A hydrogenation process in the production of hydrogen peroxide

A hydrogen peroxide and process technology, applied in the direction of peroxide/peroxy hydrate/peroxyacid/superoxide/ozonide, inorganic chemistry, chemical instruments and methods, etc., can solve the problem of no significant improvement in side reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

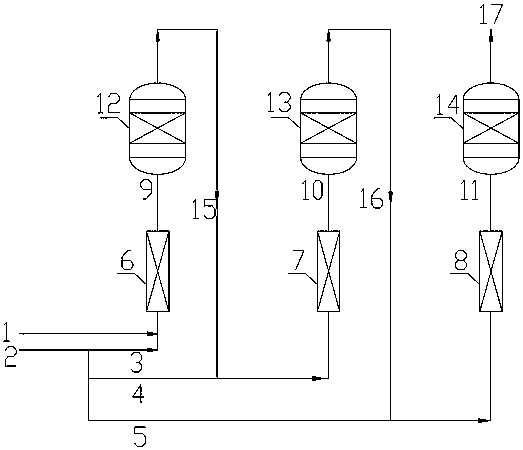

[0029] Three hydrogenation towers react in series, hydrogenation tower I is filled with catalyst 0.157m 3 , first hydrogen 46.27Nm 3 / h is divided into three equal ways to introduce respectively, one of which is 6.28m from the whole working fluid 3 After mixing / h, it is introduced into the hydrogen dissolving device I, and all the hydrogen is dissolved into the working liquid under the pressure of 7.5MPa, and then introduced from the bottom of the hydrogenation tower I, passing through the catalyst bed from bottom to top, at 7.0~7.5MPa, 45~ After a rapid hydrogenation reaction at 55°C, it flows out from the top; the effluent is mixed with the second hydrogen gas and then introduced into the hydrogen dissolving device II, and all the hydrogen is dissolved into the working fluid at a pressure of 5.5 MPa, and then from the hydrogenation tower II Introduced at the bottom, passing through the catalyst bed from bottom to top, after a transition hydrogenation reaction occurs at 5.0...

Embodiment 2

[0031] Three hydrogenation towers react in series, hydrogenation tower I is filled with catalyst 0.157m 3 , first hydrogen 46.27Nm 3 / h is divided into three roads: the first road is 23.14Nm 3 / h, the second road is 15.42Nm 3 / h, the third road is 7.71Nm 3 / h. Firstly, the first road and all working fluids are 6.28m 3 After mixing / h, it is introduced into the hydrogen dissolving device I, and all the hydrogen is dissolved into the working liquid under the pressure of 10.0 MPa, and then introduced from the bottom of the hydrogenation tower I, passing through the catalyst bed from bottom to top, at 9.5~10.0MPa, 45~ After a rapid hydrogenation reaction at 55°C, it flows out from the top; the effluent is mixed with the second hydrogen gas and then introduced into the hydrogen dissolving device II, and all the hydrogen is dissolved into the working fluid at a pressure of 7.0 MPa, and then from the hydrogenation tower II Introduced at the bottom, passing through the catalyst b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| crushing resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com