Patents

Literature

73results about How to "Color emerald green" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

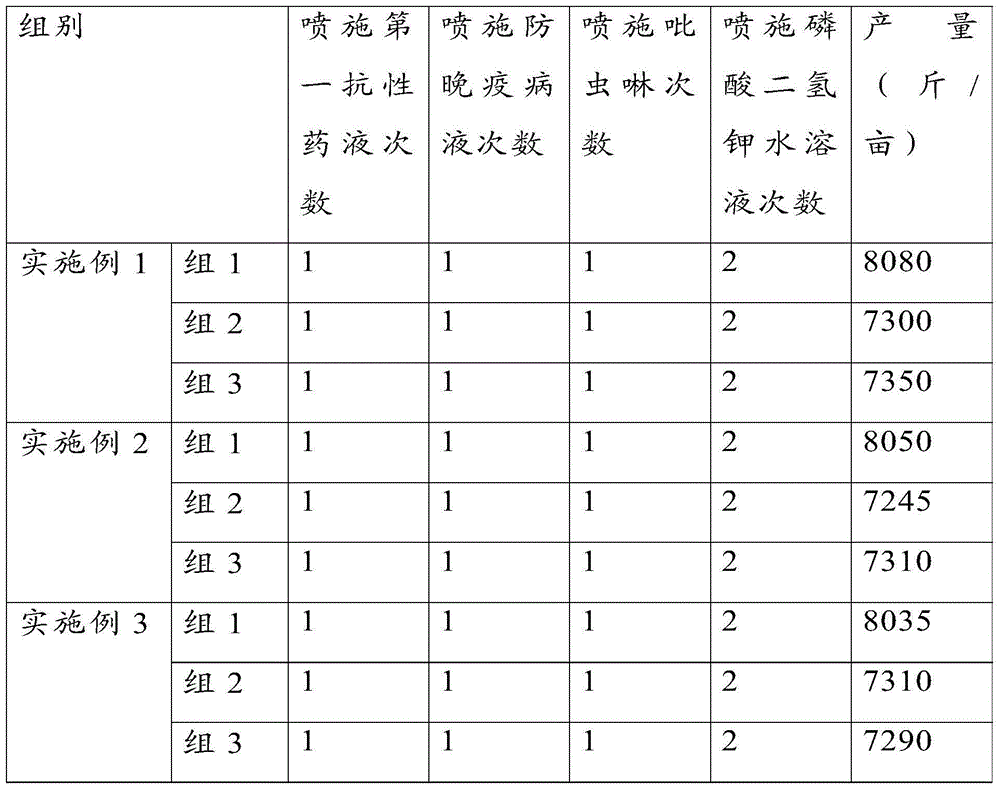

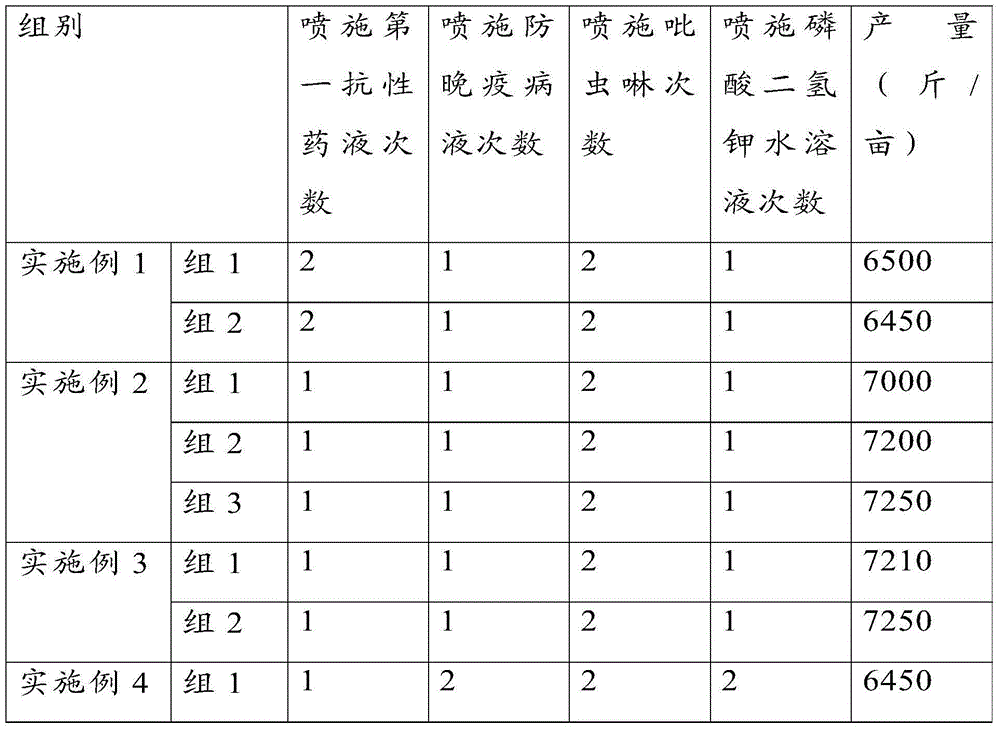

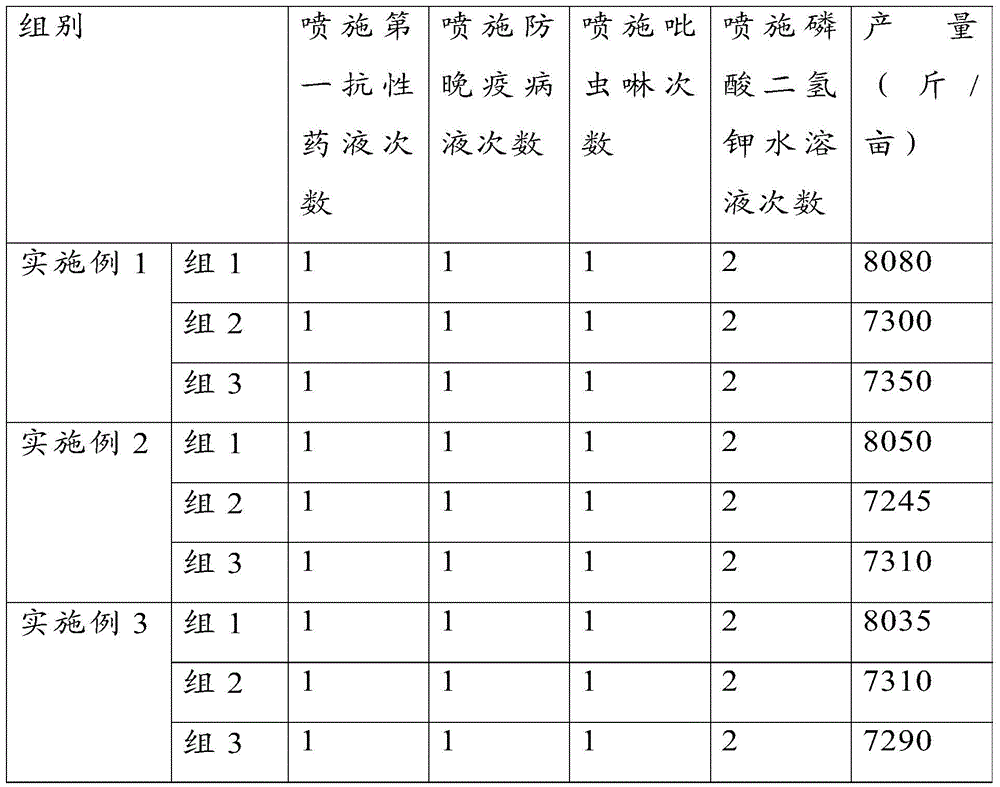

Method for planting potatoes

InactiveCN104472165AWarming up fastNo effectSeed and root treatmentPlant cultivationGround temperaturePlastic mulch

The invention relates to the field of crop planting, and particularly to a method for planting potatoes, which comprises the following steps: preparing land, fertilizing, and ditching; putting the potato seedlings into ditches, ridging, covering soil, covering parts on ridges, where the potato seedlings are planted, with colorless and transparent film, and covering two sides of the colorless and transparent film with black film; conducting field management, and harvesting potatoes. The method adopts the colorless and transparent film and the black film, which are in a matched manner, to plant the potatoes, the colorless and transparent film has good light transmittance and increases temperature quickly at the early stage, so the potatoes can root early; the black film has low visible light transmittance and can restrain weeds from growing, and the weeding rate can reach about 90 percent; during the middle and later periods of growth, the root systems enter below the black film, high temperature below the film, caused by strong sunlight, is prevented, and the premature senility of the root systems is avoided; the method can create a good environment for potato tuber growth in the period of tuberization, and has a ground temperature adjusting function that other film does not have; not only is the labor intensity of weeding reduced, but also the yield is increased by a large margin.

