High-concentration odor pollutant waste gas treatment equipment

A technology for treating equipment and pollutants, which is applied to the separation of dispersed particles, chemical instruments and methods, and filtration of dispersed particles. It can solve the problems of poor control of microbial activity, difficulty in guaranteeing treatment efficiency, and long time periods, etc., and achieves a small footprint. , Stable work and small investment in equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

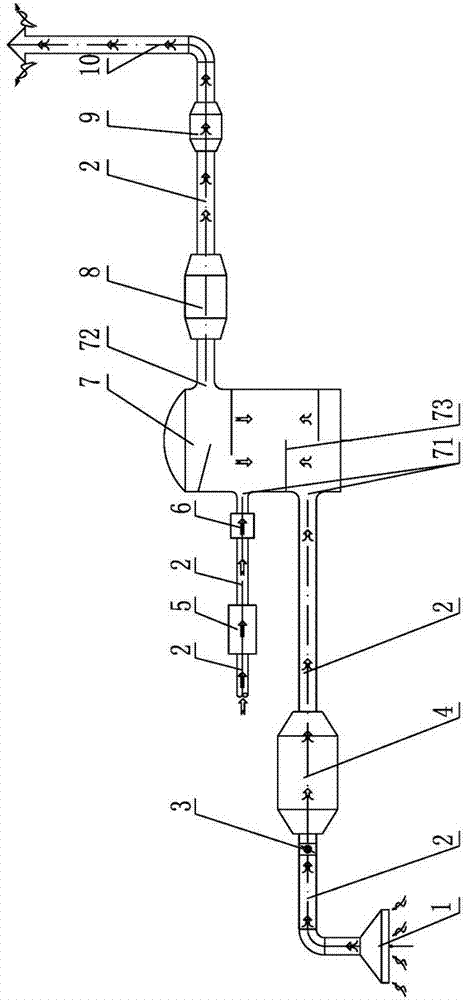

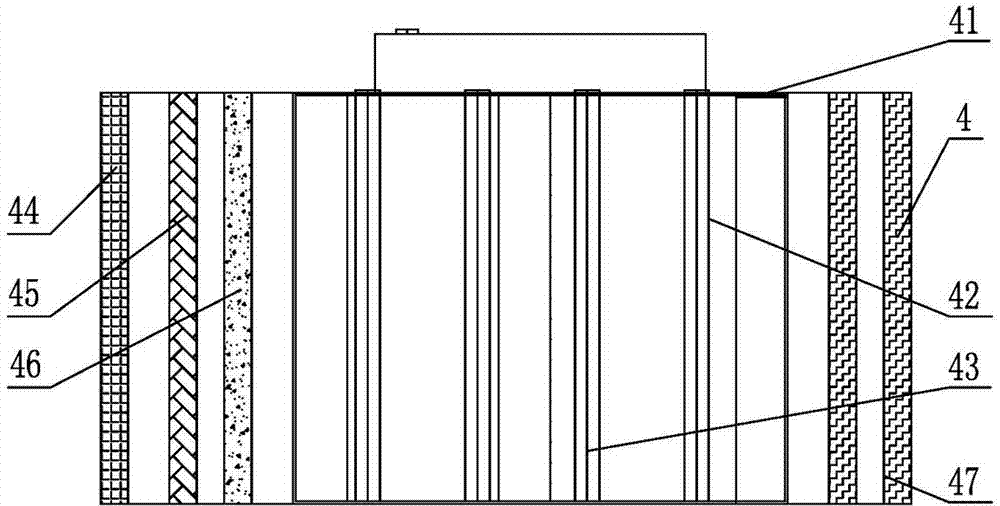

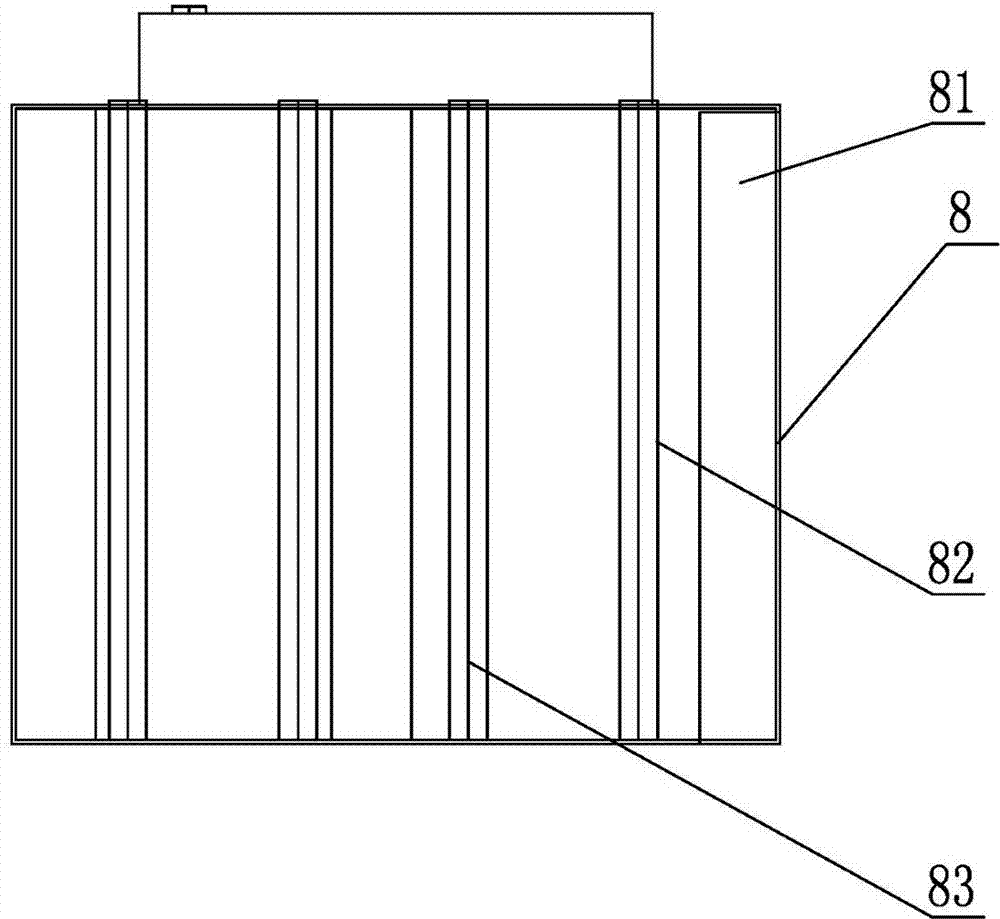

[0028] Figure 1 to Figure 3The reference numerals in the figure are: gas collecting hood 1; pipeline 2; control valve 3; plasma integrated device 4; plasma integrated box 41; high-energy plasma generating device 42; Flow layer 44; Filter paper 45; Non-woven cotton 46; Activated carbon adsorption layer 47; Ozone generator 5; 72 ; deflector 73 ; UV photocatalytic device 8 ; UV photocatalytic box 81 ; UV generator 82 ; UV lamp 83 ;

[0029] Such as Figure 1 to Figure 3 As shown, a treatment equipment for high-concentration malodorous pollutant waste gas includes a plasma integration device 4 connected through a pipeline 2, an ozone generator 5, an oxidation purification tower 7 and a photolysis catalytic device, wherein the plasma integration The oxidation device 4 and the ozone generator 5 are respectively connected to the two air inlets of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com