Arrangement structure of all levels of superheaters of circulating fluidized bed boiler

A technology of circulating fluidized bed and layout structure, used in fluidized bed boilers, superheat temperature control, steam boilers, etc. Affect the safe and stable operation of the boiler, and achieve the effect of small change, improved safety and service life, and improved wall temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

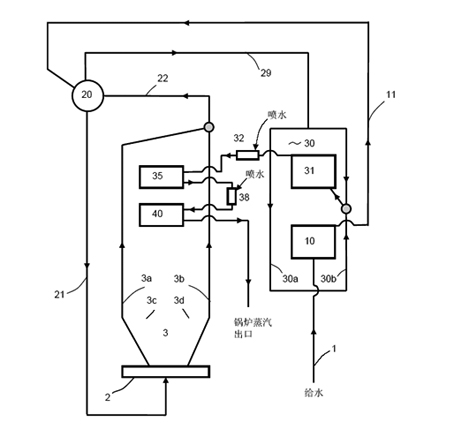

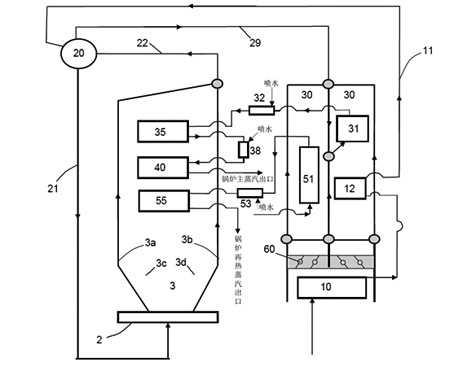

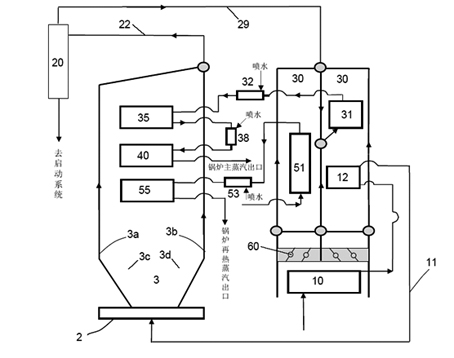

[0028] based on the following Figure 1 ~ Figure 4 , specify the preferred embodiment of the present invention:

[0029] Such as figure 1 As shown, it is a structural schematic diagram of the first embodiment of the arrangement structure of the superheaters at all stages of the circulating fluidized bed boiler provided by the present invention. The boiler feed water enters the economizer 10 arranged in the tail convection flue through the feed water pipe 1, and after heating The connecting pipe 11 from the economizer to the boiler drum enters the steam drum 20, and the water in the steam drum enters the lower header 2 of the water wall through the downcomer 21. The four walls of the water wall) are heated to form a steam-water mixture from the furnace to the steam drum connecting pipe 22 and enter the steam drum 20, and the steam drum 20 separates the steam-water mixture formed in the water-cooled wall 3, and the water enters the downcomer 21, and the saturated steam The ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com