Cationic high-molecular low-temperature self-crosslinking formaldehyde-free color fixing agent and preparation method thereof

A self-crosslinking, polymer technology, used in dyeing, textiles and papermaking, etc., can solve the problems of unsatisfactory color fixing effect, non-environmental protection and high product price, achieve good color fixing effect, improve utilization rate and cost low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

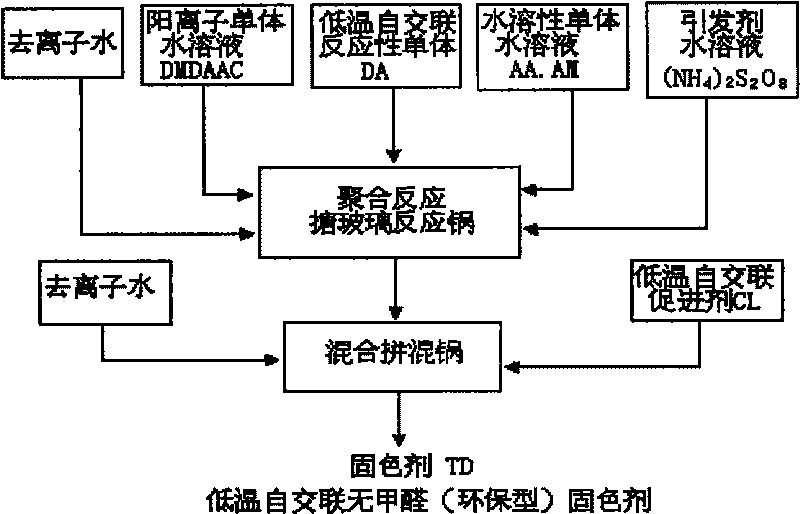

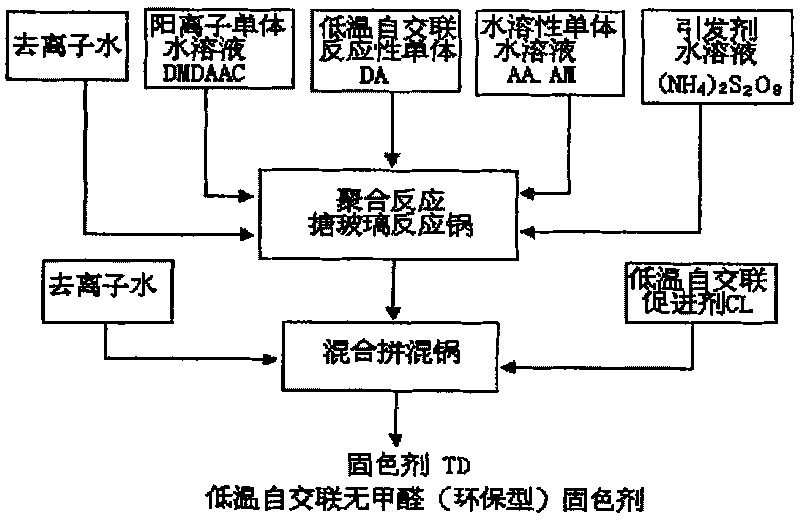

Image

Examples

Embodiment 1

[0018] Embodiment 1: Cationic monomer: 350 kilograms of dimethyl diallyl ammonium chloride (DMDAAC), water-soluble monomer comprises 1 kilogram of acrylamide (AM) and 1 kilogram of allylamine, low-temperature self-crossing 10 kg of reactive monomer (DA), 10 kg of low-temperature self-crosslinking accelerator (CL), initiator: 1.0 kg of ammonium persulfate, 380 kg of deionized water.

Embodiment 2

[0019] Embodiment 2: Cationic monomer: 420 kilograms of dimethyl diallyl ammonium chloride (DMDAAC), water-soluble monomer comprises 20 kilograms of acrylamide (AM) and 20 kilograms of allylamine, low-temperature self-crossing 20 kg of reactive monomer (DA), 20 kg of low-temperature self-crosslinking accelerator (CL), initiator: 2.0 kg of ammonium persulfate, 450 kg of deionized water.

Embodiment 3

[0020] Embodiment 3: Cationic monomer: 400 kilograms of dimethyl diallyl ammonium chloride (DMDAAC), water-soluble monomer comprises 10 kilograms of acrylamide (AM) and 10 kilograms of allylamine, low-temperature self-crossing 15 kg of reactive monomer (DA), 15 kg of low-temperature self-crosslinking accelerator (CL), initiator: 1.5 kg of ammonium persulfate, 400 kg of deionized water.

[0021] The preparation method of cationic polymer low-temperature self-crosslinking formaldehyde-free color-fixing agent of the present invention, the steps are as follows: in 1000 liters of glass-lined reaction pots with agitator, pressure gauge, thermometer, safety valve, reflux condenser Add 100-150 kg of deionized water to the tank, start stirring; slowly heat up to 70-75C with jacketed water, then add it dropwise from four high-level tanks at the same time, the first high-level tank is a cationic monomer with a concentration of 60% Aqueous solution, the second high tank is a low-temperatu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com