Automobile rope wheel type glass lifter system

A glass lifter and rope pulley technology, applied in the field of auto parts, can solve the problems of internal efficiency loss, large waste of motor performance, strict strength requirements, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

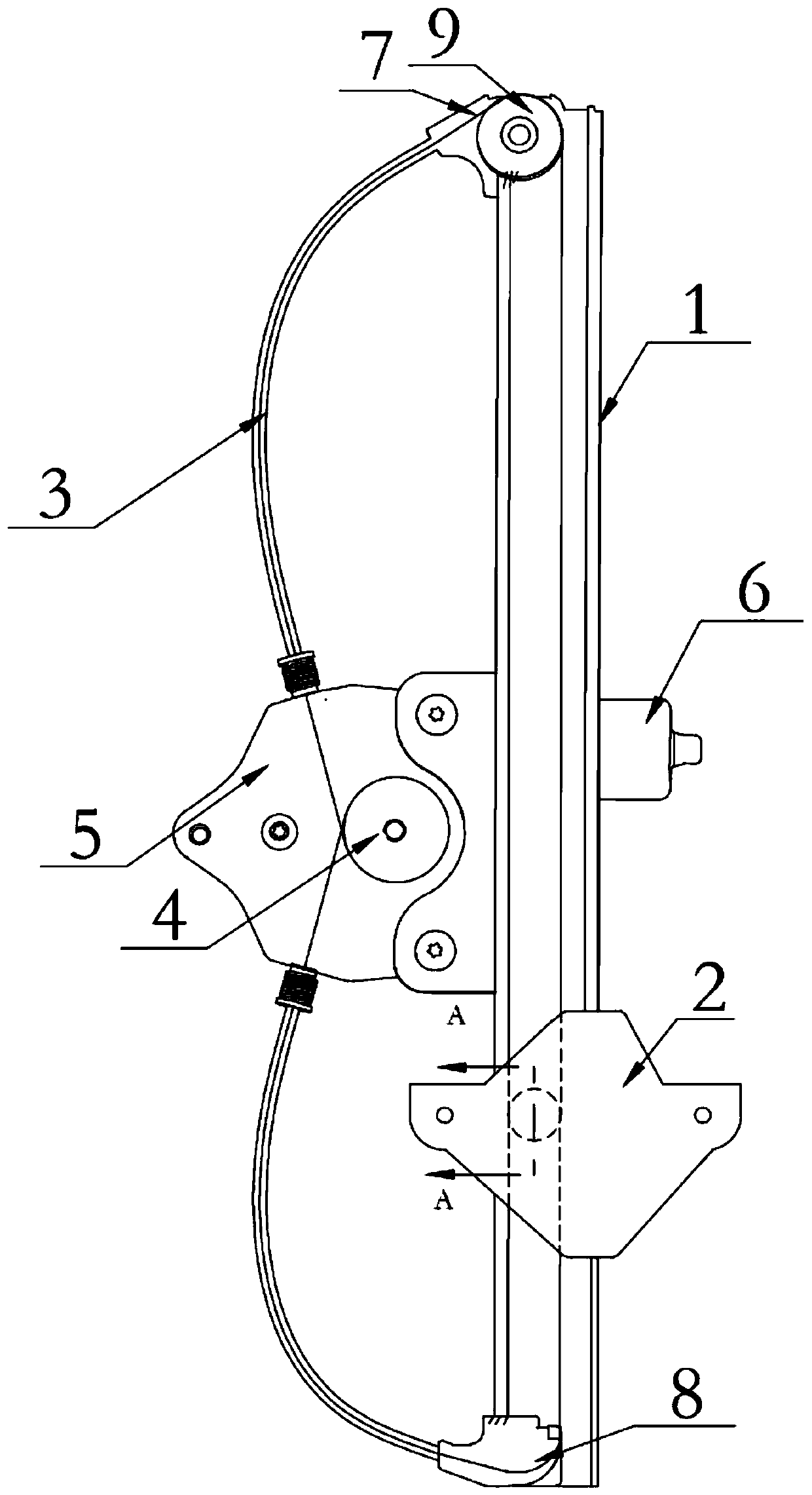

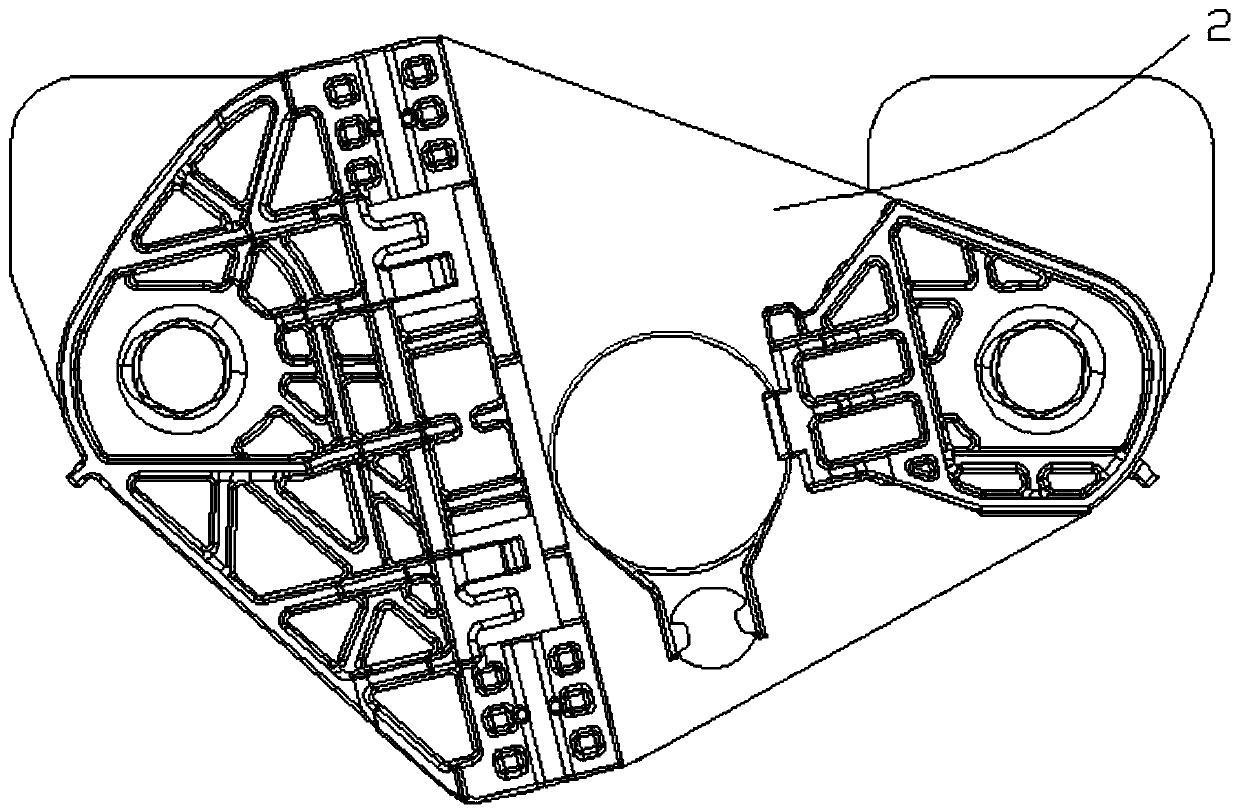

[0052] figure 2 It is a schematic diagram of the structure of the B-type monorail glass regulator, see figure 2 and image 3 . In this embodiment, the reel 4 of the driving part, the reel seat 5 and the motor 6 are assembled on the guide rail 1, and the output shaft of the motor 6 is connected with the reel 4 to drive the reel 4 to rotate forward or reversely. The upper guide 7 is arranged on the upper end of the guide rail 1 , the runner 9 is installed on the upper guide 7 , and the lower guide 8 is arranged on the lower end of the guide rail 1 . The dragline 3 includes two, respectively the first dragline and the second dragline, one end of the first dragline is fixed and wound on the reel 4 from one direction, and the other end passes through the runner 9 of the upper guide 7 1. After the upper guide part 21 of the bracket 2, its end is fixed on the upper end of the guide rail 1; one end of the second cable is fixed and wound on the reel 4 from the other direction, and...

