Drum-type automatic final-panning aroma raising machine and processing method thereof

A drum-type and aroma-tipping machine technology, which is applied in the direction of tea processing before extraction, can solve the problems such as being unable to be used on an automatic tea production line and not having automatic feeding and discharging functions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

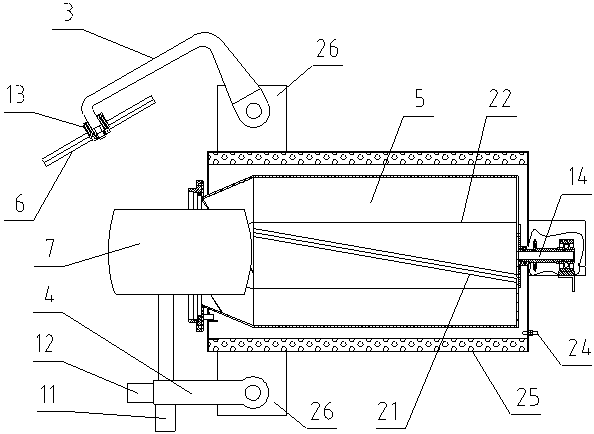

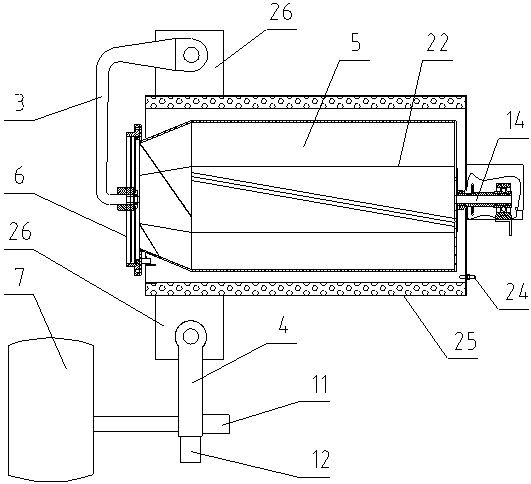

[0033] exist figure 1 figure 2 In the shown embodiment 1, a drum-type automatic hui pot aroma extractor includes a frame, a drum and a drum dumping mechanism arranged on the rack, one end of the drum is provided with a tea inlet and outlet, and the other end is closed and heated The air duct is connected to the hot air generating device. On the side of the frame 1 close to the tea inlet and outlet 2, a door opening and closing manipulator 3 for opening and closing the tea inlet and outlet and a material feeding and discharging manipulator 4 for tea feeding and discharging are provided. The drum type automatic The Huiguo aroma extractor is also equipped with an automatic control system 8, which is connected to and controls the drum rotating mechanism, the drum dumping mechanism 9, the drum heating device 10, the hot air generating device, the opening and closing manipulator and the feeding and discharging manipulator. The manipulator for opening and closing the door and the m...

Embodiment 2

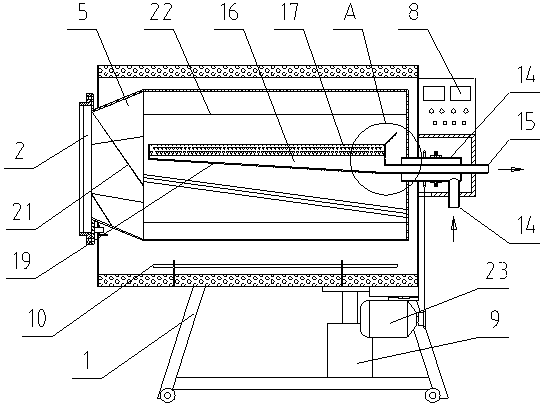

[0035] exist image 3 In the shown embodiment 2, a mechanical linkage mechanism (not shown in the figure) is provided between the opening and closing manipulator and the feeding and discharging manipulator, and a fixed 90-degree angle is set between the opening and closing manipulator and the feeding and discharging manipulator. The manipulator and the feeding and discharging manipulator are driven by the same manipulator drive mechanism, and the opening and closing manipulator and the feeding and discharging manipulator rotate synchronously and at the same rotation angle. The hot air pipe 14 on the drum is provided with a waste gas discharge pipe 15, and the drum is provided with a tea powder collection tank 16, one end of the collection tank near the tea inlet and outlet is suspended, and the other end is fixedly connected and communicated with the waste gas discharge pipe (see Figure 4 ), the top of the collection tank is provided with a tea powder filter cover 17, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com