Liquid crystal display panel, manufacturing method thereof, and liquid display device

A liquid crystal display panel and liquid crystal display device technology, applied in nonlinear optics, instruments, optics, etc., can solve the problems of light transmittance change and uneven display of liquid crystal display devices, and achieve uniform light transmittance and thick liquid crystal cells Even, improve the effect of display unevenness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

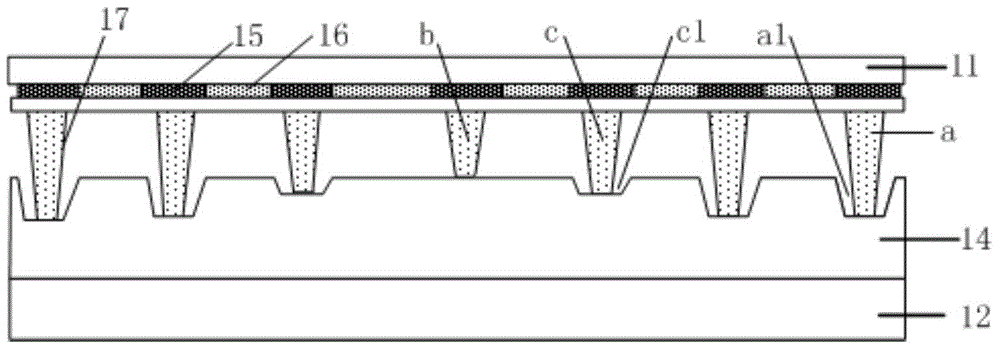

[0040] Such as Figure 4 Shown is a cross-sectional view of the liquid crystal display panel provided by Embodiment 2 of the present invention, and the supporting pillars in the liquid crystal display panel are the main supporting pillars.

[0041] Specifically, the liquid crystal display panel includes:

