Method for setting pretilt angle of liquid crystal molecules

A liquid crystal molecule, pre-tilt technology, applied in nonlinear optics, instruments, optics, etc., can solve the problems of reducing the production efficiency of liquid crystal displays, large changes in pre-tilt angle, different settings, etc., to eliminate image retention and improve production efficiency. , to ensure the effect of contrast

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] In order to further illustrate the technical means adopted by the present invention and its effects, the following describes in detail in conjunction with preferred embodiments of the present invention and accompanying drawings.

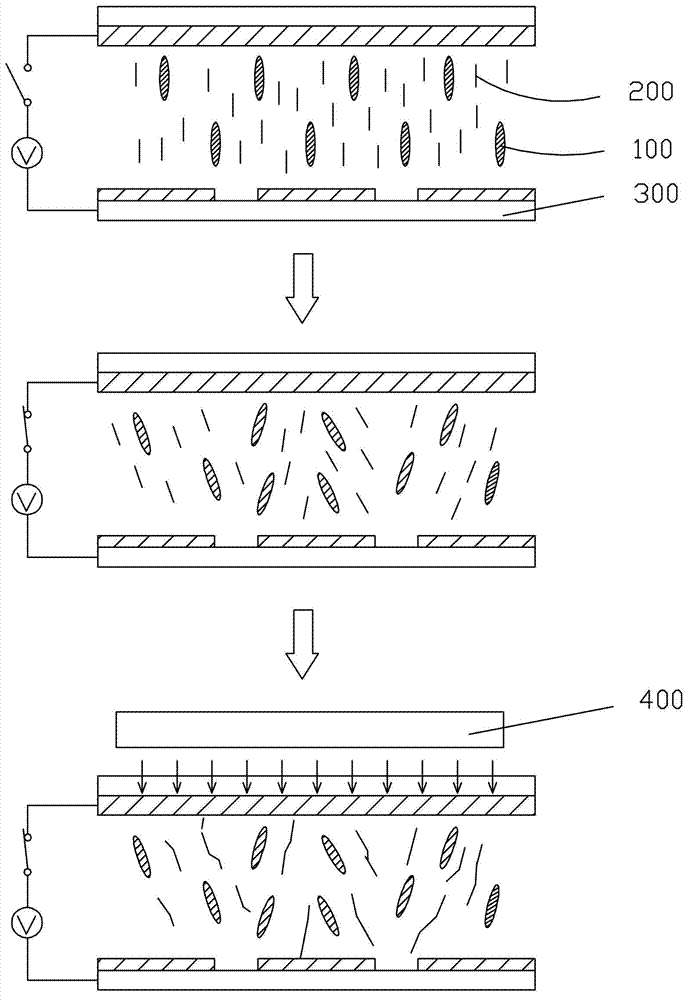

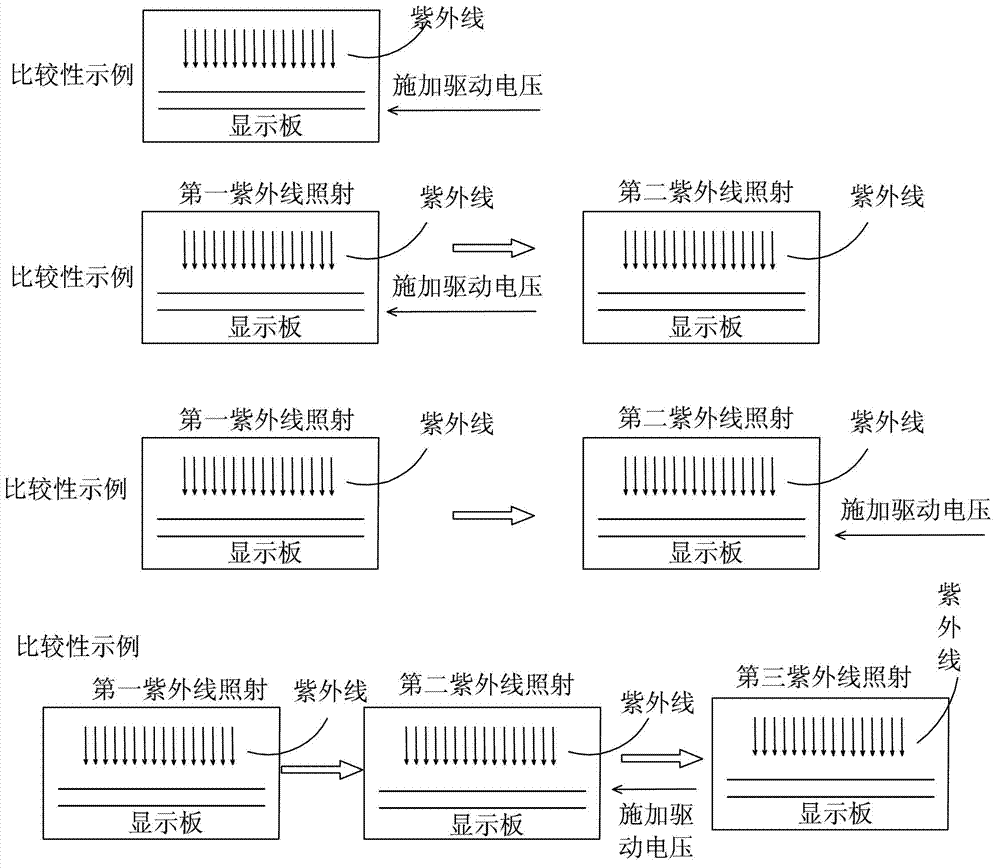

[0047] see Figure 4-6 , the present invention provides a method for setting the pretilt angle of liquid crystal molecules, comprising the following steps:

[0048] Step 1. Provide liquid crystal material, CF (color filter, color filter) substrate and TFT (Thin Film Transistor, thin film field effect transistor) substrate;

[0049] The TFT substrate is provided with a light-shielding pattern, and the liquid crystal material includes: polymer monomers and liquid crystal molecules that can be photopolymerized or thermally polymerized, and the polymer monomers that can be photopolymerized or thermally polymerized are polymerized under the irradiation of an ultraviolet light source. The stronger the strength, the faster the polymerization rate. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com