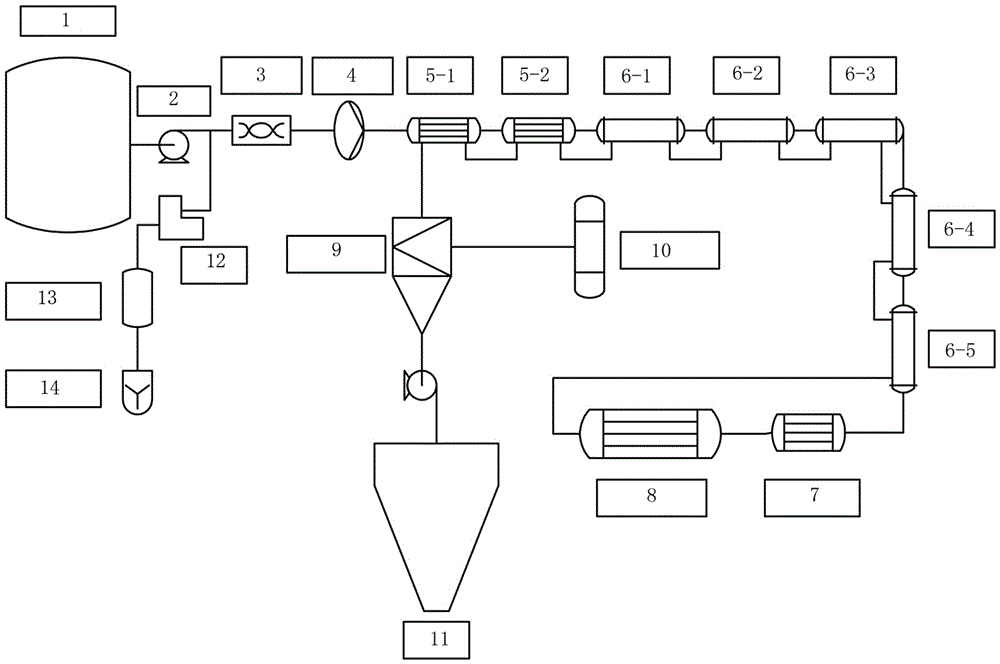

A kind of glyphosate mother liquor catalytic oxidation treatment equipment and process

A glyphosate mother liquor, catalytic oxidation technology, applied in the fields of oxidized water/sewage treatment, phosphorus compounds, inorganic chemistry, etc., can solve the problems of continuous one-time treatment in place, short service life of equipment, and high cost of filter element consumption. The effect of reducing selection requirements, low investment cost and saving equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

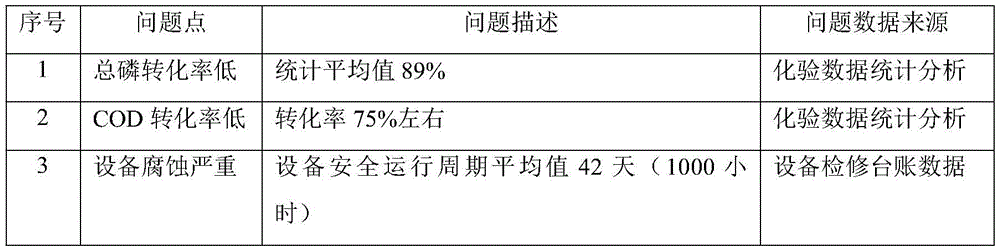

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] The present invention utilizes copper nitrate trihydrate to have strong catalytic properties. Copper nitrate trihydrate begins to decompose at 170°C, and its copper ions can reduce the positive reaction activity of organic phosphorus and macromolecular COD, and increase its oxidation reaction rate. Under the conditions far lower than the current status of the ECO device operation process, the phosphorus and COD in the mother liquor are converted into small molecular inorganic phosphorus and small molecular gas. The gas is treated by the ammonia nitrogen absorption device and discharged up to the standard. The inorganic phosphorus is cooled and crystallized in the extraction process to produce the product mixed phosphoric acid Sodium salt (not less than 90% disodium hydrogen phosphate), the raffinate is sent to the MVR process to continue to do steaming salt (sodium chloride) treatment.

[0040] Specifically, it is a catalytic oxidation treatment process of glyphosate mot...

Embodiment 2

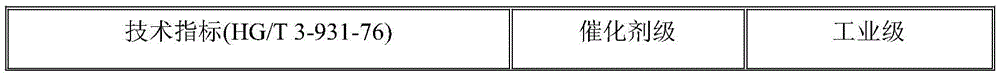

[0049] All processing steps of the present embodiment are as embodiment 1, and only catalyst is copper sulfate aqueous solution. The quality standard of the obtained product is:

[0050]

[0051]

[0052] Example 2

[0053] All the process steps of this embodiment are as in embodiment 1, only the catalyst is the mixed suspension of copper nitrate and alumina. The quality standard of the obtained product is:

[0054] Test items

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com