Preparation method of hydrogen peroxide

A technology of hydrogen peroxide and oxidizing liquid, applied in chemical instruments and methods, peroxide/peroxyhydrate/peroxyacid/superoxide/ozone, inorganic chemistry, etc. Catalyst deactivation and other problems, to achieve the effect of simple device structure, easy installation and maintenance, and high hydrogen efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

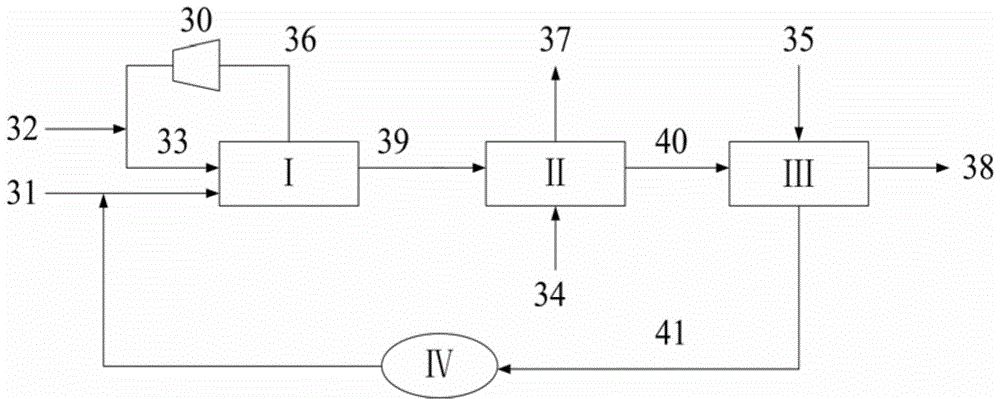

[0016] A method for preparing hydrogen peroxide, comprising: introducing a working fluid and a hydrogen-containing gas into a hydrogenation reactor; in the presence of a catalyst, the working fluid reacts with hydrogen; after gas-liquid separation, the gas is discharged from a gas outlet; and the slurry is filtered The clear liquid obtained afterward is a hydrogenated liquid; the hydrogenated liquid reacts with oxygen in an oxidation reactor to obtain an oxidized liquid containing hydrogen peroxide; the oxidized liquid is extracted and separated in an extraction tower to obtain a hydrogen peroxide solution and a working liquid; the hydrogenation reaction The reactor is a slurry bed reactor.

[0017] The method provided by the invention comprises a hydrogenation reaction unit, an oxidation reaction unit and an extraction unit.

[0018] (1) Hydrogenation reaction unit:

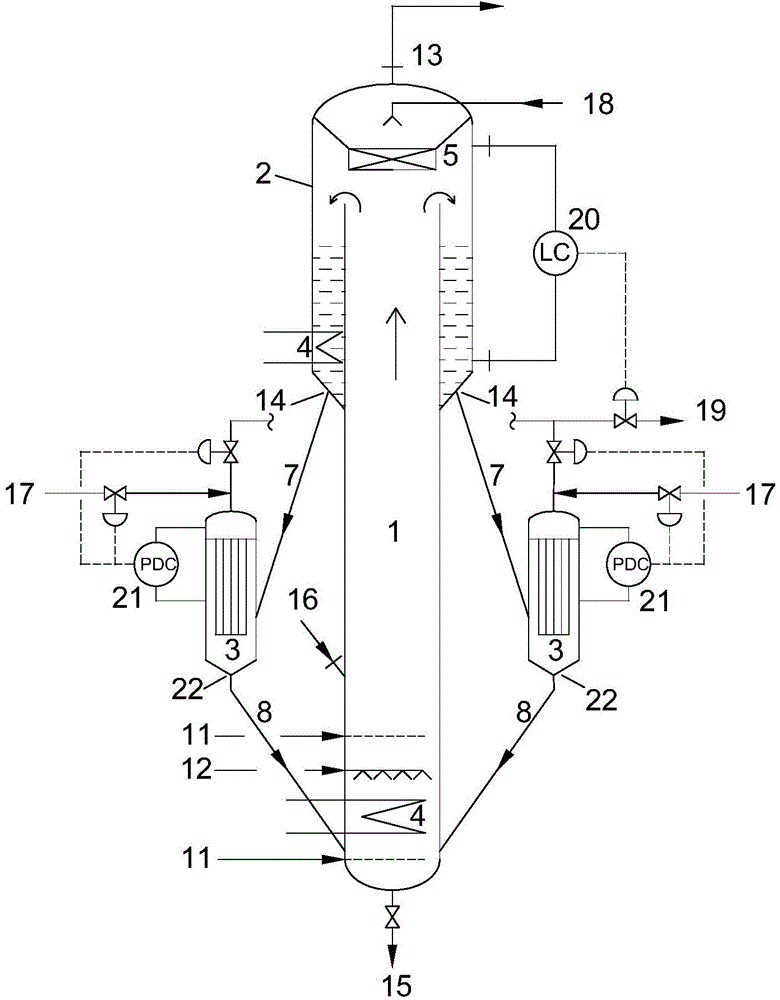

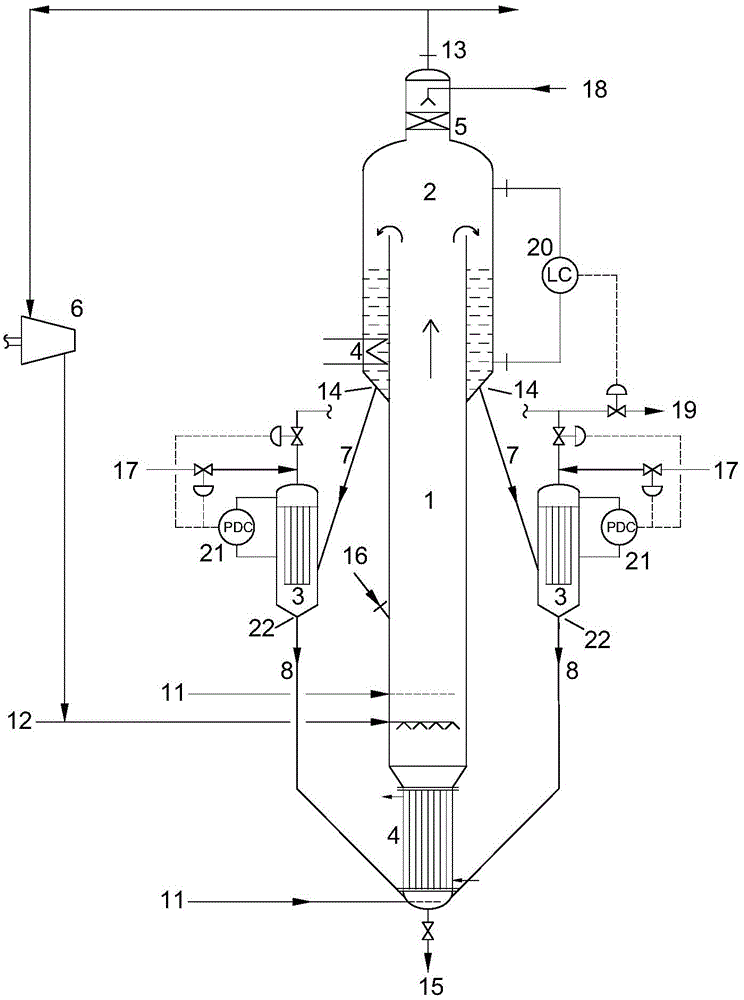

[0019] In the method provided by the present invention, the hydrogenation reactor used in the hydrogenation ...

Embodiment 1

[0075] as attached image 3 As shown, the hydrogenation reaction unit adopts a slurry bed reactor. The diameter of the reaction cylinder is 300, the diameter of the separator is 800; the diameter of the washing section is 300, and the BX500 packing with a height of 300mm is installed inside. Pure hydrogen 42Nm 3 / h enters the slurry bed reactor through the gas inlet, and 4.8m working fluid preheated to 60°C by the heater 3 / h enters the slurry bed reactor from the liquid phase inlet, and 72kg of catalyst is added to the slurry bed reactor from the catalyst feeding port. Under the reaction conditions of 60°C and 0.4MPa, the anthraquinone in the working fluid undergoes hydrogenation reaction to form a hydrogenated fluid. The formed hydrogenated liquid slurry is passed through the filter, using three sets of parallel filters with metal filter elements inside, and the hydrogenated liquid clear liquid is used as the backflush liquid, and backwashed every 1 hour. The filtered sl...

Embodiment 2

[0080] The device and flow process that adopt are the same as embodiment 1, and the amount of pure hydrogen that the hydrogenation unit enters is 32Nm 3 / h, the intake air volume of the oxidation reactor is 198Nm 3 / h, the pure water containing phosphoric acid that the extraction unit enters is 73kg / h, and other conditions are the same as embodiment 1. The hydrogen effect of the hydrogenation liquid clear liquid is 10.1g / l, and the final product is a 35% hydrogen peroxide solution.

[0081] As can be seen from Examples 1, 2 and Comparative Example 1, the hydrogen efficiency of the hydrogen peroxide preparation method provided by the present invention can be increased to more than 10g / l, and the concentration of the prepared hydrogen peroxide solution can also be increased to more than 30% accordingly. It has good economic benefits and contributes to energy saving, consumption reduction and environmental protection of downstream industries.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com