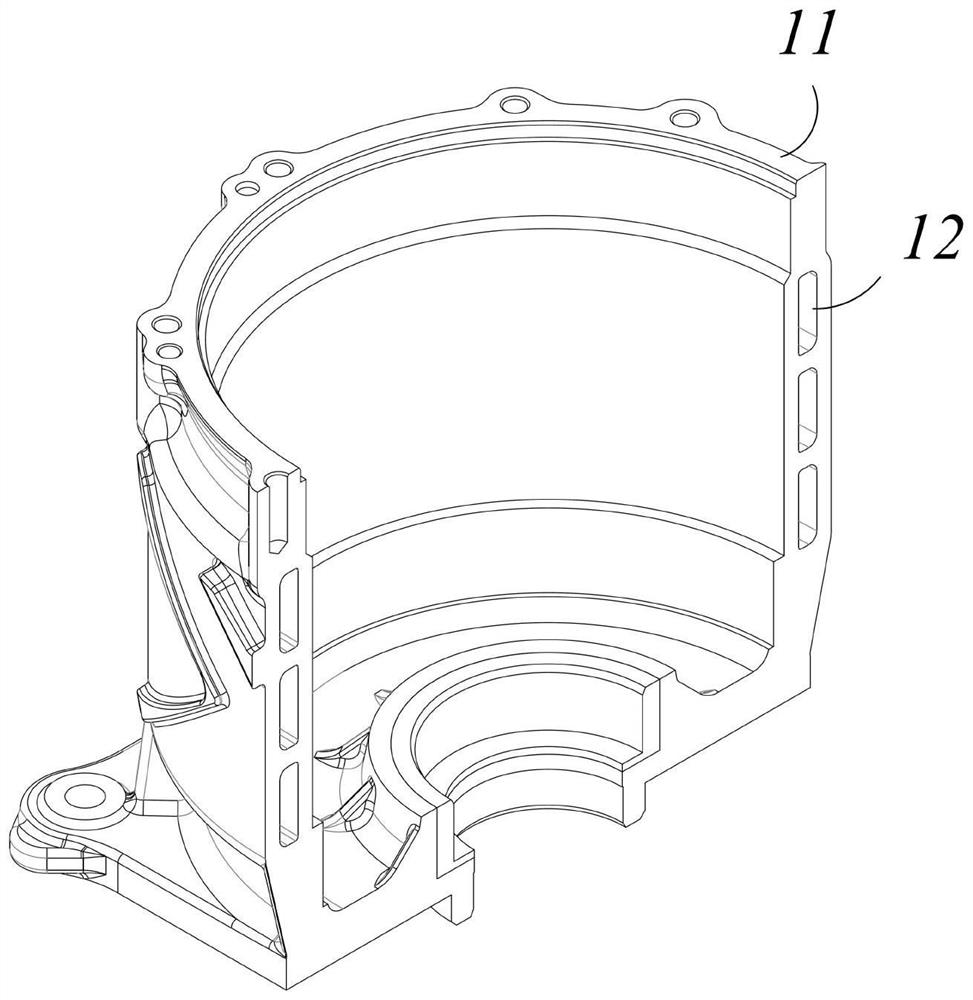

Casting method of integrated water-cooled motor casing of prefabricated spiral channel

A water-cooled motor, integrated technology, applied in the direction of manufacturing tools, casting molding equipment, casting molds, etc., can solve the problems of different materials of the spiral coil water channel and shell, to avoid material pollution problems, strong versatility, material selection less demanding effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be more fully understood from the following detailed description, which should be read in conjunction with the accompanying drawings. Detailed embodiments of the present invention are disclosed herein; however, it is to be understood that the disclosed embodiments are merely exemplary of the invention, which may be embodied in various forms. Therefore, specific functional details disclosed herein are not to be interpreted as limiting, but merely as a basis for the claims and as a teaching to one skilled in the art that, in fact, any suitably detailed embodiment may differ in any suitably detailed embodiment. The manner employs the representative basis of the present invention.