Owner:孔祥宜 +2

Method for uniformly drying lettuce by normal pressure and negative pressure combined microwave spouted bed

InactiveCN102405958AReduce lossesHigh retention rateFruits/vegetable preservation by dehydrationMicrowaveMagnesium acetate

The invention relates to a method for uniformly drying lettuce by a normal pressure and negative pressure combined microwave spouted bed, and belongs to the technical field of fruit and vegetable food processing. The main processes of the method comprises: removing leaves and peels from fresh lettuce, cleaning, cutting into cubes (cutting into sheets), adding a EDTA-Na solution to carry out colorprotection, blanching, adding a magnesium acetate solution and a zinc acetate solution to carry out color protection, and carrying out treatments of microwave spouted drying, packaging and storage. With the present invention, the microwave drying technology is adopted so as to shorten the drying time, reduce the drying energy consumption, and reduce the loss of the chlorophyll in the lettuce during the processing process; the normal pressure spouted bed drying technology and the negative pressure spouted bed drying technology are combined to dry the lettuce, and the material has the circular motion, such that the disadvantage of the nonuniformity of the microwave drying is overcome; the product dried by the microwave spouted drying method has characteristics of good water reabsorbing capacity, high water reabsorbing rate, good crisp taste after water reabsorbing, unique lettuce aroma, high chlorophyll content, good and uniform color.

Owner:NINGBO HAITONG FOOD SCI & TECH CO LTD +1

Low-calorie solid milk tea containing prebiotics and preparation method of solid milk tea

InactiveCN104397188APromote absorptionImprove immunityMilk preparationPre-extraction tea treatmentBiotechnologySkimmed milk powder

The invention relates to low-calorie solid milk tea containing prebiotics and a preparation method of the solid milk tea, and belongs to the technical field of solid drinks and nutritional foods. The low-calorie solid milk comprises the following raw materials: skimmed milk powder, maltodextrin, optimized tea powder, water-soluble dietary fibers, prebiotics, wheat oligopeptides, erythritol and stevioside. The milk tea product produced by the technology is rich in nutrients such as prebiotic factors, dietary fibers, small molecule peptides and trace elements and very low in fat and heat, has the effects of relaxing bowels, resisting fatigue, improving immunity, resisting oxidation, regulating microecological balance and health of a human body and the like, is simple to prepare, low in cost and suitable for most of people, and has a wide market prospect.

Owner:BAOLINGBAO BIOLOGY

Compound colour conserving method for prolonging storage period of dehydrated lettuce slices

The invention relates to a compound colour conserving method for prolonging the storage period of dehydrated lettuce slices, belonging to the technical field of fruit and vegetable processing. The method in the invention comprises the following steps: pretreating lettuce utilized as a raw material, soaking with a colour conserving solution, and conserving the colour by adopting a mixed solution of lactose, saccharose and table salt, thus not only can the colour conserving cost be reduced, but also the colour and lustre of the lettuce slices preserved at different temperatures; then blanching,carrying out secondary soaking, and drying; and finally packaging and storing, wherein the storage temperature is 4-22 DEG C. In the invention, the degradation of chlorophyll in the processing process of each step is ensured to reach the minimum, so as to realize a good green conserving effect in the storage period.

Owner:NINGBO HAITONG FOOD SCI & TECH CO LTD +1

High-protein moringa oleifera nutritive noodles

InactiveCN104489504ARetain nutritionImprove absorption rateFood ingredient functionsFood preparationMORINGA OLEIFERA LEAFEmerald

The invention discloses high-protein moringa oleifera nutritive noodles. The high-protein moringa oleifera nutritive noodles consist of the following raw materials in parts by weight: 5-20 parts of moringa oleifera leaf superfine powder, 60-100 parts of high gluten flour, 0-3 parts of table salt, 0-3 parts of dietary alkali, 0-2 parts of algin, 3-12 parts of soybeans and 15-28 parts of water. The preparation method comprises the following steps: preparing full-bean milk by soybeans, adding moringa oleifera superfine powder, table salt, dietary alkali and algin into the full-bean milk, stirring uniformly, adding flour, kneading, curing, tableting, slitting and drying so as to obtain the high-protein moringa oleifera nutritive noodles. The nutritive noodles are emerald green in color, good in toughness and mouthfeel, do not enable soup to be muddy, and are rich in nutrition; the processing technology is simple, and industrialization can be realized easily.

Owner:刘祥义

Processing process of jade-colored noodles

InactiveCN105581246ASmooth tasteHigh nutritional valueFood ingredient as mouthfeel improving agentNutritive valuesPremna microphylla

The invention discloses a processing process of jade-colored noodles. The processing process comprises the following steps: (1) picking premna microphylla turcz fresh leaves and removing impurities; (2) washing and immersing; (3) spin-drying by using a spin-drying machine; (4) drying at a low temperature for 8 to 15 hours, and then rapidly drying; when the moisture content is lower than or equal to 10%, taking out and crushing by a crushing machine to obtain premna microphylla turcz dried powder; (5) putting, by weight, 60 to 70 parts of fine wheat flour, 20 to 40 parts of the premna microphylla turcz dried powder, 10 to 20 parts of starch, 0.1 to 2 parts of table salt, 0.1 to 2 parts of edible alkali, 0.5 to 2 parts of edible oil and 20 to 35 parts of water the following raw materials into a dough mixer to be stirred for 10 to 20 minutes; (6) curing for 10 to 25 minutes; (7) pressing and airing; and (8) slicing and packaging. The premna microphylla turcz fresh leaves are processed into the jade-colored noodles, and the prepared jade-colored noodles have a smooth and chewy taste and have a dark green color, so that the appetite of people is increased, and nutritive values are extremely high; and the jade-colored noodles have the effects of clearing away internal heat, moistening lung, eliminating toxin and beautifying skin.

