Slurry bed hydrogenation reactor for preparing hydrogen peroxide by adopting anthraquinone process and application of slurry bed hydrogenation reactor

A hydrogenation reactor and hydrogen peroxide technology, applied in the direction of peroxide/peroxy hydrate/peroxyacid/superoxide/ozonide, inorganic chemistry, chemical instruments and methods, etc., can solve the problems in the bed Uneven temperature distribution, low catalyst utilization efficiency, large catalyst liquid holding capacity, etc., to avoid adverse effects, uniform concentration and temperature distribution, and reduce operating burden

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

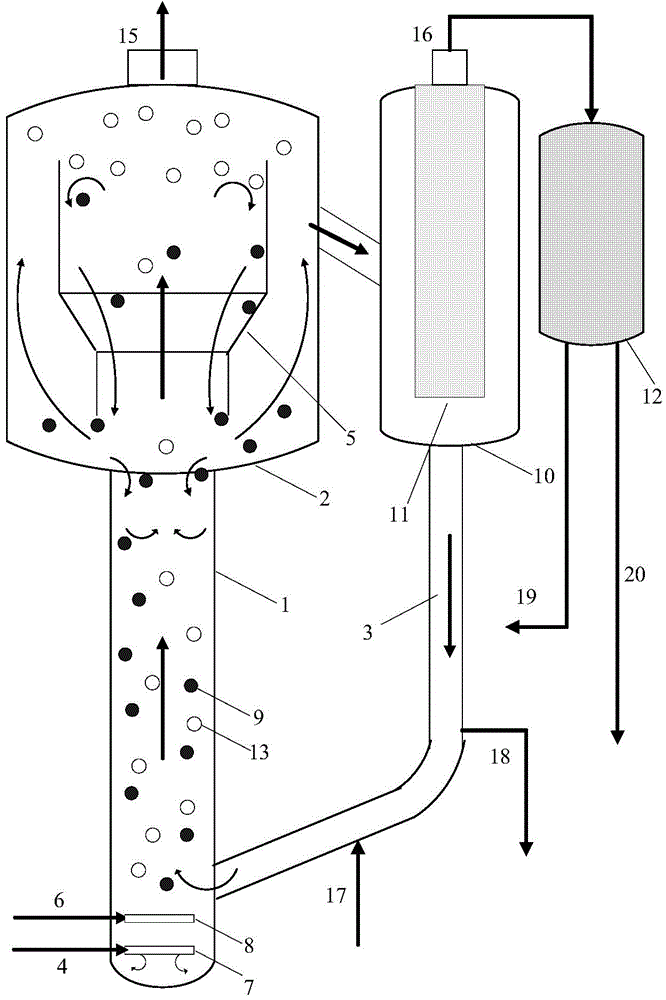

[0033] In the method for preparing hydrogen peroxide provided by the present invention, the reaction temperature in the riser is 35-80° C., preferably 55-75° C.; the reaction pressure is 0.1-0.5 MPa, preferably 0.2-0.3 MPa.

[0034] In the method for preparing hydrogen peroxide provided by the present invention, the working solution is prepared by dissolving alkylanthraquinone in an organic solvent. The working fluid disclosed in the prior art can be used, which is generally composed of anthraquinone derivatives, heavy aromatic hydrocarbons, trioctyl phosphate and other components mixed in a certain proportion.

[0035] In the method for preparing hydrogen peroxide provided by the present invention, the catalyst used is a supported catalyst in which Group VIII metals are supported on heat-resistant inorganic oxides. Catalysts with hydrogenation / dehydrogenation performance in the prior art can be used, preferably catalysts supporting Group VIII noble metals, such as palladium, ...

Embodiment 1

[0055] Example 1 illustrates the effect of the slurry bed reactor provided by the present invention applied to the preparation of hydrogen peroxide by anthraquinone method.

[0056] Attached figure 1 In the slurry bed reactor shown, the size of the reaction riser is Φ150×5000mm, the size of the expansion section is Φ450×1500mm, the guide tube is composed of two sections, the size of the upper section is Φ400×500mm, and the size of the lower section is Φ300×500mm. The size of the solid-liquid separator is Φ150×1500mm, and there are two sets of ceramic membrane filter components with a height of 500mm installed inside. It is set to automatically recoil when the pressure difference of each filter reaches 0.06MPa, and the recoil liquid is the filtered reaction clear liquid . The filtered clear liquid enters the secondary filter, and the filter medium installed in the secondary filter is a non-woven bag.

[0057] After the hydrogen-containing gas and the working fluid are pre-mix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com