Heavy oil hydro-conversion method

A hydrogen conversion and heavy oil technology, which is applied in the petroleum industry, hydrocarbon oil treatment, hydrotreating process, etc., can solve the problems such as difficult to achieve the upgrading effect, achieve the goal of reducing external rejection, reducing environmental pollution, and maintaining catalyst activity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

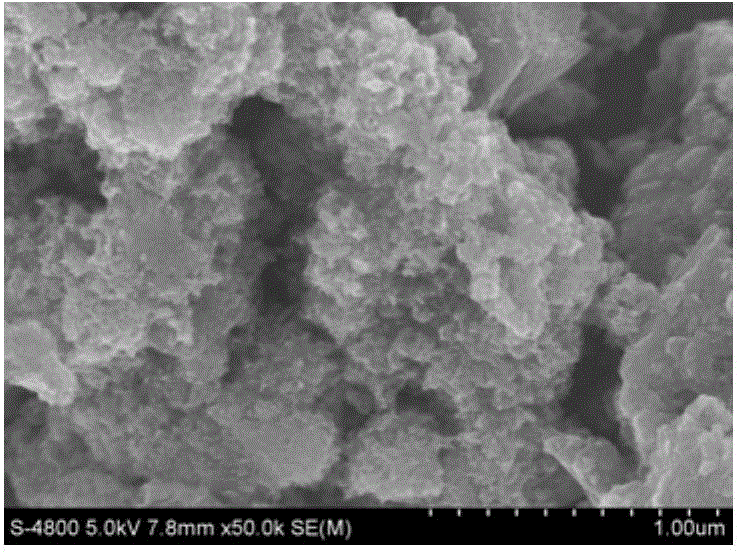

[0034] In the method provided by the present invention, the preparation method of the hydrothermal cracking catalyst comprises: contacting the metal source and the nonmetal source with a sulfidation agent in the presence of a solvent and under sulfidation reaction conditions to obtain the hydrothermal cracking catalyst. Wherein, the metal source is a substance containing V, Ni and lanthanide metal elements and / or Group VIB metal elements, the non-metal source is a substance containing carbon, and the metal source, non-metal source and vulcanizing agent The amount of the metal element contained in the solid product obtained after contacting contains 2-15% by weight of metal elements and 85-98% by weight of non-metallic elements, and based on the weight of the metal elements, the metal elements of more than 95% by weight are V, Ni and lanthanide metal elements and / or Group VIB metal elements; based on the weight of non-metal elements, more than 95% by weight of the non-metal elem...