Owner:WUSHAN TIANYU QIYE AGRI DEV CO LTD

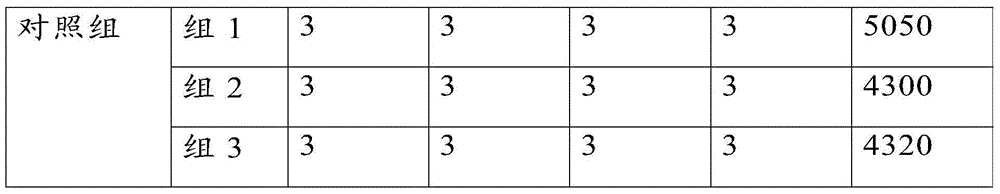

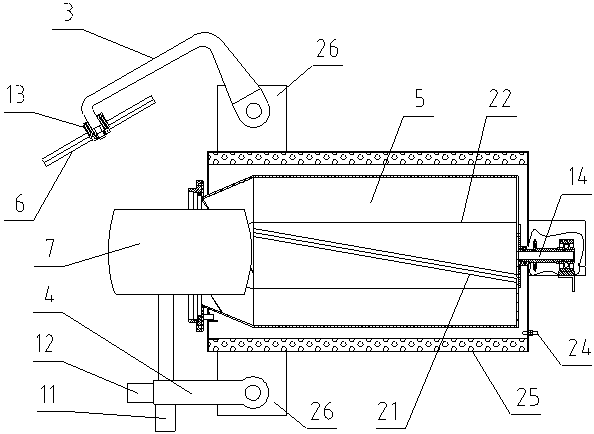

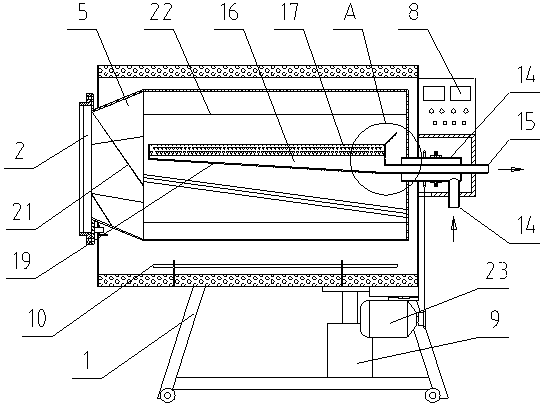

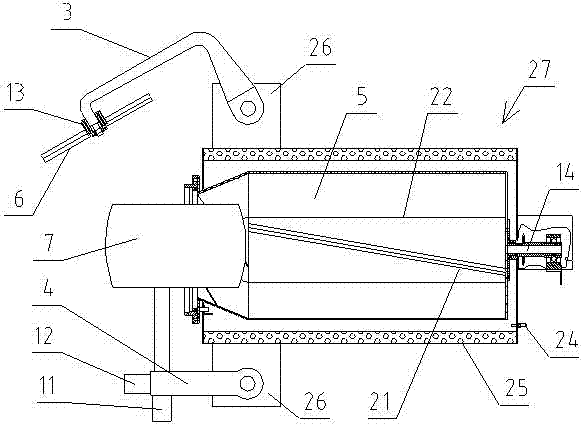

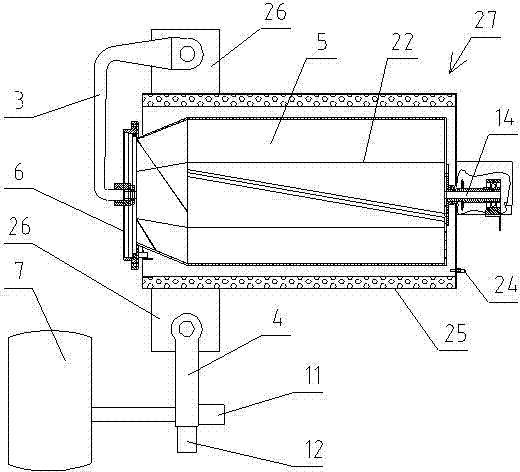

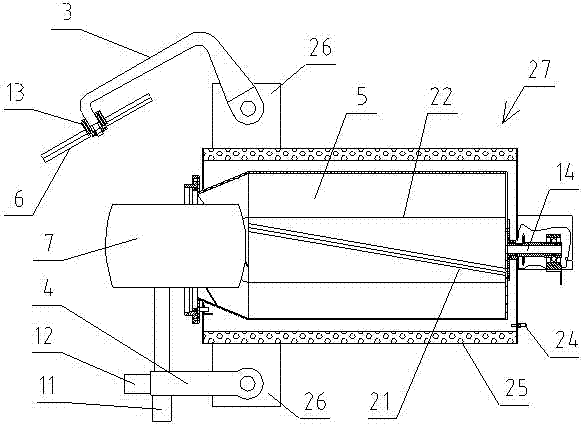

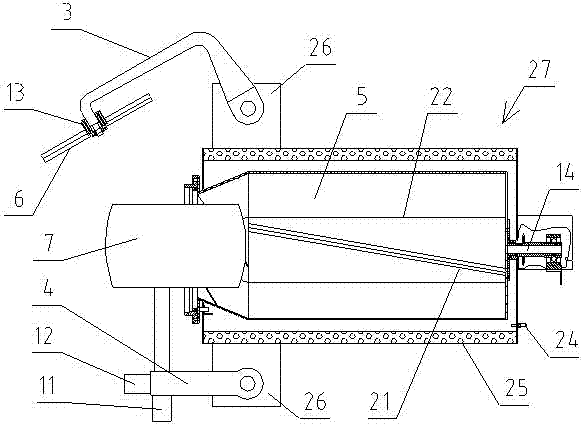

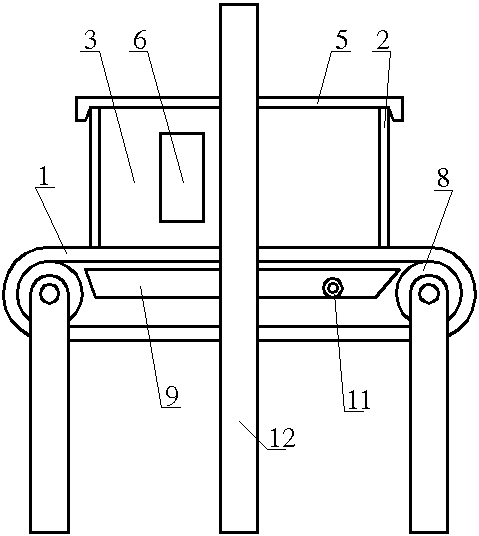

Drum-type automatic final-panning aroma raising machine and processing method thereof

InactiveCN102754705ACompact and smooth shapeColor emerald greenPre-extraction tea treatmentProduction lineAutomatic control

The invention discloses a drum-type automatic final-panning aroma raising machine. The drum-type automatic final-panning aroma raising machine comprises a frame, a drum, a drum heater and a drum dumping mechanism, wherein the drum, the drum heater and the drum dumping mechanism are disposed on the frame. One end of the drum is provided with a tea leaf access hole, and the other end of the drum isclosed and is connected with an air heating device through a hot air pipe. A door opening and closing manipulator and a feeding and discharging manipulator are arranged on two sides of the drum on the frame. A moving door is disposed at the tail end of the door opening and closing manipulator. A tea leaf chute is arranged at the tail end of the feeding and discharging manipulator. The drum-type automatic final-panning aroma raising machine is further provided with an automatic control system. By the drum-type automatic final-panning aroma raising machine, the problem that an existing drum-type tea leaf final-panning machine is unavailable for an automatic tea leaf production line is solved effectively, and the problem that dustiness of the drum-type tea leaf final-panning machine endangers physical health of workers and possibly causes dust explosion is also solved. The drum-type automatic final-panning aroma raising machine is ingenious in structure, suitable for automatic tea leaf production lines, clean and safe and has broad market prospect.

Owner:苏和生

Cultivating method of potato seedlings

InactiveCN104472056ASeedlings grow vigorouslyColor emerald greenSeed coating/dressingEmeraldSolanum tuberosum

The invention relates to the field of crop planting, and particularly relates to a cultivating method of potato seedlings, which comprises the following steps: slicing potato seeds into blocks to obtain seed potato blocks; soaking the seed potato blocks in a rooting solution; then coating the soaked seed potato blocks and sprouting to obtain potato seedlings. According to the cultivating method of potato seedlings, the sliced seed potato blocks are soaked in the rooting solution so that the rooting solution penetrates into the seed potato blocks so as to provide a good base for the subsequent sprouting and rooting; after being coated, the soaked seed potato blocks are sprouted, and the coating treatment is mainly used for prevention of pests and diseases. Finally, the potato seedlings vigorously grow and have emerald green color. After the obtained potato seedlings are sown, the yield is greatly increased, the pests and diseases during planting can be alleviated, and a remarkable effect can be achieved.

