Solvent system and variable working solution for producing hydrogen peroxide through anthraquinone method, and applications of variable working solution

An anthraquinone method, working fluid technology, applied in peroxide/peroxyhydrate/peroxyacid/superoxide/ozonide, chemical instruments and methods, inorganic chemistry, etc., can solve the problem of low product dissolution rate, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

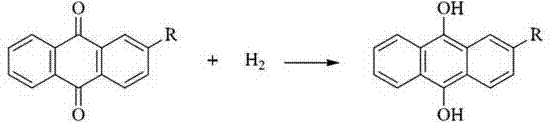

Method used

Image

Examples

Embodiment 1

[0044] According to volume percentage, measure 50% of C 9 ~C 10 Aromatic hydrocarbons, 20% tetrabutylurea and 30% benzophenone (55°C) are mixed thoroughly at room temperature, then 10 liters of the above mixed solvent is taken, and 2-ethylanthraquinone is added to it until it reaches saturation, and the calculation The mass content of 2-ethylanthraquinone in this working solution is 154g / L. In order to prevent the precipitation of working substances due to temperature fluctuations during evaluation, 10% of the above-mentioned mixed solvent is added to the saturated working solution. Under certain experimental conditions, the reaction performance of the working solution was evaluated. After hydrogenation, oxidation and extraction, the calculated hydrogen efficiency was 13.3gH 2 o 2 / L working fluid.

Embodiment 2~20

[0046] The preparation process and experimental method are the same as in Example 1. The solvent composition is different from that of Example 1, as shown in Table 1. The mass content and hydrogen efficiency of the working substance (ie, alkylanthraquinone) in the obtained working solution are shown in Table 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com