Integrated dyeing kettle

A dyeing kettle and integrated technology, applied in the field of dyeing devices, can solve the problems of incapable of large-scale and continuous production, and achieve the effects of saving loading and unloading time, saving energy consumption, and accelerating dissolution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

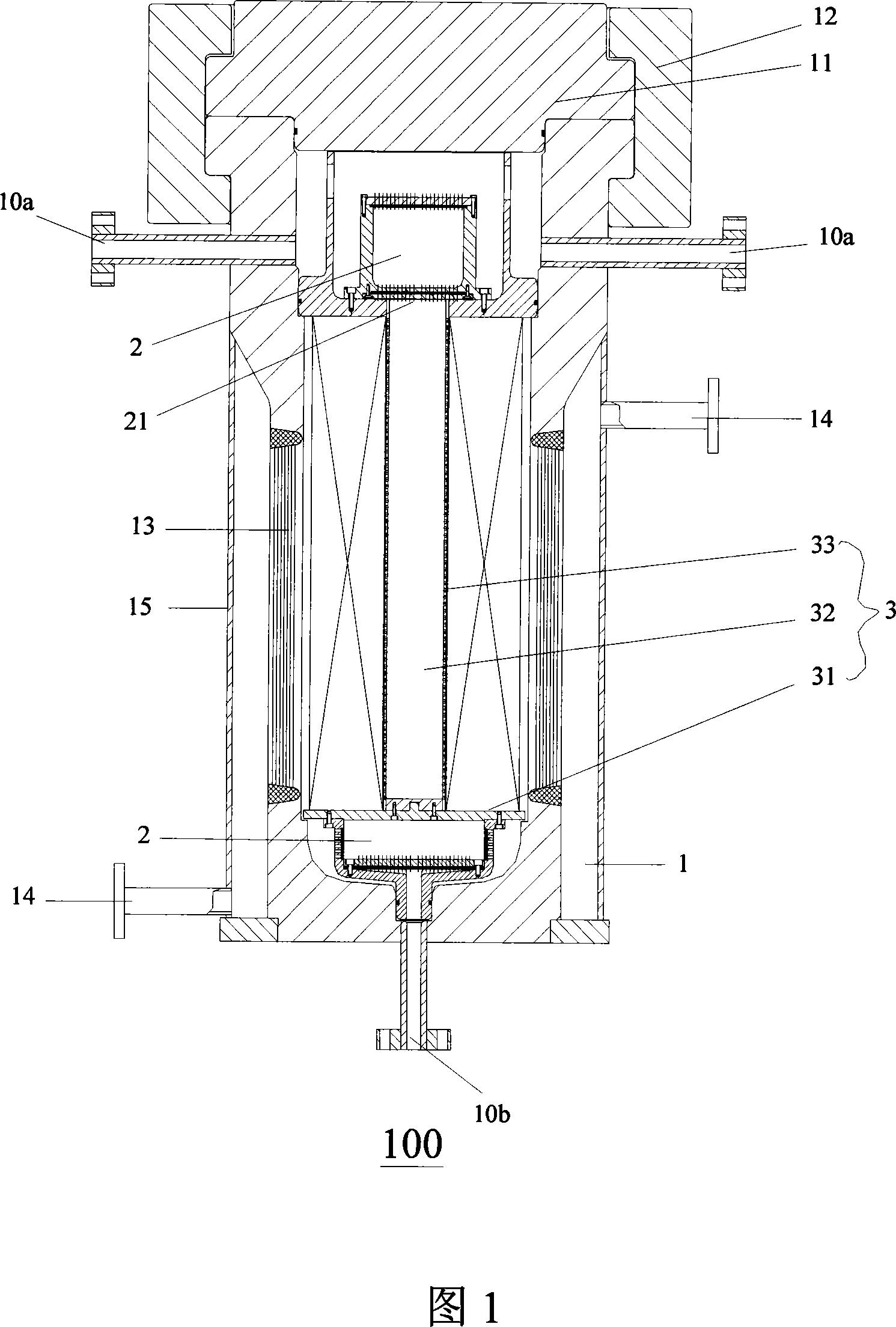

[0020] Referring to Fig. 1, the present invention provides an integrated dyeing kettle 100 for continuous dyeing, which includes a kettle body 1, a fabric fixing device 2 and at least one dye storage device 3, wherein the fabric fixing The device 2 and the dye storage device 3 are built in the kettle body 1 .

