Steam-water separation corrugated plate and separation device

A steam-water separator and a technology for steam-water separation, which are applied in separation methods, dispersed particle separation, chemical instruments and methods, etc., can solve the problem of difficult processing and ensure the manufacturing accuracy of corrugated plates, the separation efficiency cannot meet the design requirements, and the separator equipment is bulky. and other problems, to achieve the effect of reducing secondary carry, increasing the effective flow area, and improving the separation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

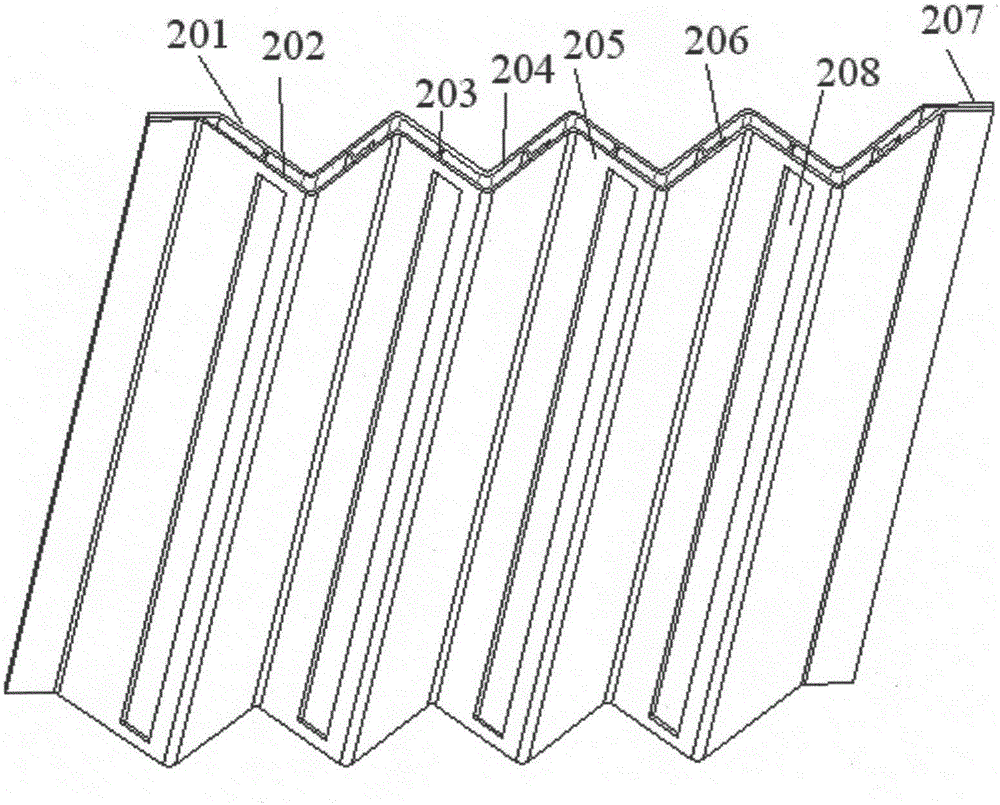

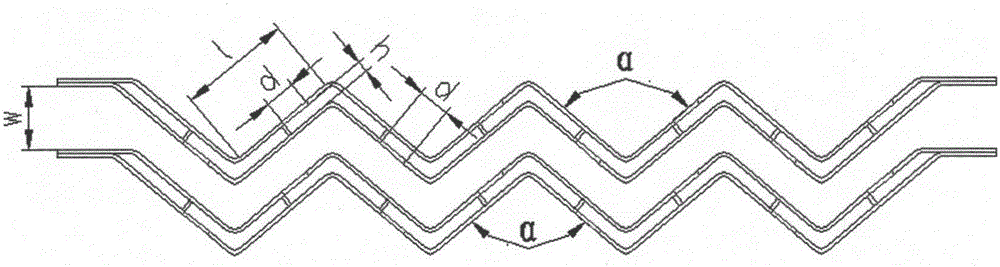

[0025] figure 1 and figure 2 The three-dimensional and planar structural diagrams of the steam-water separation corrugated plate provided in this embodiment are respectively, and the steam-water separation corrugated plate is composed of two hookless corrugated plate combination plates 201, 202, and the middle of the two hookless corrugated plate combination plates 201, 202 The corrugated sections have the same profile and are arranged in parallel to ensure that the gap between the plates remains unchanged, and the corrugated section in the middle is welded and fixed by the connecting plate 203, and the straight plate sections 207 at the two ends of the two hookless corrugated plate composite plates 201 and 202 are partially overlapped and connected. Fixed to form a double-layer hollow plate structure.

