Computer control apparatus for printing ink viscosity

A technology of computer control and printing ink, applied in the direction of printing, printing machines, general parts of printing machinery, etc., can solve the problems of high dependence on operators, untimely adjustment and control, and low production efficiency, so as to reduce the qualified rate and quality The effect of stability, reduction of scrap rate and defective rate, and improvement of quality stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The implementation of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0039] Technical solutions:

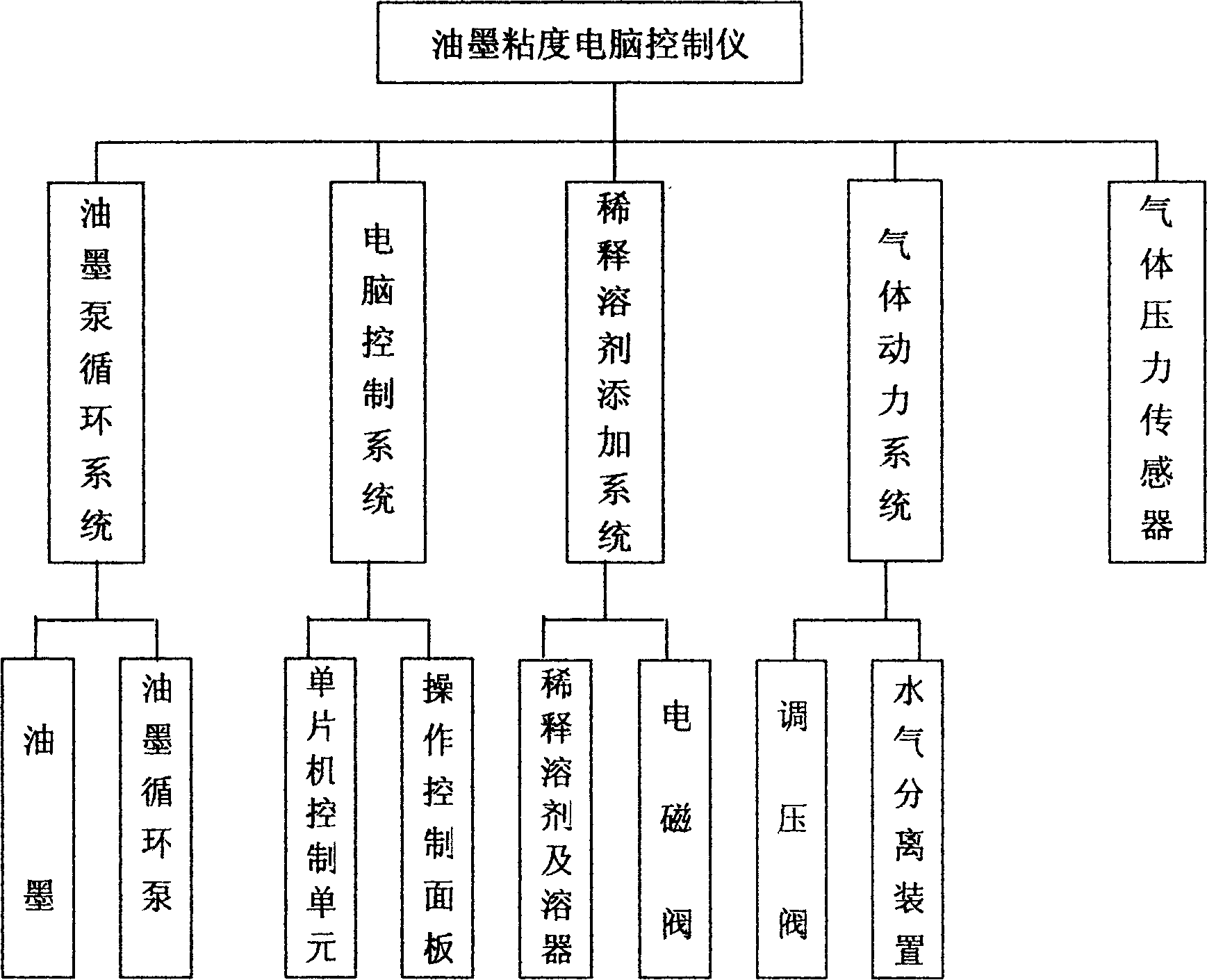

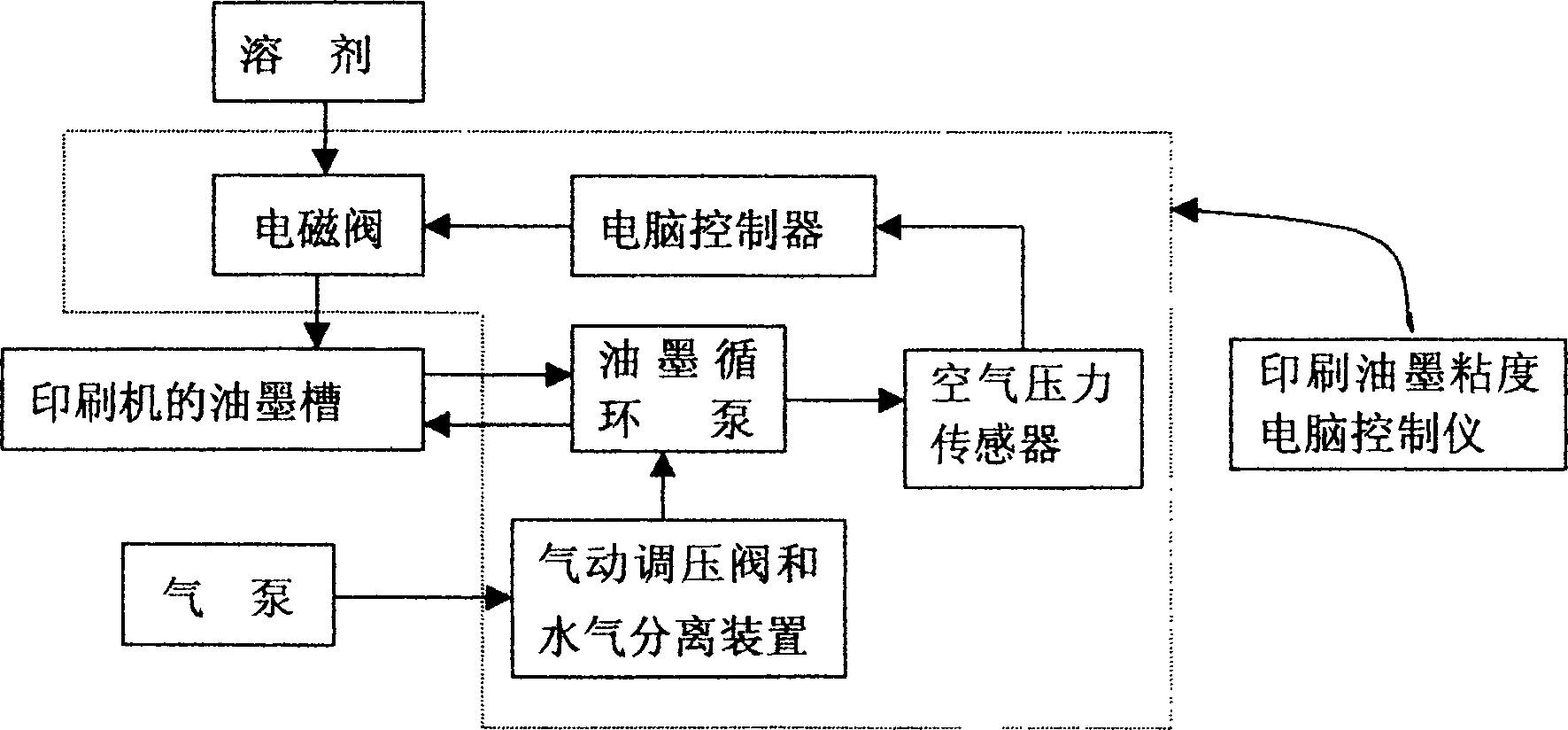

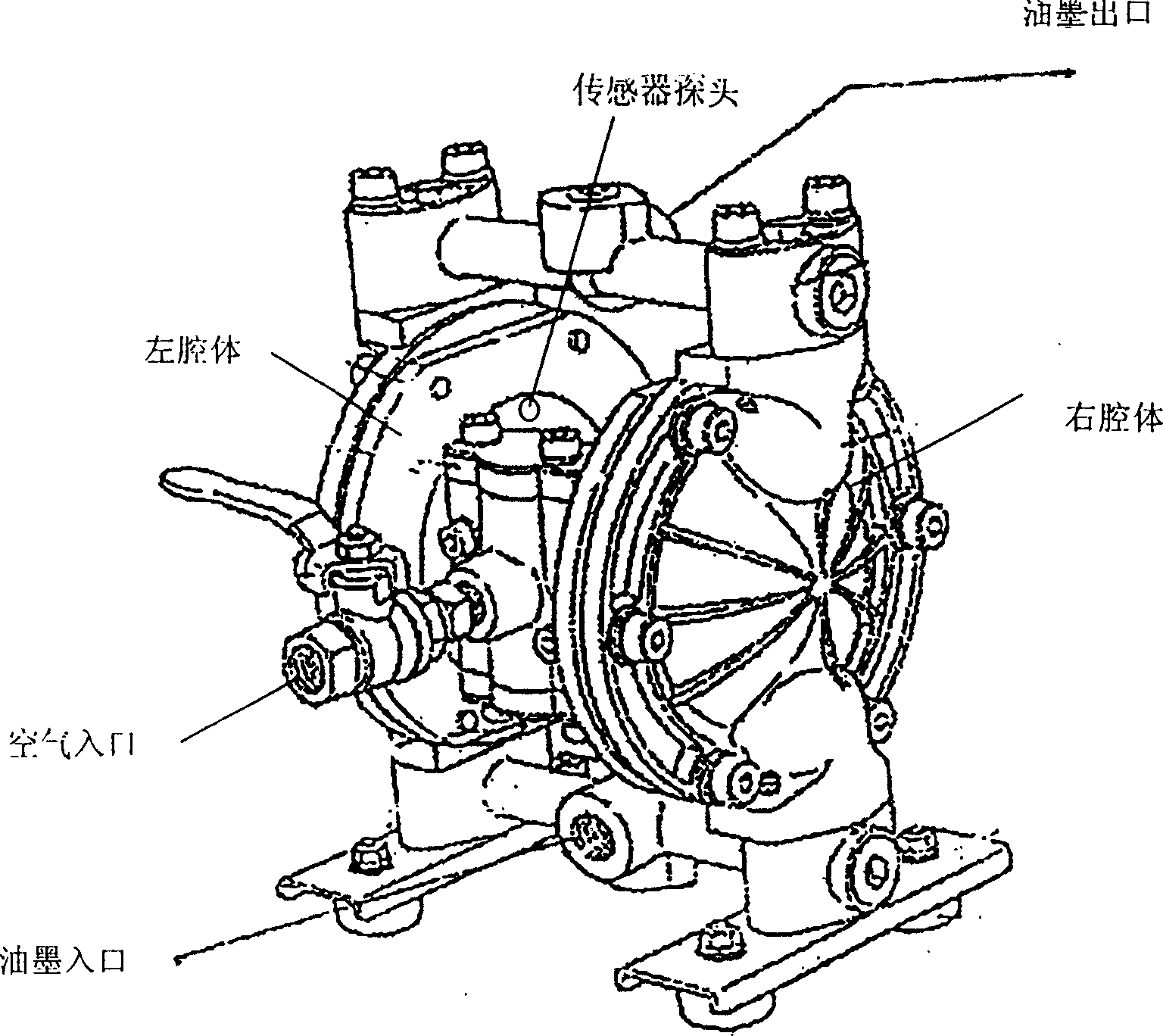

[0040] 1. Basic functions and main parameters of ink viscosity controller.

[0041] Control: Microcomputer control system is adopted.

[0042] Display: digital or liquid crystal display.

[0043] Input indication: A light indicates that the sensor has output.

[0044] Output indication: Light B is on to indicate that the solenoid valve is open.

[0045] Valve cleaning button: When pressed, the solenoid valve will automatically open for T seconds (default value), and the ink pump will inhale solvent to clean the solenoid valve. The solenoid valve opening time can be set according to needs.

[0046] Setting button: Press this button to enter the parameter setting state.

[0047] Select button: In the parameter setting state, every time you press this button, the parameter code will increase by 1 (cycle).

[0048...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com