Aluminum oxide as well as preparation method and application thereof

A kind of alumina and aluminum source technology, applied in the direction of alumina/hydroxide preparation, chemical instruments and methods, catalyst activation/preparation, etc., can solve the problems of poor anti-carbon deposition performance and anti-heavy metal pollution performance, and achieve high performance Optimization, effect of high hydrocarbon oil catalytic cracking activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

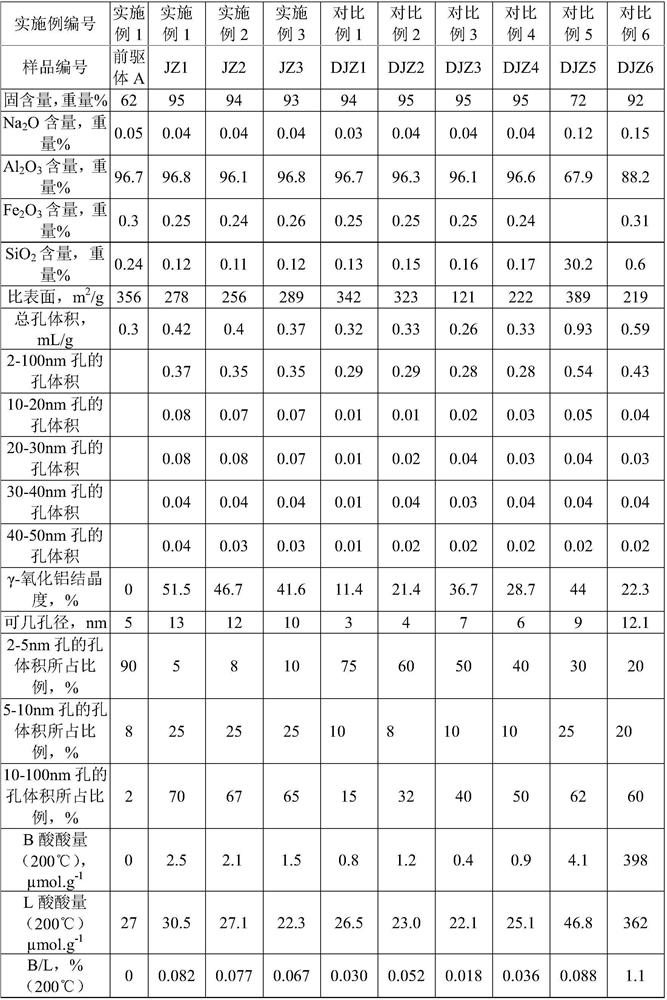

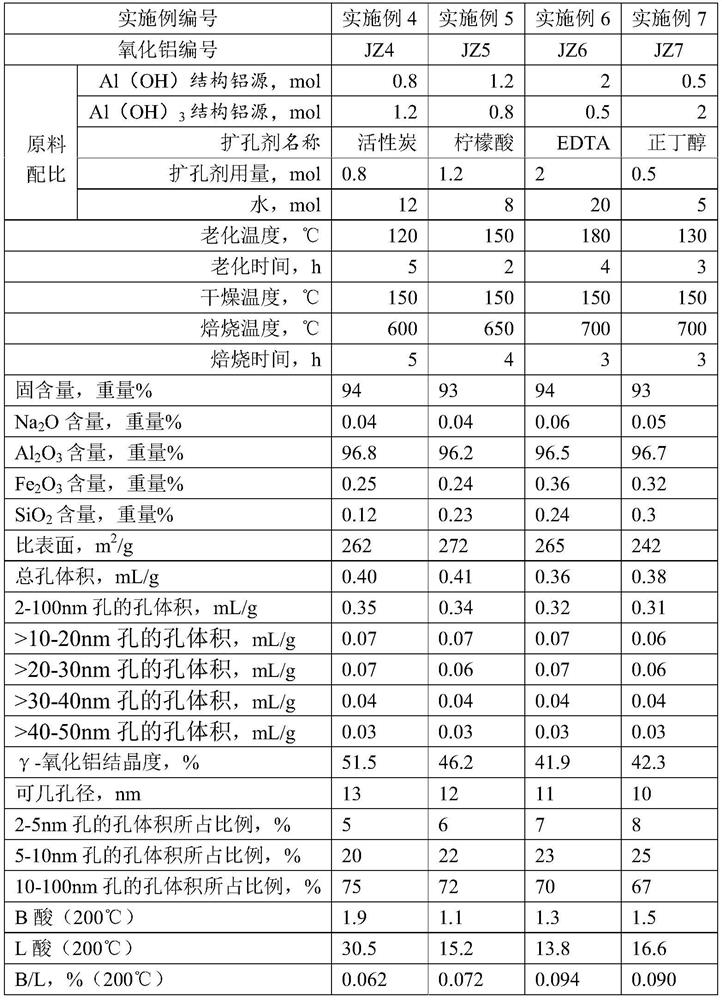

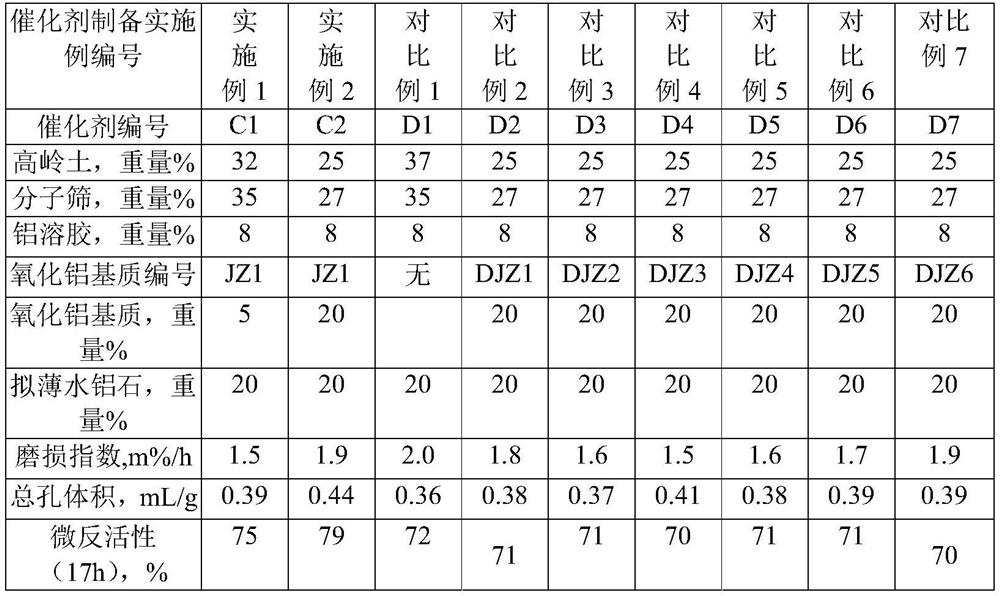

[0042] The method for preparing alumina provided by the invention, one embodiment is as follows: Al(OH) source (using Al 2 o 3 meter), Al(OH) 3 source (in Al 2 o 3 According to the molar ratio of 0.5-2: 0.5-2: 0.5-2: 5-20, such as 0.8-1.2: 0.8-1.2: 0.8-1.2: 8-12, the pore expander and water are mixed evenly, and the obtained mixture Aging at greater than 110-200°C, such as 120-180 or 120-150°C, in the presence of water vapor for 2-5h. During the aging treatment, the moisture outside the solid in the mixture evaporates at the boiling point to make the mixture solid, and then the solid state is contacted with water vapor at 110-180° C. for aging treatment for 2-5 hours. Then the obtained solid is dried in an air atmosphere at 100-180° C., for example, dried at 120-150° C. to obtain a precursor of alumina, and the obtained alumina precursor is calcined at 500-1000° C. for 2-5 hours, for example Calcining at 500-700° C. for 3-5 hours to obtain the alumina or alumina matrix pr...