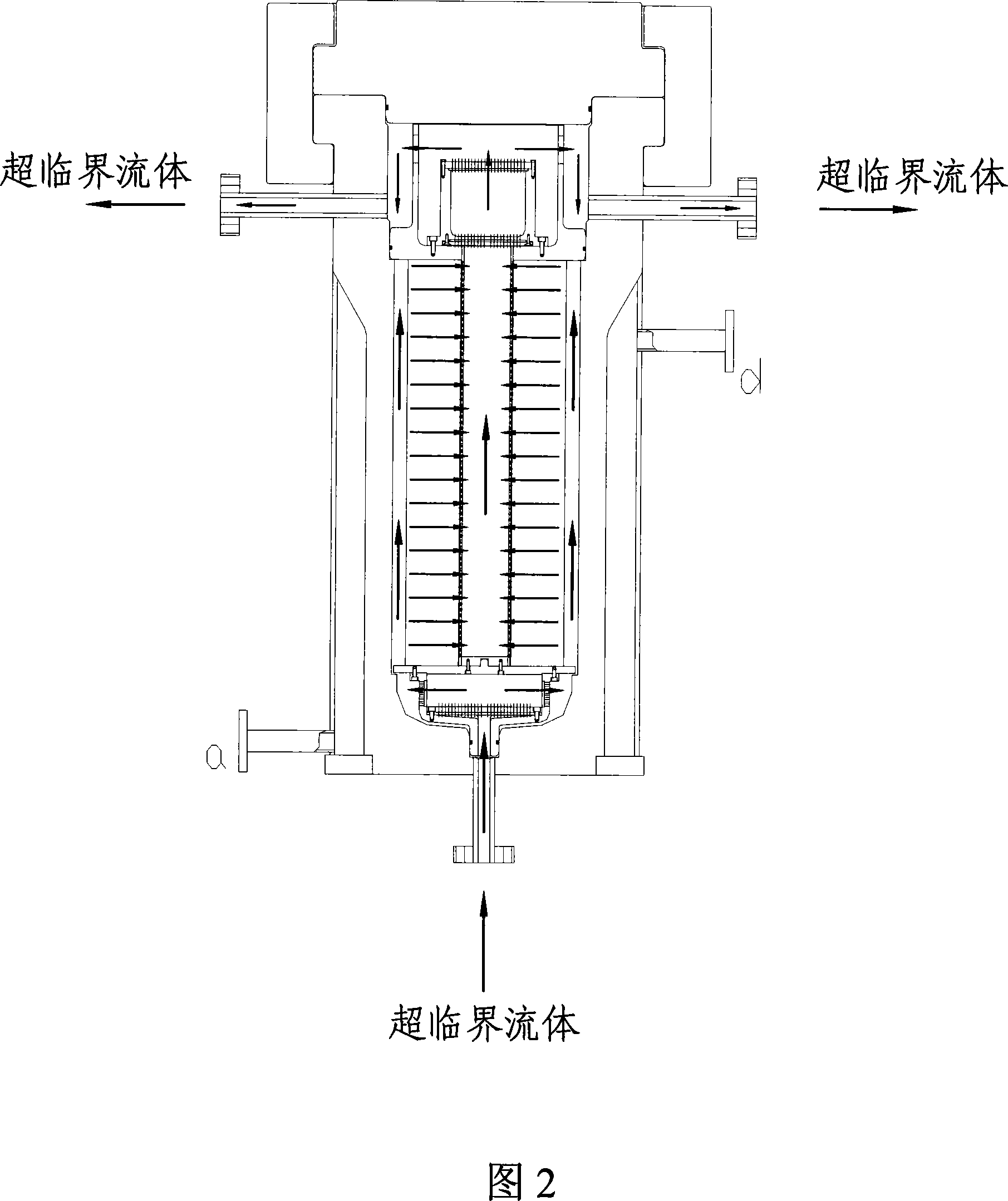

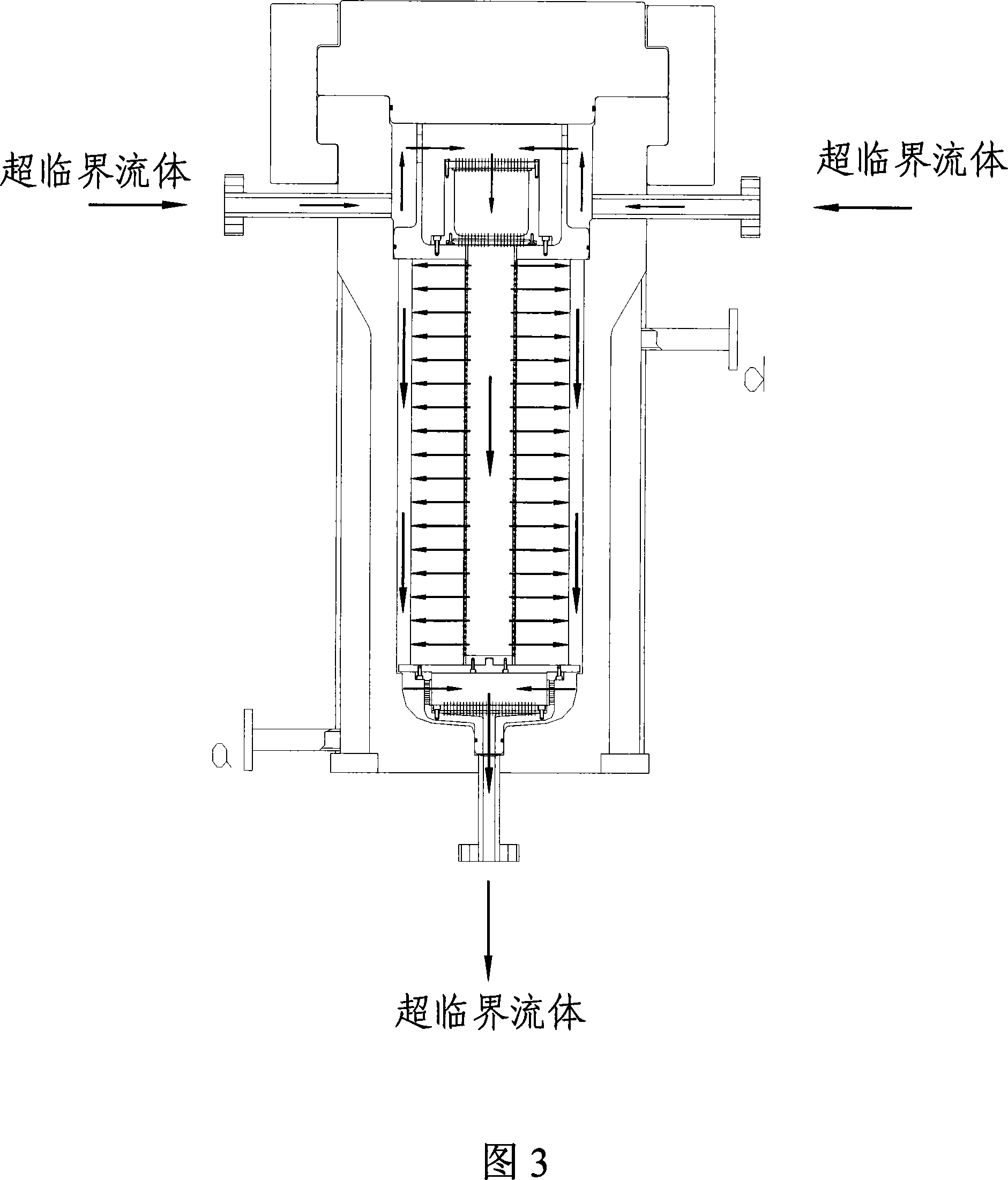

[0021] In one embodiment of the present invention, the kettle body 1 provides passages through which the supercritical fluid flows through the dyestuff and the fabric at the same time under a high-pressure working environment, which includes a supercritical fluid inlet / outlet, a kettle cover 11, and a clamp 12 And multi-layer wrapping cylinder 13. Wherein, there are three supercritical fluid inlets / outlets, wherein two supercritical fluid inlets / outlets 10a are oppositely set on the top of the kettle body 1, and another supercritical fluid inlet / outlet 10b is opened on the bottom of the kettle body 1; The valve can control the supercritical fluid to enter or exit the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com