A combined process for producing fuel oil, aromatic oil and asphalt

A combination process and aromatic oil technology, which is applied in the field of aromatic oil, asphalt combination process, and fuel oil production, can solve the problems of waste of resources, low actual utilization efficiency of oil slurry, etc., to improve aromaticity, improve comprehensive utilization efficiency, and improve Effect of Aromatics Content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

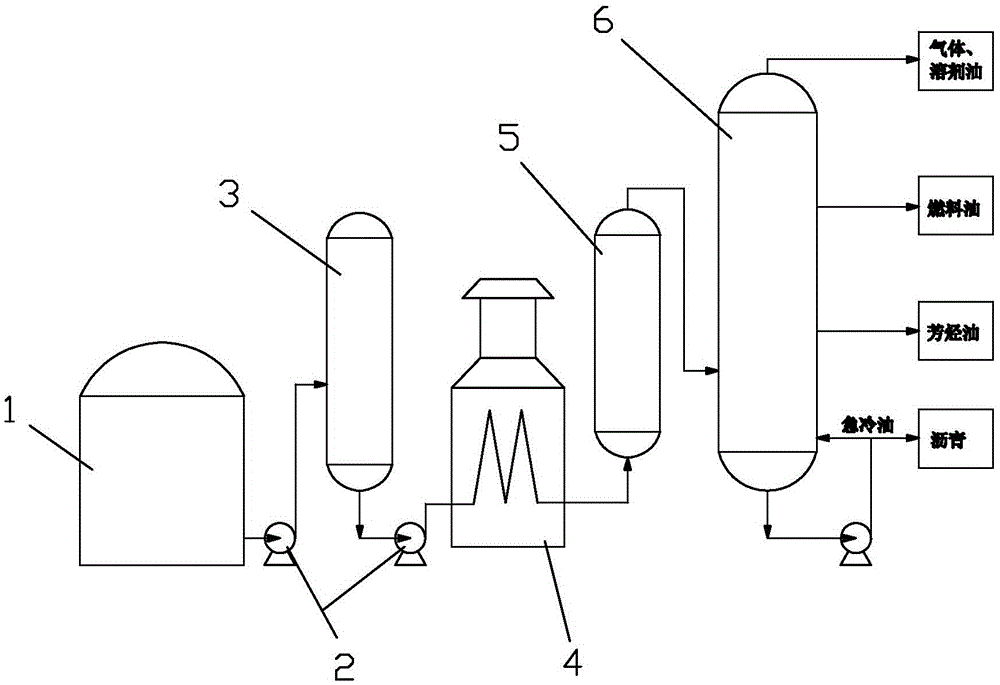

[0023] Such as figure 1 Shown, a kind of combined process of producing fuel oil, aromatic oil, asphalt described in the present invention utilizes catalytic oil slurry raw material, produces fuel oil, aromatic oil, asphalt by visbreaking (thermal cracking)-vacuum distillation combined process, improves Catalyze the yield of light oil from slurry processing, increase the aromatic content of aromatic oil, and improve the quality of aromatic oil and asphalt products.

[0024] The specific process flow is as follows: the catalytic oil slurry or mixed raw material stored in the raw material tank 1 is transported to the buffer tank 3 by the pump 2, then sent to the heatin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com