After-boosted turbo expander for gas bearing

A technology of gas bearings and supercharged turbines, which is applied to bearings, shafts, bearings, mechanical equipment, etc., can solve the problems of low reliability, small processing gas volume, and low efficiency, and achieve high reliability and large processing gas volume.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The best mode for carrying out the present invention will be described below with reference to the drawings.

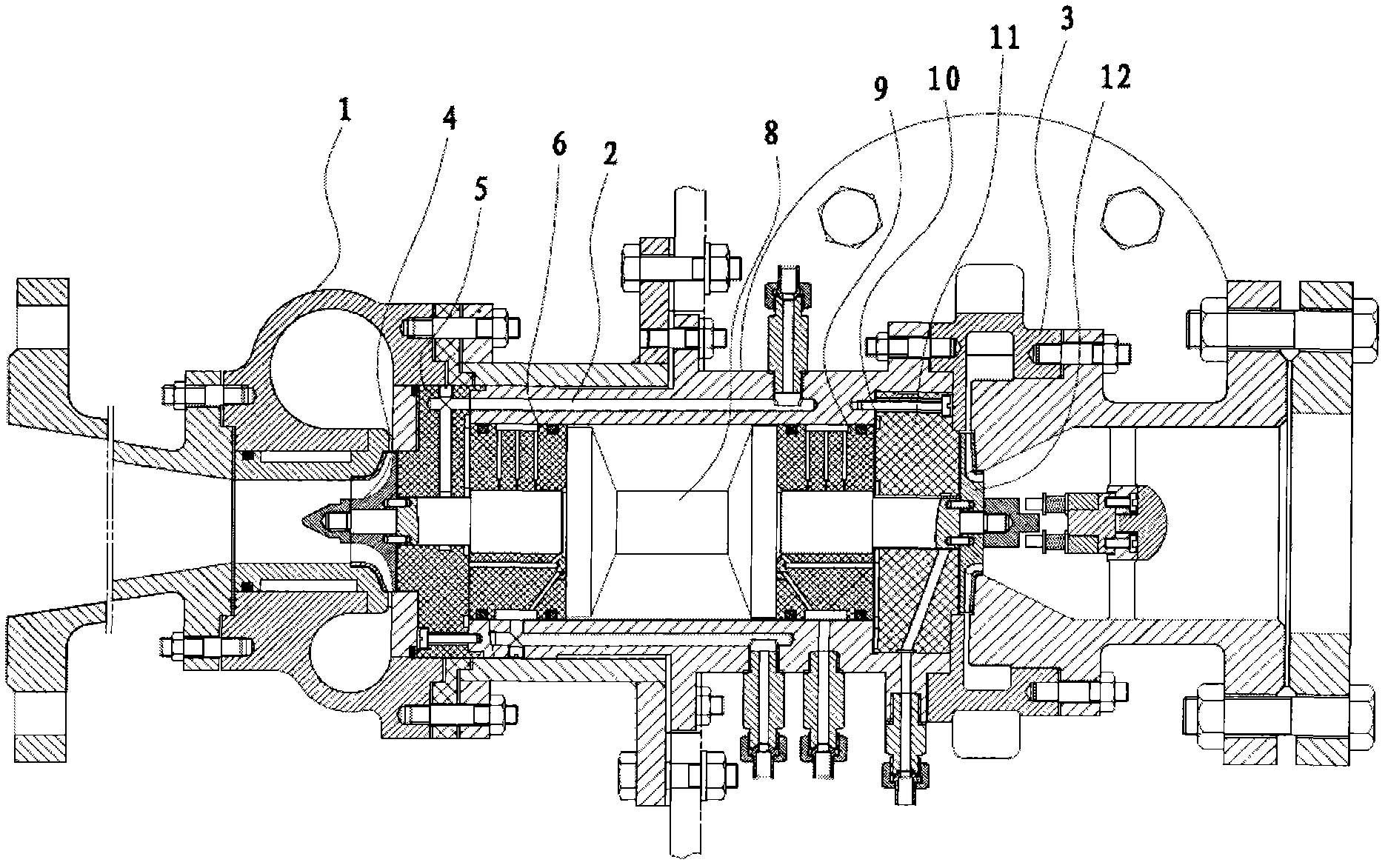

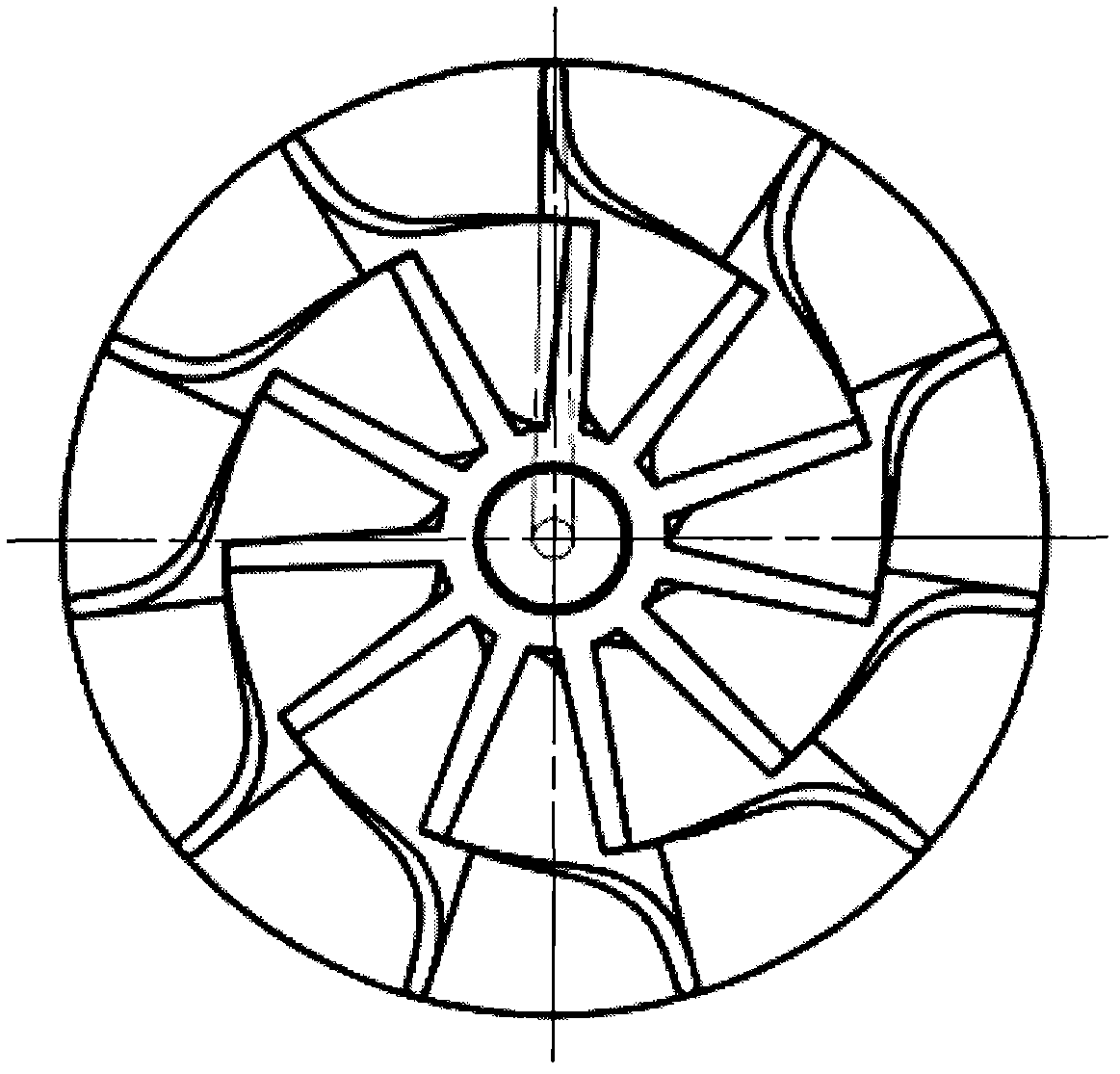

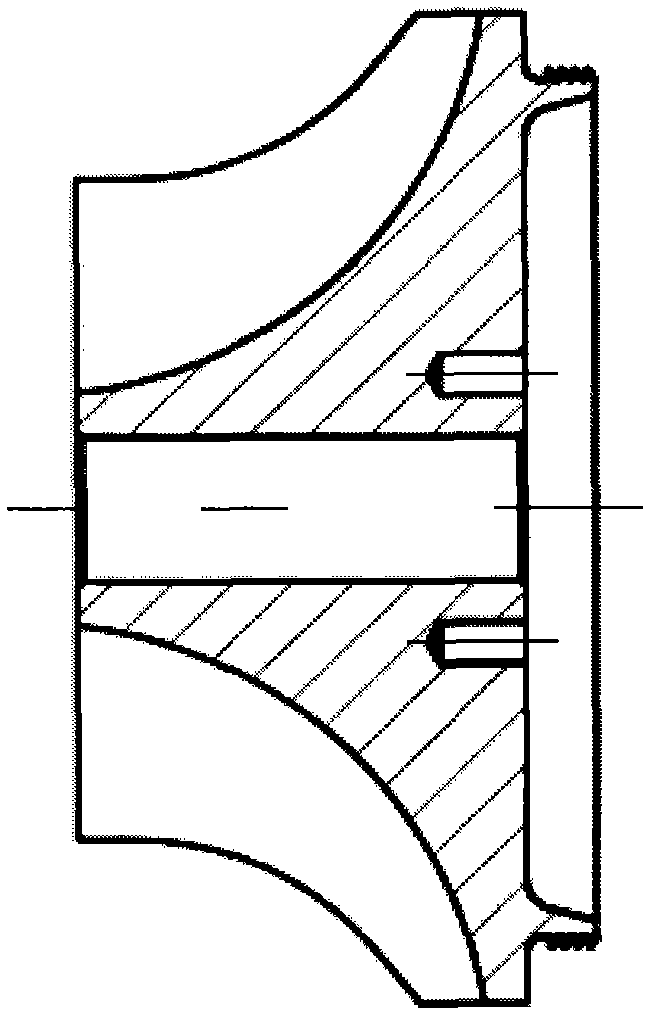

[0021] Such as figure 1 As shown, the gas bearing post-supercharged turbo expander involved in the present invention includes an intermediate casing 2, a turbine volute 1 is installed on the left end of the intermediate casing 2, and a turbocharger volute 3 is installed on the right end of the intermediate casing 2. A rotor 8 is rotatably arranged in the middle casing 2, and an expansion wheel 4 and a supercharging wheel 12 are respectively arranged in the turbine volute 1 and the turbocharger volute 3 at both ends of the rotor 8. It should be noted that: the rotor 8 is sleeved with a left gas bearing 6 and a right gas bearing 9, the left gas bearing 6 is used to support the expansion wheel 4, and the right gas bearing 9 is used to support the supercharging wheel 12 . The expansion wheel 4 is a high-efficiency radial-axis flow centripetal reaction type; the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com