Method for quickly preparing magnesium alloy fine crystalline wire and superfine magnesium alloy wire based on drawing process

A drawing process and magnesium alloy technology, which is applied in the field of preparing magnesium alloy fine-grained wire and ultra-fine magnesium alloy wire, can solve the problem of increasing the cumulative deformation of drawing, the grain size of easily broken wire, and reducing the size of magnesium alloy And other problems, to reduce the number of intermediate heat treatment, reduce the number of intermediate annealing, improve the effect of strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

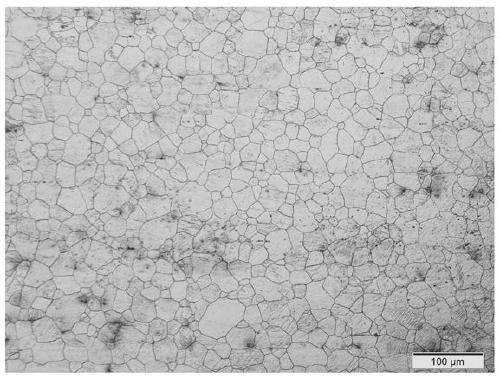

[0036] Example 1: In this example, AZ31 magnesium alloy is used to quickly prepare fine-grained wires with a diameter of more than 1.0 mm and ultra-fine magnesium alloy wires with a composition of 3.28% by weight of Al through high temperature hot drawing and room temperature cold drawing; 0.46% by weight of Zn; 0.27% by weight of Mn; 0.018% by weight of Fe; 0.026% by weight of Si; Completed:

[0037] Step 1. Turn the cast alloy ingot into a round rod ingot with a diameter of 30 mm, hot extrude the round rod ingot into a rod with a specification of 6.0 mm, and then anneal at 350°C for 30 minutes;

[0038] Step 2. Grinding the end of the rod obtained in step 1 until it can pass through the wire drawing die, lubricate the rod and the wire drawing die with graphite oil, first heat the die to the set (400°C) temperature, and then install the rod On the drawing die, the bar is hot-drawn for 5 times, the hot-drawing temperature is 400°C, the drawing speed is 25mm / s, the average def...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com