Process for producing steam and/or power from oil residues with high sulfur content

a technology of oil residues and high sulfur content, which is applied in the direction of combustion process, exhaust treatment, combustion treatment, etc., can solve the problems of increasing the cost of upgrading the fuel derived therefrom, increasing the cost of searching for inexpensive fuel sources, and difficulty in extracting bitumen from oil sands and other deposits, so as to reduce energy costs, improve the economics of producing bitumen, and reduce energy and diluent costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026]As used herein, the term “lower alkane” when used in connection with a solvent refers to a branched or straight chain acyclic alkyl group containing four to about ten carbon atoms, preferably four to about seven carbon atoms, and preferably five carbon atoms. Examples of suitable solvents include n-butane, iso-pentane, n-pentane, n-hexane, n-heptane, and mixtures thereof.

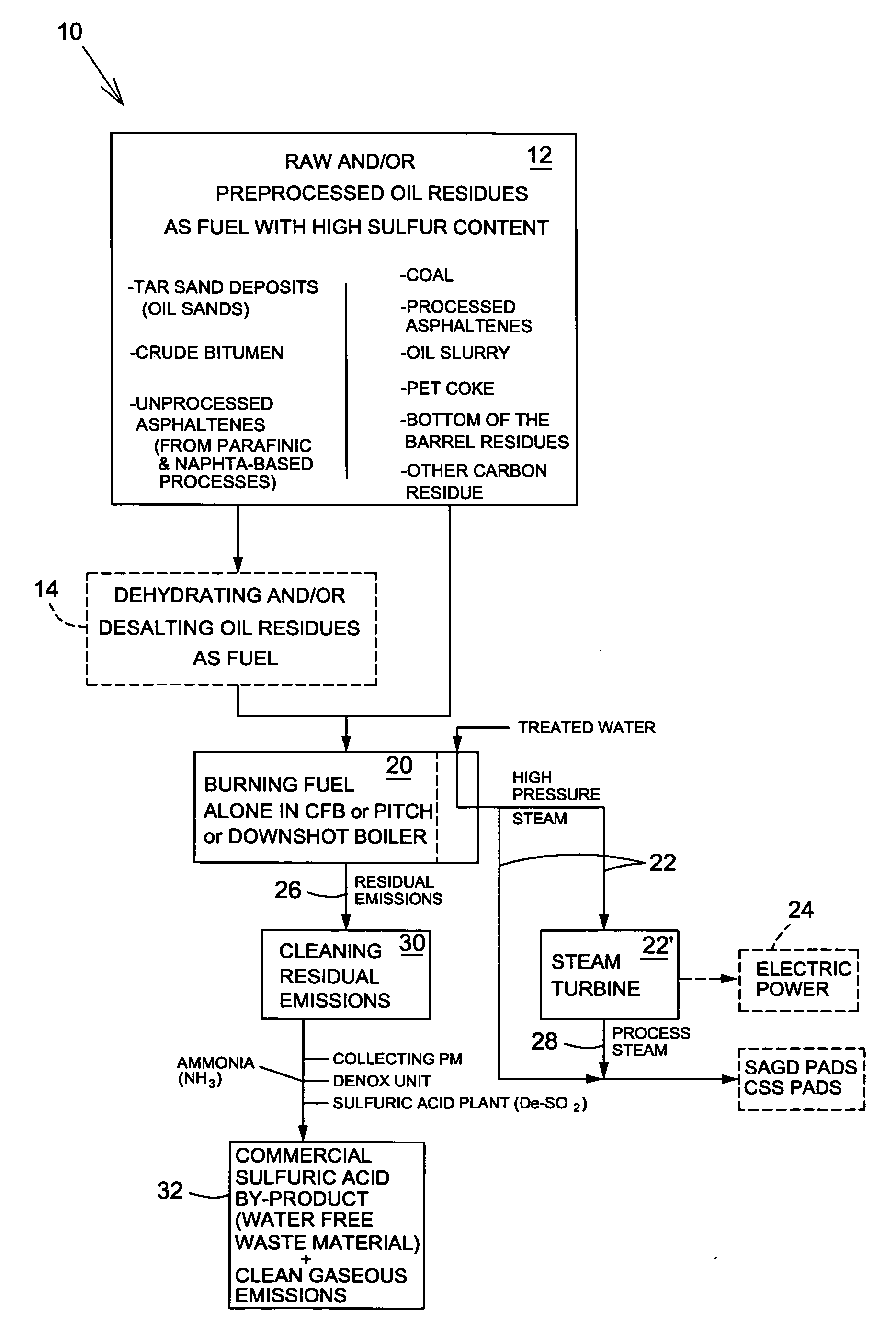

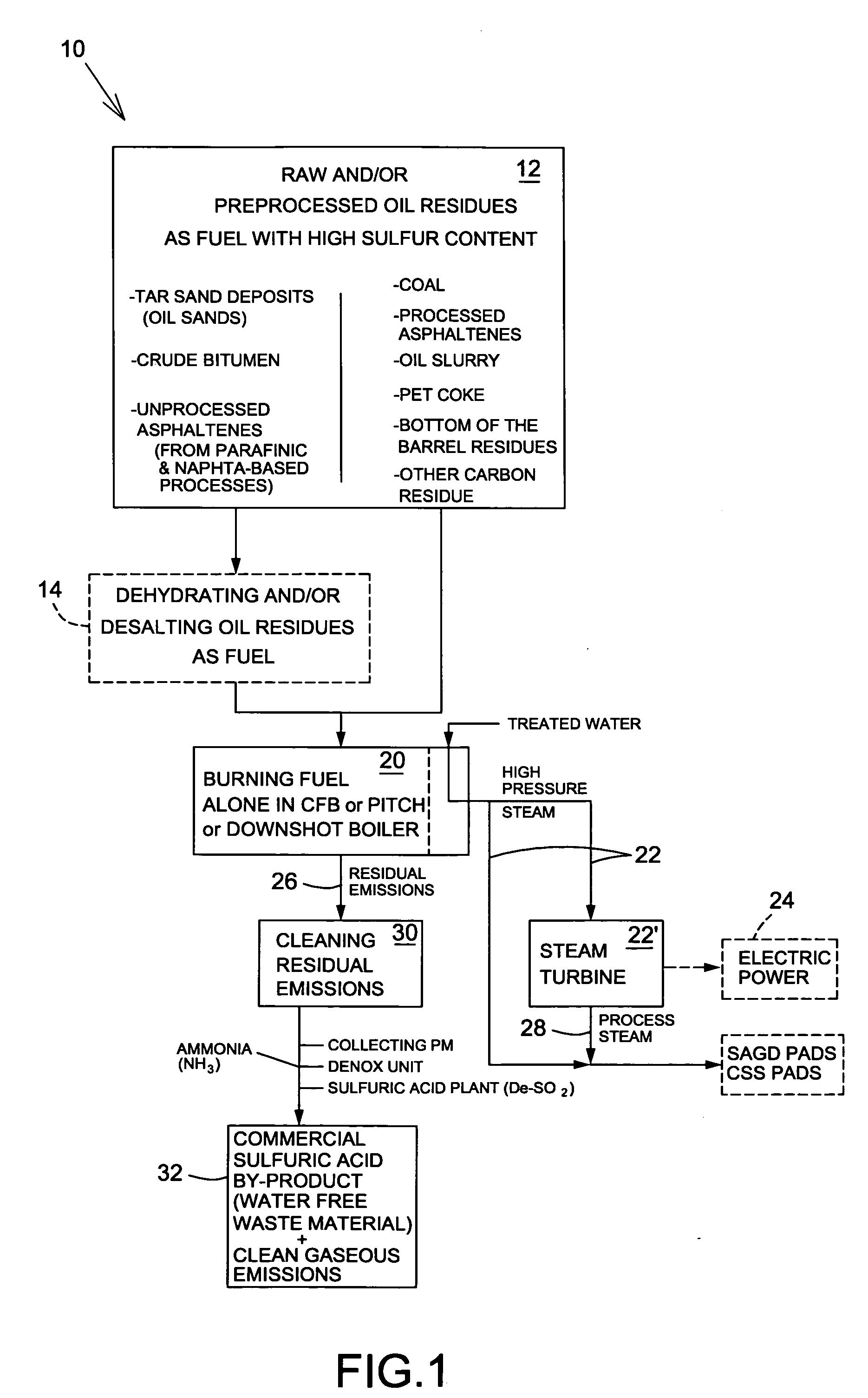

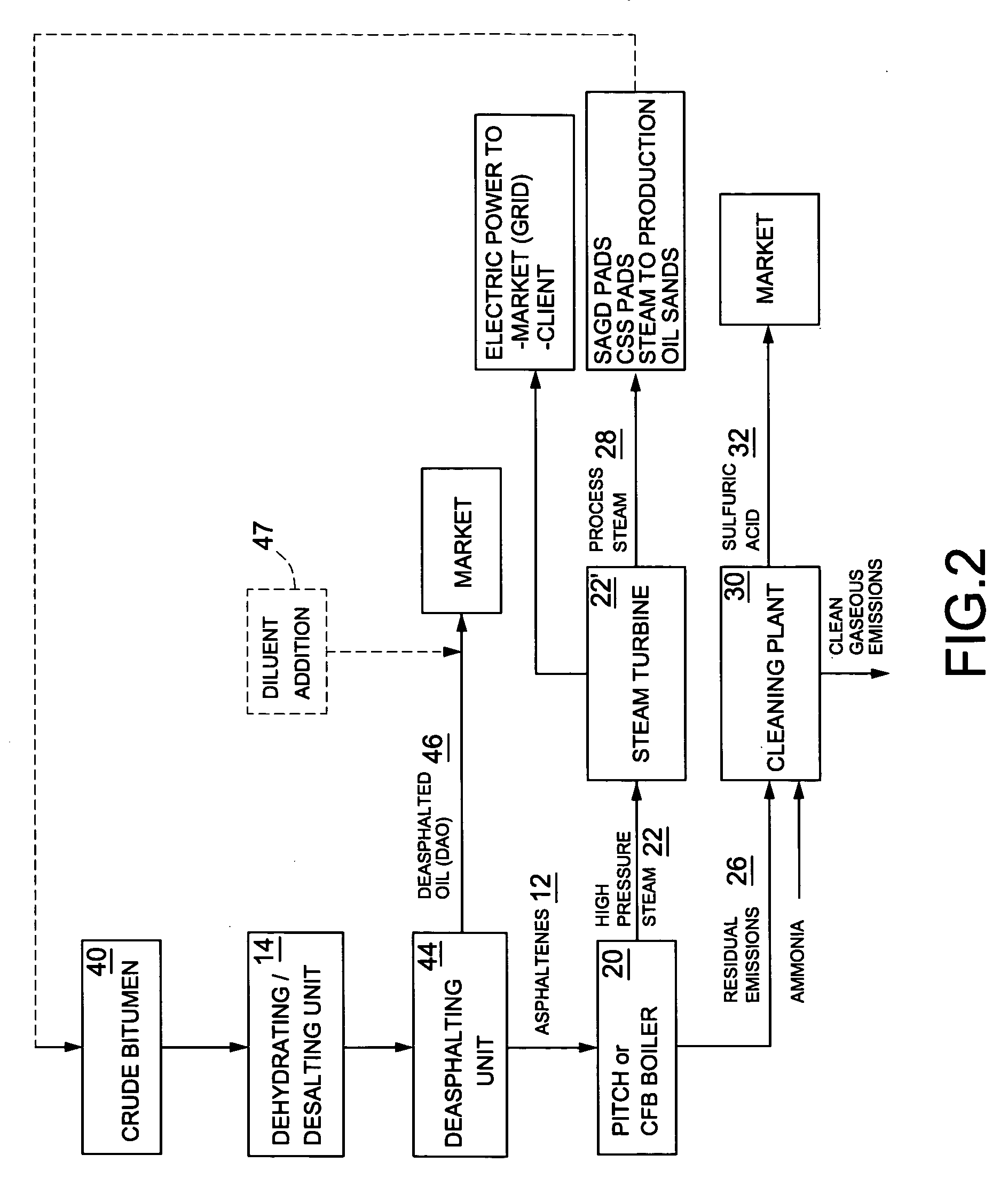

[0027]With reference to FIG. 1, there is shown a flow diagram of a clean process 10 for producing steam and / or power and using fuel from raw and / or preprocessed oil residues 12 in accordance with an embodiment of the present invention. Generally, the process 10 includes the steps of burning 20, or combusting, alone (i.e. without chemical additive such as sorbents, solvents, diluents, reagents, surfactants, limestone, lime or the like) the oil residues 12 as a fuel to generate high pressure steam 22 (from treated or distilled water), power 24 and residual emissions 26; and cleaning 30 the residual emissions 26 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com