Owner:孔祥宜 +2

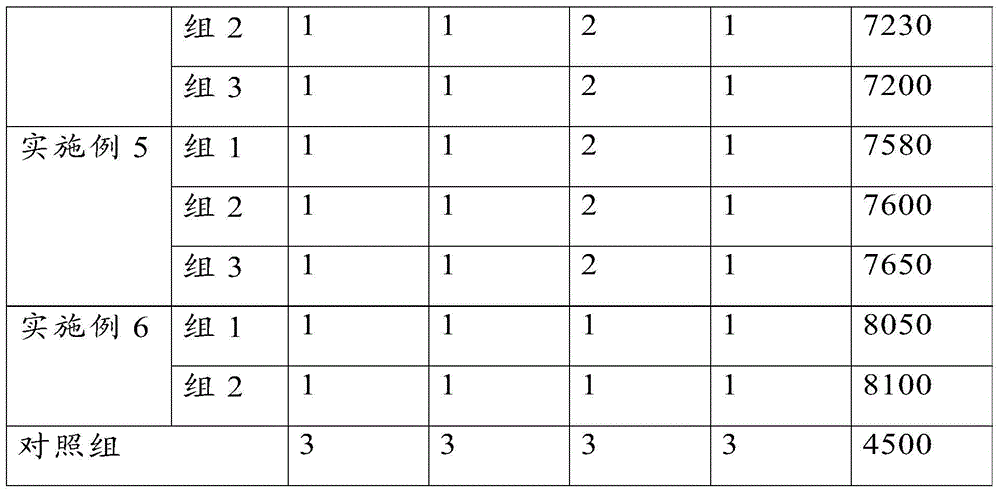

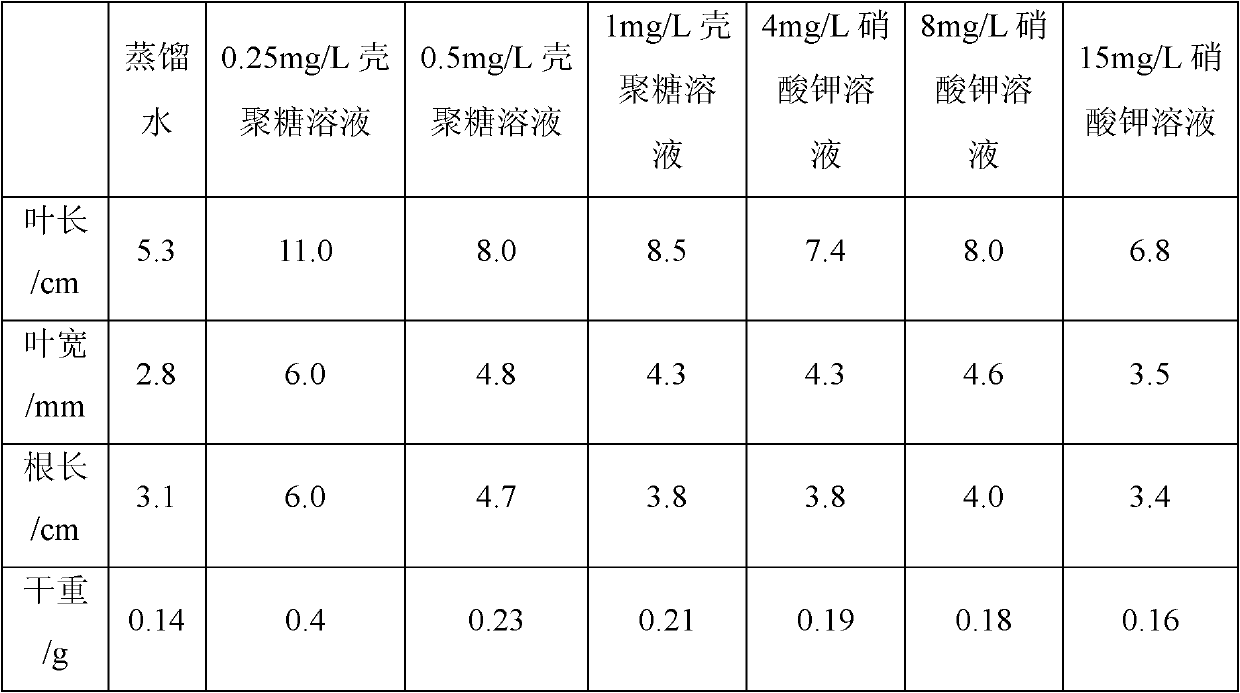

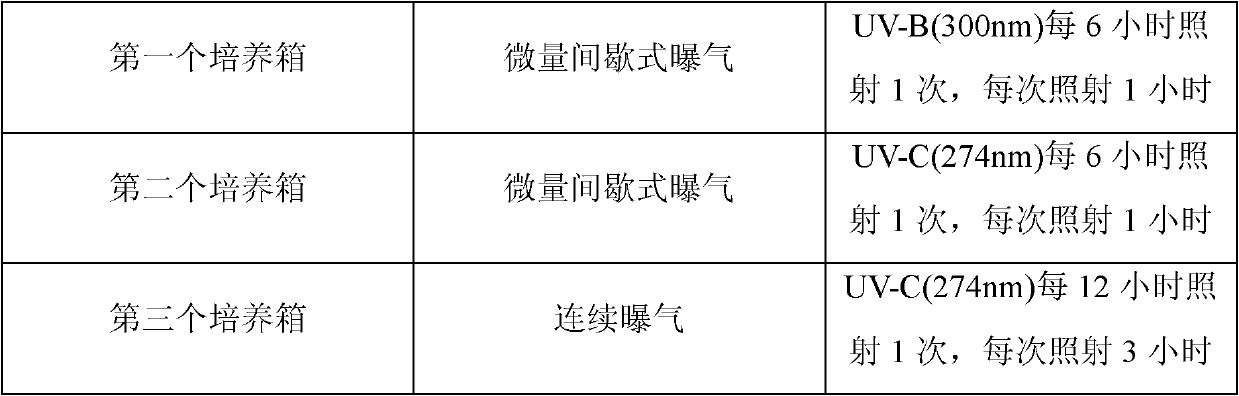

Method for promoting eel grass seeds to germinate and grow

The invention relates to a method for promoting eel grass seeds to germinate and grow. The method comprises the following steps that: in a culture box, potassium nitrate solution or chitosan solution is added, in addition, trace intermittent aeration is used as an auxiliary measure, and the eel grass seeds are added for soaking; the soaked eel grass seeds are cultured in a beaker with lake bottom sediment as substrates; and after the eel grass seeds germinate, the young eel grass seedlings are placed into a culture box containing the potassium nitrate to be soaked, and meanwhile, trace intermittent aeration and intermittent short wave ultraviolet ray radiation are used as auxiliary measures. The method provided by the invention is simple, the germinating time of the eel grass seeds is short, the germinating rate is high, the growth speed is high, in addition, the economic cost is low, and great significance is realized on the fast breeding and large-scale production seedling culture of the eel grass.

Owner:CHINESE RES ACAD OF ENVIRONMENTAL SCI

Green tea processing method

InactiveCN104621278AIncrease aromaGreat tastePre-extraction tea treatmentHigh temperature storageEmerald

The invention belongs to the technical field of processing of teas, and in particular relates to a green tea processing method. Green teas are prepared by sequentially spreading, removing green, refreshing breeze, cooling by spreading, primarily kneading, primarily drying, kneading again, shaping and showing tea hair of fresh teas. According to the invention, the teas are blown by cold wind before and after removing green; protein and saccharides in the teas are sufficiently decomposed in the spreading process before removing green; therefore, the contents and the concentrations of effective components in tea soup are ensured, and beneficial substances in the teas are promoted to dissolve out; by means of blowing cold wind after removing green, the temperature of the teas can be rapidly reduced; the teas are prevented from becoming yellow due to high-temperature storage; by adopting the kneading process for two times, cells in the teas are broken step by step after primarily kneading; therefore, the effective components are dissolved and leached easily in the brewing process; and the tea soup is kept emerald green in colour, strong in fragrance and high in soluble content.

Owner:HUNAN XIANGWEI TEA CO LTD

Microwave freeze drying method for dendrobium

InactiveCN106546070ABrew wellShorten drying timeDrying using combination processesDrying solid materials with heatTime rangeMicrowave

The invention discloses a microwave freeze drying method for dendrobium and belongs to the field of health care product or food processing. The method comprises the following steps that leaves and roots of fresh dendrobium are picked off, the left dendrobium is washed and poured into color-protecting liquid to be immersed for 1 h, the immersed dendrobium is taken out, water is drained off, the dendrobium is subjected to prefreezing, the prefreezing temperature ranges from -20 DEG C to -5 DEG C, and the prefreezing time ranges from 1.5 hours to 4 hours; then, after the dendrobium is cut into segments being 2 mm-18 mm long, the segments are put into a tray and spread into a thin layer, the tray is put into a microwave dryer, the microwave strength ranges from 4 W / g to 7W / g, and the drying time ranges from 3 min to 8 min; and microwave drying is stopped, the tray is taken out and transferred into a vacuum freeze dryer, freeze drying is carried out at the temperature of -20 DEG C and the vacuum degree of -80 kPa, the segments are dried until the water content is smaller than 16%, and through packing and storing treatment, the finished products are obtained.

