Combined comb

A combined, comb technology, applied in hair combs, clothing, hairdressing equipment, etc., can solve the problems of dull appearance, inability to remove or replace, and heavy production, and achieve the effect of simple coordination and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] (Embodiment 1, combined comb)

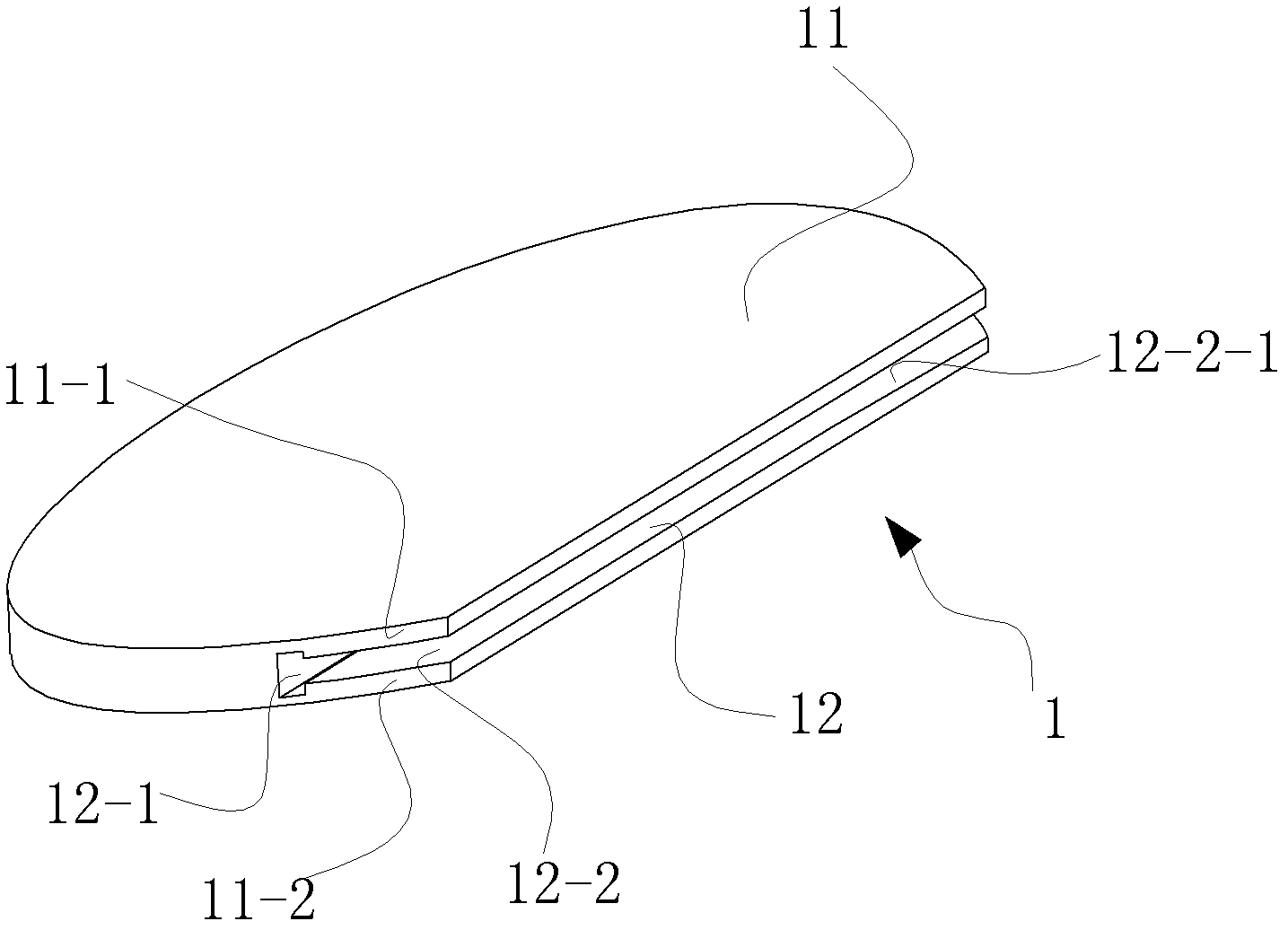

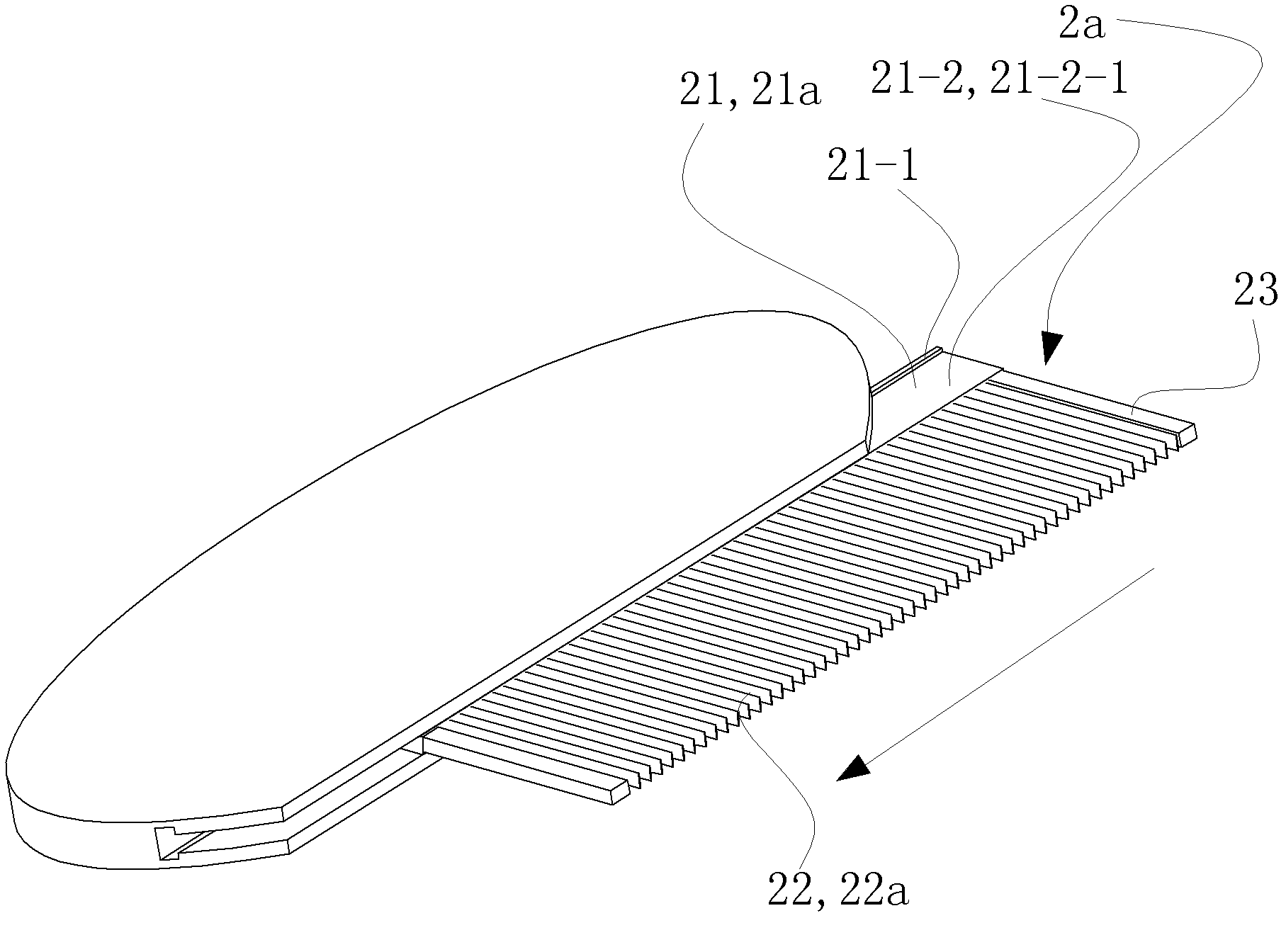

[0059] See figure 1 and figure 2 , the combined comb of the present embodiment (combined comb and combined comb) is a combined comb. The combined comb includes a horizontally arranged handle 1 and a horizontally arranged comb member 2a as a tooth member 2, and the tooth member 2 includes a horizontally arranged root plate 21 and an overall horizontally arranged comb connected to the root plate 21 A set of comb teeth 22 , and the tooth tips of the comb teeth 22 are located in front of the root plate 21 . The combined comb is composed of a comb member 2a and a handle 1 inserted in the left and right directions and detachably fitted with interference.

[0060] See figure 1 The handle 1 includes a handle body 11 and an insertion slot 12 disposed on the handle body 11 along the left and right directions and located at the front of the handle body 11 , the insertion slot 12 is provided with a front notch facing forward.

[0061] still s...

Embodiment 2

[0071] (Example 2, combined grate)