Embodiment 1-4

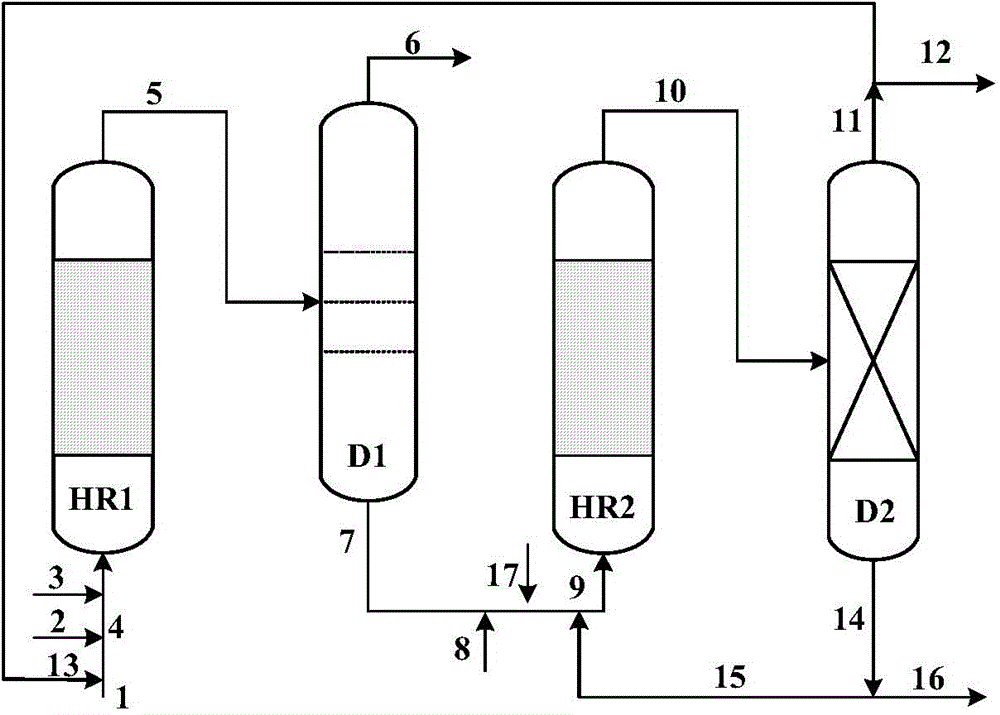

[0056] The experimental flow chart is attached figure 1 As shown, two separation devices are used to mix the residual oil raw material with hydrogen, fresh catalyst, and heavy wax oil in the second reactor in the raw material tank, and then transport it to the preheating furnace through a pump, and preheat it to 400°C and enter the first reactor The reaction is carried out, the reaction product of the first reactor enters the separation unit D1, and at least the product of 524°C residual oil in the heavy oil feedstock based on the yield of <524°C distillate oil. The experimental conditions and reaction results are listed in Table 3.

Embodiment 5

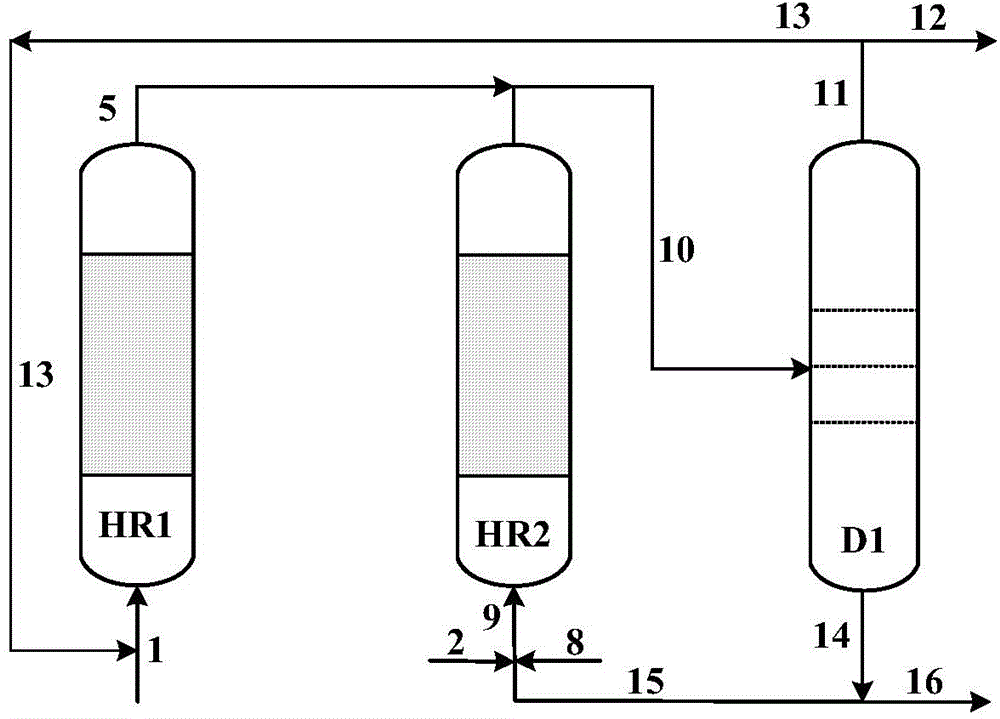

[0058] Use as attached figure 2 As shown in the device and process, the first reactor and the second reactor products use the same set of separation equipment D1, and the residual oil raw material, hydrogen, and heavy wax oil from the separation unit are evenly mixed in the raw material tank, and then pumped to the pre-processing stage. The furnace is preheated to a certain temperature and enters the first reactor to react. The reaction product of the first reactor enters the separation unit D1, and at least the product <430°C is separated. The obtained residue is mixed with hydrogen and fresh catalyst and then enters the second Reactor, the reaction product of the second reactor enters the separation unit D1, and separates to obtain light distillate oil, heavy wax oil and residual oil. After the device stabilizes, a small amount of residual oil is thrown out, and the rest is recycled back to the first and second reactors. The experimental conditions and reaction results are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com