Comprehensive utilization method of oil shale

A technology of oil shale and dry distillation, which is applied in the field of comprehensive utilization of oil shale and clean oil products, and can solve the problem of low efficiency of comprehensive utilization of oil shale

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

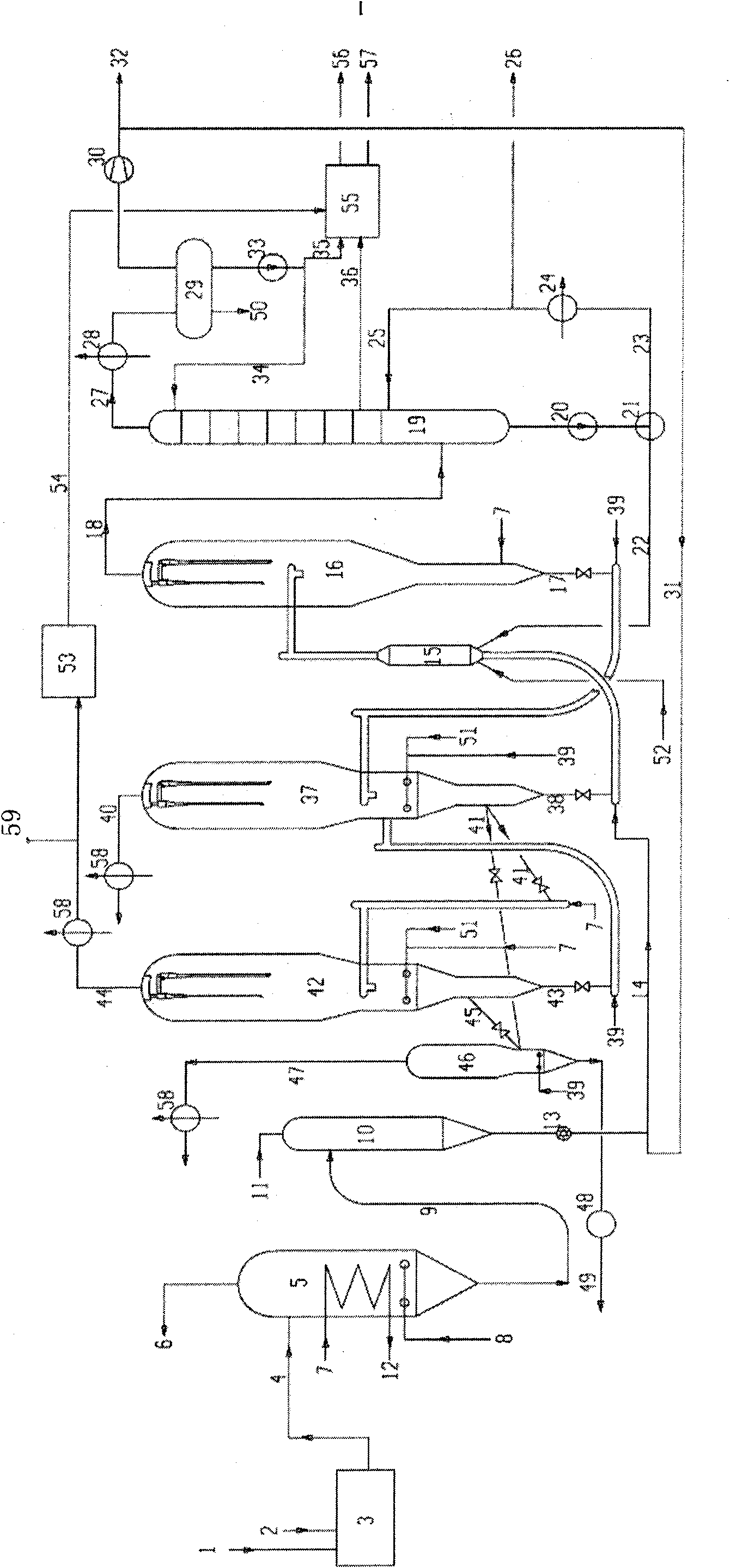

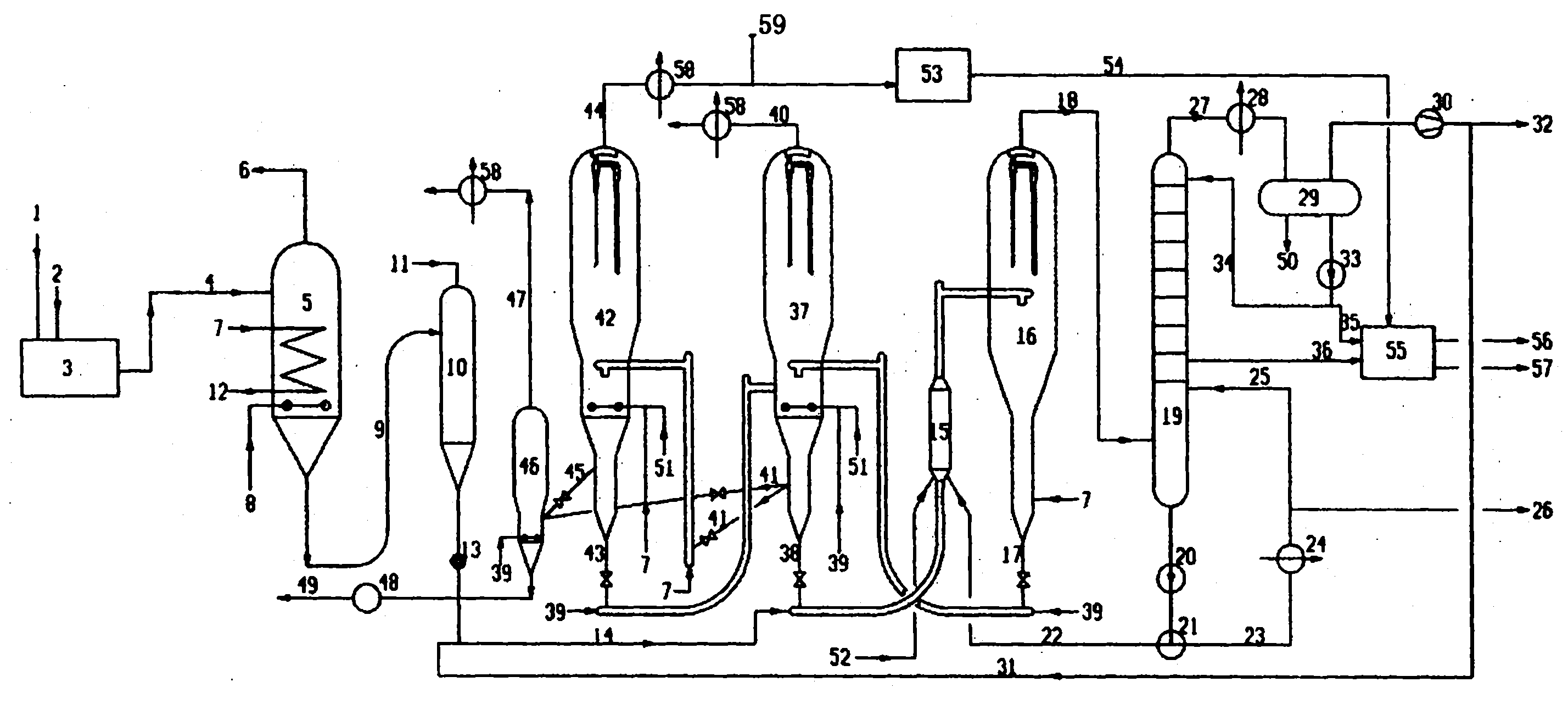

Method used

Image

Examples

Embodiment

[0063] This embodiment is a 600,000-ton / year oil shale comprehensive utilization and processing device built in an oil shale mining area. The oil shale mining area is accompanied by lignite, and at the same time, there are low-quality heavy oil sources locally. The comprehensive utilization processing equipment is mainly used to process oil shale, and when there is lignite and / or foreign low-quality heavy oil, it is mixed with lignite and / or heavy oil for processing.

[0064] Option 1: Processing oil shale

[0065] The comprehensive utilization processing device processes the oil shale extracted from the mining area when there is no lignite and foreign heavy oil.

[0066] Option 2: Processing oil shale and lignite

[0067] When the lignite is produced together, the oil shale and the lignite are processed together, and the mass composition of the oil shale and the lignite is: 90%:10%.

[0068] Scenario 3: Processing oil shale and heavy oil

[0069] When foreign heavy oil is pu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com