Owner:GUANGXI BAMALAN LONG LIFE TECH CO LTD

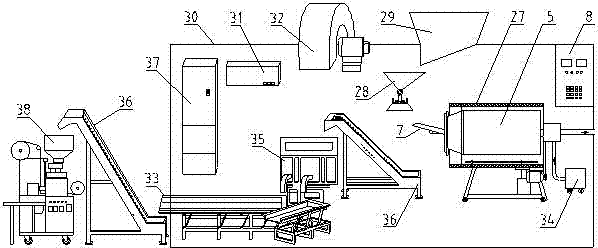

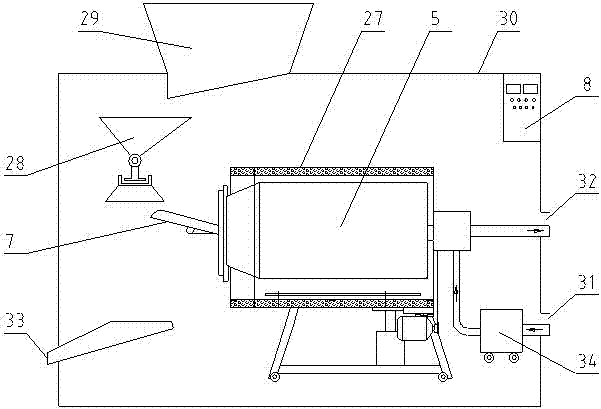

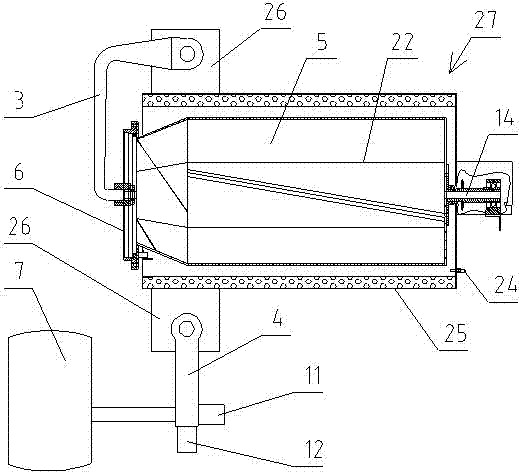

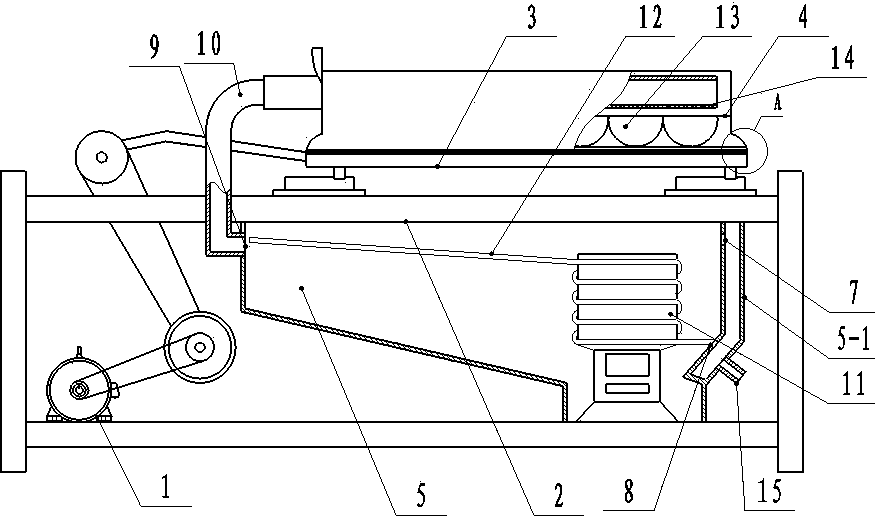

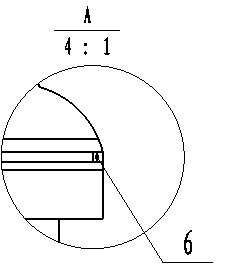

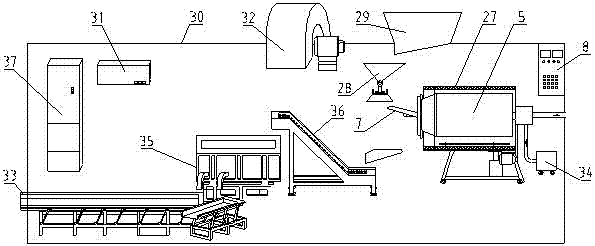

Complete automatic tea-leaf finishing, packaging equipment and processing method

ActiveCN102783527ACompact and smooth shapeColor emerald greenPre-extraction tea treatmentProcess equipmentPhysical health

The invention discloses complete automatic tea-leaf finishing, packaging equipment and a processing method, which comprises an automatic tea-leaf packager, a drum type automatic final-panning and fragrance raising machine and a tea-leaf vibrating sorter. The drum type automatic final-panning and fragrance raising machine and the tea-leaf vibrating sorter are disposed in a closed box, the drum type automatic final-panning and fragrance raising machine is connected with the tea-leaf vibrating sorter through a tea-leaf lifting conveyor, the tea-leaf vibrating sorter is connected with the automatic tea-leaf packager through another tea-leaf lifting conveyor, an automatic quantitation feeding device is connected to the front of the drum type automatic final-panning and fragrance raising machine, and an air inlet, an air outlet and a tea-leaf discharge outlet are arranged on the wall of the closed box. The complete automatic tea-leaf finishing and packaging equipment is further provided with an automatic control system, is clean, safe, high in production efficiency and capable of automatically producing tea leaves, and effectively solves the problem that processing equipment for subsequent procedures of tea leaves generates more dust in the prior art, which endangers physical health of production workers, and may cause safety accidents such as dust deflagration and the like.

Owner:浙江丰凯机械股份有限公司

Method for updating and intersowing of golf course lawn

ActiveCN107466630ASmooth appearanceFlat surfacePlant cultivationCultivating equipmentsPunchingGolf course turf

The invention relates to a method for updating and intersowing of golf course lawn. The method comprises the steps of selecting agrostis stolonifera and other grass seeds which have high infectivity, conducting stress treatment on original lawn firstly, such as low shearing, grass combing, punching so as to provide a turf bed which facilitates the growth of sown Bentgrass, wherein the turf bed treatment in a stage before sowing is crucial, over-treatment can cause the death of blue grass and other grass, and insufficient treatment can affect the germination of the updated Bentgrass and thus affect the overall schedule of overseeding replacement. The updated lawn looks smooth and dense, the surface is smooth, and the color is green; the duration of entire intersowing is short, the cost is low, and the method is simple; besides, only 20 days are needed from the beginning of intersowing to normal use.

Owner:山东文旅崮云湖国际高尔夫俱乐部有限公司

Method for preparing quick-freezing dishes of medlar buds

InactiveCN1600110AAchieve freshnessAchieve color retentionFruits/vegetable preservation by heatingFruits/vegetable preservation by freezing/coolingLycium barbarum fruitBud

A quickly frozen wolfberry bud as a dish is prepared from fresh wolfberry buds through washing, boiling for 1-3 min, precooling to 18-25 deg.C, cooling to 0-15 deg.C, centrifugal dewatering, and quickly freezing at -30- -40 deg.C.

Owner:刘国祥

Potato planting method

InactiveCN106818179APlanting method is simpleImprove germination survival rateSeed and root treatmentAnimal corpse fertilisersSolanum tuberosumHigh survival rate

The invention discloses a potato planting method, relating to the technical field of agricultural planting. The potato planting method comprises (1) field selection and soil preparation, (2) ridging, (3) seed treatment, (4) seed sowing, (5) field management and (6) recovery. The potato planting method is simple and applicable to large-scale cultivation of potatoes; potatoes planted by the method have high survival rate of germination and high yield without rotten potatoes or deformed potatoes.

Owner:安徽菲扬新材料有限公司

Closed tea automatic cooling-roasting flavor-extracting system and processing method thereof

ActiveCN102783525ACompact and smooth shapeColor emerald greenPre-extraction tea treatmentTea flavoringAutomatic controlFlavor

The invention discloses a closed tea automatic cooling-roasting flavor-extracting system and a processing method thereof; the closed tea automatic cooling-roasting flavor-extracting system comprises an automatic quantitative charging device and a drum type automatic cooling-roasting flavor-extracting machine disposed in a closed case; a frame of the drum type automatic cooling-roasting flavor-extracting machine is provided with a door opening-closing manipulator and a charging-discharging manipulator; a tea inlet-outlet movable door is disposed at the end of the door opening-closing manipulator; a rotatable tea chute is disposed at the end of the charging-discharging manipulator; an automatic control system is connected with and controls the automatic quantitative charging device and the drum type automatic cooling-roasting flavor-extracting machine. The invention effectively solves the problem of great dust of tea cooling-roasting machines in the prior art, wherein the problem can not only damage body health of production workers, but also cause potential safety accidents such as dust explosion and the like; and the provided closed tea automatic cooling-roasting flavor-extractingsystem is clean, safe, high in production efficiency, and suitable for being used on complete equipment for tea automatic production.