Embodiment 2

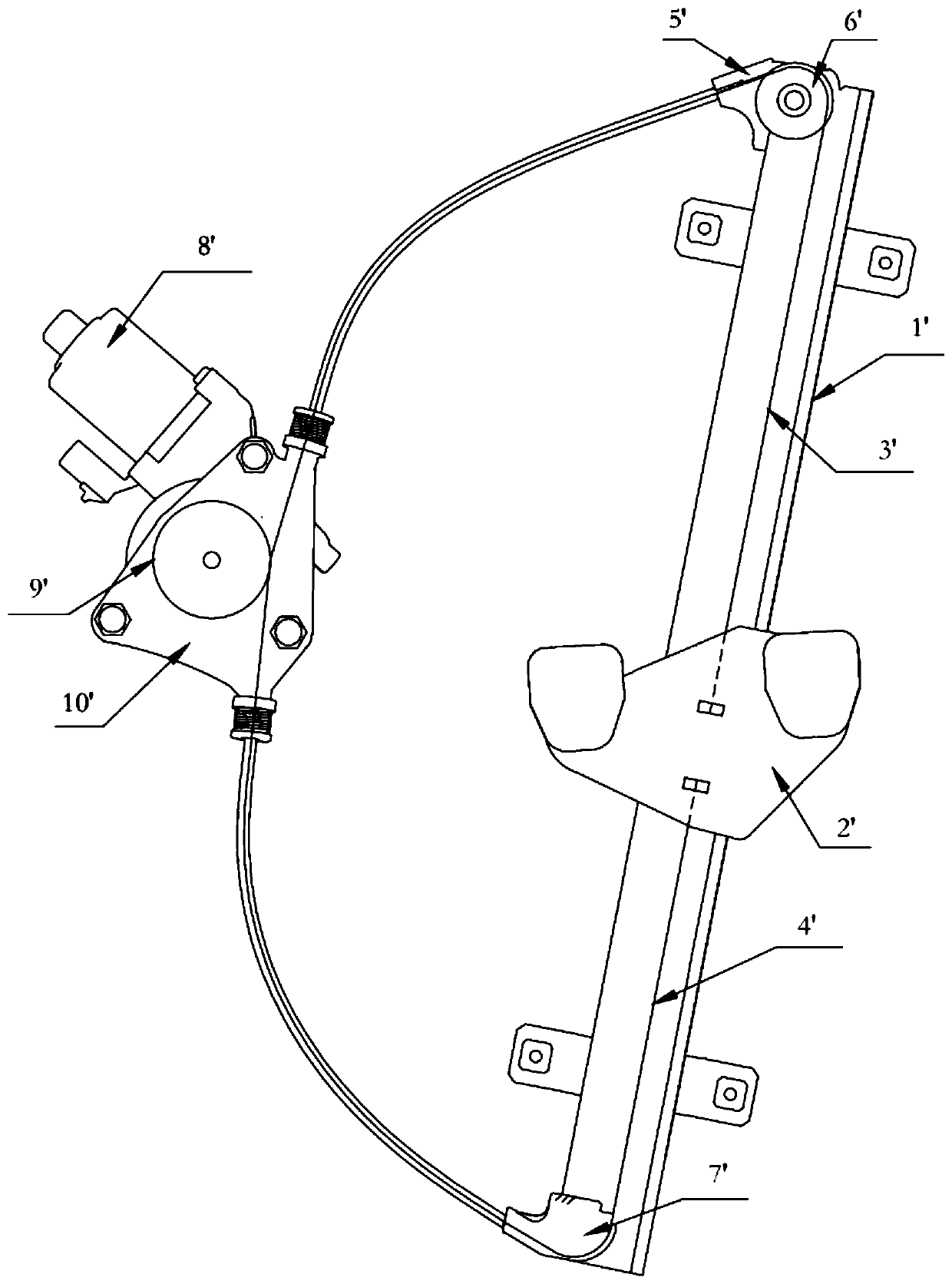

[0055] Figure 4 It is a structural schematic diagram of a D-type single-track glass regulator. The difference from Embodiment 1 is that in this embodiment, the reel 4, reel seat 5 and motor 6 of the driving part are arranged on one side of the guide rail 1, and the motor 6 outputs The shaft is connected with the reel 4, and the reel 4 is driven to rotate forward or reversely. The overall structure is D-shaped.

Embodiment 3

[0057] Figure 5 It is a structural schematic diagram of a lower-end driven glass regulator. The difference from Embodiment 1 and Embodiment 2 is that in this embodiment, the reel 4, reel seat 5 and motor 6 of the driving part are arranged at the lower end of the guide rail 1. The output shaft of the motor 6 is connected with the reel 4 to drive the reel 4 to rotate forward or reversely. Because the reel 4 is arranged on the lower end of the guide rail 1, in this embodiment, the lower guide 8 is not provided, and one end of the cable 3 is fixedly wound on the reel 4, and the other end passes through the runner of the upper guide 7. 9. After the upper guide part 21 of the bracket 2, its end is fixed on the upper end of the guide rail 1; one end of the cable 4 is fixed and wound on the reel 4, and after passing through the lower guide part 22 of the bracket 2, the other end is fixed at the lower end of rail 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com