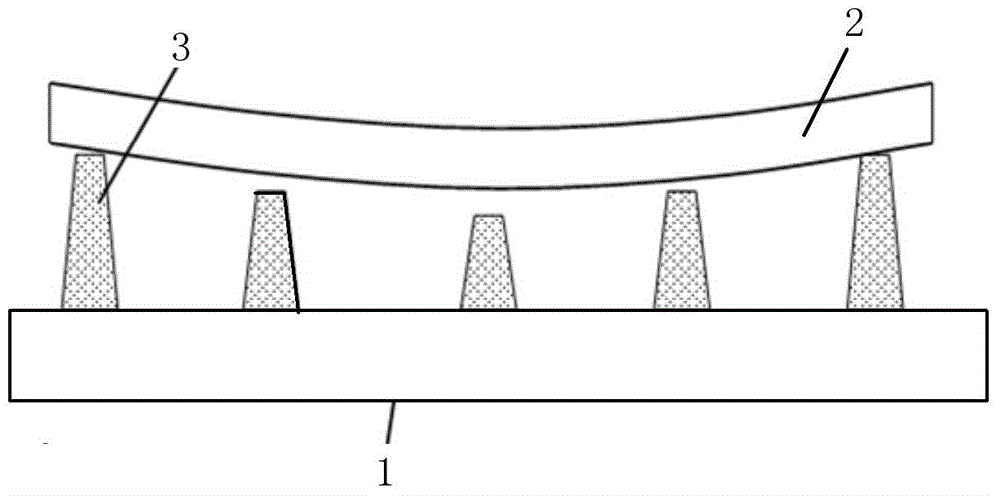

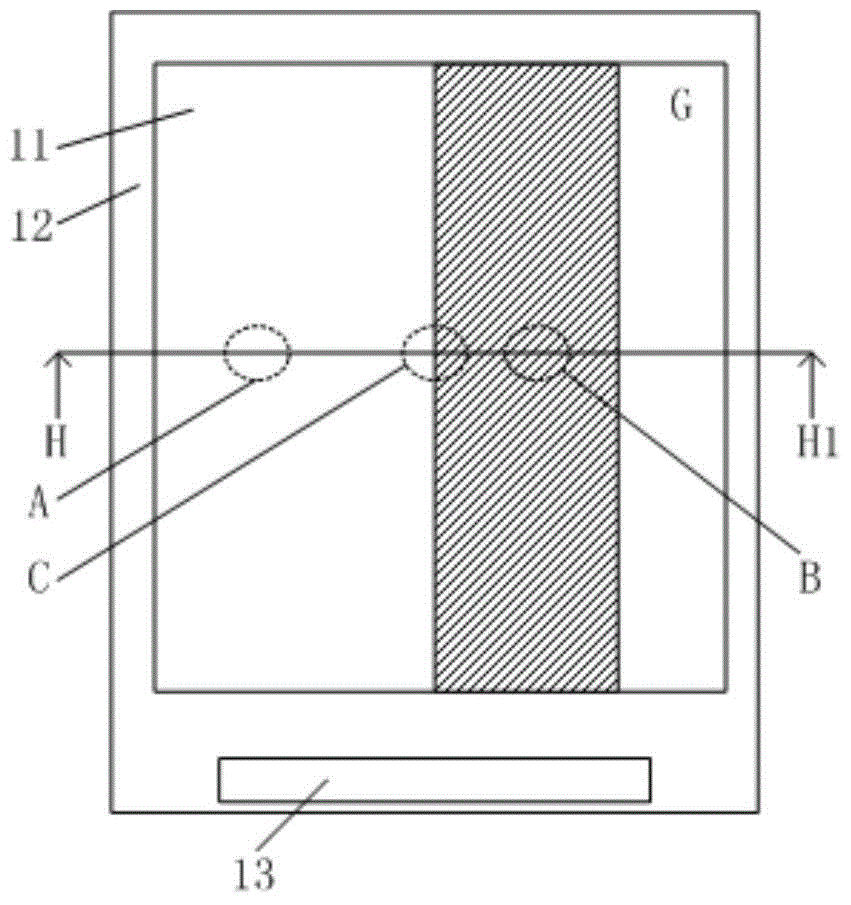

[0042] The first substrate 11, the second substrate 12 opposite to the first substrate 11, a plurality of support columns arranged between the first substrate 11 and the second substrate 12, the plurality of support columns include main support columns 17 and auxiliary support columns. Support columns 18, wherein the diameter of the main support columns 17 is greater than the diameter of the auxiliary support columns 18, the first end of each support column is connected to the first substrate 11, the thin film structure 14 arranged on the second substrate 12, the thin film structure 14 The surface of the film structure 14 is provided with a concave-convex structure, and the...

Embodiment 3

[0046] Figure 5a It is a schematic diagram of the height distribution of the prisms of the exposure machine in the production process of the liquid crystal display panel. In the process of making the support column, because the exposure energy of the prism connection part of the exposure machine is smaller than that of the normal area, generally 15mj, the exposure machine can Ultraviolet light is used for exposure, and the exposure is divided into two parts, so that the height of the support column corresponding to the prism connection part of the exposure machine is lower than the height of the support column in the normal area. Such as Figure 5a As shown, for example: in the connecting part of the exposure machine prism M4 and the exposure machine prism M5, the length of the exposure machine prism tip is 16.8mm, and the length of the exposure machine prism after removing the prism tip is 105mm. Different exposure machines There are different exposure machine prism lengths...

Embodiment 4

[0058] Such as Figure 8 Shown is a cross-sectional view of the liquid crystal display panel provided by Embodiment 4 of the present invention. In this embodiment, the first ends of each support column are arranged on the color filter substrate, and the second ends of the support columns are in contact with the surface of the film structure. , each support column is the same as the support column in the third embodiment of the present invention, and the difference from the third embodiment is that the film structure on the array substrate in this embodiment includes spacers with different heights, each of the spacers The surface of the mat is in contact with the second end of the main support column.

[0059] Specifically, such as Figure 5b and Figure 8 As shown, spacers with different heights can be set on the film structure 14, and the supporting columns 171 are Figure 5b The support column corresponding to the middle area E, the support column 172 is Figure 5b The s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com