Method for bleaching complexing catalysis human hair fibers

A technology of complex catalysis and catalysis, applied in the field of complex catalysis of human hair fiber bleaching and human hair fiber bleaching, to achieve the effects of improving bleaching efficiency, reducing ineffective decomposition, and improving permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

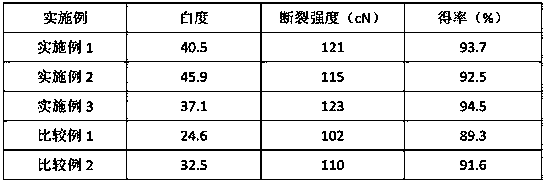

[0017] Add the compound amino acid and ferrous sulfate obtained by hydrolyzing keratin into water, so that the concentration of compound amino acid is 3g / L, and the concentration of ferrous sulfate is 5g / L, and stir for 20 minutes; heat up to 50°C, add human hair to be treated Fiber, make the mass ratio of human hair fiber to water 1:15, soak for 20 minutes; add hydrogen peroxide with a concentration of 30%, make the mass ratio of hydrogen peroxide to human hair fiber 0.5:1, bleach for 50 minutes, take out the human hair Fiber, washed. The whiteness, breaking strength and yield of the product are shown in Table 1.

Embodiment 2

[0019] Add the compound amino acid and ferrous sulfate obtained by hydrolyzing keratin into water so that the concentration of the compound amino acid is 1g / L, and the concentration of ferrous sulfate is 3g / L. Stir and react for 30 minutes; raise the temperature to 60°C, add human hair to be treated fiber, make the mass ratio of human hair fiber to water 1:5, soak for 30 minutes; add 30% hydrogen peroxide, make the mass ratio of hydrogen peroxide and human hair fiber 2:1, bleach for 30 minutes, take out the human hair Fiber, washed. The whiteness, breaking strength and yield of the product are shown in Table 1.

Embodiment 3

[0021] Add the compound amino acid and ferrous sulfate obtained by hydrolyzing keratin into water, so that the concentration of compound amino acid is 5g / L, and the concentration of ferrous sulfate is 10g / L, and stir for 10 minutes; heat up to 40°C, add human hair to be treated fibers, so that the mass ratio of human hair fibers to water is 1:30, soak for 10 minutes; add hydrogen peroxide, so that the mass ratio of 30% hydrogen peroxide to human hair fibers is 0.3:1, bleach for 100 minutes, take out the human hair Fiber, washed. The whiteness, breaking strength and yield of the product are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com