Back washing free dyeing method for cashmere slivers

A dyeing method and cashmere technology, which is applied in the field of textile printing and dyeing, can solve the problems of rewashing cashmere strands, etc., and achieve the effects of simple process control, convenient and reliable use, and remarkable color brightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

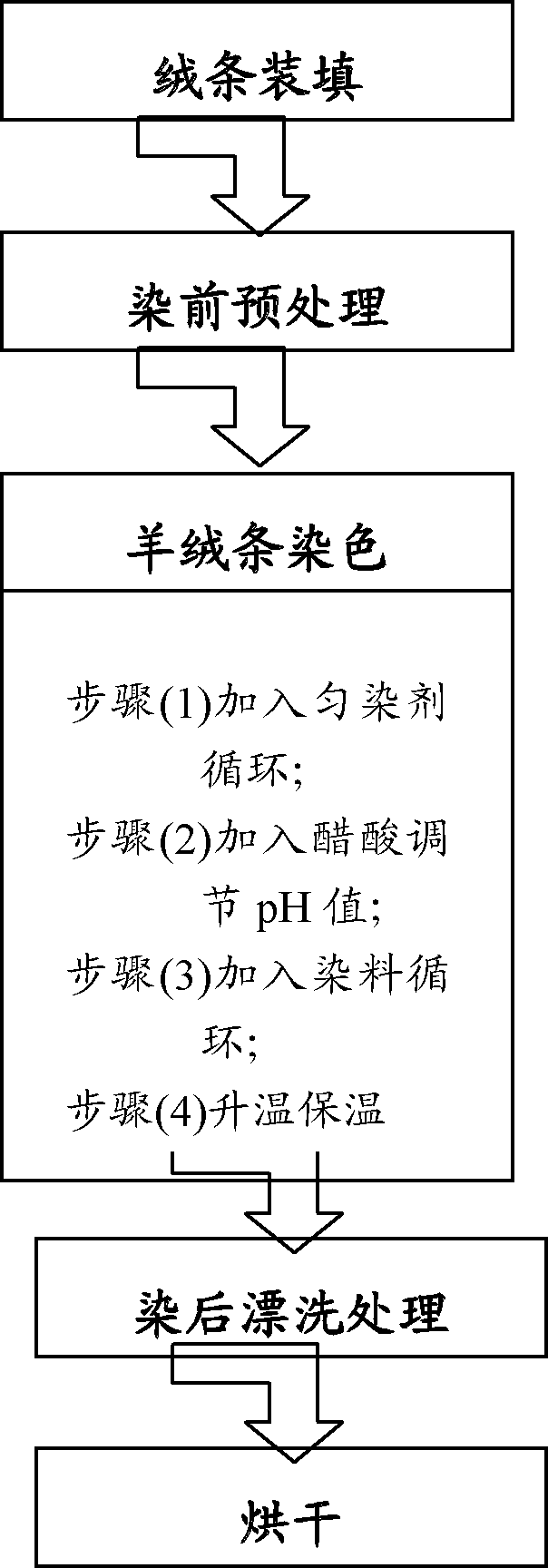

Method used

Image

Examples

Embodiment 1

[0022] When the dye weight / cashmere strands weight ratio is 0.5%, the cashmere strands are wound up layer by layer in the axial direction to form a cylindrical cashmere ball with a central hole with a diameter of 80 mm. The outer diameter of the cashmere ball is 400 mm. Fill the cashmere ball strings on the core of the dyeing cage, pressurize the core cashmere balls and lock the core. The compacted cashmere fiber has a density of 0.1 g / cm3. After filling, hang the cashmere ball into the dye vat. Then put water in the dye vat, heat it to 30°C, turn on the circulation pump of the dye vat, and use the pressure of the circulation pump of the dye vat to make the lotion pass through the cashmere ball and the hole of the cylinder wall from the outside of the cashmere ball to the inside, and enter the core of the cylinder. Then it is sprayed from the top of the barrel core and flows back to the circulation pump of the dye vat. Cycle wash for 10 minutes, then drain the washing solut...

Embodiment 2

[0024] When the dye weight / cashmere strands weight ratio is 0.5%, the cashmere strands are wound up layer by layer in the axial direction to form a cylindrical cashmere ball with a central hole with a diameter of 90 mm. The outer diameter of the cashmere ball is 400mm. Fill the cashmere ball strings on the core of the dyeing cage, pressurize the core cashmere balls and lock the core. The density of compacted cashmere fibers is 0.15 g / cm3. After filling, hang the cashmere ball into the dye vat. Then put water in the dye vat, heat it to 40°C, turn on the circulation pump of the dye vat, and use the pressure of the circulation pump of the dye vat to make the lotion pass through the cashmere ball and the hole of the cylinder wall from the outside of the cashmere ball to the inside, and enter the core of the cylinder. Then it is sprayed from the top of the barrel core and flows back to the circulation pump of the dye vat. Cycle wash for 10 minutes, then drain the washing solutio...

Embodiment 3

[0026]When the dye weight / cashmere strands weight ratio is 0.5%, the cashmere strands are wound up layer by layer in the axial direction to form a cylindrical cashmere ball with a central hole with a diameter of 100 mm. The outer diameter of the cashmere ball is 400mm. Fill the cashmere ball strings on the core of the dyeing cage, pressurize the core cashmere balls and lock the core. The compacted cashmere fiber has a density of 0.2 g / cm3. After filling, hang the cashmere ball into the dye vat. Then put water in the dye vat, heat it to 45°C, turn on the circulation pump of the dye vat, and use the pressure of the circulation pump of the dye vat to make the lotion pass through the cashmere ball and the hole of the cylinder wall from the outside of the cashmere ball to the inside, and enter the core of the cylinder. Then it is sprayed from the top of the barrel core and flows back to the circulation pump of the dye vat. Cycle wash for 10 minutes, then drain the washing soluti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com