Processing method for honeysuckle

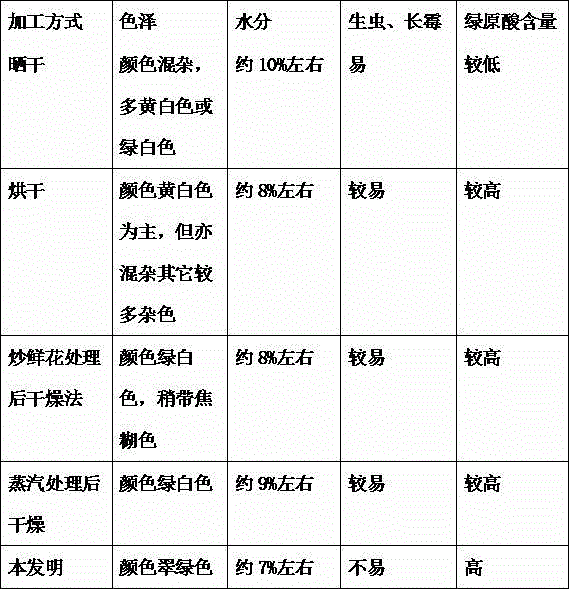

A processing method, the technology of honeysuckle, applied in tea treatment before extraction, etc., can solve the problems of mold-prone chlorogenic acid content, poor color of honeysuckle, prone to insects, etc., to avoid the loss of chlorogenic acid, emerald green color, and not easy to grow The effect of fungus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] Embodiment 1: a kind of honeysuckle processing method, concrete steps are as follows:

[0015] a. Flower picking time: The flower picking time is from 9:00 am to 12:00 am, and it is not suitable for picking on dew or rainy days; because the honeysuckle picked in the morning has not been exposed to the sun and the loss of medicinal ingredients is less;

[0016] b. Fixing: kill the picked flowers in time; use a fixing machine to quickly fix the honeysuckle, the fixing temperature is 115°C, the finishing time is 28 seconds, and the weight of each honeysuckle is 190g. After finishing, the honeysuckle should be spread out in time cold;

[0017] c. Drying: After the honeysuckle is finished and cooled, it is quickly dried in an oven; the temperature of the hot air in the oven is gradually increased from bottom to top, and the temperature of the hot air is from bottom to top. The temperature of the upper part is 48°C, check the drying condition of each layer every 15 seconds, ...

Embodiment 3

[0022] Embodiment 3: a kind of honeysuckle processing method, concrete steps are as follows:

[0023] a. Flower picking time: The flower picking time is from 9:00 am to 12:00 am, and it is not suitable for picking in dew or rainy days;

[0024] b. Fixing: kill the picked flowers in time; use the fixing machine to quickly fix the honeysuckle, the fixing temperature is 125°C, the finishing time is 34 seconds, and the weight of each honeysuckle is 210g. After finishing, the honeysuckle should be spread out in time cold;

[0025] c. Drying: After the honeysuckle is finished and cooled, it is quickly dried in an oven; the temperature of the hot air in the oven is gradually increased from bottom to top, and the temperature of the hot air is from bottom to top. The temperature of the upper part is 55°C, check the drying condition of each layer every 20 seconds, and take out the dried honeysuckle from the lower layer; After the lower layer of honeysuckle is dried, the honeysuckle ab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com