Embodiment 1

[0065] Al(OH) structure aluminum source, Al(OH) 3 Structural aluminum source, citric acid, ammonium bicarbonate, and water are mixed according to the molar ratio of 1:1:0.5:0.5:10, stirred for 1 hour, and the obtained mixture is heated at 130°C, 1 atm (absolute pressure, the same below), and 100% water vapor by volume. Conditions (the water vapor content in the atmosphere is 100% by volume, the same below) was aged for 3 hours, and then the obtained solid was dried at 120°C in an air atmosphere to obtain the precursor A of alumina, and the obtained precursor A was heated at 700°C Calcined for 3 hours, the alumina matrix provided by the present invention was finally obtained, denoted as JZ1, and the analysis data of its physical and chemical properties are shown in Table 1.

[0066] Composition of alumina precursor A: based on dry weight, Al 2 o 3 Content 96.7% by weight, Fe 2 o 3 Content 0.3 wt%, Na 2 O content 0.05% by weight, SiO 2 The content is 0.24% by weight, and t...

Embodiment 2

[0068] Al(OH) structure aluminum source, Al(OH) 3 The structural aluminum source, n-butylamine, and water were stirred and mixed for 1 hour according to the molar ratio of 1:1:1:10, and the obtained slurry was aged for 3 hours at 130°C, 1 atm, and 100% volume water vapor atmosphere, and then the obtained solid was heated at 120°C Drying in an air atmosphere, and calcining at 700°C for 3 hours, the alumina provided by the present invention is finally obtained, denoted as JZ2, and its physical and chemical property analysis data are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com