Supercritical fluid continuous yarn dyeing instrument

A technology of supercritical fluid and dyeing yarn, applied in liquid/gas/vapor yarn/filament processing, dyeing method, liquid/gas/vapor processing of textile materials of a certain length, etc., can solve the problem of increasing device and control complexity, It is difficult to ensure uniformity, low production efficiency, etc., to achieve the effect of improving production efficiency and dyeing quality, reducing energy consumption and saving costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The best embodiment of the present invention will be described in detail with reference to the accompanying drawings.

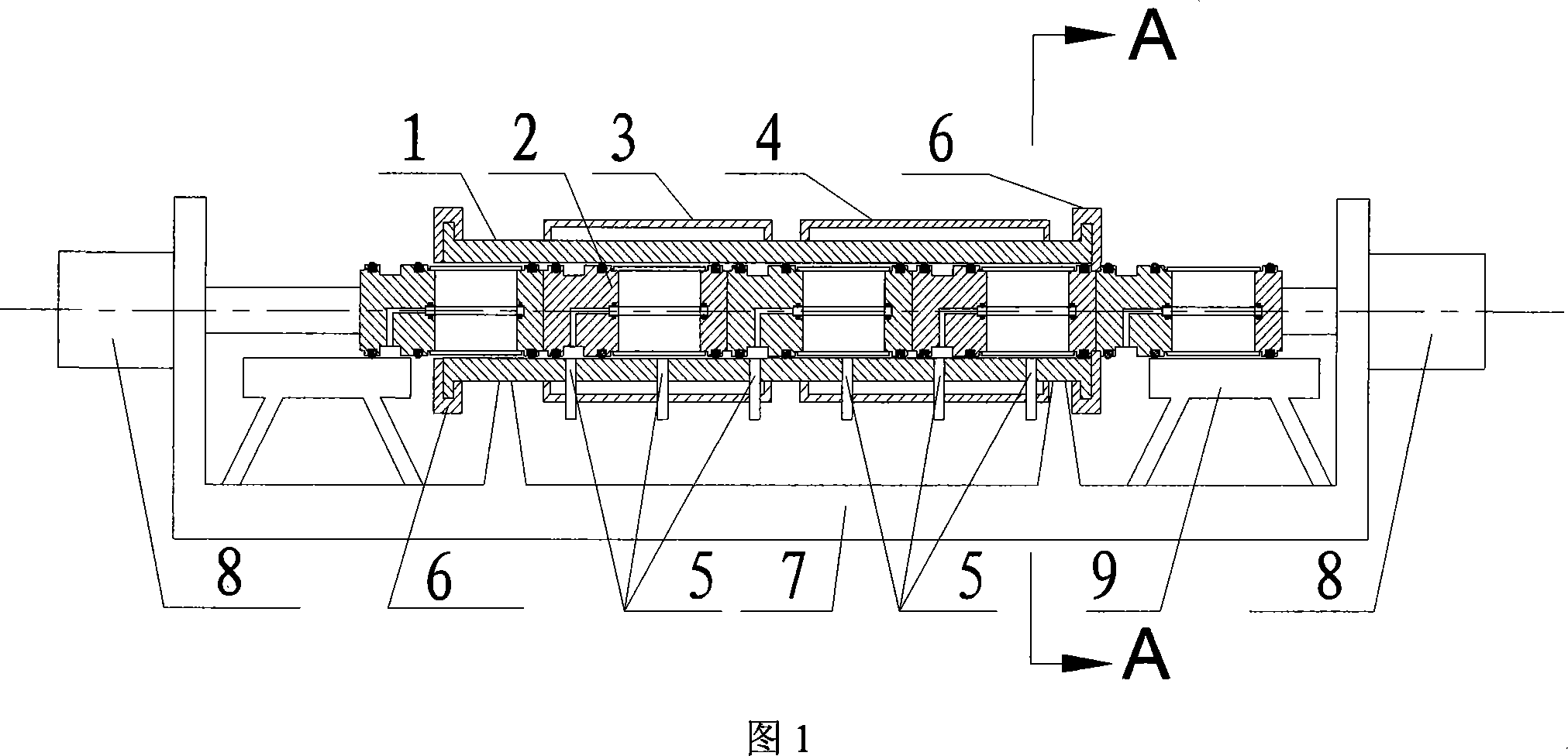

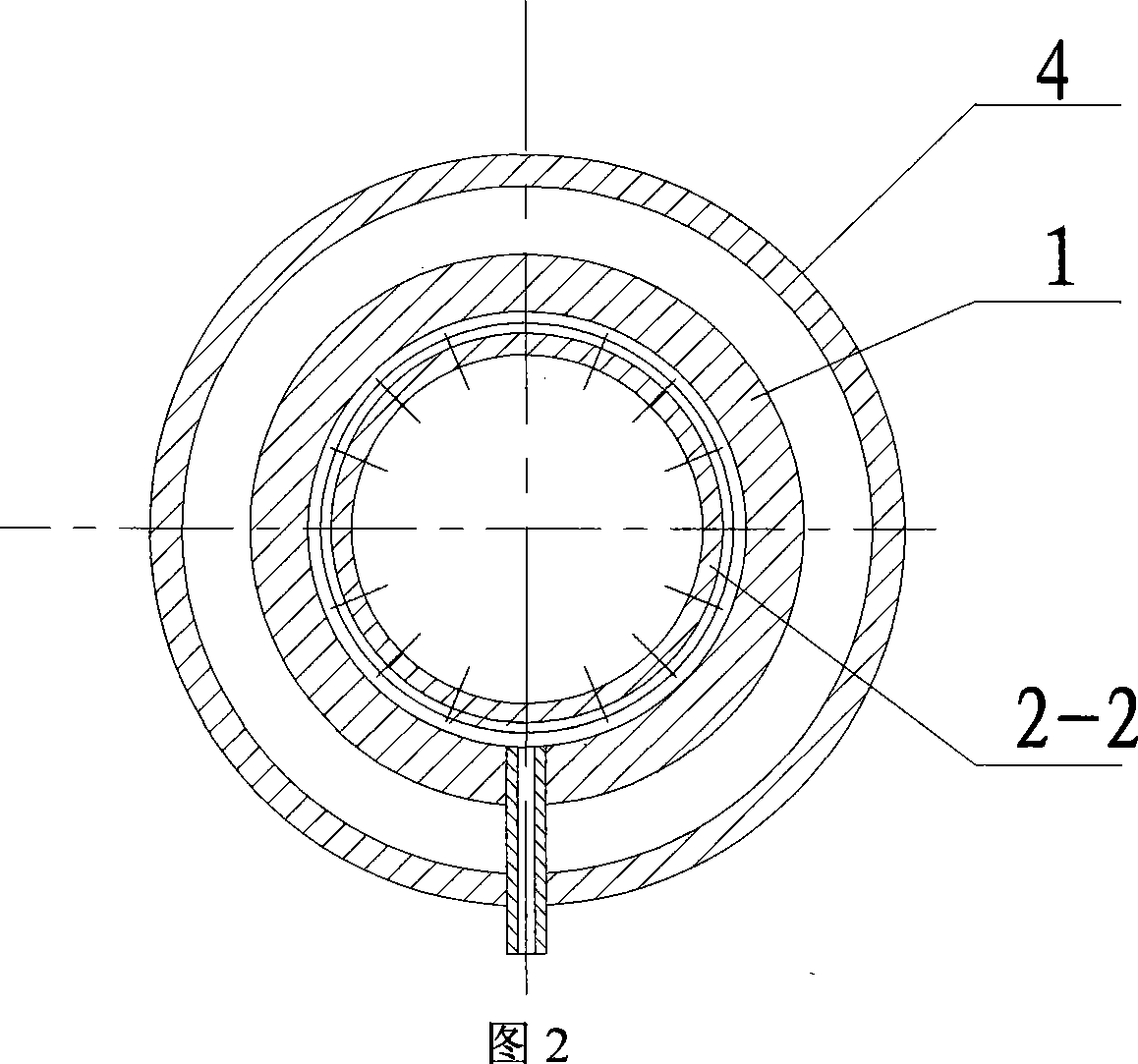

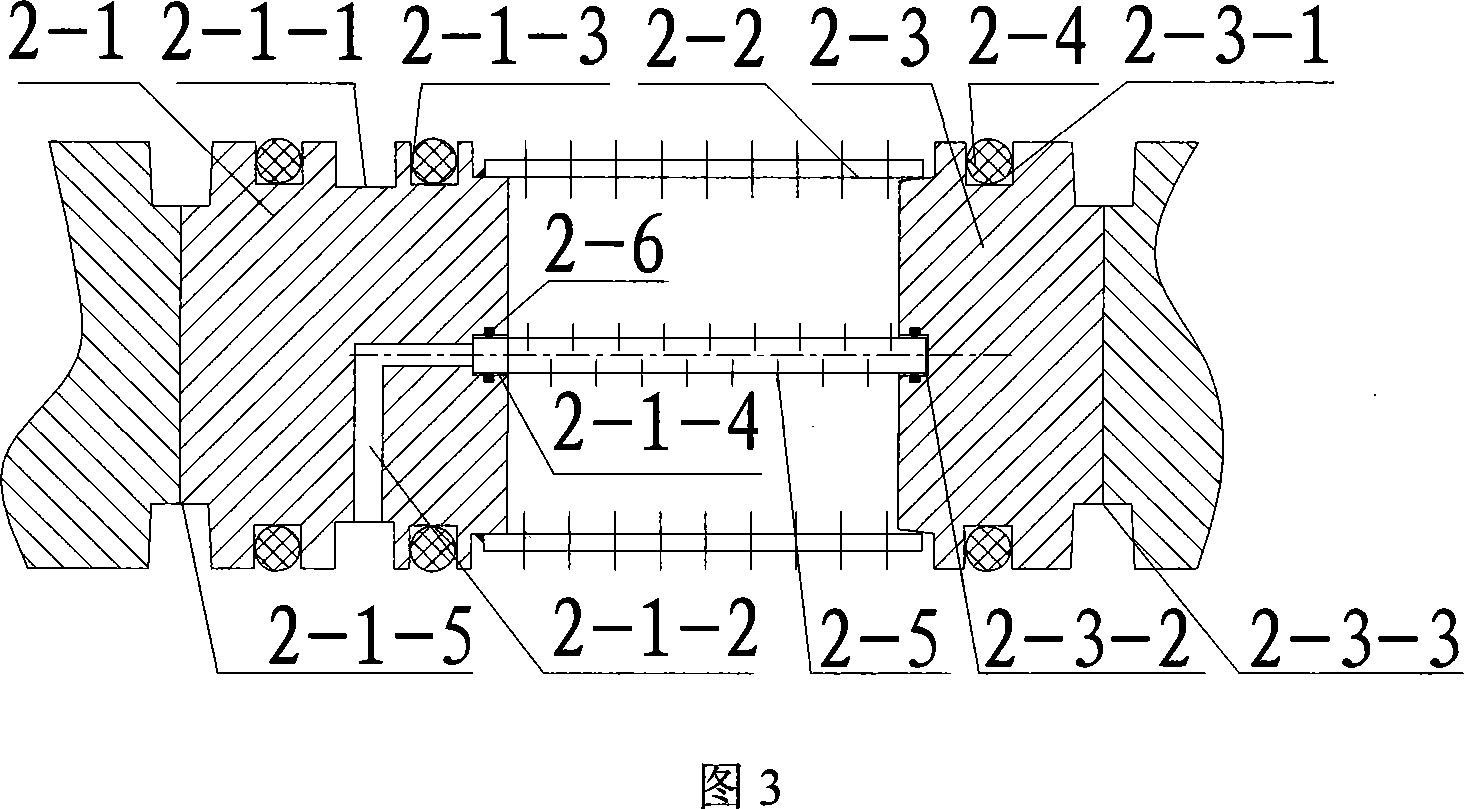

[0022] As shown in Figure 1, Figure 2 and Figure 3:

[0023] The cylinder body 1 of the yarn dyeing device is installed on the base 7, and there is a fluid pipeline interface 5 on the cylinder body 1, and heaters 3 and 4 are installed outside the cylinder body 1; Installed at both ends of the barrel 1; the driving mechanism 8 is installed at both ends of the base 7, and the power output part corresponds to the yarn bin 2 entering and leaving the barrel 1; the yarn bin bracket 9 is installed at the inlet and outlet of the barrel 1 , supporting the yarn bin 2 that goes in and out of the barrel 1.

[0024] The yarn bin 2 is composed of a yarn bin base 2-1, a fluid distribution cylinder 2-2, an end cover 2-3, a seal 2-4, a bobbin 2-5 and a seal 2-6; the yarn bin base 2- The seal 2-4 in the sealing groove 2-1-3 of 1 is sealed with at least two metal or po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com