Owner:苏和生

Green tea processing method

ActiveCN104886289AGood for color retentionColor emerald greenPre-extraction tea treatmentTea flavoringGreen teaMoisture

The invention discloses a green tea processing method and belongs to the technical field of tea processing. The green tea processing method includes the steps of spreading and cooling, water removing, dehumidifying, twisting, strip making, shaping, drying and aroma extracting. The moisture content of tea leaves subjected to spreading and cooling ranges from 55% to 63%, and the temperature during strip making ranges from 300DEG C to 400DEG C. Color of the tea leaves is favorably sustained by reducing the moisture content of the tea leaves after spreading and cooling, and the color of the tea leaves is enabled to be bright green; through dehumidification of an fan additionally mounted at an outlet of an enzyme deactivation machine, the color of the tea leaves subjected to enzyme deactivation is bright green; the tea leaves are enabled to have stronger aroma and are more tasty by raising the temperature in strip making, and bar molding is performed after fluff removing during strip making, so that the processed tea leaves are more rich in luster and better in integrity; the stripped leaves are returned to be shaped by the enzyme deactivation machine after strip making, the shrinkage degree of the tea leaves is increased, tea leaves are more compact and tiny, and the aroma of the tea leaves is stronger; during aroma extracting, two stages are performed, so that the processed tea leaves are better in appearance and tasty.

Owner:JIANGKOU COUNTY TONGJIANG BIOTECH CO LTD

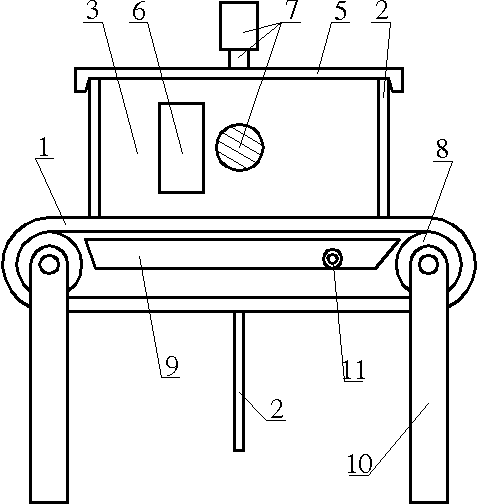

Tea leaf strip-tidying machine

InactiveCN104920655AEasy to operateTake advantage ofPre-extraction tea treatmentAgricultural engineeringTea leaf

The invention discloses a tea leaf strip-tidying machine and relates to the technical field of tea leaf machinery. The tea leaf strip-tidying machine comprises a motor and a frame, wherein a reciprocating rack is arranged on the frame; a tea leaf strip-tidying hopper is arranged on the reciprocating rack; the motor is connected with the reciprocating rack through a speed change mechanism; a combustion chamber is formed below frame; the reciprocating rack is slidably connected with the tea leaf strip-tidying hopper; a sliding nail is hinged in a bottom chute at the first end of the tea leaf strip-tidying hopper; a sliding nail is mounted in a top chute at the tail end of the reciprocating rack. Compared to the prior art, as the reciprocating rack is slidably connected with the tea leaf strip-tidying hopper and the sliding nail is hinged in the bottom chute at the first end of the tea leaf strip-tidying hopper, the tea leaf strip-tidying hopper is pulled from outside after the tea leaf strips are tidied, the tea leaf strip-tidying hopper moves outward to the tail end and dumps the tea leaves, so that the tea leaf strip-tidying machine is convenient and efficient to operate.

Owner:三江县陆氏茶叶机械制造有限公司

Petrocosmea sinensis tissue culture and rapid propagation method

InactiveCN105309312AIncrease production rateReduce incubation timeHorticulture methodsPlant tissue cultureBudCell budding

A petrocosmea sinensis tissue culture and rapid propagation method comprises the following steps: (1), taking tender leaves of petrocosmea sinensis as an explant and sterilizing the explant; (2), placing the sterilized explant in an MS minimal medium to induce sterile buds; (3), placing the sterile buds into an MS inducing medium for strengthening seedlings so as to obtain robust plants; (4), placing the robust plants into an MS rooting medium for culture so as to obtain complete rooted seedlings; (5), taking the complete rooted seedlings, hardening the seedlings, enabling the seedlings to grow in sandy soil for one month and then transplanting the seedlings to a field. The plants obtained by adopting the method provided by the invention are thick and strong and high in survival rate, and the method can provide a large number of petrocosmea sinensis seedlings which are high in quality and suitable for cultivation in the short term, so that the problem of scale seedling cultivation of petrocosmea sinensis is solved effectively.

Owner:GUANGXI BOTANICAL GARDEN OF MEDICINAL PLANTS

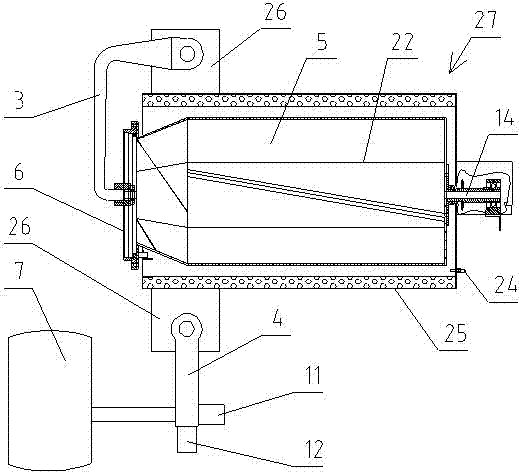

Complete equipment for tea clean automatic fine processing and processing method thereof

ActiveCN102783526ACompact and smooth shapeColor emerald greenPre-extraction tea treatmentFlavoring extractState of art

The invention discloses complete equipment for tea clean automatic fine processing and a processing method thereof; the complete equipment comprises a drum type automatic cooling-roasting flavor-extracting machine and a tea vibrating screening machine which are disposed in a closed case and are connected with each other through a tea lifting conveyer; an automatic quantitative feeding device is connected in front of the tea cooling-roasting flavor-extracting machine; an air inlet, an air outlet and a tea discharging port are disposed on the case wall of the closed case; the complete equipmentfor tea clean automatic fine processing is also provided with an automatic control system; the automatic control system is connected with and controls the automatic quantitative feeding device, the drum type automatic cooling-roasting flavor-extracting machine, the tea lifting conveyer, and the tea vibrating screening machine. The invention effectively solves the problem of great dust of tea fineprocessing equipment in the prior art, wherein the problem can not only damage body health of production workers, but also cause potential safety accidents such as dust explosion and the like; and the provided complete equipment for tea clean automatic fine processing is clean, safe, high in production efficiency, and can realize automatic production.

Owner:苏和生

Production method for lily tea

InactiveCN104397287AEfficient use ofEffectively exert medicinal propertiesTea substituesSide effectLilium

The invention discloses a production method for lily tea. The production method comprises the production steps of material selection, drying, shearing, mixing and bagging. The production method has the advantages that whole plants of lilium davidii are utilized, lily plants are efficiently utilized, flowers and bulbs are medicative, and the herbal property can be neutralized by seeds, leaves and stems, so that the lily tea can be taken for a long time without side effects, and is very good for health if being taken for a long time, and the effects of moistening the lung to arrest cough, clearing away fire and treating inflammation can be achieved; with the adoption of a method of drying in shade, original pigments of the plants can be effectively reserved and prevented from being damaged; dandelion leaves and lily stems are green, so that the made tea tastes good, and has great mouth-feel; the tea is clear and beautiful in color, and is green and transparent, so that the tea is pleasing and suitable for use as daily drink, and the cognitive bias of people that lilium davidii tea is bitter in taste and dark is eliminated.

Owner:吴云

Technological shredded preserved szechuan pickle and making equipment thereof

ActiveCN104366389AHigh speedIncrease productivityClimate change adaptationFood preparationFlavorGreen Vegetable

The invention discloses technological shredded preserved szechuan pickle and making equipment thereof. The making equipment of the technological shredded preserved szechuan pickle comprises three parts, including a preserved szechuan pickle wringing and kneading machine, a preserved szechuan pickle shredding machine and a kneading packaging machine, wherein the preserved szechuan pickle wringing and kneading machine is used for kneading salt-dehydrated preserved szechuan pickle to extrude out water so that the preserved szechuan pickle becomes soft; the preserved szechuan pickle shredding machine is used for shredding the kneaded and salt-dehydrated preserved szechuan pickle into shredded preserved szechuan pickle; the kneading packaging machine is used for packaging the shredded preserved szechuan pickle by using green vegetable leave segments and kneading the shredded preserved szechuan pickle and the green vegetable leave segments during the packaging process so that the packaged technological shredded preserved szechuan pickle is green in color, soft, crisp, tender, fragrant and fresh. The making equipment of the technological shredded preserved szechuan pickle is reasonable in structure, convenient to manufacture and use, high in speed when being used for making the technological shredded preserved szechuan pickle, high in production efficiency and unique in processing technology; the prepared shredded technological preserved szechuan pickle is jade green in color, soft, crisp and tender in taste, fragrant and fresh in flavor and beneficial for industrial production.

