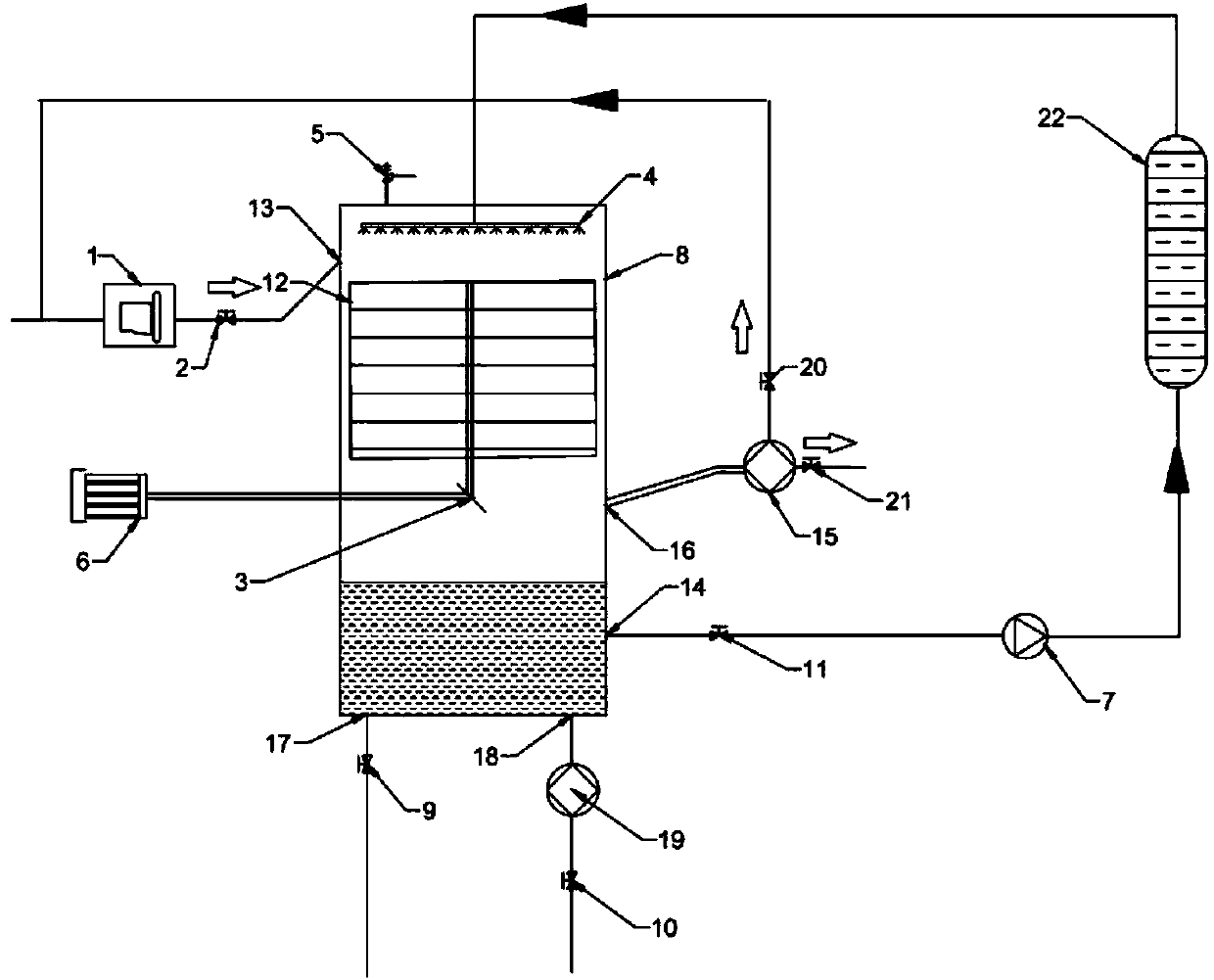

[0036] Such as figure 1 Shown: is a kind of supergravity ammonia removal device of the present invention, including a box body 8, an explosion-proof motor 6, a liquid circulation circuit and a gas circulation circuit, and the liquid circulation circuit includes a water outlet 14 arranged on the box body 8 And the fourth regulating valve 11, the water pump 7, the heat exchanger 22 and the shower head 4 that communicate with the water outlet 14 in sequence, and the gas circulation circuit includes the blower fan 1, the first regulating valve 2, the The air inlet 13 on one side of the casing 8, the gas outlet 16 on the other side of the casing 8 and the ammonia concentration detection device 15, the outlet of the ammonia concentration detecti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mesh | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com