[0026] A hydrophobic channel 206 is formed in the hollow between the two hookless corrugated board composite boards 201 and 202 . Drain outlet 208 is set on the windward si...

Embodiment 2

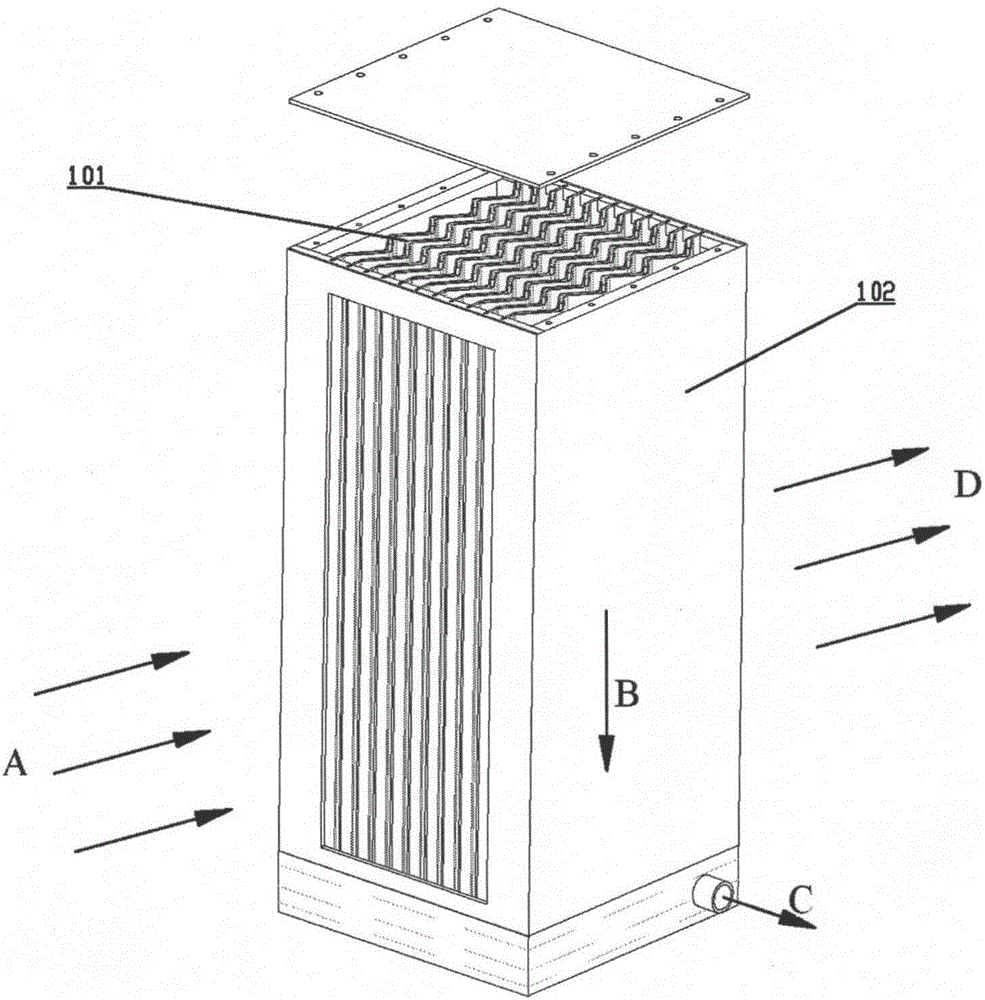

[0034] image 3 The structure schematic diagram of the corrugated plate steam-water separator provided in this embodiment, the corrugated plate steam-water separator includes a housing 102, and several steam-water separating corrugated plates 101 provided in Embodiment 1 are arranged in the housing 102 .

[0035] combine Figure 4 , a number of steam-water separation corrugated plates 101 are equally spaced and parallel arranged in the housing 102, and steam-water separation channels are formed between adjacent steam-water separation corrugated plates 101, Figure 4 The middle arrow indicates the air flow direction.

[0036] combine Figure 5 , the housing 102 consists of a cover plate 301, a distance plate 302, a sealing baffle 303, a windshield 304, a corrugated plate support plate and a hydrophobic buffer plate 305, a hydrophobic groove 306, a cover fixing strip 307, a housing side plate 308 and Drainage pipe 309 is formed, sealing baffle 303 and windshield 304 jointly f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com