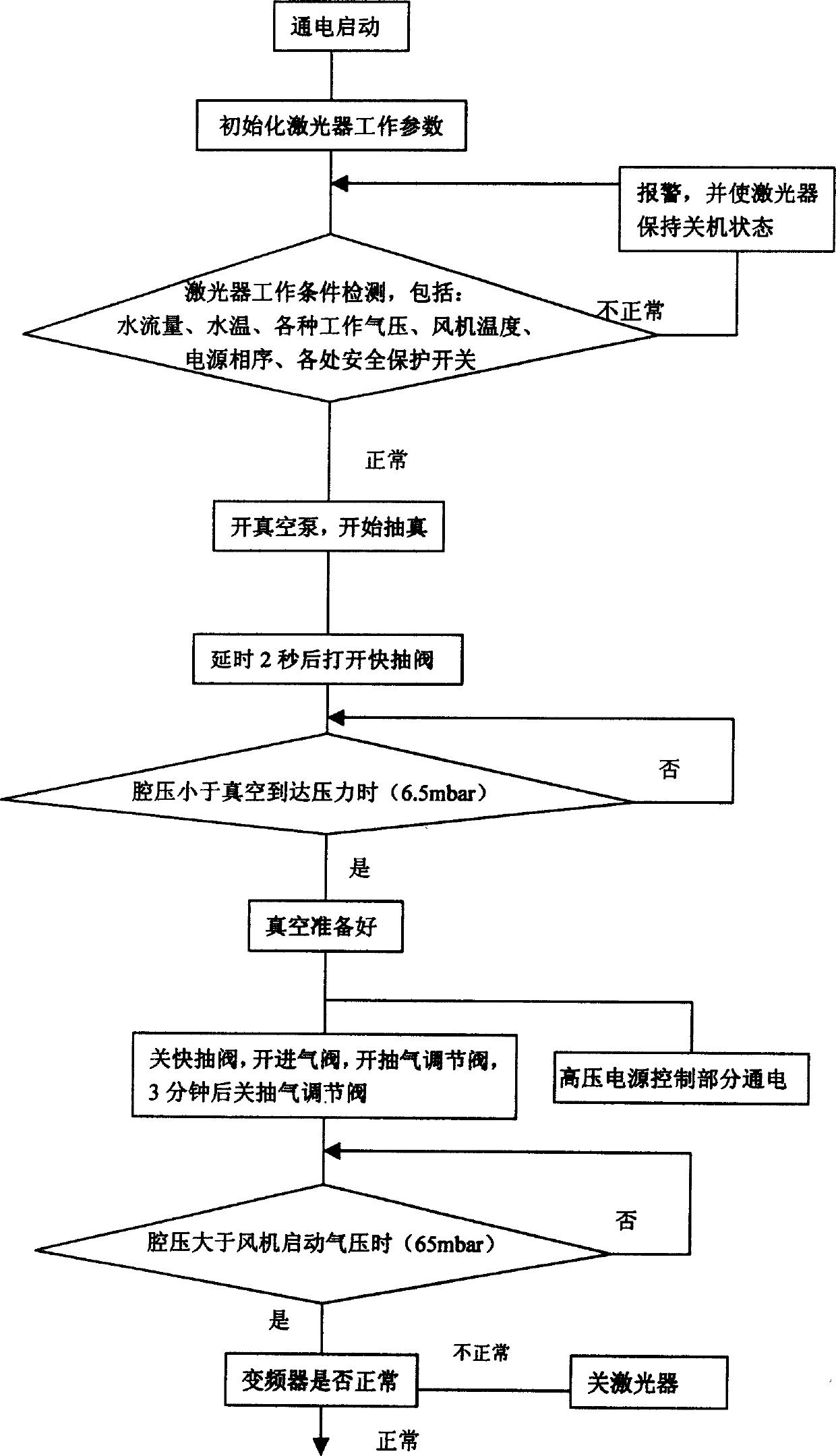

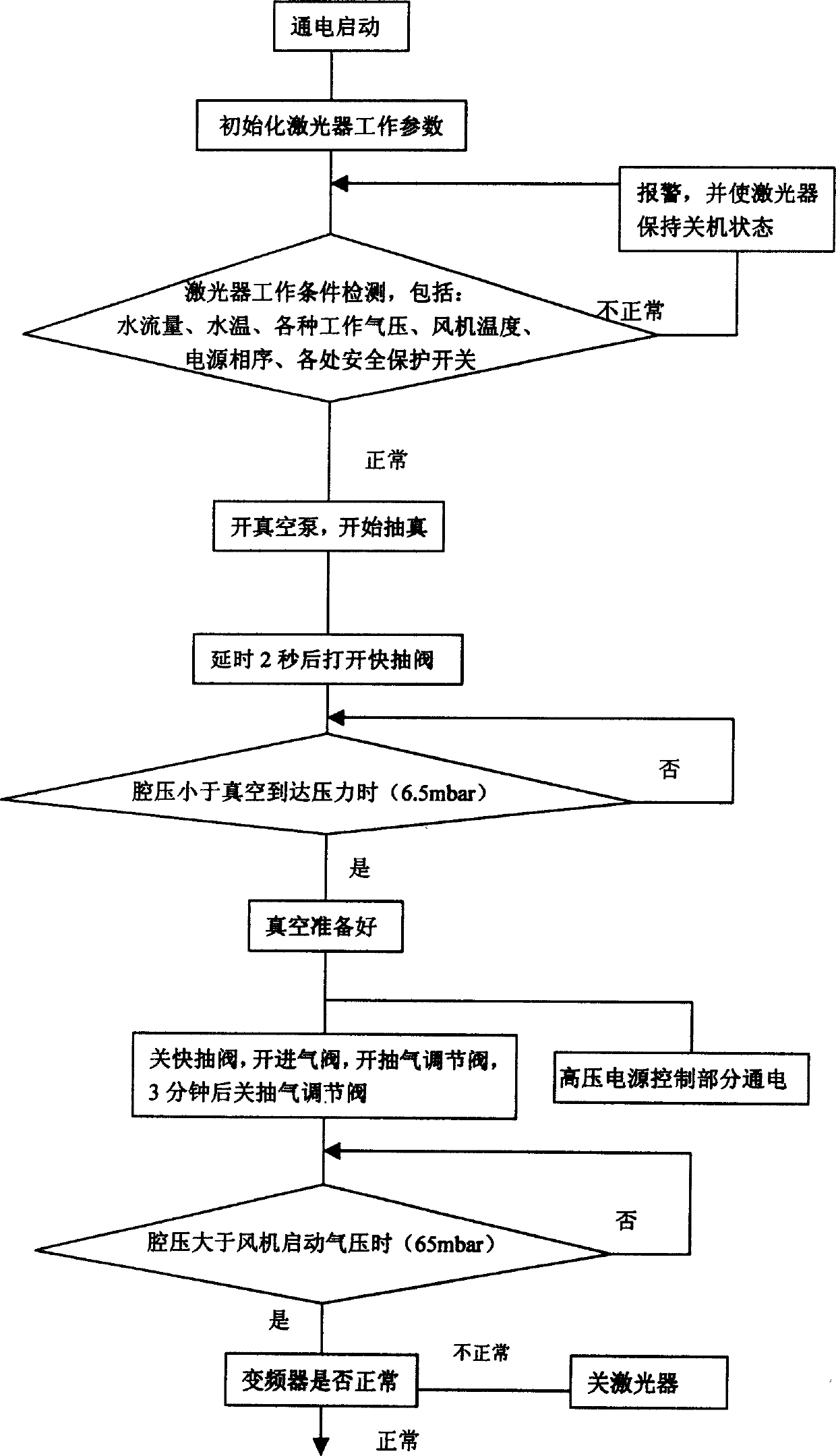

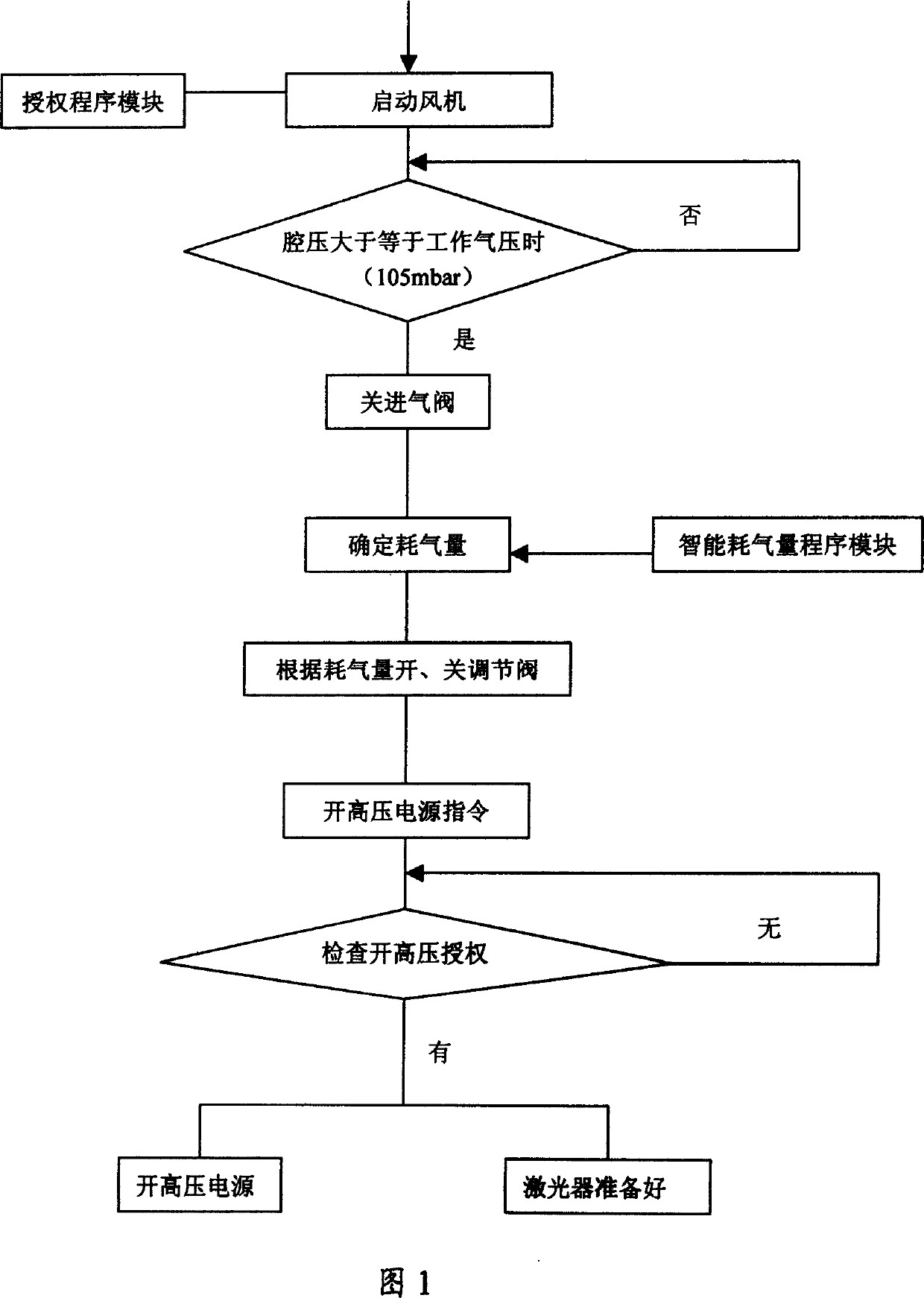

Large power CO2 laser PLC control method

A control method and laser technology, applied in the control field, can solve the problems of many analog/digital circuit boards, difficult to operate, poor reliability, etc., and achieve the effects of intuitive operation, improved control performance, and reduced possibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0094] Now with 3500W high power shaft fast flow CO 2 The laser control system is taken as an example to illustrate the implementation of the present invention. The programmable controller (Siemens CPU224) produced by Siemens and the touch screen produced by Delta are used as the main components, together with the peripheral electrical components and detection components to form the hardware of the control system, and the PLC and touch screen software that can realize the aforementioned functions are developed. Control objectives were successfully achieved. See Figure 11 for the PLC I / O function table, and Figure 12 for the Siemens CPU224 specific hardware I / O address table. Its control method is the same as the aforementioned method.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com