Machining method and device for sheet metal part with variable wall thickness based on 3D printing and incremental forming technology

A technology of incremental forming and sheet metal parts, applied in the direction of additive processing, metal material coating process, additive manufacturing, etc., can solve the problems of difficult parts, difficulty in rapid response, increase in manufacturing costs, etc., to reduce deformation resistance, The method is simple and feasible, and the effect of improving the forming accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in detail below in conjunction with specific embodiments.

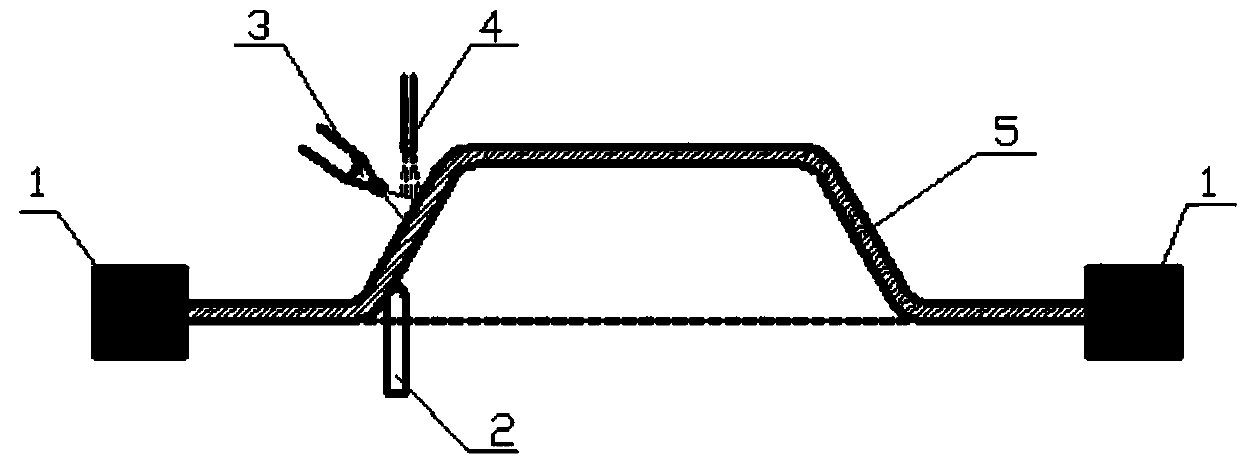

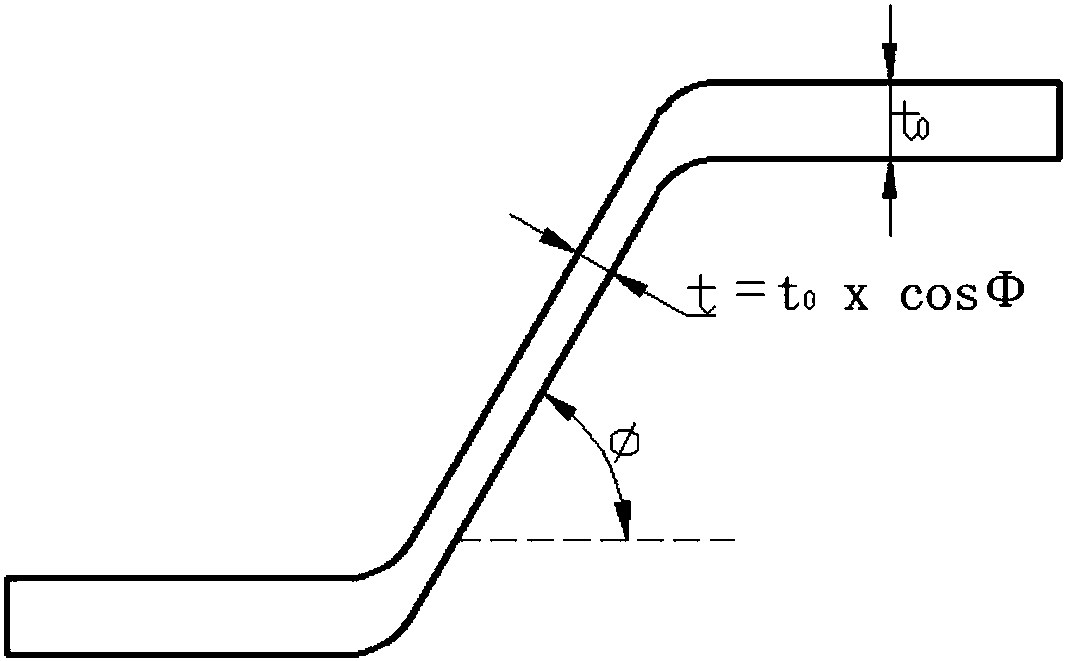

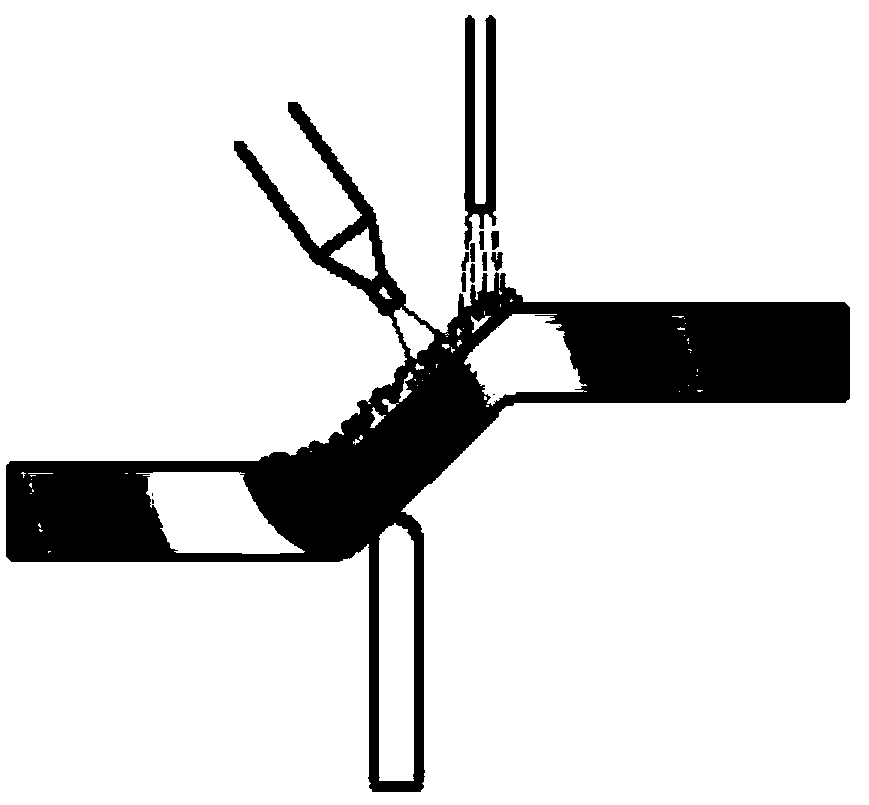

[0025] figure 1 It is a schematic diagram of the structure of the variable-wall-thickness sheet metal parts processing device based on 3D printing and incremental forming technology. The variable-wall-thickness sheet metal parts processing device based on 3D printing and incremental forming technology includes incremental forming chuck 1 and incremental forming tool head 2 , a laser beam 3 and a powder spray head 4 . The powder nozzle 4 sprays powder on the sheet where the wall thickness needs to be increased or where it is easy to become thinner during the forming process. The laser beam 3 is used to clad the powder on the surface of the sheet to increase the thickness of the material. For other parts, there is almost no thinning or no In the area where the wall thickness needs to be increased, the powder feeding operation is not performed; at the same time, the laser ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com