Owner:CHONGQING BEIJING TECH RES & DEV

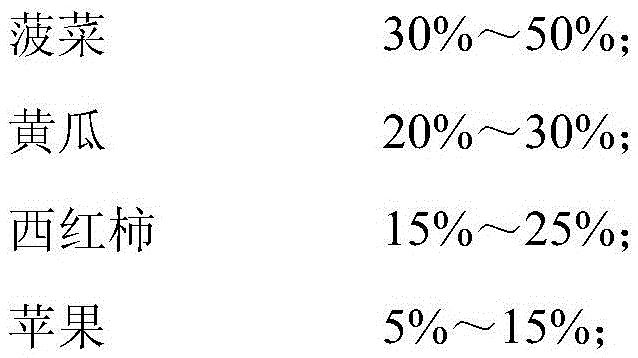

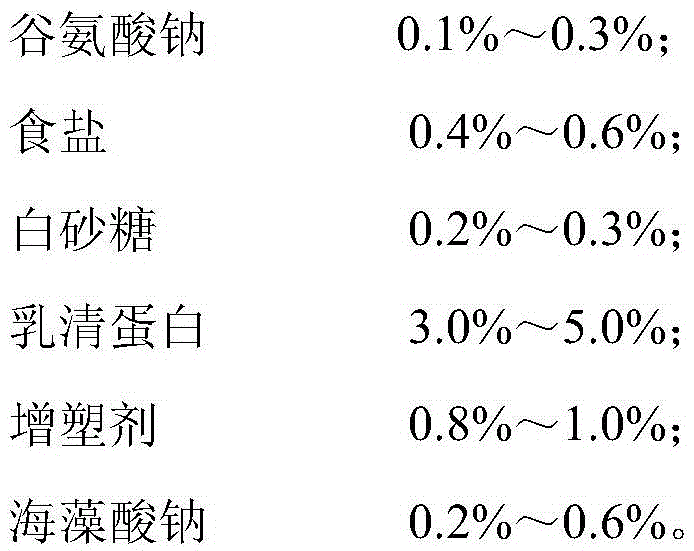

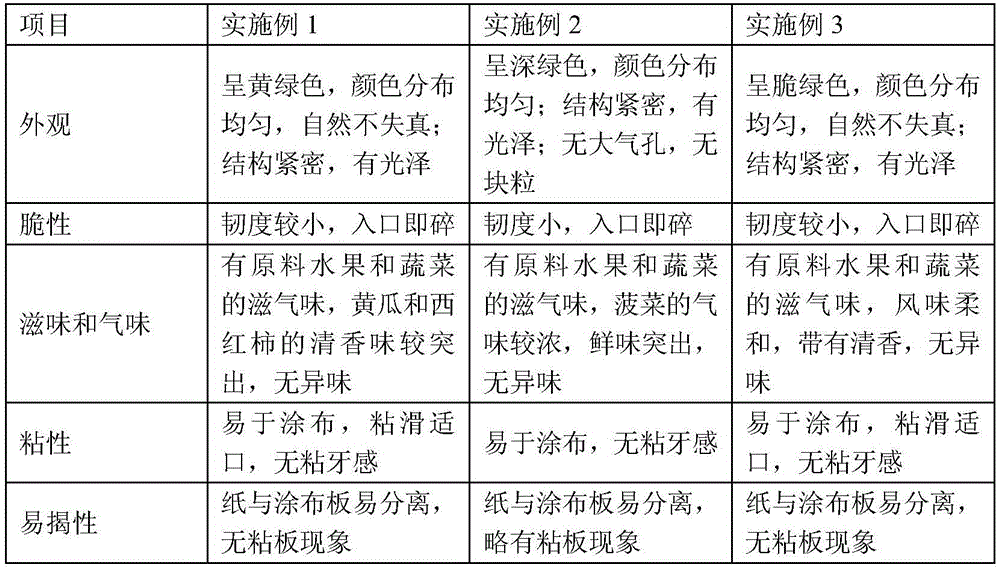

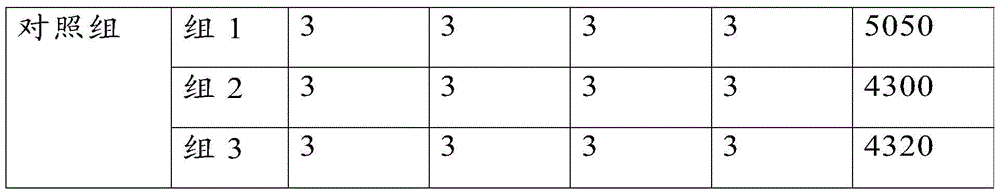

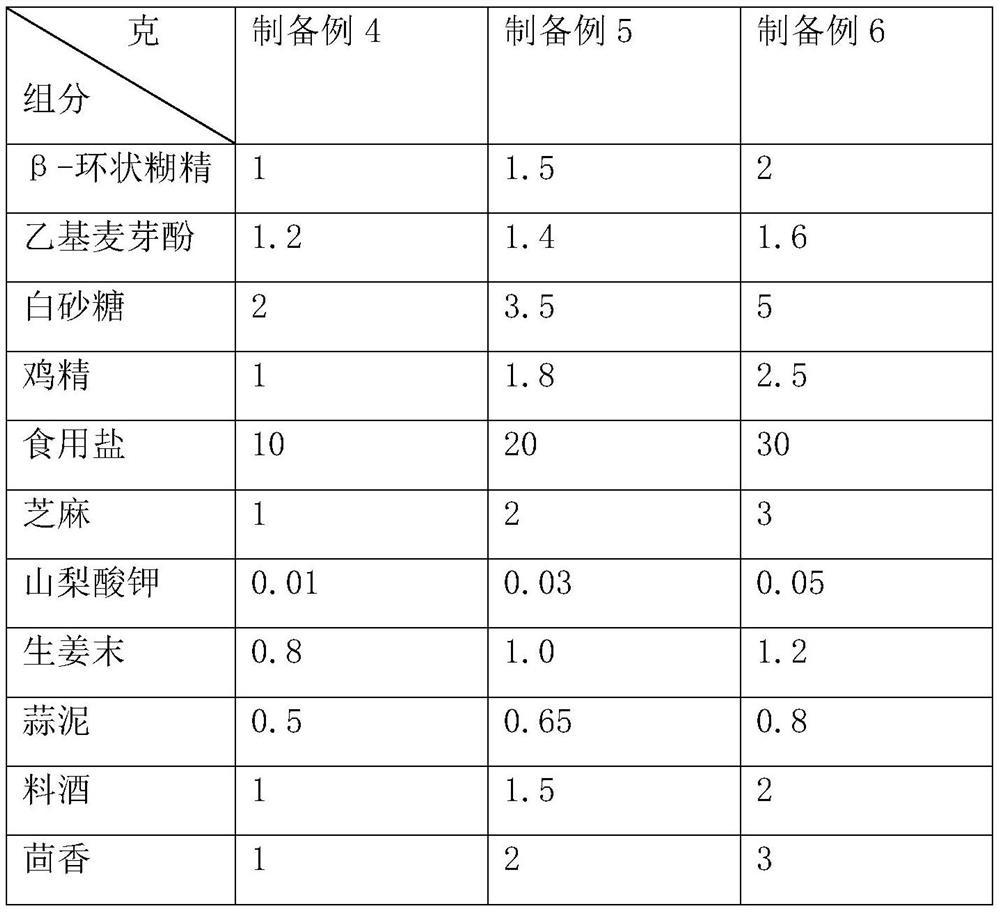

Nutritional-type instant compound fruit and vegetable paper and preparation method thereof

InactiveCN105475910AWide variety of sourcesColor emerald greenFood ingredient as gelling agentFlavorWhey protein

The invention discloses nutritional-type instant compound fruit and vegetable paper and a preparation method thereof. The preparation method comprises the following steps: cutting cleaned spinach into sections; cutting cucumbers, tomatoes and apples into blocks; mixing the spinach sections, the cucumber blocks, the tomato blocks and the apple blocks after performing color protection treatment; adding whey protein, a plasticizer and sodium alginate into the mixture; then, adding seasonings, such as table salt, white granulated sugar and sodium glutamate, to the mixture; pulping, performing refining treatment on the obtained fruit and vegetable pulp in a colloid mill, homogenizing the fruit and vegetable pulp which is subjected to the refining treatment by using a homogenizer, uniformly coating the fruit and vegetable pulp on a glass plate, feeding the glass plate into a drying box for drying, peeling, and re-drying the peels in the drying box to obtain the nutritional-type instant compound fruit and vegetable paper. The nutritional-type instant compound fruit and vegetable paper has the advantages that the raw materials are wide in source; the prepared compound fruit and vegetable paper product is green in color, and clear and crisp in taste; the raw materials are not required to be boiled during processing, so that the nutritional values of the raw materials and the fragrant flavor of the raw materials, such as the cucumbers and the apples, are remained better; the quality of the fruit and vegetable paper is improved by the improvement of the formula and process conditions; the nutritional value of the fruit and vegetable paper is increased.

