Tea leaf strip-tidying machine

A tea slitting machine and tea slicing technology, which is applied in the field of tea machinery, can solve the problems of operators' hand burns and inconvenient operation of the tea slitting machine, and achieve the effects of bright colors, convenient and quick operation, and improved quality and output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

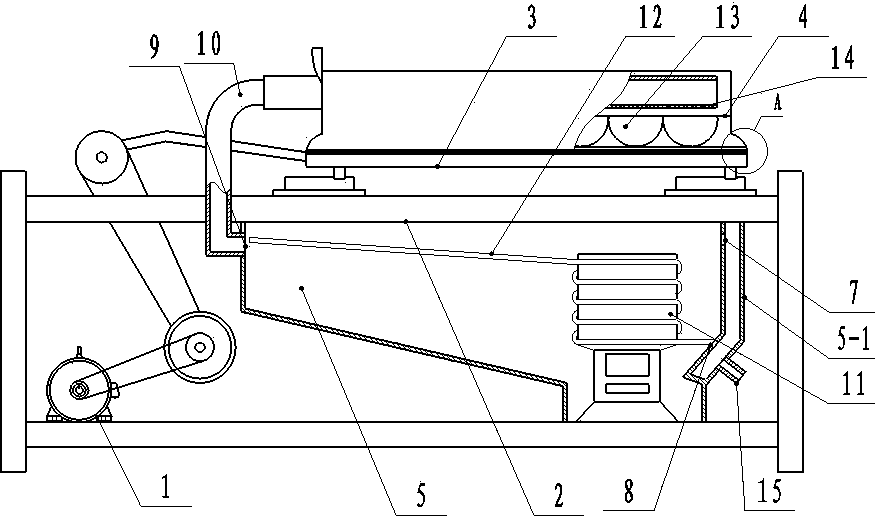

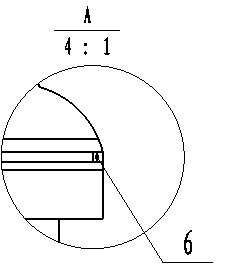

[0014] Such as figure 1 with figure 2 The present invention shown, it comprises motor 1 and frame 2, and this frame is provided with reciprocating frame 3, and this reciprocating frame is provided with tea bar bucket 4, and motor 1 is connected with reciprocating frame 3 by speed change mechanism, in The bottom of the frame 2 is provided with a combustion chamber 5, and the reciprocating frame 3 is slidingly connected with the tea stripping bucket 4. After the tea stripping is completed, the tea stripping bucket is pulled from the outside, and the tea stripping bucket moves outwards. There are sliding nails hinged in the chute at the bottom of the end, and the tea leaves will be poured out automatically after moving to the end, which is convenient and quick to operate; a sliding nail 6 is installed in the top chute at the tail end of the reciprocating frame 3; an air inlet 7 is arranged on the upper right side of the combustion chamber 5 , the bottom is provided with an air ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com