A kind of 140tdsn printing rotary screen, preparation method and application thereof

A printing rotary screen and mesh technology, which is applied in the field of textile printing, can solve the problems of high maintenance costs of machines, affect the printing effect, and high labor intensity, and achieve the effects of low production cost, rich colors, and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] Embodiment 1: A kind of preparation method of 140TDSN printing cylinder screen

[0053] Include the following steps:

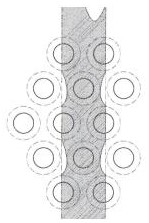

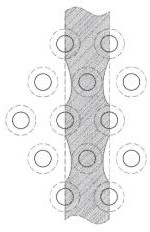

[0054] 1. Production of tire mold

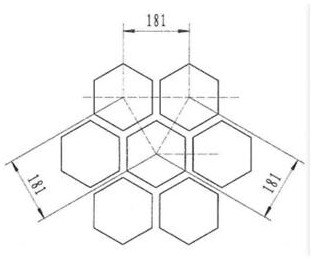

[0055] Use a 140-mesh male mold to press the regular hexagonal mesh, including the following steps: seamless steel pipe processing, nickel plating, copper plating, 140-mesh mesh rolling, chrome plating, embedding insulating glue, curing, polishing, Produced 140TDSN-type printing rotary screen mesh series dedicated tire mold, the specific indicators are: the mesh number is 140 mesh, that is, there are 140 regular hexagonal mesh holes on 1 inch, and the distance between the mesh holes is 181µm,

[0056] The prepared 140TDSN printing cylinder mesh series dedicated tire mold, the tire mold circumference is selected as 640mm, the length is selected as 4000mm, and the rib width is selected as 13µm.

[0057] 2. Primary plating

[0058] Based on the prepared tire mold, electroplating was carried out once in the electroplatin...

Embodiment 2

[0077] Embodiment 2 A kind of preparation method of 140TDSN printing cylinder screen

[0078] Include the following steps:

[0079] 1. Production of tire mold

[0080] Use a 140-mesh male mold to press the regular hexagonal mesh, including the following steps: seamless steel pipe processing, nickel plating, copper plating, 140-mesh mesh rolling, chrome plating, embedding insulating glue, curing, polishing, Produced 140TDSN special tire molds for printing rotary screen series mesh.

[0081] The prepared 140TDSN type printing rotary screen mesh series special tire mold, the specific index is: the mesh number is 140 mesh, that is, there are 140 regular hexagonal mesh holes on 1 inch, and the distance between the mesh holes is 181µm,

[0082] 140TDSN type printing rotary screen mesh series dedicated tire mold, the circumference is 820mm, the length is 3250mm, and the rib width is 11µm.

[0083] 2. Primary plating

[0084] Based on the prepared tire mold, electroplating is carr...

Embodiment 3

[0103] Embodiment 3: A kind of preparation method of 140TDSN printing cylinder screen

[0104] Include the following steps:

[0105] 1. Production of tire mold

[0106] Use a 140-mesh male mold to press the regular hexagonal mesh, including the following steps: seamless steel pipe processing, nickel plating, copper plating, 140-mesh mesh rolling, chrome plating, embedding insulating glue, curing, polishing, Produced 140TDSN special tire molds for printing rotary screen series mesh.

[0107] The prepared 140TDSN type printing rotary screen mesh series dedicated tire mold, the specific indicators are: the mesh number is 140 mesh, that is, there are 140 regular hexagonal mesh holes on 1 inch, and the distance between the mesh holes is 181µm;

[0108] 140TDSN is a special tire mold for printing rotary screen series mesh. The tire mold adopts a circumference of 914mm, a length of 2000mm, and a rib width of 10µm.

[0109] 2. Primary plating

[0110] Based on the prepared tire mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com