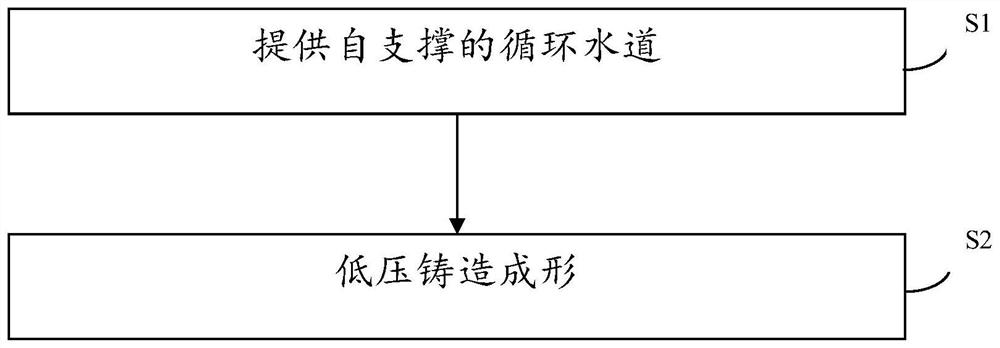

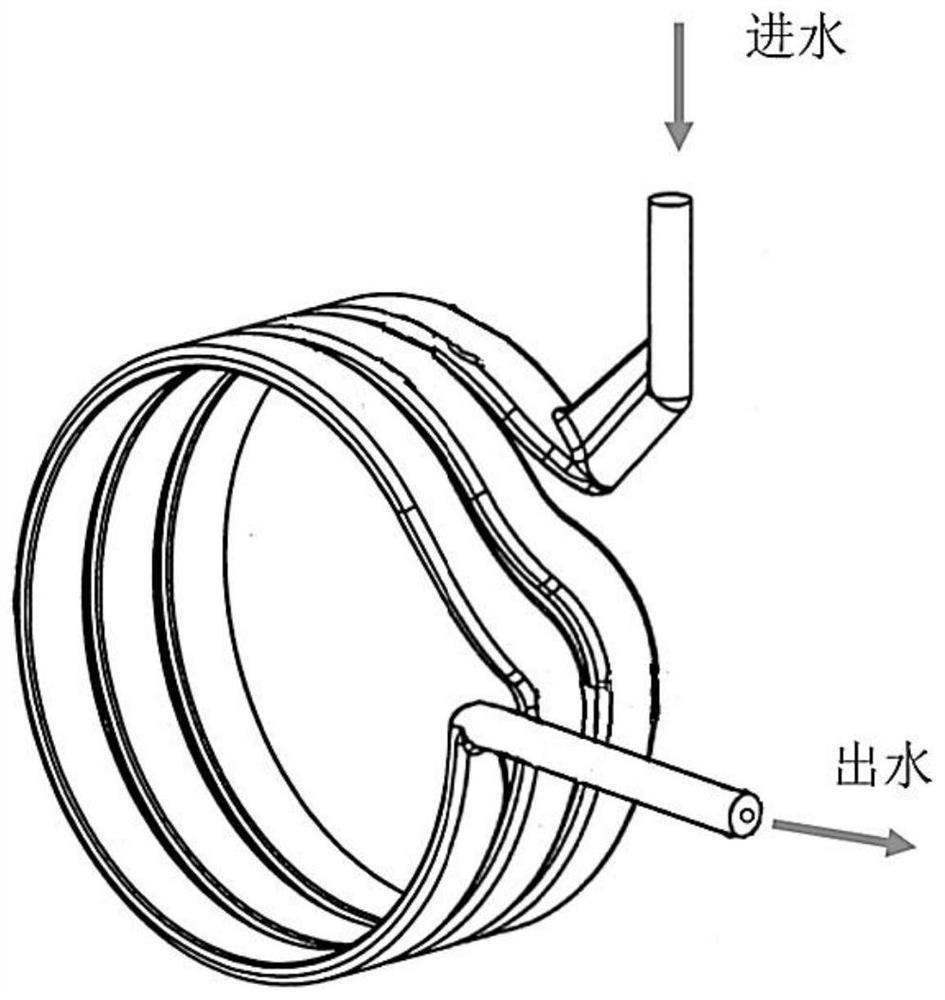

[0035] combine figure 2 As shown, in one embodiment of the present application, a casting process for an integral water-cooled motor casing of a prefabricated spiral circulating water channel is provided, which includes the following steps:

[0036] s1. Provide pref...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com