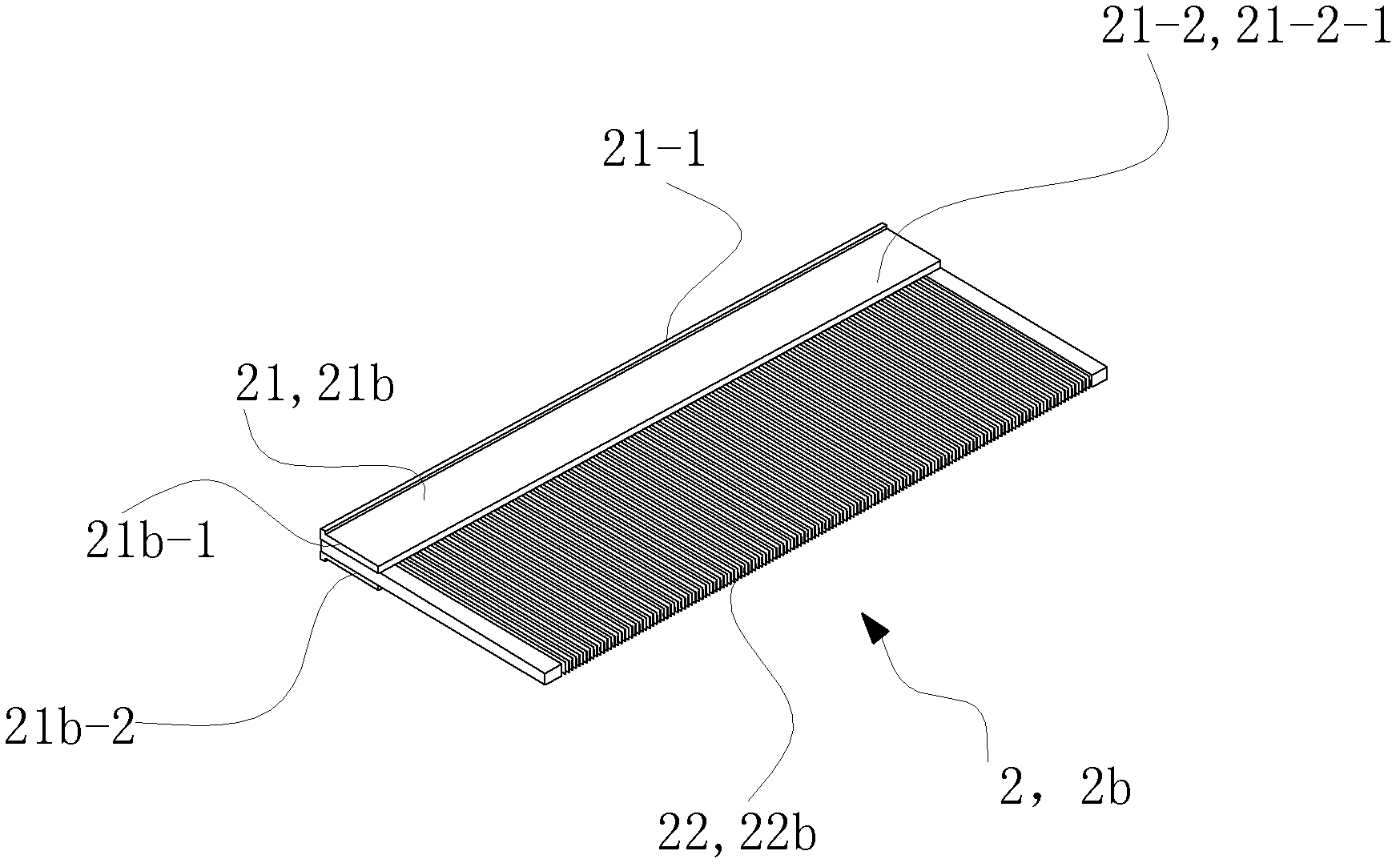

[0072] See figure 1 , image 3 and Figure 4 , The combined comb grate of the present embodiment is a combined comb grate. The combined grate includes a horizontally arranged handle 1 and a horizontally arranged grate member 2b as a tooth member 2. The combined grate is formed by inserting the grate member 2b and the handle 1 along the left and right directions and detachable interference fit. The handle 1 of this embodiment is the same as that of Embodiment 1.

[0073] See image 3 , The grate tooth member 2b is composed of a grate tooth root plate 21b, a set of grate tooth 22b and two retaining bars 23; the grate tooth root plate 21b is made up of an upper splint 21b-1 and a lower splint 21b-2. And composed of split panels. The grate teeth of the above-mentioned group of grate teeth 22b are arranged in a row to form a grate tooth group, and then a retaining bar 23 is respectively arranged on the left and right sides of the grate toot...

Embodiment 3

[0080] (Embodiment 3, combined comb)

[0081] The remainder of the combined grate of the present embodiment is identical with embodiment 1, and difference is:

[0082] See Figure 5 The insertion groove 12 of the handle 1 is a groove with left and right groove walls arranged on the handle main body 11, that is, the left and right ends of the insertion groove 12 of the handle 1 are in a closed state, and the insertion direction of the insertion groove 12 For forward and backward. The cross-section of the insertion slot 12 is a trapezoid placed transversely. The insertion groove 12 is located at the left-right central part of the front portion of the handle main body 11; The distance between the groove wall and the right end of the front end surface of the handle main body 11 is 5 mm to 25 mm. The distance between the upper groove wall and the lower groove wall of the insertion groove 12 gradually decreases from front to back, so that the insertion groove 12 is an inclined p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com