Owner:BOHAI UNIV

Tea processing method

InactiveCN106035774AIncrease fresh and mellow tasteIncrease aromaPre-extraction tea treatmentFixation timeEmerald

The invention discloses a tea processing method in the field of tea processing technologies. The tea processing method includes the following steps that wilting is performed: indoor natural wilting is performed for 1.5-2.5 hours, and then hot-air wilting is performed for 20-35 minutes; fixation is performed: the temperature of a roller fixation machine is 295-310 DEG C, and the fixation time is 1-2 seconds; processing is performed: the temperature of a processing machine is 100 DEG C, and the processing temperature is 35-45 minutes; processes leaves obtained after processing are fed into a polishing and tomentum removing machine, and tomentum removing is performed at the temperature of 0-5 DEG C for 2 hours; shaping is performed: the shaping temperature is 70-80 DEG C, and the time is 3-5 minutes; drying is performed: the tea leaves are put into a dryer, the drying temperature is 70-80 DEG C, and the time is 2 hours; aroma raising is performed: the tea leaves are put into an aroma raising machine, the moisture content of the tea leaves undergoing aroma raising is 7%. The tea processing method integrates indoor natural wilting and hot-air wilting, effectively improves the aroma of finished tea to make the taste of the tea mellow and then is assisted by low-temperature and long-time tomentum removing, the problems of small aroma and slight taste brought by conventional low-temperature tomentum removing are avoided while the characteristics of emerald green color, bright tea water and little tomentum or tomentum absence are kept, and the tea processing method is suitable for production of brand-name and high-quality green tea.

Owner:正安县清新种养殖农民专业合作社

A kind of planting method of potato

InactiveCN104472165BReduce labor intensityAvoid disadvantagesSeed and root treatmentPlant cultivationGround temperaturePlastic mulch

The invention relates to the field of crop planting, and particularly to a method for planting potatoes, which comprises the following steps: preparing land, fertilizing, and ditching; putting the potato seedlings into ditches, ridging, covering soil, covering parts on ridges, where the potato seedlings are planted, with colorless and transparent film, and covering two sides of the colorless and transparent film with black film; conducting field management, and harvesting potatoes. The method adopts the colorless and transparent film and the black film, which are in a matched manner, to plant the potatoes, the colorless and transparent film has good light transmittance and increases temperature quickly at the early stage, so the potatoes can root early; the black film has low visible light transmittance and can restrain weeds from growing, and the weeding rate can reach about 90 percent; during the middle and later periods of growth, the root systems enter below the black film, high temperature below the film, caused by strong sunlight, is prevented, and the premature senility of the root systems is avoided; the method can create a good environment for potato tuber growth in the period of tuberization, and has a ground temperature adjusting function that other film does not have; not only is the labor intensity of weeding reduced, but also the yield is increased by a large margin.

Owner:孔祥宜 +2

Pteris wallichiana tissue culture rapid breeding method

InactiveCN105379626AReduce incubation timeReduced cultivation stepsClimate change adaptationHorticulture methodsProthalliumCulture mediums

A pteris wallichiana tissue culture rapid breeding method comprises the following steps: (1) taking pteris wallichiana mature spores as explants for disinfection; (2) putting the disinfected explants into a MS basic culture medium for inducing prothallium; (3) putting the prothallium into the MS basic culture medium for strong seedling culture to obtain sporozoites differentiated into plantlets; (4) putting the sporozoites differentiated into plantlets in a 1 / 2MS rooting culture medium for culture to obtain complete rooted seedlings; and (5) taking the complete rooted seedlings for hardening and then transplanting to a nursery greenhouse. Plants obtained by the method are strong and thick and high in survival rate, a lot of high-quality pteris wallichiana seedlings suitable for cultivation are provided, and the pteris wallichiana scale breeding problem can be effectively solved.

Owner:GUANGXI BOTANICAL GARDEN OF MEDICINAL PLANTS

Processing method of Queshe tea

The present invention discloses a processing method of Queshe tea. The method comprises the steps of: spreading, enzyme deactivation by machine, cooling by spreading, manual shaping, polishing by machine and final manual panning to increase the aroma. The processing method of Queshe tea employs enzyme deactivation by machine, shaping by hand, polishing and manual panning to increase the aroma. On the one hand, the produced Queshe tea has unified appearance (smoothness, flatness, smoothness, straightness and uniform green color), lasting aroma and multiple brewing times; on the other hand, the method increases the product yield, reduces labor costs and increases value.

Owner:贵州省黎平雀舌茶业有限公司

Production process of flavored kelp salad

InactiveCN111631340AColor emerald greenGood flexibilityFood preservationFood ingredientsBiotechnologyMicrobiology

The invention discloses a production process of flavored kelp salad, and relates to the technical field of food processing. The process comprises the following steps: S1, cleaning; S2, soaking and cutting; S3, color protection treatment: putting shredded kelp into a copper sulfate solution and a D-sodium erythorbate solution in a mass ratio of 1:(0.8-1.2), performing boiling for 3-6min, and performing color protection treatment, wherein the mass concentration of the copper sulfate solution is 200-220mg / L and the mass concentration of the D-sodium erythorbate is 200-240mg / L; S4, blanching; S5,disinfection and dehydration; S6, ingredient adding; S7, metal powder detection; and S8, packaging, sterilizing and storing. The production process of the flavored kelp salad can prepare the kelp salad which is emerald green in color, free of fishy smell and good in mouth feel.

Owner:北京康一品农产品物流有限公司

Solid beverage containing prebiotics and preparing method of solid beverage

InactiveCN109938130APrevent drynessHigh chemical activityMilk preparationPre-extraction tea treatmentHealthy dietFructose

The invention discloses a solid beverage containing prebiotics and a preparing method of the solid beverage, and relates to the technical field of solid beverages. The solid beverage is prepared from,by weight, 35-45 parts of whole milk powder, 35-45 parts of crystallized fructose, 10-15 parts of the prebiotics and 6-10 parts of tea powder. According to the preparing method, the crystallized fructose and the oligomerization prebiotics are combined to achieve a synergistic effect, improvement of the health care effect of the prebiotics is facilitated, the sweetness is high, and the caloric value is low; moreover, the solid beverage has the health care functions of reinforcing intestinal health care, promoting calcium absorption, reducing atherosclerosis and cardiovascular diseases and thelike, through a cooking technology, the flavor of the finished product is further improved, and the mouthfeel of the product is good; an independent small packet design is adopted, and the problem that the solid beverage cannot be stored in an exposed way for a long term when preservatives are not added is solved. No essence, preservatives or other additives are adopted for the solid beverage, thesolid beverage has the advantages of being simple in ingredient, simple in preparing technology, low in cost and good in mouthfeel, accords with the development tendency of healthy diets, and has high market value.

Owner:广州市品度食品供应链管理有限公司

Making method of avocado pear noodles

The invention discloses a making method of avocado pear noodles. The making method comprises the following steps of mixing 200 parts by weight of flour with 60-80 parts by weight of avocado pears, 10-20 parts by weight of mashed bananas, 10-20 parts by weight of apple juice, 10-20 parts by weight of mashed laver, 2-3 parts by weight of table salt and 1-2 parts by weight of pepper powder to obtaina mixture, adding 200-250 parts by weight of cold boiling water to the mixture, performing mixing, and performing fermentation at 25 DEG C for 24h. The noodles made by the method disclosed by the invention are emerald green in color, rich in nutrition, chewy in mouth feel, and unique in taste, can well promote the appetite of people, and can meet requirements of people for various nutrient elements.

Owner:颜强

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com